80Plus Titanium Certification for Telecom Cabinet Communication Power Systems: Full-Process Compliance Strategy from Design to Testing

You can achieve 80Plus Titanium Certification for Telecom Power Systems by following a clear, step-by-step process. Meeting strict efficiency and power factor targets at every stage matters. When you reach Titanium-level certification, you gain major operational and environmental advantages:

Benefit Type | Description |

|---|---|

Energy Efficiency Improvement | Titanium-certified supplies reach up to 96% efficiency at 50% load. |

Cost Reduction | Deployments show up to 43% less annual server power consumption. |

Cooling and Maintenance Savings | Lower heat output cuts cooling and maintenance costs. |

Environmental Impact | Some routers achieve up to 63% less CO2 emissions. |

Reliability and Lifespan | Less heat extends equipment life and reduces thermal stress. |

Key Takeaways

Achieving 80Plus Titanium Certification requires a step-by-step approach. Start with requirement analysis and follow through design, testing, and documentation.

Focus on energy efficiency to gain significant benefits. Titanium-certified systems can reach up to 96% efficiency, leading to lower energy costs and reduced environmental impact.

Select high-quality components and advanced designs. Use wide-bandgap semiconductors and modular architectures to enhance efficiency and reliability.

Conduct thorough pre-compliance testing. Early checks help identify issues and ensure your system meets the strict efficiency and power factor standards.

Maintain clear documentation throughout the process. Organized records speed up certification and help resolve any issues quickly.

Compliance Path

Step Overview

You need a clear roadmap to achieve 80Plus Titanium Certification for Telecom Power Systems. Start by understanding the requirements and breaking down the process into manageable steps. Each step builds on the previous one, so you can track progress and avoid missing critical details.

Here is a typical step-by-step approach:

Requirement Analysis

Review the 80Plus Titanium standards. Identify efficiency and power factor targets for your system.Design Planning

Set design goals that align with certification benchmarks. Choose components that support high efficiency.Prototype Development

Build a prototype based on your design. Integrate energy-saving features and modular architecture.Pre-Compliance Testing

Test the prototype under different load conditions. Check if it meets efficiency and power factor standards.Documentation Preparation

Collect all test results and technical documents. Prepare them for submission.Final Certification Testing

Submit your system for official testing. Address any feedback from the certification body.

Tip: Document each step carefully. Good records help you resolve issues quickly and streamline the certification process.

Key Milestones

You should focus on reaching specific milestones during your compliance journey. These milestones help you measure progress and ensure you stay on track.

Milestone | Description | Outcome |

|---|---|---|

Requirement Review | Analyze Titanium standards and system needs | Clear compliance targets |

Design Freeze | Finalize design and component choices | Ready for prototyping |

Prototype Completion | Build and integrate system modules | System ready for testing |

Pre-Compliance Pass | Achieve target efficiency and power factor in tests | Eligible for documentation |

Documentation Submission | Prepare and submit all required materials | Ready for certification review |

Certification Approval | Pass official testing and receive Titanium certification | Market-ready product |

You can use these milestones as checkpoints. Each one marks a significant achievement in your path to certification.

80Plus Titanium in Telecom Power Systems

Certification Levels

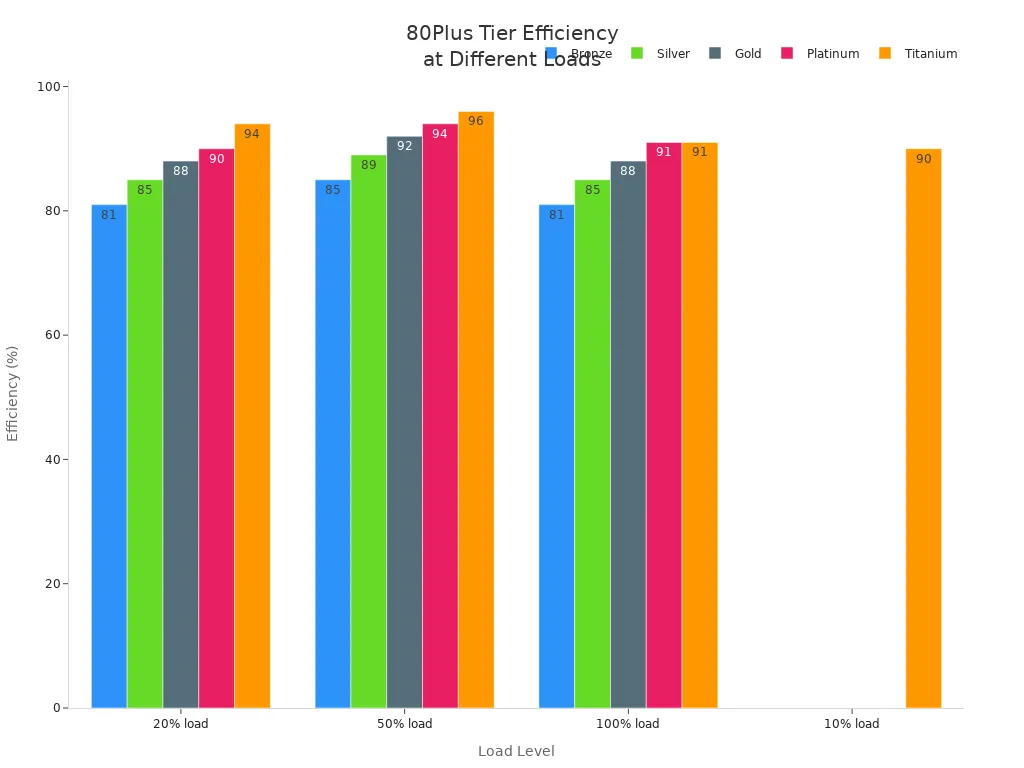

You need to understand how 80Plus Titanium compares to other certification tiers. Each level sets different standards for efficiency and power factor. Titanium stands at the top, demanding the highest performance from your power supply. The table below shows how Titanium stacks up against Bronze, Silver, Gold, and Platinum:

Efficiency Level | 10% load | 20% load | 50% load | 100% load | Power Factor min at 50% load |

|---|---|---|---|---|---|

Bronze | N/A | 81% | 85% | 81% | 0.9 |

Silver | N/A | 85% | 89% | 85% | 0.9 |

Gold | N/A | 88% | 92% | 88% | 0.9 |

Platinum | N/A | 90% | 94% | 91% | 0.95 |

Titanium | 90% | 94% | 96% | 91% | 0.95 @ 20% load |

Titanium certification pushes you to reach the highest efficiency and power factor standards in Telecom Power Systems.

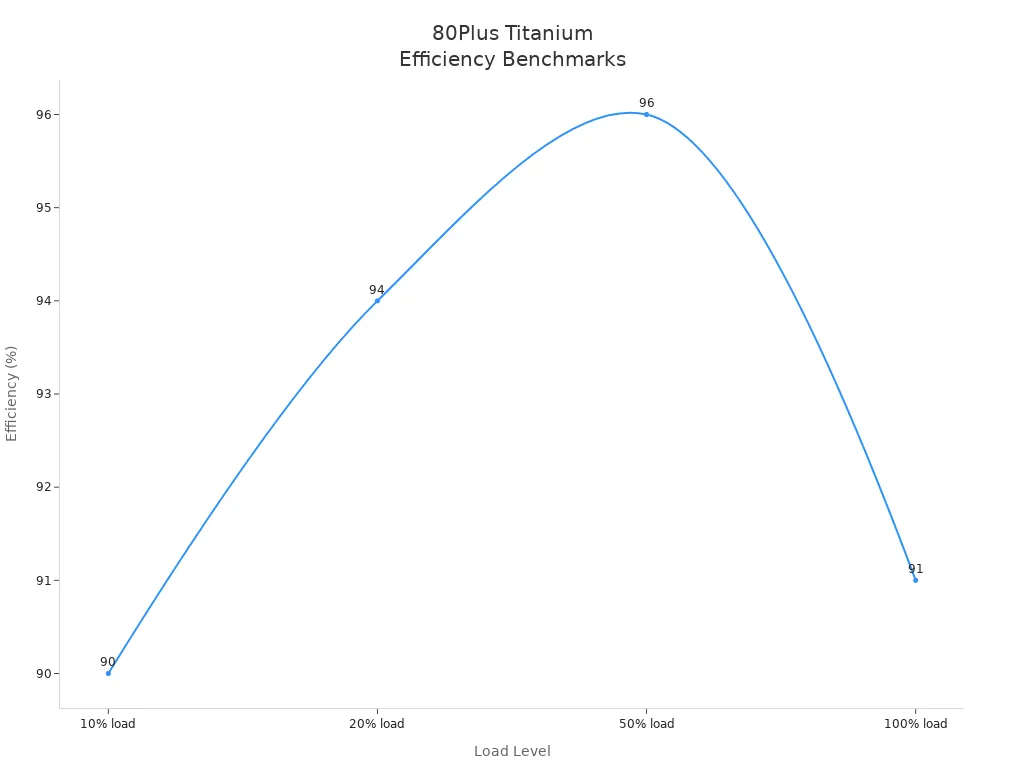

Efficiency Benchmarks

You must meet strict efficiency targets at every load level to achieve Titanium certification. These benchmarks ensure your system uses energy wisely and reduces waste. Here are the required efficiency levels:

Load Level | Efficiency |

|---|---|

10% | 90% |

20% | 94% |

50% | 96% |

100% | 91% |

10% load: 90%

20% load: 94%

50% load: 96%

100% load: 91%

You can see that Titanium sets higher efficiency requirements than Platinum, especially at 50% load. This means your system must perform well even when not running at full capacity.

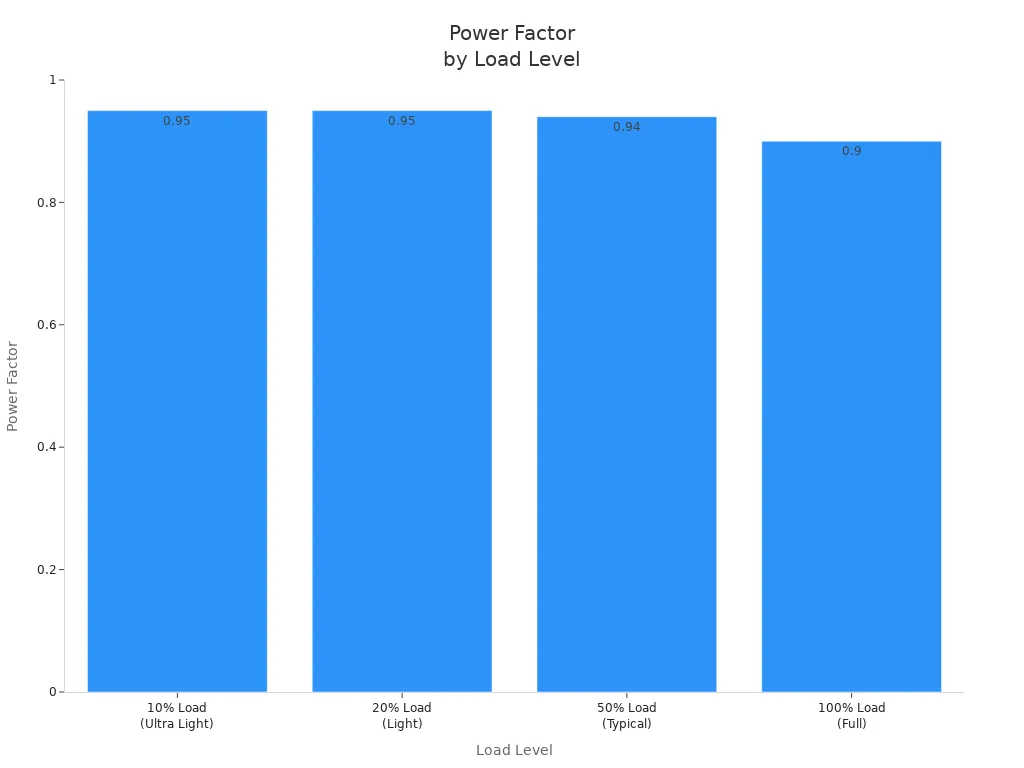

Power Factor Standards

You also need to meet power factor standards at different load levels. Power factor measures how effectively your system uses electricity. A higher power factor means less wasted energy. The table below shows the minimum power factor you must achieve:

Load Level | Power Factor |

|---|---|

10% Load (Ultra Light) | 0.95 |

20% Load (Light) | 0.95 |

50% Load (Typical) | 0.94 |

100% Load (Full) | 0.90 |

You must pay close attention to these numbers during design and testing. Meeting these standards helps your Telecom Power Systems run efficiently and reliably.

Design Phase

Efficiency Targets

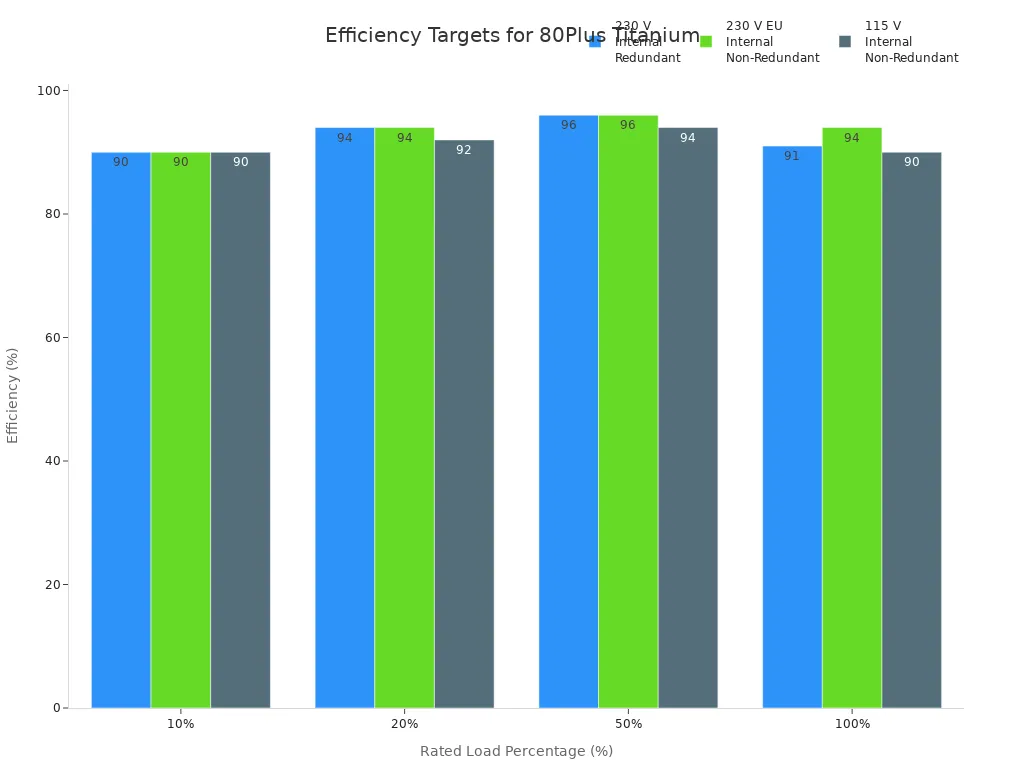

You should set clear efficiency targets at the start of your design process. Meeting 80Plus Titanium standards means your system must reach high efficiency at different load levels. The table below shows the required efficiency for various configurations:

Rated load percentage (%) | 230 V Internal Redundant | 230 V EU Internal Non-Redundant | 115 V Internal Non-Redundant |

|---|---|---|---|

10 | 90% | 90% | 90% |

20 | 94% | 94% | 92% |

50 | 96% | 96% | 94% |

100 | 91% | 94% | 90% |

You need to design your system to meet or exceed these numbers at every stage. This approach helps you avoid costly redesigns later.

Component Selection

Choosing the right components is essential for both efficiency and reliability. Focus on these critical factors:

Wattage: Select a power supply unit (PSU) that can handle at least 20% more than your total system wattage. This extra capacity helps manage power surges.

Efficiency Rating: Pick components with high efficiency ratings, such as 80 PLUS Titanium. These parts lower electricity costs and reduce heat.

Redundancy: Use multiple power supplies. If one fails, your system keeps running without interruption.

Tip: High-quality components not only improve efficiency but also extend the lifespan of your equipment.

System Architecture

You can boost efficiency by using advanced design strategies. The table below outlines some effective approaches:

Strategy | Description |

|---|---|

Advanced Power Factor Correction | Use highly efficient active PFC, like totem pole topology, to meet strict efficiency requirements. |

Wide-Bandgap Semiconductors | Choose SiC and GaN devices for faster switching and lower resistance, which improves efficiency. |

Bridgeless PFC Topologies | Implement bridgeless PFC circuits to reduce conduction losses and increase overall efficiency. |

Target Efficiency | Aim for 96% peak efficiency and 98.5% PFC circuit efficiency to comply with Titanium standards. |

These strategies help you reach the demanding benchmarks set for Telecom Power Systems.

Thermal Planning

Effective thermal planning protects your system from overheating and ensures stable operation. Cooling systems, such as cold water-based solutions, efficiently remove heat from critical components. Water’s high heat capacity allows you to target hot spots and maintain optimal temperatures. In environments with high ambient temperatures, TEC air conditioning can keep internal conditions stable, preventing failures and extending hardware life. Always evaluate your cooling options during the design phase. The right choice depends on your equipment’s needs and the environment where it will operate.

Note: Good thermal management reduces maintenance costs and increases the reliability of your power system.

Development and Integration

Energy-Saving Features

You can boost the efficiency of Telecom Power Systems by adding advanced energy-saving features. These features help you minimize energy loss and maximize performance. The table below highlights the most effective options:

Feature | Description |

|---|---|

High Energy Efficiency | Achieves up to 96% efficiency at 50% load, minimizing energy loss and maximizing performance. |

Reduced System Heat | Less energy loss as heat leads to more stable systems and lower fan speeds, enhancing reliability. |

Energy Savings | Saves up to 135W compared to 80PLUS Bronze and 46W compared to 80PLUS Gold, leading to lower costs. |

Cost-Effectiveness | Can save up to 201€ annually compared to 80PLUS Bronze, ensuring a quick return on investment. |

You should select features that match your system’s needs. High efficiency and reduced heat output not only lower costs but also improve reliability.

Modularity

You can improve flexibility and scalability by designing your power system with modular architecture. Modular systems allow you to add or remove power modules based on demand. This approach helps you optimize energy use and maintain high efficiency during varying load conditions.

You can replace faulty modules quickly, reducing downtime.

You can scale your system as your network grows.

You can maintain performance without overhauling the entire system.

Tip: Modular designs make upgrades and maintenance easier, saving you time and resources.

Firmware Strategies

You should use smart firmware to manage energy consumption and system performance. Firmware controls how your power system responds to different loads and environmental conditions. You can program firmware to:

Adjust fan speeds based on temperature.

Switch between power-saving modes during low demand.

Monitor efficiency and trigger alerts for abnormal conditions.

Smart firmware helps you maintain compliance with Titanium standards and ensures stable operation.

Pre-Compliance Checks

You need to run thorough pre-compliance checks before official testing. These checks help you identify issues early and avoid costly delays. Test your system under different load levels and verify that efficiency and power factor meet Titanium requirements. Document all results and make adjustments as needed.

Note: Early testing gives you confidence that your system will pass certification and perform reliably in real-world conditions.

Testing and Validation

Test Preparation

You need to prepare your system carefully before starting official tests. Begin by reviewing the 80Plus Titanium standards. Check the required efficiency at 20%, 50%, and 100% load. The targets are 94% at 20% load, 96% at 50% load, and 91% at 100% load. The power factor must reach at least 0.9 at full load.

Create a checklist for your test setup. Include calibrated measurement equipment, stable input voltage, and controlled ambient temperature. Make sure your test environment matches the conditions specified by the certification body. You should also verify that all firmware and hardware updates are complete. This step helps you avoid unexpected results during testing.

Tip: Run a mock test with your team. This practice session helps you catch errors and improve your test process.

Test Procedures

You must follow strict procedures to ensure accurate results. Start by measuring efficiency at each load level. Use certified equipment to record input and output power. Test at 10%, 20%, 50%, and 100% load. For each load, document the efficiency and power factor.

Follow these steps for each test:

Set the input voltage to the required level.

Apply the specified load to the power system.

Measure input power, output power, and power factor.

Record all data in a test log.

Repeat the test three times for consistency.

You should also test the system under different environmental conditions. This approach ensures your results reflect real-world performance.

Note: Consistent procedures help you build reliable data for certification.

Meeting Benchmarks

You need to compare your test results to the 80Plus Titanium benchmarks. The table below shows the required values:

Load Level | Efficiency Target | Power Factor Target |

|---|---|---|

20% | 94% | 0.95 |

50% | 96% | 0.94 |

100% | 91% | 0.90 |

If your system meets or exceeds these numbers, you are ready for certification. If you fall short, analyze the data and identify the cause. You may need to adjust components, firmware, or cooling systems. Always aim for consistent performance across all load levels.

Callout: Meeting these benchmarks proves your system is efficient and ready for deployment in Telecom Power Systems.

Documentation

You must prepare detailed documentation for the certification process. Collect all test logs, calibration certificates, and environmental data. Organize your documents by test type and load level. Include a summary table of results and a description of your test setup.

Your documentation should contain:

Test procedures and protocols

Raw data and calculated results

Calibration records for all equipment

Photos of the test environment

Firmware and hardware revision history

Submit your documentation to the certification body along with your application. Clear and complete records speed up the review process and reduce the risk of rejection.

Tip: Keep digital backups of all documents. Quick access to records helps you answer questions from reviewers.

Challenges and Solutions

Design Trade-Offs

You face tough choices when you design for 80Plus Titanium certification. High efficiency often means higher costs or more complex systems. You must balance performance, reliability, and budget. Sometimes, you need to choose between advanced components and simpler, proven designs. If you select wide-bandgap semiconductors, you gain efficiency but increase costs. If you use traditional silicon, you save money but may miss efficiency targets.

Tip: Create a decision matrix. List your options, compare efficiency, cost, and reliability. This tool helps you make informed choices.

Thermal Management

Heat can threaten your system’s stability and lifespan. You need to plan for effective cooling from the start. Water-based cooling works well for high-density cabinets. Air cooling with TEC units suits smaller setups. You should monitor temperature at critical points. If you see rising temperatures, adjust fan speeds or cooling modes.

Cooling Method | Best Use Case | Pros | Cons |

|---|---|---|---|

Water Cooling | High-density cabinets | High efficiency | Complex setup |

TEC Air Conditioning | Small/medium cabinets | Easy installation | Higher energy use |

Passive Heatsinks | Low-power modules | Low cost | Limited cooling |

Note: Regular maintenance keeps cooling systems working at peak performance.

Production Consistency

You must ensure every unit meets Titanium standards. Variations in manufacturing can cause failures. You should set strict quality control procedures. Test random samples from each batch. Use automated testing to catch errors early. If you find a problem, trace it back to the source and fix it before shipping.

Standardize your assembly process.

Train staff on critical steps.

Use checklists for each production stage.

Callout: Consistent production protects your reputation and reduces costly returns.

Best Practices

You can follow proven strategies to overcome challenges. Start with clear documentation for every phase. Use modular designs to simplify upgrades and repairs. Select components with verified efficiency ratings. Run pre-compliance tests before official certification. Keep your team updated on the latest standards.

Document all design changes.

Schedule regular training sessions.

Review test results with your team.

Emoji: 🛠️ Continuous improvement leads to reliable, efficient telecom power systems.

Recommendations for Telecom Power Systems

Compliance Team

You need a dedicated compliance team to guide your project through certification. Build your team with experts in power electronics, thermal management, and regulatory standards. Assign clear roles for documentation, testing, and quality control. Regular meetings help everyone stay updated on progress and changes in requirements.

Role | Responsibility |

|---|---|

Project Manager | Oversees timeline and milestones |

Design Engineer | Ensures efficiency and reliability |

Test Specialist | Conducts and verifies all testing |

Documentation Lead | Prepares and organizes records |

Quality Inspector | Monitors production consistency |

Tip: Encourage open communication within your team. Quick feedback helps you solve problems before they affect compliance.

Industry Resources

You can use industry resources to stay informed and improve your system design. Subscribe to technical journals and join professional organizations. Attend webinars and workshops to learn about new technologies and best practices. Many certification bodies offer guidelines and updates on standards.

IEEE and IEC publish standards for power systems.

80Plus program provides detailed certification requirements.

Online forums connect you with other engineers and share troubleshooting tips.

Trade shows display the latest components and solutions.

Note: Industry resources help you keep your knowledge current and avoid costly mistakes.

Continuous Improvement

You should adopt continuous improvement strategies to maintain compliance with evolving standards. Focus on energy efficiency and modularity in your power supply design. Use advanced technologies like digital power management and GaN transistors to boost performance. Hot-swappable and modular CRPS models reduce downtime and make upgrades easier. Develop thermally robust designs to handle higher thermal stress from AI and HPC workloads. Transition to recyclable and RoHS-compliant materials in manufacturing to support sustainability. Integrate power redundancy configurations, such as N+1 and 2N, in edge server environments to ensure high uptime.

Upgrade your system with modular power supplies.

Implement digital controls for better energy management.

Choose recyclable materials for new designs.

Add redundancy to improve reliability.

Emoji: 🔄 Continuous improvement keeps Telecom Power Systems efficient, reliable, and ready for future challenges.

You can achieve 80Plus Titanium Certification by following a clear compliance strategy. Focus on upgrading to certified power supplies, using dynamic power-saving techniques, and adopting advanced designs like multicell power supplies. Build your system with modular components and smart sensors for easy upgrades and real-time monitoring. Plan phased upgrades and select equipment designed for tough environments. Explore industry resources and AI-driven management tools to support ongoing improvement and sustainability.

FAQ

What is the main benefit of 80Plus Titanium Certification for telecom power systems?

You gain higher energy efficiency, which lowers electricity costs and reduces heat output. This leads to longer equipment life and less maintenance. You also help reduce your carbon footprint.

How do you prepare for the 80Plus Titanium testing process?

You should review the certification standards, calibrate your test equipment, and set up a controlled environment. Run mock tests to check efficiency and power factor at all required load levels.

Which components help you achieve Titanium-level efficiency?

You can select wide-bandgap semiconductors, advanced power factor correction circuits, and modular power supply units. These components improve efficiency and reliability in your telecom cabinet.

What documentation do you need for certification submission?

You must include test logs, calibration certificates, environmental data, and a summary of results. Organize your documents by test type and load level for easy review.

See Also

Ensuring Consistent Power Supply for Telecom Equipment Cabinets

Essential Materials Needed for Outdoor Telecom Cabinets

Telecom Cabinet Specifications for Communication Gear by ESTEL

Key Requirements for Outdoor Cabinets in Telecom Communication

Design Guidelines for ESTEL Outdoor Communication Base Station Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA