How ESTEL Helps Beginners Build a DC Rectifier System

Starting your first DC rectifier system can feel overwhelming. You might wonder, "Where do I even begin?" With so many components, from transformers to regulators, it’s easy to make mistakes. Maybe you’re unsure how to design a power supply that works efficiently or how to ensure your system delivers stable DC output. That’s where ESTEL steps in. They offer modular kits, clear instructions, and tools tailored for beginners. Instead of feeling lost, you’ll have a step-by-step guide to help you create a reliable system without the guesswork.

Key Takeaways

ESTEL provides kits that make building DC rectifier systems simple. Beginners can use them without needing advanced skills.

It is important to know the main parts: transformer, rectifier, filter, and regulator, to create a good DC rectifier system.

Use a step-by-step guide to set goals, pick parts, build the system, and check how it works for success.

Check out ESTEL's tutorials and guides to learn more and fix common problems easily.

Testing and fixing problems are key to making sure your system works well and stays reliable.

Understanding DC Rectifier Systems

What is a DC rectifier system?

A DC rectifier system is an essential part of many electrical setups. At its core, it’s a device that converts alternating current (AC) into direct current (DC). This process, known as rectification, ensures the current flows in only one direction. Think of it as a one-way street for electricity. Without this step, many devices that rely on steady DC power wouldn’t function properly.

There are two main types of rectifiers you’ll encounter:

Half-Wave Rectifier: This uses a single diode to convert AC into pulsating DC. It’s simple and works well for low-power applications.

Full-Wave Rectifier: This type captures both halves of the AC waveform, making it more efficient and producing a smoother DC output.

Purpose and importance of DC rectifier systems

Why are DC rectifier systems so important? Well, they’re the backbone of many electronic devices. They ensure a stable DC voltage output, which is crucial for powering sensitive equipment. For instance, a DC linear power supply relies on a rectifier to provide consistent power to devices like computers, medical equipment, and communication systems.

Without a rectifier, your power supply circuit wouldn’t be able to deliver the steady voltage output needed for these applications. This stability is especially critical in systems where fluctuations could cause damage or interruptions.

Applications of DC rectifier systems

You’ll find DC rectifier systems in a wide range of applications. They’re used in:

Power supplies: These systems convert AC from the grid into usable DC for electronics.

Battery chargers: Rectifiers play a key role in charging batteries by providing the necessary DC voltage.

DC motors: Many industrial machines rely on rectifiers to power their motors.

The global demand for DC rectifier systems is growing rapidly. Industries like telecom, electrical engineering, and industrial manufacturing are driving this growth. For example, the telecom sector heavily depends on low-current rectifiers to maintain uninterrupted communication services. As technology advances, the need for efficient DC-dc system design and rectifying steps will only increase.

Key Components of a DC Rectifier System

Transformer: Voltage conversion

The transformer is the first major component in your DC rectifier system. Its job is to adjust the voltage level of the AC input to match your system's requirements. For example, if your device needs 12V DC, the transformer reduces the higher AC voltage from the power grid to a lower level before rectification.

Modern transformers, like solid-state transformers (SSTs), are incredibly efficient. They use high-frequency AC/AC converters, which allow for compact designs and better performance. Here’s what makes them stand out:

High-frequency transformers (HFTs) use advanced magnetic materials to reduce size while maintaining high power density.

Wide-bandgap semiconductors, such as SiC and GaN, enable higher switching frequencies and minimize energy losses.

Modular designs and intelligent control systems make them adaptable to various voltage levels.

These advancements ensure your transformer operates efficiently, saving energy and space.

Rectifier: AC to DC conversion

Once the transformer adjusts the voltage, the rectifier takes over. This component converts AC into DC, ensuring the current flows in one direction. The most common type is the diode bridge rectifier, which uses four diodes arranged in a specific configuration. This setup captures both halves of the AC waveform, providing a smoother DC output compared to a single-diode rectifier.

The diode bridge is reliable and widely used in power supplies. It’s a key player in ensuring your system delivers the steady DC current needed for your devices. Without it, your system wouldn’t function as intended.

Filter: Reducing ripple in DC output

After rectification, the DC output still contains ripples—small fluctuations in voltage. This is where the filter comes in. Its role is to filter the rectified voltage and smooth out these ripples, providing a more stable DC output. A capacitor filter is the most common choice for this task. It stores energy and releases it when the voltage drops, effectively reducing ripple.

Here’s a quick comparison of how different capacitance values affect ripple voltage and input current spikes:

Capacitance (uF) | Ripple Voltage | Input Current Spikes |

|---|---|---|

100 | High | Moderate |

1000 | Low | High |

As you can see, a higher capacitance reduces ripple but increases current spikes. Choosing the right filter depends on your system’s needs. With the right capacitor filter, your DC rectifier system will deliver a clean and stable output.

Regulator: Stabilizing DC voltage.

Once the filter smooths out the ripples, the voltage regulator steps in to ensure your DC output remains steady. This component is like the system’s final checkpoint, keeping the voltage stable even when conditions change. Whether the input voltage fluctuates or the load varies, the regulator works to maintain a consistent output. Without it, your devices could experience erratic performance or even damage.

So, how does a voltage regulator achieve this? It actively monitors the output and adjusts as needed. For instance, if the input voltage spikes, the regulator compensates by reducing the output. Similarly, when the load increases, it ensures the voltage doesn’t drop below the required level. This ability to regulate the DC voltage is what makes it indispensable in any rectifier system.

Performance statistics highlight just how effective regulators are. For example:

Load regulation: The output voltage typically changes by only 15 mV, even with varying load currents. In extreme cases, this change might reach 100 mV.

Line regulation: The output voltage remains stable, with variations as low as 13 mV/V or within ±2% across a specified input range.

These numbers show how well regulators maintain a stable DC voltage, ensuring your system operates reliably. Whether you’re powering sensitive electronics or industrial equipment, a regulator is your best friend for consistent performance. With ESTEL’s modular kits, you’ll find it easy to integrate a high-quality regulator into your design.

How ESTEL Simplifies the Design Process

Modular systems for easy assembly

When you're just starting out, assembling a DC rectifier system can feel like solving a puzzle without a picture. ESTEL takes the guesswork out of the process by offering modular systems that are designed for easy assembly. These modular kits come with pre-configured components that fit together seamlessly, like building blocks. You don’t need to be an expert in circuit design to get started.

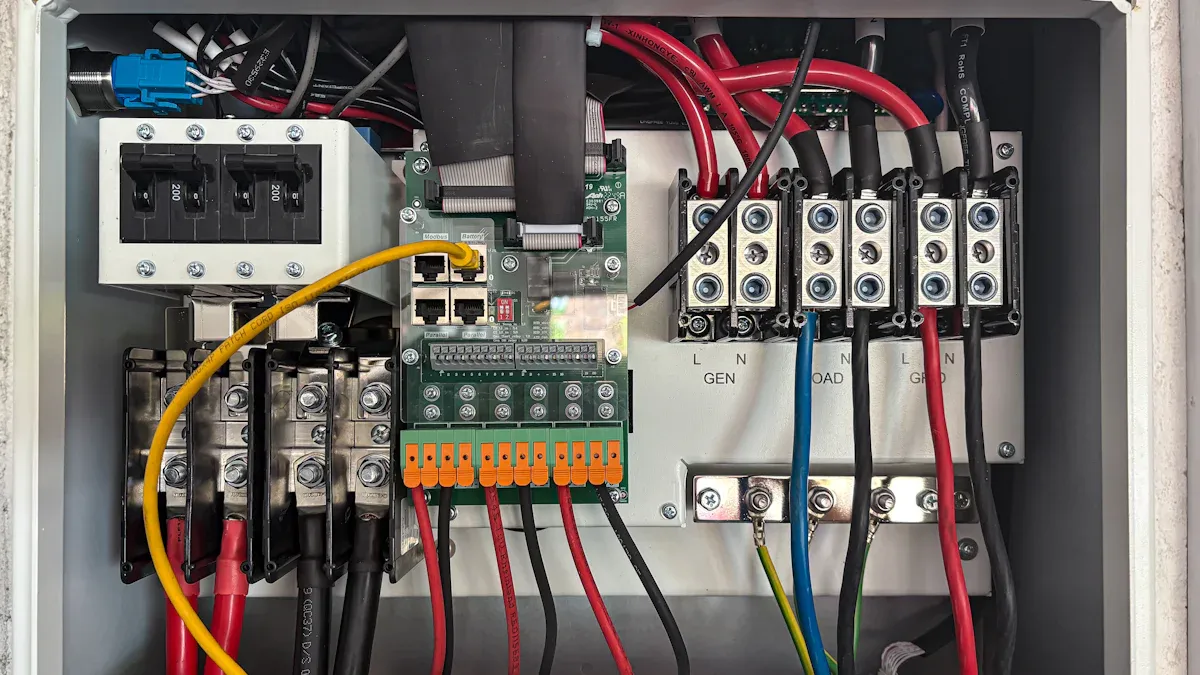

Each module in the kit serves a specific purpose. For example, you’ll find a transformer module for voltage conversion, a rectifier module for AC to DC conversion, and a filter module to smooth out the output. These modules are labeled clearly, so you know exactly where each one fits in your system. This approach not only saves time but also reduces the chances of making mistakes during assembly.

Tip: Modular systems are perfect for beginners because they allow you to focus on understanding how each component works without worrying about complex wiring or compatibility issues.

With ESTEL’s modular kits, you can build a fully functional DC rectifier system in no time. It’s like having a roadmap that guides you every step of the way.

Tools and resources for beginners

ESTEL doesn’t just stop at providing modular kits. They also equip you with the tools and resources you need to succeed. Imagine having access to a library of tutorials, videos, and guides that explain every aspect of your DC rectifier system in simple terms. That’s exactly what ESTEL offers.

Their beginner-friendly tools include:

Interactive Simulators: Test your circuit design virtually before assembling it.

Component Selection Guides: Learn how to choose the right transformer, rectifier, filter, and voltage regulator for your system.

Troubleshooting Checklists: Quickly identify and fix common issues in your circuit.

These resources are designed to make the learning curve less steep. For instance, if you’re unsure about how a diode bridge works, you can watch a short video that breaks it down step by step. Or, if you’re struggling to achieve a stable DC voltage, their troubleshooting guide can help you pinpoint the problem.

Note: ESTEL’s tools are tailored for beginners, so you won’t feel overwhelmed by technical jargon or overly complex explanations.

By using these resources, you’ll not only build a working system but also gain a deeper understanding of how it operates.

Step-by-step guidance for building a rectifier

One of the standout features of ESTEL is their step-by-step guidance. They don’t just hand you a box of components and leave you to figure it out. Instead, they provide detailed instructions that walk you through the entire process of building your DC rectifier system.

Here’s a quick overview of what their step-by-step guide includes:

Define Your Requirements: Determine the voltage output and power supply needs for your system.

Select Your Components: Use ESTEL’s recommendations to choose the right transformer, rectifier, filter, and voltage regulator.

Assemble the System: Follow the illustrated guide to connect each module. The instructions are so clear that even a beginner can assemble the system without confusion.

Test and Troubleshoot: Learn how to test your system for issues like ripple voltage or unstable output. ESTEL’s guide includes tips for fine-tuning your circuit to achieve optimal performance.

This step-by-step approach ensures that you don’t miss any critical details. For example, when connecting the rectifier module, the guide explains how to align the diodes correctly to avoid errors. Similarly, it shows you how to test the filter module to ensure it’s reducing ripples effectively.

By the time you finish, you’ll have a fully functional DC rectifier system that delivers a stable DC voltage. More importantly, you’ll feel confident in your ability to design and build similar systems in the future.

Step-by-Step Guide to Building a DC Rectifier System

Define system requirements

Before you dive into building your DC rectifier system, you need to define its requirements. Think of this step as creating a blueprint for your project. Start by asking yourself a few key questions:

What voltage and current does your system need to deliver?

Will it power sensitive devices like a dc linear power supply, or is it for a less demanding application?

What kind of environment will the system operate in?

For example, if you’re designing a dc-dc power supply for industrial equipment, you’ll need a robust system that can handle high power loads and fluctuating conditions. On the other hand, a dc linear power supply for a small electronic device might require a lower voltage and a more compact design.

Once you’ve outlined these details, you’ll have a clear idea of what components to choose and how to design your circuit. This step ensures your system meets your needs without overcomplicating the design.

Tip: Write down your requirements in a checklist. It’ll help you stay organized and ensure you don’t miss any critical details.

Select components with ESTEL's support

Choosing the right components can feel overwhelming, especially if you’re new to circuit design. This is where ESTEL’s support becomes invaluable. They simplify the process by offering pre-vetted components that are compatible and reliable.

Here’s how ESTEL helps you select the best parts for your system:

Efficient cable management: Their components prevent tangling and damage, making your system easier to maintain.

Advanced environmental protection: Designed to withstand harsh conditions like dust and water, ensuring long-term reliability.

Modular design: Allows you to expand your system in the future, adapting to increasing workloads.

Feature | Benefit |

|---|---|

Efficient cable management | Prevents tangling and damage, enhancing functionality and maintenance. |

Advanced Environmental Protection | Designed to withstand harsh weather, including dust and water ingress. |

Modular Design | Allows for future expansion and adapts to increasing workloads. |

Additionally, ESTEL’s components include features that optimize performance:

Perforated doors improve cooling efficiency by allowing air to flow freely.

Adjustable mounting rails help position equipment for better airflow.

Blanking panels prevent air recirculation, directing cool air to where it’s needed most.

By using ESTEL’s resources, you’ll save time and avoid common pitfalls like selecting incompatible parts. Their support ensures your system operates efficiently and reliably.

Assemble the system using ESTEL's modular kits

Now comes the fun part—assembling your DC rectifier system! With ESTEL’s modular kits, this step is straightforward and beginner-friendly. Each kit includes pre-configured modules that fit together seamlessly, so you don’t have to worry about complex wiring or compatibility issues.

Here’s a simple guide to assembling your system:

Start with the transformer module: Connect it to the AC input to adjust the voltage level.

Add the rectifier module: Attach it to the transformer’s output to convert AC to DC.

Install the filter module: Place it after the rectifier to smooth out ripples in the DC output.

Finish with the regulator module: Connect it to the filter to stabilize the DC voltage.

Each module comes with clear labels and instructions, making it easy to follow along. For example, the rectifier module includes diagrams showing how to align the diodes correctly. Similarly, the filter module provides tips for selecting the right capacitor to reduce ripple effectively.

Note: Double-check all connections before powering up your system. This step ensures everything is wired correctly and prevents potential issues.

Once you’ve assembled the system, test it to ensure it meets your requirements. ESTEL’s troubleshooting guides can help you identify and fix any issues, such as unstable output or excessive ripple. By the end of this process, you’ll have a fully functional DC rectifier system that’s ready to power your devices.

Test and troubleshoot effectively.

Testing and troubleshooting are the final steps in building your DC rectifier system. These steps ensure your system works as intended and help you catch any issues before they become bigger problems. With ESTEL’s tools and guidance, you’ll find this process straightforward and rewarding.

Why testing matters

Testing isn’t just about flipping the switch and hoping for the best. It’s about verifying that every component performs as expected. For example, you need to check if the transformer delivers the correct voltage, the rectifier converts AC to DC efficiently, and the regulator stabilizes the output. Skipping this step could lead to unstable performance or even damage to your devices.

Tip: Think of testing as a health check for your system. It’s better to catch small issues now than deal with major failures later.

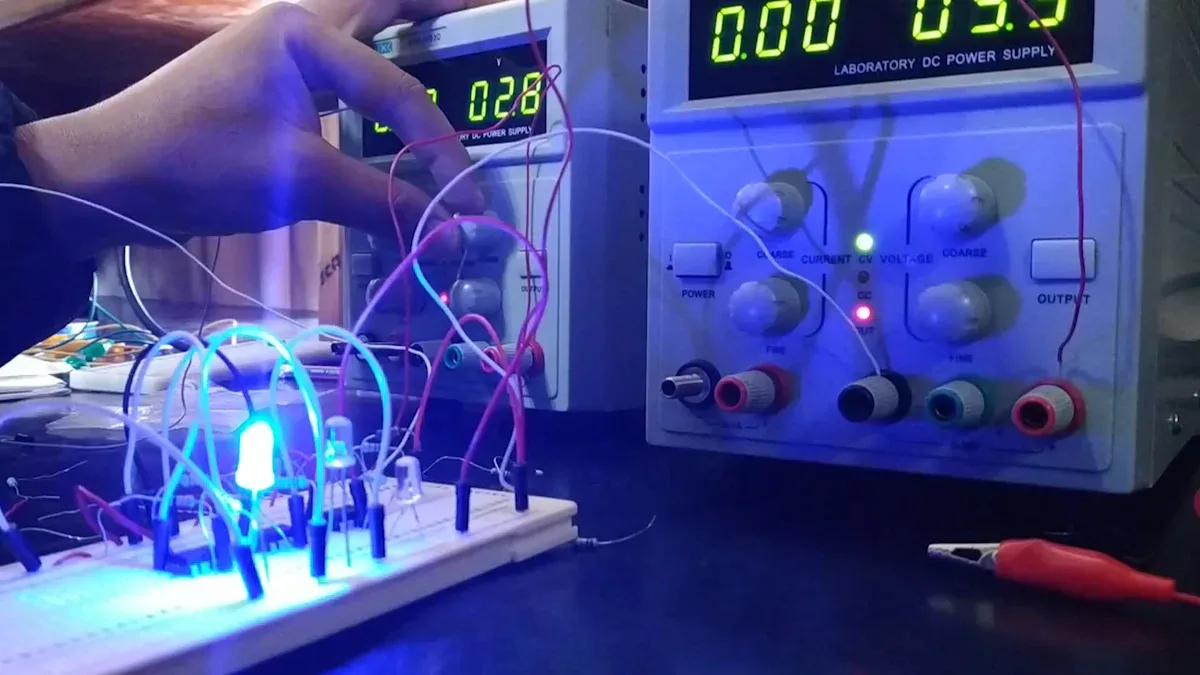

How to test your system

ESTEL provides a clear roadmap for testing your DC rectifier system. Here’s a step-by-step process to follow:

Check input and output timing: Measure how long it takes for your system to turn on and off. This ensures the components respond quickly and reliably.

Verify voltage ranges: Use a multimeter to confirm the input voltage matches your design requirements. Then, check the output voltage to ensure it’s stable and within the expected range.

Inspect ripple noise: Test the DC output for ripple noise using an oscilloscope. A clean waveform indicates your filter is working effectively.

Simulate load conditions: Apply different loads to your system and observe how it performs. This helps you identify issues like voltage drops or overheating.

Test protection features: Check for overcurrent and overvoltage protection. These safeguards prevent damage during unexpected conditions.

Troubleshooting common issues

Even with careful assembly, problems can arise. ESTEL’s troubleshooting guides make it easy to pinpoint and fix issues. Here are some common problems and how to address them:

Unstable output voltage: This often points to a faulty regulator. Double-check the connections and replace the regulator if needed.

Excessive ripple noise: If the DC output isn’t smooth, your filter might be undersized. Try using a capacitor with higher capacitance.

Overheating components: Poor airflow can cause overheating. Ensure your system has proper ventilation and consider adding cooling features like perforated panels.

Note: ESTEL’s troubleshooting checklist includes advanced tests like dielectric voltage withstand (DCWV) and insulation resistance (IR). These tests validate the system’s durability and safety.

Validating your results

Once you’ve tested and fixed any issues, it’s time to validate your system’s performance. Here’s a list of key metrics to check:

Input/output timing and hold-up time

Line and load regulation

Transient response and ripple noise

Efficiency and operating temperature

These metrics give you a complete picture of how well your system operates. For example, good line regulation means the output voltage stays stable even when the input voltage fluctuates. Similarly, low ripple noise ensures your DC output is clean and reliable.

ESTEL’s support for testing

ESTEL simplifies testing with tools like simulators and diagnostic equipment. Their resources help you test your system thoroughly without needing advanced technical skills. For instance, their custom load waveform simulation lets you replicate real-world conditions to see how your system performs under stress.

By following ESTEL’s testing and troubleshooting process, you’ll gain confidence in your design and ensure your DC rectifier system operates flawlessly.

Avoiding Common Mistakes with ESTEL

Selecting compatible components

Choosing the right components is one of the most critical steps in building a DC rectifier system. If the components don’t match your system’s requirements, you’ll likely face performance issues or even complete failure. For instance, using a transformer with the wrong voltage rating can lead to an unstable circuit. Similarly, selecting a diode that can’t handle the current load might cause overheating or damage.

ESTEL simplifies this process by offering pre-vetted components that are designed to work together seamlessly. Their modular kits eliminate the guesswork, ensuring that every part—from the transformer to the regulator—fits perfectly into your design. This compatibility not only saves time but also reduces the risk of errors. You can focus on understanding how the system works instead of worrying about mismatched parts.

Tip: Always double-check the specifications of each component against your system’s requirements. This small step can save you from big headaches later.

Ensuring correct assembly and wiring

Even with the right components, improper assembly or wiring can lead to serious problems. Misaligned connections or poorly stripped wires can disrupt the flow of electricity, causing your circuit to malfunction. To avoid these issues, it’s essential to follow a systematic approach during assembly.

Here’s a breakdown of why accuracy matters at each stage of the process:

Stage of Assembly | Importance of Accuracy | Consequences of Inaccuracy |

|---|---|---|

Inbound Inspection | Ensures components meet specifications before assembly. | Potential delays and increased costs. |

Assembly | Quality checks during assembly prevent errors and ensure functionality. | Defective products and loss of reputation. |

Wire Stripping | Careful stripping prevents damage to wires, ensuring safety and functionality. | Safety issues and signal discontinuity. |

Wire Crimping | Proper crimping is crucial to maintain signal integrity. | Excess or insufficient crimping can lead to failures. |

Wire Termination | Correct termination is essential for compact designs and functionality. | Defects and damages in compact electrical devices. |

Final Testing | Ensures the wire harness functions as intended before mass production. | Undetected issues can lead to product failures. |

Accurate cable assembly drawings also play a key role. They help align designers, engineers, and production teams, ensuring everyone is on the same page. Without precise drawings, miscommunication can lead to faulty parts and delays.

Importance of testing and troubleshooting

Testing and troubleshooting are the final checkpoints in your project. Skipping these steps is like driving a car without checking the brakes—it’s risky and can lead to failure. Testing ensures that your DC rectifier system operates as intended, while troubleshooting helps you identify and fix any issues.

Start by testing the voltage output of your circuit. Use a multimeter to confirm that the DC output matches your design specifications. Next, check for ripple noise using an oscilloscope. A clean waveform indicates that your filter is working effectively. If you notice any irregularities, ESTEL’s troubleshooting guides can help you pinpoint the problem.

Note: Common issues like unstable voltage or excessive ripple often stem from incorrect wiring or undersized components. Double-check your connections and consider upgrading your filter if needed.

By taking the time to test and troubleshoot, you’ll ensure your system is reliable and safe. With ESTEL’s resources, even beginners can confidently navigate this process.

How ESTEL mitigates errors.

Mistakes happen, especially when you're new to building DC rectifier systems. But ESTEL has your back. They’ve designed their tools and resources to help you avoid common errors and fix issues quickly. Here’s how they make your life easier.

1. Pre-vetted components

ESTEL ensures every component in their modular kits is compatible and reliable. You won’t have to worry about mismatched parts or faulty designs. For example, their transformers are tested to deliver the correct voltage, and their rectifiers are built to handle the current load efficiently. This saves you from the headache of troubleshooting compatibility issues.

2. Clear assembly instructions

Ever felt lost staring at a pile of wires and components? ESTEL’s step-by-step guides eliminate confusion. They include detailed diagrams and tips to help you connect everything correctly. For instance, their instructions show you how to align diodes in the rectifier module or choose the right capacitor for the filter. These guides reduce assembly errors and boost your confidence.

Tip: Double-check your wiring against ESTEL’s diagrams before powering up your system. It’s a simple step that can prevent major problems.

3. Built-in testing tools

ESTEL doesn’t just help you build your system—they help you test it too. Their kits come with built-in diagnostic features, like voltage monitors and ripple testers. These tools let you spot issues early, such as unstable output or overheating components. You’ll know exactly what’s wrong and how to fix it.

4. Troubleshooting resources

If something goes wrong, ESTEL’s troubleshooting guides are your safety net. They cover common problems like excessive ripple noise or faulty regulators. Each guide walks you through the solution step by step, so you can fix the issue without feeling overwhelmed.

With ESTEL, you’re not just building a DC rectifier system—you’re building it right. Their tools and resources make sure you avoid errors and create a system that works flawlessly.

Building a DC rectifier system doesn’t have to feel like an uphill battle. With ESTEL, you get everything you need to design a reliable system, from modular kits to beginner-friendly tools. Their step-by-step guidance makes the process simple, even if you’re just starting out. You’ll learn how to create stable DC power while avoiding common mistakes. Why struggle when you can have a clear path to success? Dive into ESTEL’s resources today and bring your project to life with confidence!

FAQ

What makes ESTEL’s modular kits beginner-friendly?

ESTEL’s modular kits simplify assembly by providing pre-configured components that fit together seamlessly. Each module is clearly labeled, so you know exactly where it goes. You don’t need advanced technical skills to get started. It’s like building with LEGO blocks—straightforward and fun!

Can I expand my DC rectifier system later?

Absolutely! ESTEL’s modular design allows for easy expansion. You can add more components or upgrade existing ones as your needs grow. This flexibility ensures your system stays relevant, whether you’re powering small devices or scaling up for industrial applications.

How do I know if my system is working correctly?

Use ESTEL’s testing tools to check your system. Start by measuring the output voltage with a multimeter. Then, inspect the ripple noise using an oscilloscope. If something seems off, ESTEL’s troubleshooting guides will help you pinpoint and fix the issue quickly.

Do I need special tools to assemble the system?

Not at all! ESTEL provides everything you need, including detailed instructions and basic tools. You won’t need soldering equipment or advanced diagnostic devices. Their kits are designed to make the process as beginner-friendly as possible.

What if I make a mistake during assembly?

Don’t worry! Mistakes happen, especially when you’re learning. ESTEL’s troubleshooting resources guide you through fixing common errors. Plus, their pre-vetted components and clear instructions minimize the chances of making mistakes in the first place.

See Also

Ensuring Correct Voltage Levels in Communication Cabinets with ESTEL

Understanding Telecom Power Supply Systems: A Newcomer's Overview

Exploring the ESTEL Power System for Telecom Cabinets

Photovoltaic Inverter and Battery Systems for Telecom Cabinets Explained

Ensuring Consistent Power Supply for Telecom Cabinets Effectively

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA