EATEL Highlights Emerging Trends in Rectifier Modules for 2025

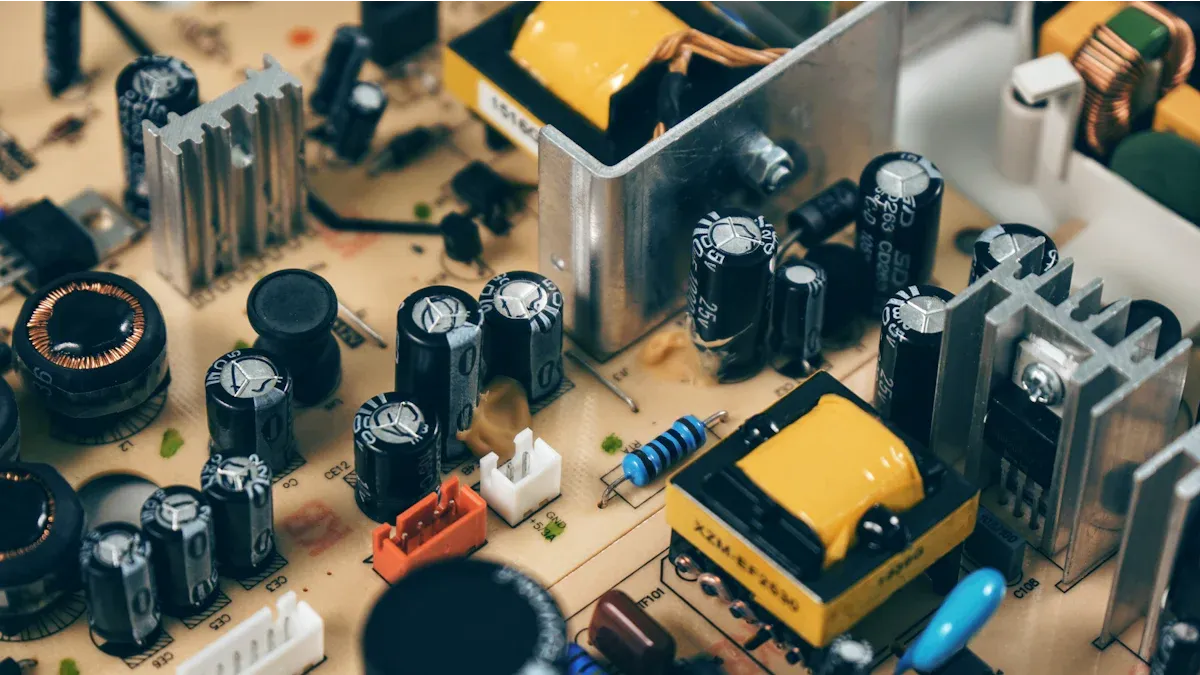

Rectifier modules play a crucial role in powering modern advancements across industries. Their ability to convert alternating current (AC) to direct current (DC) is pivotal for efficient energy utilization. In 2025, the global market for high-frequency switching rectifiers is expected to experience substantial growth, driven by the demand for energy-efficient solutions across sectors.

The automotive industry's shift toward electrification relies heavily on rectifier technology to enhance power electronics in electric vehicles. Similarly, renewable energy applications, such as solar inverters and wind converters, leverage rectifier modules to achieve superior power conversion efficiency.

Emerging trends in rectifier modules are transforming applications in telecommunications, renewable energy, and industrial systems. EATEL remains at the forefront of innovation, setting benchmarks for advancements in rectifier technology.

Key Takeaways

Special materials like SiC and GaN make rectifiers work better. They use less energy and perform faster.

New cooling methods, like vapor chambers, help rectifiers last longer and work more reliably.

Smaller rectifier designs save space and energy, perfect for data centers and telecoms.

IoT helps check rectifiers in real-time, keeping them stable and fixing problems early.

Making rectifiers eco-friendly uses green materials and methods, helping the planet and meeting energy rules.

Advancements in Rectifier Modules

Wide Bandgap Semiconductors Revolutionizing Performance

Wide bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), are transforming the industrial rectifiers market. These materials enable rectifiers to operate at higher voltages, frequencies, and temperatures compared to traditional silicon-based technologies. Their ability to minimize energy loss during power conversion makes them a cornerstone of compact and energy-efficient solutions.

The US Department of Energy highlights the potential of wide bandgap semiconductors in improving performance across various applications, including rectifier modules. For instance, a case study on motor drives demonstrated significant efficiency gains in high-frequency operations. Additionally, research on 5G telecom rectifiers emphasizes the role of these semiconductors in developing reliable power supply units. Gallium nitride technology, in particular, has shown remarkable advantages in server and telecom applications, further solidifying its position in global market trends for diode modules.

These advancements not only enhance the efficiency of rectifiers but also reduce operational costs for industries. By achieving efficiency levels of up to 97%, modern rectifiers significantly lower energy loss, making them indispensable in sectors like telecommunications and renewable energy.

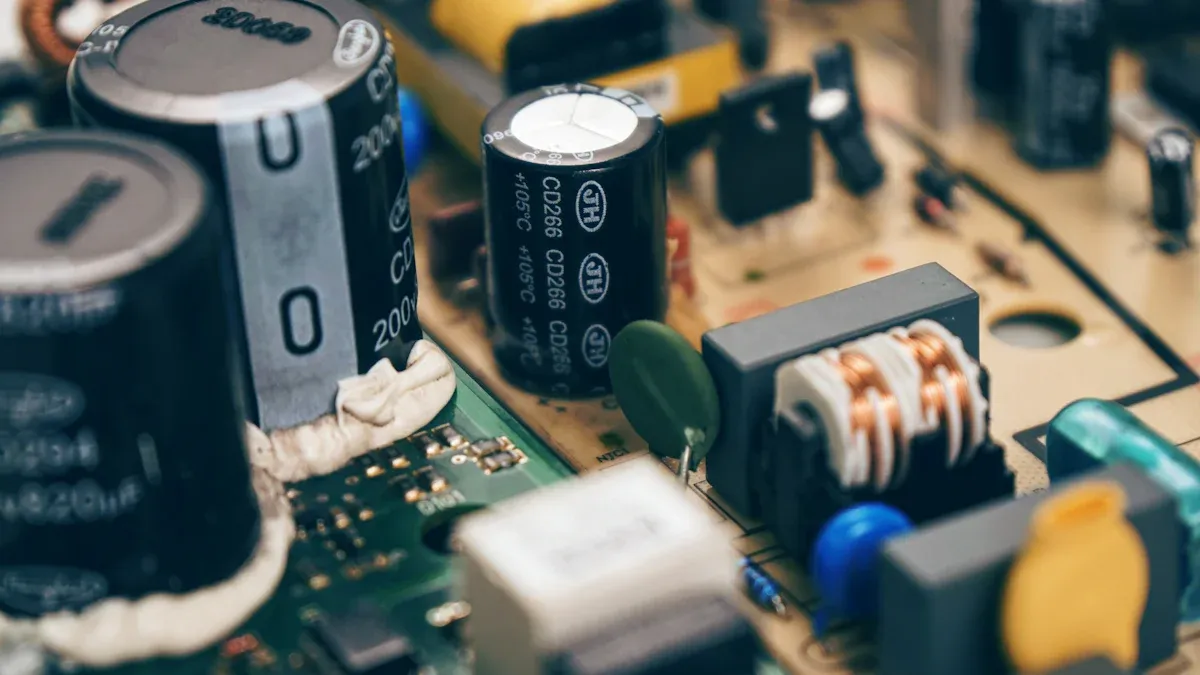

Enhanced Thermal Management for Longevity

Thermal management plays a critical role in extending the lifespan of rectifier modules. Innovations in this area focus on improving temperature uniformity and reducing thermal resistance. For example, vapor chamber technology has proven to be a game-changer. It provides a temperature difference of just 1.3 ºC compared to 5.5 ºC for traditional copper baseplates under a 240 W heat input. This improvement ensures better temperature distribution and reduces thermal stress.

A study on insulated-gate bipolar transistors (IGBTs) with vapor chamber modules revealed a 45.2% reduction in junction-to-ambient thermal resistance. This reduction not only decreases thermal stress by 21.8% but also increases the cycles to failure for die solder joints by 9%. These findings underscore the importance of advanced thermal management in enhancing the reliability and durability of rectifiers.

By addressing thermal challenges, manufacturers can develop rectifiers that perform consistently under demanding conditions. This innovation is particularly crucial for applications in harsh environments, where maintaining operational stability is essential.

Compact Designs for Space Optimization

The demand for compact rectifiers has surged as industries prioritize space-saving solutions without compromising performance. Recent advancements in design metrics have enabled the development of smaller, more efficient rectifier modules. For instance, two control structures for capacitor voltage balancing in cascaded rectifier stages have been analyzed, introducing ultra-fast balance modulation trajectories. These innovations ensure reliable operation while minimizing the physical footprint of the modules.

Simulation studies and experiments validate these design strategies, demonstrating their effectiveness in achieving space optimization. Modulation methods, such as phase-shifting carrier modulation and specific harmonic elimination, further enhance the performance of compact rectifiers. These techniques allow for precise control and improved efficiency, making them ideal for applications in data centers and telecommunications.

Compact rectifiers not only save space but also contribute to energy efficiency by reducing standby power losses. As industries continue to adopt these advanced designs, the global market trends for diode modules are expected to shift toward more compact and energy-efficient solutions.

Integration of Rectifiers with Smart Systems

IoT-Enabled Monitoring and Control

The integration of IoT (Internet of Things) into rectifiers has revolutionized how industries manage power systems. IoT-enabled rectifiers provide real-time monitoring capabilities, allowing operators to track performance metrics such as voltage, current, and temperature. This level of monitoring ensures that systems remain stable and efficient, even under varying load conditions.

Smart manufacturing facilities benefit significantly from IoT-enabled rectifiers. These systems can send alerts when performance deviates from optimal levels, enabling quick corrective actions. For example, in emerging applications of diode modules, IoT technology ensures seamless operation by detecting and addressing potential issues before they escalate. This proactive approach reduces downtime and enhances overall system reliability.

AI-Powered Predictive Maintenance

Artificial intelligence (AI) has introduced predictive maintenance capabilities to rectifier technology. By analyzing historical data and identifying patterns, AI systems can predict when a rectifier might fail or require maintenance. This approach minimizes unexpected breakdowns and reduces downtime.

The table below highlights the key features and benefits of AI-powered predictive maintenance:

Feature | Benefit |

|---|---|

Real-time monitoring | Identifies potential issues early, ensuring uninterrupted performance. |

Predictive maintenance | Optimizes operations, reducing energy consumption and maintenance costs. |

Performance metrics tracking | Ensures stable and consistent power delivery. |

These advancements in smart manufacturing have made rectifiers more reliable and cost-effective. Industries now rely on AI-driven solutions to maintain operational efficiency and extend the lifespan of their equipment.

Real-Time Data Analytics for Efficiency

Real-time data analytics has become a cornerstone of modern rectifier systems. By continuously analyzing performance data, these systems can optimize power delivery and improve energy efficiency.

Recent reports highlight the growing adoption of real-time monitoring and analytics in rectifier technology:

Over 34% of new rectifier units launched in 2024 include digital control systems for monitoring voltage stability and predicting maintenance cycles.

44% of DC rectifier units shipped in 2024 are equipped with predictive maintenance software, enabling real-time system analysis.

More than 45% of product launches in 2023-2024 feature compact, fanless, and modular designs to enhance flexibility.

Approximately 37% of companies are now looking for rectifiers with energy efficiency ratings exceeding 90%.

These trends demonstrate the importance of real-time analytics in emerging applications of diode modules. By leveraging data-driven insights, industries can achieve reduced downtime and improved operational performance.

Trends in Energy Efficiency

High-Efficiency Power Conversion Technologies

High-efficiency power conversion technologies are reshaping the landscape of rectifiers. These innovations focus on minimizing energy loss during the conversion process, ensuring optimal performance across various applications. Modern rectifiers now achieve conversion efficiencies exceeding 95%, a significant leap from earlier designs. This enhanced efficiency reduces energy waste and lowers operational costs, making these systems indispensable for industries prioritizing energy-efficient solutions.

One notable advancement is the adoption of synchronous rectification. This technique replaces traditional diodes with MOSFETs (metal-oxide-semiconductor field-effect transistors), which exhibit lower conduction losses. As a result, rectifiers equipped with synchronous rectification deliver superior power quality and reliability. Additionally, advancements in control algorithms have enabled dynamic load balancing, further improving energy optimization in real-time.

These technologies are particularly beneficial in sectors such as telecommunications and renewable energy, where consistent power delivery is critical. By integrating high-efficiency power conversion technologies, industries can achieve both energy efficiency and operational sustainability.

Reducing Standby Power Losses

Standby power losses, often referred to as "vampire power," account for a significant portion of energy waste in modern systems. Rectifiers designed with advanced energy-saving features address this issue by minimizing power consumption during idle states.

One effective approach involves the use of low-power sleep modes. These modes allow rectifiers to reduce energy usage when demand is low, without compromising system readiness. For example, rectifiers in data centers now incorporate intelligent power management systems that automatically transition between active and standby states based on real-time load requirements.

Another innovation is the implementation of zero-power standby circuits. These circuits eliminate energy consumption during idle periods, ensuring maximum energy efficiency. Industries adopting these solutions report substantial reductions in energy costs and carbon emissions.

Reducing standby power losses not only supports energy-efficient solutions but also aligns with global trends in energy optimization. As more industries embrace these advancements, the demand for rectifiers with low standby power consumption continues to grow.

Meeting Global Energy Standards

Compliance with global energy standards has become a key driver of innovation in rectifier technology. Manufacturers now design rectifiers to meet stringent efficiency benchmarks, ensuring compatibility with international regulations. These standards promote energy optimization and encourage the adoption of energy-efficient solutions across industries.

The table below highlights some of the key metrics used to evaluate compliance with global energy standards:

Evidence Type | Description |

|---|---|

Compares national energy consumption between standards cases and no new standards. | |

Full-Fuel-Cycle (FFC) Energy Savings | Measures energy use and emissions, ensuring comprehensive evaluation of energy efficiency standards. |

Compliance Dates | Specifies when standards must be met, providing a timeline for adherence to international requirements. |

Rectifiers designed to meet these standards often incorporate advanced features such as real-time monitoring and adaptive control systems. These features ensure consistent power quality while maintaining compliance with energy efficiency regulations.

By adhering to global energy standards, industries can achieve enhanced efficiency and contribute to a more sustainable future. The integration of these standards into rectifier design reflects broader trends in energy efficiency and sustainability.

Industry-Specific Customization of Rectifier Modules

Renewable Energy Applications

The renewable energy sector demands rectifier modules tailored to its unique requirements. Standard rectifiers often fail to address the challenges posed by intermittent power sources like solar and wind. Customized rectifier solutions enhance performance and efficiency, making them indispensable for renewable energy solutions. For instance, Germany’s Energiepark Mainz employs advanced rectifiers to stabilize the output of a 6 MW PEM electrolyzer, ensuring rapid response to fluctuating power inputs. Similarly, California’s hydrogen refueling stations rely on modular electrolysers with high-efficiency rectifiers to maintain strict voltage tolerances. These innovations highlight the growing trend toward sector-specific rectifier customization.

A 2023 study by MIT demonstrated the impact of GaN-enabled rectifiers in renewable energy projects. These rectifiers reduced hydrogen production costs by €0.18/kg in PEM configurations, showcasing their role in improving cost-efficiency. As renewable energy adoption grows, the demand for rectifiers designed to meet these specific challenges will continue to rise.

High-Density Solutions for Data Centers

Data centers require high-density rectifiers to meet the increasing power demands of modern computing platforms. These rectifiers must deliver exceptional performance while minimizing space and energy consumption. The TDM2254xD series exemplifies innovation in this area. Its robust design combines OptiMOS TM MOSFET technology with advanced packaging to achieve industry-leading electrical and thermal performance. This allows data centers to operate at higher efficiency, reducing total cost of ownership.

The modules’ unique design enables efficient heat transfer through optimized inductor structures. This innovation achieves a 2% higher efficiency than the industry average at full load, ensuring reliable operation under demanding conditions.

High-density rectifiers also support the integration of AI-driven systems, which require consistent and efficient power delivery. By adopting these solutions, data centers can enhance operational efficiency while addressing the growing energy demands of AI and cloud computing platforms.

Ruggedized Modules for Harsh Environments

Industries operating in extreme conditions require ruggedized rectifier modules capable of withstanding harsh environments. These modules must maintain performance under wide temperature ranges and high thermal stress. Advanced designs now feature operating temperature ranges from -40°C to 75°C and power outputs exceeding 2400W at 65°C. Their efficiency approaches 96.9%, making them ideal for high-density telecom applications.

Feature | Specification |

|---|---|

Operating Temperature Range | -40 to 75°C (-40 to 176°F) |

Full Rated Output | Up to 55°C (131°F) |

Power Output at High Temperature | >2400W @ 65°C (149°F) |

Efficiency | Approaching 96.9% |

Power Density | 35W/in3 |

Applications | High-density telecom applications |

These ruggedized rectifiers ensure reliability in industries such as telecommunications and defense. Their ability to perform under extreme conditions underscores the importance of innovation in rectifier technology.

Sustainability in Rectifier Technology

Eco-Friendly Materials and Manufacturing

Sustainability considerations in diode module production have led to the adoption of eco-friendly materials and manufacturing processes. Manufacturers now prioritize materials with lower environmental impact, such as recycled metals and biodegradable polymers. These materials reduce waste and promote resource efficiency during production. For instance, silicon carbide (SiC) and gallium nitride (GaN) components are increasingly used due to their durability and energy-saving properties.

Innovative manufacturing techniques further enhance sustainability. Processes like additive manufacturing minimize material waste by building components layer by layer. This approach not only reduces resource consumption but also improves production efficiency. By adopting these practices, industries align with global trends in sustainable manufacturing, ensuring rectifier modules contribute to a greener future.

Reducing Carbon Footprint in Production

Sustainability considerations in diode module production extend to reducing carbon footprints during manufacturing. The Life Cycle Assessment (LCA) methodology evaluates the environmental impact of SiC MOSFETs, quantifying CO2-equivalent emissions. This metric highlights how production changes can improve sustainability outcomes. Similarly, greenhouse gas emissions from ultra-low power MCUs are measured to assess climate change impacts. These assessments underscore the importance of optimizing manufacturing processes to reduce emissions.

Energy-efficient production techniques play a pivotal role in lowering carbon footprints. For example, manufacturers now use renewable energy sources to power production facilities. This shift reduces reliance on fossil fuels and minimizes greenhouse gas emissions. By implementing these strategies, industries demonstrate their commitment to sustainability while meeting global energy standards.

Supporting Circular Economy Practices

Sustainability considerations in diode module production increasingly focus on supporting circular economy practices. These practices emphasize resource recovery and reuse, reducing waste and extending the lifecycle of materials. Manufacturers now design rectifier modules with modular components that can be easily replaced or upgraded. This approach minimizes electronic waste and promotes long-term sustainability.

Recycling programs further enhance circular economy efforts. Industries collect and process used rectifier modules to recover valuable materials like copper and aluminum. These materials are then reintroduced into production cycles, reducing the need for virgin resources. By adopting circular economy practices, manufacturers contribute to sustainability while addressing environmental challenges.

The transformative trends in rectifier module technology for 2025 are reshaping industries with remarkable advancements. Manufacturers are achieving higher efficiency and power density, with modules now exceeding 90% efficiency. Compact and lightweight designs are meeting the growing demand for space-saving solutions, especially in consumer electronics. The integration of smart technologies, such as real-time monitoring and predictive maintenance, is enhancing operational reliability. Sustainability initiatives, including the use of recyclable materials and eco-friendly manufacturing, are further driving innovation in the sector.

These advancements are significantly impacting industries like telecommunications, renewable energy, and AI-driven data centers. For example, the growth of solar and wind energy installations has increased the demand for efficient rectification solutions. Similarly, data centers benefit from high-density rectifiers that optimize energy use while supporting AI systems.

EATEL continues to lead the way in innovation, setting benchmarks for rectifier module performance and sustainability. By addressing industry-specific needs and embracing cutting-edge technologies, EATEL is shaping the future of rectifier technology.

FAQ

What are rectifier modules, and why are they important?

Rectifier modules convert alternating current (AC) into direct current (DC). This process is essential for powering devices and systems that require stable DC power, such as telecommunications equipment, renewable energy systems, and industrial machinery.

How do wide bandgap semiconductors improve rectifier performance?

Wide bandgap semiconductors, like silicon carbide (SiC) and gallium nitride (GaN), enable higher voltage, frequency, and temperature operation. These materials reduce energy loss, enhance efficiency, and support compact designs, making them ideal for advanced applications.

What role does AI play in rectifier technology?

AI enables predictive maintenance by analyzing performance data to forecast potential failures. This approach minimizes downtime, reduces maintenance costs, and ensures consistent power delivery. AI also optimizes energy efficiency through real-time adjustments.

How do rectifiers contribute to sustainability?

Rectifiers support sustainability by using eco-friendly materials, reducing standby power losses, and meeting global energy standards. Manufacturers also adopt circular economy practices, such as recycling components, to minimize environmental impact.

Can rectifier modules be customized for specific industries?

Yes, manufacturers design rectifiers to meet industry-specific needs. For example, renewable energy systems use rectifiers optimized for fluctuating power inputs, while data centers require high-density modules for efficient energy use in limited spaces.

See Also

New Developments Shaping Outdoor Telecom Cabinet Designs

Innovative Energy Storage Solutions for ESTEL Telecom Cabinets

Best Materials for ESTEL Outdoor Telecom Cabinets by 2025

Integrated Solar Inverter and Battery Systems for Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA