What’s New in DC Rectifier Systems for High-Efficiency Power Conversion

In 2025, the dc rectifier system landscape transforms with breakthroughs in semiconductor materials and system design. Leading companies like Siemens and ABB drive advancements by integrating silicon carbide and gallium nitride, as shown by a 4.7% annual growth rate in adoption. These innovations enable ultra-fast charging, higher power density, and improved energy efficiency. Engineers now see advancements in digital integration, thermal management, and sustainability that support reliable energy conversion across sectors, from electric vehicle charging to renewables.

Aspect

Details

Semiconductor Materials Trend

Increasing adoption of silicon carbide (SiC) and gallium nitride (GaN) in DC rectifiers

Market CAGR (Forecast Period)

4.7% growth rate driven by advanced semiconductor technologies

Key Industry Drivers

Demand from electric vehicles, renewable energy sectors requiring efficient rectification

Key Takeaways

New semiconductor materials like silicon carbide and gallium nitride boost efficiency and power density in DC rectifiers.

Modular and multi-level designs improve system reliability, scalability, and ease of maintenance.

AI and IoT integration enable smarter control, real-time monitoring, and predictive maintenance for better performance.

Advanced cooling solutions and thermal materials keep rectifiers safe and efficient under high power demands.

High-efficiency rectifiers support fast EV charging, renewable energy, and sustainability goals by reducing energy loss and waste.

DC Rectifier Technology Trends

Next-Gen Semiconductors

The dc rectifier system market has entered a new era with the adoption of advanced semiconductor materials. Silicon carbide (SiC) and gallium nitride (GaN) now dominate the landscape, replacing traditional silicon in many telecom rectifiers. These materials deliver significant improvements in efficiency, power density, and reliability. SiC and GaN devices operate at higher voltages and frequencies, which reduces switching losses and enables more compact designs.

Onsemi’s SiC JFET technology addresses high-voltage challenges in dc rectifier systems, enhancing both safety and performance. Engineers see these materials as essential for meeting the demands of modern energy conversion. The shift to SiC and GaN supports the development of energy-efficient electronics, especially in sectors such as electric vehicles and renewable energy.

Note: Industry leaders like Eaton, Texas Instruments, Bosch Mobility Solutions, STMicroelectronics, and Onsemi drive these advancements. Their focus on integration and smart charging solutions shapes the future of telecom rectifier technology.

Aspect | Details |

|---|---|

Market Growth Driver | Increasing EV adoption, energy efficiency demands, miniaturization of components |

Key Players | Eaton, Texas Instruments, Bosch Mobility Solutions, STMicroelectronics, Onsemi |

Market Projection | CAGR of ~20% over next 5 years |

Critical Trends | Integration, smart charging solutions, sustainability |

Market Segmentation by Type | Single Phase (residential/light-duty), Three Phase (heavy-duty, higher efficiency) |

Market Segmentation by Application | Passenger Cars (faster charging, energy management), Commercial Vehicles (robust power conversion) |

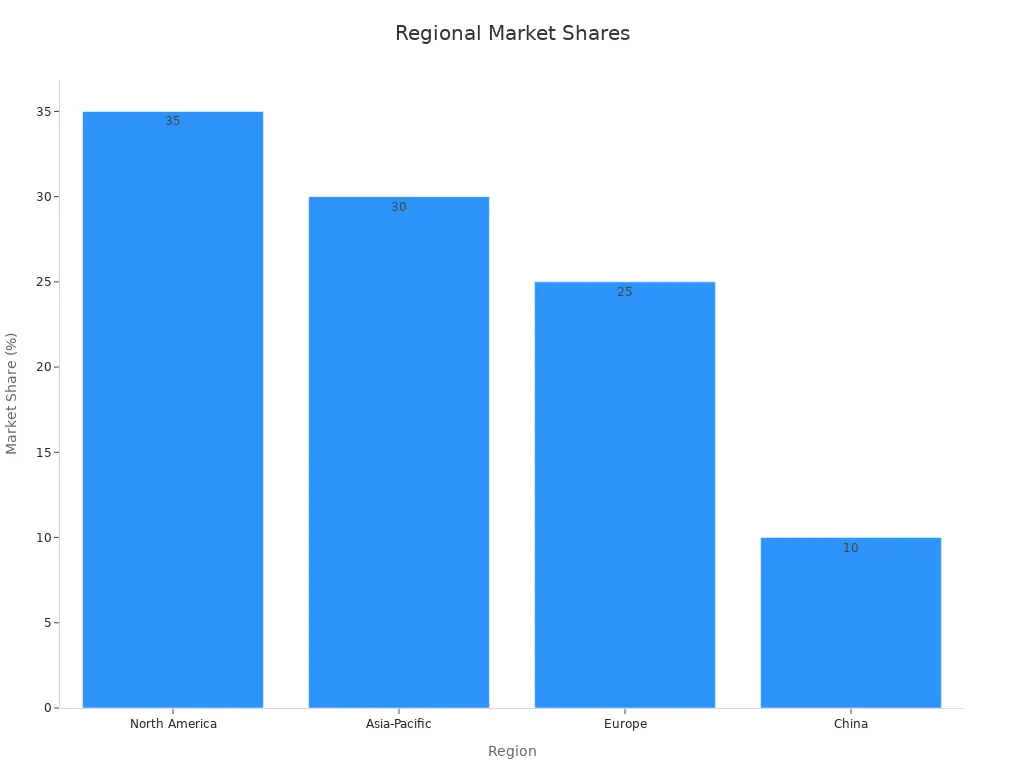

Regional Market Shares | North America (35%), Asia-Pacific (30%), Europe (25%), China (10%) |

Market Size Projection | Expected to surpass $10 billion globally by 2030 |

High-Efficiency Devices

Telecom rectifier technology continues to evolve with the introduction of high-efficiency devices. New half-bridge ICs and inductor-less converters set new standards for efficiency and compactness. These innovations allow telecom rectifiers to achieve efficiency levels above 98%, which reduces energy loss and operating costs.

Engineers now design telecom rectifiers with advanced power management ICs that streamline isolation and accelerate time-to-market. The evolution of batteries and their integration with telecom rectifier technology further enhances energy storage and delivery.

Key trends in telecom rectifier technology include:

Adoption of modular designs for scalability and maintenance.

Integration of smart charging solutions for dynamic energy management.

Focus on sustainability and reduced environmental impact.

Telecom rectifiers now play a critical role in supporting fast EV charging, robust data center operations, and renewable energy systems. The demand for high-efficiency, reliable, and compact solutions drives continuous innovation in dc rectifier technology.

The global market for telecom rectifiers reflects these trends, with North America, Asia-Pacific, and Europe leading in adoption. The market is expected to surpass $10 billion by 2030, fueled by the need for efficient energy conversion and advanced telecom rectifier technology.

Advanced Topologies

Multi-Level Designs

Engineers now implement multi-level designs to improve the performance of dc rectifier systems. These topologies use several voltage levels within the conversion process. Each level reduces the voltage stress on individual components. This approach leads to lower switching losses and higher efficiency. Multi-level rectifiers also minimize electromagnetic interference. As a result, systems achieve smoother voltage waveforms and better power quality. Many high-power applications, such as grid-tied renewable systems and industrial drives, benefit from these advancements.

Note: Multi-level designs often require sophisticated control algorithms. These algorithms ensure stable operation and precise voltage regulation.

Modular Systems

Manufacturers increasingly adopt modular systems to enhance scalability and reliability. In a modular design, engineers build rectifier systems from standardized, interchangeable modules. This structure allows for easy expansion and simplified maintenance. If a module fails, technicians can replace it without shutting down the entire system. Modular systems also support parallel operation, which increases total power output and redundancy.

Benefits of Modular Systems:

Quick installation and commissioning

Flexible adaptation to changing power demands

Reduced downtime during repairs

Telecom, data centers, and EV charging stations rely on modular systems for uninterrupted service and efficient upgrades.

Resonant Circuits

Resonant circuits have become essential in next-generation dc rectifier systems. These circuits use resonance between inductors and capacitors to achieve soft switching. Soft switching reduces switching losses and electromagnetic noise. Resonant topologies enable higher operating frequencies, which leads to smaller passive components and increased power density. Many designers choose resonant circuits for applications that demand high efficiency and compact size, such as on-board chargers and fast EV charging infrastructure.

Tip: Resonant circuits often require precise tuning to maintain optimal performance under varying load conditions.

Intelligent Control

AI Control

AI-driven control systems now play a central role in smart rectifiers. These systems use machine learning algorithms to analyze real-time data and adjust power conversion parameters. Engineers see significant gains in reliability and efficiency. AI enables dynamic voltage scaling and precise voltage regulation, which leads to better energy management and reduced transmission losses.

The following table highlights key performance improvements from AI integration in power converters:

Performance Metric | Improvement / Value |

|---|---|

Current Density | Up to 2X higher (3-4 A/mm² vs 1.5-2 A/mm²) |

Transmission Loss Reduction | Up to 85% reduction |

Voltage Regulation | Improved precision |

Dynamic Voltage Scaling | Real-time power tuning |

Power Delivery System Size | Smaller, integrated silicon chips |

Power Delivery Efficiency | Enhanced through reduced losses |

Smart rectifiers with AI control deliver higher current density and smaller system size. These features support advanced energy management and drive continuous optimization in demanding applications.

IoT Integration

IoT integration transforms smart rectifiers into connected devices. Sensors and communication modules collect and transmit operational data to cloud platforms. This connectivity allows remote monitoring, real-time diagnostics, and seamless updates. Engineers use IoT data for ongoing optimization and predictive analytics.

Key benefits of IoT-enabled smart rectifiers:

Continuous performance monitoring

Automated fault detection

Remote firmware upgrades

IoT integration supports energy management by enabling adaptive control and system-wide optimization. Smart rectifiers become part of a larger digital ecosystem, improving both reliability and efficiency.

Predictive Maintenance

Predictive maintenance leverages AI and IoT data to forecast equipment health. Smart rectifiers analyze trends in voltage, temperature, and load cycles. This analysis identifies potential failures before they occur. Maintenance teams receive alerts, which reduces downtime and extends equipment lifespan.

Predictive maintenance ensures optimal operation and supports long-term optimization strategies. Energy management systems benefit from fewer disruptions and lower maintenance costs.

High-Efficiency Rectifiers

Energy Efficiency

High-efficiency rectifiers set new standards for energy conversion in modern power systems. Manufacturers now achieve efficiency benchmarks above 98%, which means less energy is lost as heat during conversion. This improvement directly impacts sectors like electric vehicle charging, renewable energy, and marine transportation. For example, fast EV charging stations rely on high-efficiency rectifiers to deliver rapid, reliable power while minimizing waste. On-board chargers (OBCs) in electric vehicles also benefit from these advancements, supporting faster charging cycles and longer battery life.

Market research from Global Growth Insights shows that high-efficiency power conversion equipment, including rectifiers, is in high demand for hybrid marine systems. These systems optimize energy flows and reduce onboard losses. Integrated electrical systems now appear in over 36% of new marine vessels, improving energy efficiency and reducing downtime. Power distribution systems in these vessels save up to 18% of energy through modular load management. Electrical propulsion systems have seen a 47% increase in adoption over five years, driven by fuel economy and emission reduction. High-efficiency rectifiers play a key role in these trends, supporting energy-saving goals and compact system design.

⚡ High-efficiency rectifiers help operators meet strict energy-saving targets and lower operational costs. Their adoption supports global efforts to reduce emissions and improve sustainability.

Power Density

Engineers continue to push the limits of high power density in rectifier design. Compact, high-efficiency rectifiers now deliver more power in smaller packages, which is essential for applications with limited space. Fast EV charging stations, for instance, require rectifiers that can handle up to 350 kW while maintaining a small footprint. Inductor-less converters represent another leap forward, offering high power density and simplified architecture. These devices reduce the need for bulky magnetic components, making them ideal for both automotive and industrial energy systems.

The trend toward modular and scalable rectifier systems allows for flexible adaptation to changing energy demands. Data centers, renewable energy installations, and marine vessels all benefit from this approach. High-efficiency rectifiers with high power density enable rapid deployment and easy maintenance. Operators can expand capacity or replace modules without major system overhauls.

Key advantages of high power density rectifiers:

Smaller size and weight

Greater installation flexibility

Enhanced energy-saving performance

Energy-saving rectifiers now support a wide range of charging and power conversion needs. Their compactness and efficiency drive innovation in electric mobility, marine transport, and distributed energy systems.

Thermal Management

Cooling Solutions

Thermal management stands as a critical factor in the performance and longevity of modern DC rectifier systems. Engineers now deploy a range of cooling solutions to address the heat generated by high-efficiency power conversion. Forced-air cooling remains a common choice for telecom and data center applications. Liquid cooling solutions, however, have gained popularity in high-power environments such as EV charging stations and industrial converters. These solutions transfer heat away from sensitive components more effectively than traditional methods.

Manufacturers design modular cooling solutions that adapt to varying power densities and installation constraints. Heat sinks with optimized fin geometry, vapor chambers, and integrated heat pipes represent advanced solutions for compact rectifier modules. Some systems use phase change cooling solutions to absorb and dissipate large amounts of heat during peak operation. These solutions ensure stable operation, reduce thermal stress, and extend equipment lifespan.

💡 Engineers select cooling solutions based on system size, power density, and environmental conditions. The right combination of solutions can improve efficiency and reliability across diverse applications.

Thermal Materials

Advanced thermal materials play a vital role in the effectiveness of cooling solutions. Researchers have developed materials with superior heat storage, conductivity, and stability. For example, multifunctional phase change composite films (MPCCF) achieve sub-ambient cooling of 7.0 °C under 732 W/m² solar irradiance, supporting all-climate thermal management in power converters. Al-Si@Void@SiO2 microencapsulated phase change materials (MEPCMs) offer a latent heat of 454.9 J/g and encapsulation efficiency of 90.7%, ensuring high thermal stability for energy storage applications.

The following table highlights key numerical evidence from recent material studies:

Material / Study | Key Numerical Evidence | Thermal Performance Aspect | Application Context |

|---|---|---|---|

Multifunctional Phase Change Composite Film (MPCCF) | Sub-ambient cooling of 7.0 °C | Adaptive solar reflectivity, passive cooling, active heating | All-climate thermal management relevant to power converters |

Al-Si@Void@SiO2 MEPCMs | Latent heat: 454.9 J/g; Encapsulation efficiency: 90.7% | High latent heat, excellent thermal stability | High temperature thermal energy storage |

Phase Change Capsules (SnBi58@Void@TiO2 MEPCMs) | Heat storage density: 496 J/g; Thermal cycling durability: up to 1300 cycles | High thermal stability, volume expansion accommodation | High temperature thermal energy storage |

Paraffin/Olefin Block Copolymer in Expanded Graphite (FPCM) | Enhanced thermal conductivity | Efficient and reliable thermal management | Battery thermal management |

Ceramic Shape-Stabilized PCMs (SSPCM) | High latent heat and thermal conductivity | Excellent thermal reliability | Next-generation thermal energy storage |

Engineers integrate these materials into cooling solutions for rectifiers, batteries, and power modules. The combination of advanced materials and innovative solutions enables higher efficiency, greater reliability, and improved safety in high-power applications. As power densities continue to rise, the demand for effective thermal management solutions will only increase.

Sustainability

Energy Recovery

Modern DC rectifier systems now play a vital role in achieving sustainability goals. Engineers design these systems to capture and reuse energy that would otherwise go to waste. Energy recovery circuits redirect excess energy from braking or load fluctuations back into the grid or storage. This process supports renewable energy sources by making power conversion more efficient and reliable.

Many renewable installations, such as solar farms and wind turbines, depend on advanced rectifiers for energy-saving performance. These systems help operators meet strict sustainability targets. Energy recovery not only reduces operational costs but also supports sustainability and carbon footprint reduction. The integration of energy recovery features in rectifiers aligns with global efforts to maximize the use of renewable resources.

⚡ Energy recovery in rectifier systems delivers clear environmental benefits and supports the transition to a cleaner energy future.

Green Materials

Manufacturers now prioritize green materials to advance sustainability in power electronics. They select components with low environmental impact and high recyclability. Many companies use biodegradable insulation, lead-free solder, and recycled metals in rectifier modules. These choices support sustainability goals and reduce the environmental burden of electronic waste.

The use of green materials also improves compatibility with renewable energy sources. Engineers design rectifiers to operate efficiently with solar, wind, and other renewable systems. This approach ensures that energy-saving technologies remain sustainable throughout their lifecycle.

Key advantages of green materials in rectifiers:

Lower resource consumption

Enhanced support for renewable integration

Improved alignment with sustainability standards

Sustainability now drives innovation in DC rectifier systems. The focus on energy recovery and green materials helps the industry meet rising demand for renewable solutions and achieve long-term sustainability.

Applications of DC Rectifier Systems

EV Charging

Modern dc rectifier system technology drives the rapid expansion of electric vehicle charging infrastructure. Engineers design telecom rectifiers for ultra-fast charging stations, enabling power delivery up to 350 kW. These systems achieve high efficiency, which reduces energy loss and supports shorter charging times. Integrated on-board chargers (OBCs) in vehicles rely on compact, high-efficiency telecom rectifiers to convert AC grid power into DC for battery storage. The result is reliable, safe, and energy-saving charging for both passenger and commercial vehicles. Operators benefit from modular solutions that scale with demand and simplify maintenance.

Data Centers

Data centers require continuous, stable energy to support critical digital operations. Telecom rectifiers play a central role in converting AC input to DC power for servers and network equipment. High efficiency ensures minimal energy waste, which lowers operational costs and reduces heat generation. Engineers select advanced rectifier technology to maximize uptime and support high-density server racks. Modular solutions allow for easy expansion and rapid replacement, ensuring that data centers can adapt to changing workloads. Energy management systems monitor and optimize power flows, further improving efficiency and reliability.

Renewables

The renewable energy sector depends on advanced dc rectifier system designs to integrate solar, wind, and other sources into the grid. Telecom rectifiers convert variable AC or DC outputs from renewable sources into stable DC power for storage or direct use. High efficiency is essential for maximizing the usable energy harvested from renewables. Engineers implement rectifier technology that supports energy recovery, reducing waste and improving overall system performance. These solutions enable seamless integration of distributed energy resources, helping operators meet sustainability targets and regulatory requirements.

Wireless Power

Wireless power transfer has emerged as a promising application for telecom rectifiers, especially in low-power and IoT environments. Engineers use specialized antenna designs to enhance energy transfer efficiency. Recent studies demonstrate that microstrip circular patch antennas with defected ground structures (DGS) improve wireless power transfer performance. The following table summarizes key findings from simulation and prototype research:

Aspect | Description |

|---|---|

Antenna Type | Microstrip circular patch, wideband circularly-polarized arrays with DGS |

Simulation Frequency | 2.45 GHz |

Substrate | FR4, dielectric constant 4.4–4.7, thickness 0.8–1.58 mm |

Patch Material | Copper, thickness 0.035 mm |

Key Results | DGS improves return loss, bandwidth, gain, and suppresses cross-polarization by up to 12 dB |

These results confirm that optimized antenna and rectifier designs can significantly boost wireless energy transfer efficiency. Telecom rectifiers in wireless power systems enable new solutions for remote sensors, medical implants, and smart devices, supporting the growth of the renewable and connected technology landscape.

Recent innovations in DC rectifier systems—such as SiC and GaN semiconductors, modular topologies, and AI-driven controls—deliver higher efficiency, reliability, and sustainability. These advancements support fast EV charging, renewable integration, and compact designs.

Engineers now achieve over 98% efficiency and greater power density.

Operators benefit from improved energy recovery and green materials.

The future promises even broader applications as rectifier systems evolve to meet growing demands in transportation, data, and clean energy.

FAQ

What advantages do SiC and GaN semiconductors offer in DC rectifier systems?

SiC and GaN semiconductors provide higher efficiency, faster switching speeds, and greater power density. These materials reduce energy loss and allow for smaller, lighter rectifier designs. Engineers use them to improve reliability and performance in demanding applications like EV charging and renewable energy.

How do modular rectifier systems benefit operators?

Modular rectifier systems enable quick installation, easy maintenance, and flexible scaling. Operators can replace faulty modules without shutting down the entire system. This approach reduces downtime and supports seamless upgrades as power demands change.

Why is thermal management important in high-efficiency rectifiers?

Effective thermal management prevents overheating, which can damage components and reduce system lifespan. Advanced cooling solutions and thermal materials help maintain stable operation. Engineers rely on these strategies to ensure safe, reliable, and efficient power conversion.

Can AI and IoT integration improve rectifier performance?

AI and IoT integration enable real-time monitoring, predictive maintenance, and adaptive control. These technologies help optimize energy use, reduce transmission losses, and extend equipment life. Operators gain valuable insights for proactive decision-making.

What role do DC rectifier systems play in sustainability?

DC rectifier systems support sustainability by enabling energy recovery, reducing waste, and using green materials. These systems help operators meet environmental goals and integrate renewable energy sources efficiently.

See Also

Telecom Cabinet Power Using Solar Inverter And Battery Setup

In-Depth Analysis Of High-Efficiency Air Conditioning Systems

Steps To Guarantee Stable Power For Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA