How to Choose the Right DC Rectifier System for Industrial Applications with ESTEL

Selecting the right DC rectifier system is critical for ensuring efficient and reliable power conversion in industrial applications. When you choose the wrong system, it can lead to energy inefficiencies, higher operational costs, and reduced performance. ESTEL, a leader in tailored rectifier solutions, consistently meets the growing demand for optimized power systems.

The global rectifier module market is projected to grow from $4.5 billion in 2023 to $7.3 billion by 2032, reflecting the need for advanced power solutions.

ESTEL drives innovation in this space, offering systems that enhance reliability and scalability.

By understanding your specific application needs and leveraging ESTEL’s expertise, you can ensure your operations remain future-ready and cost-effective.

Key Takeaways

Picking the right DC rectifier is important for good performance. A bad choice can cost more and work less effectively.

Know the voltage and current your equipment needs before choosing. This helps it run smoothly and match your machines.

Look for efficiency and good power quality in a rectifier. Efficient systems save energy and lower costs, helping you save money.

Think about future needs when picking a rectifier. Modular designs make it easy to upgrade or expand later.

Check what your application needs. Different industries need special features, so choose what works best for you.

Understanding DC Rectifier Systems

What is a DC rectifier system?

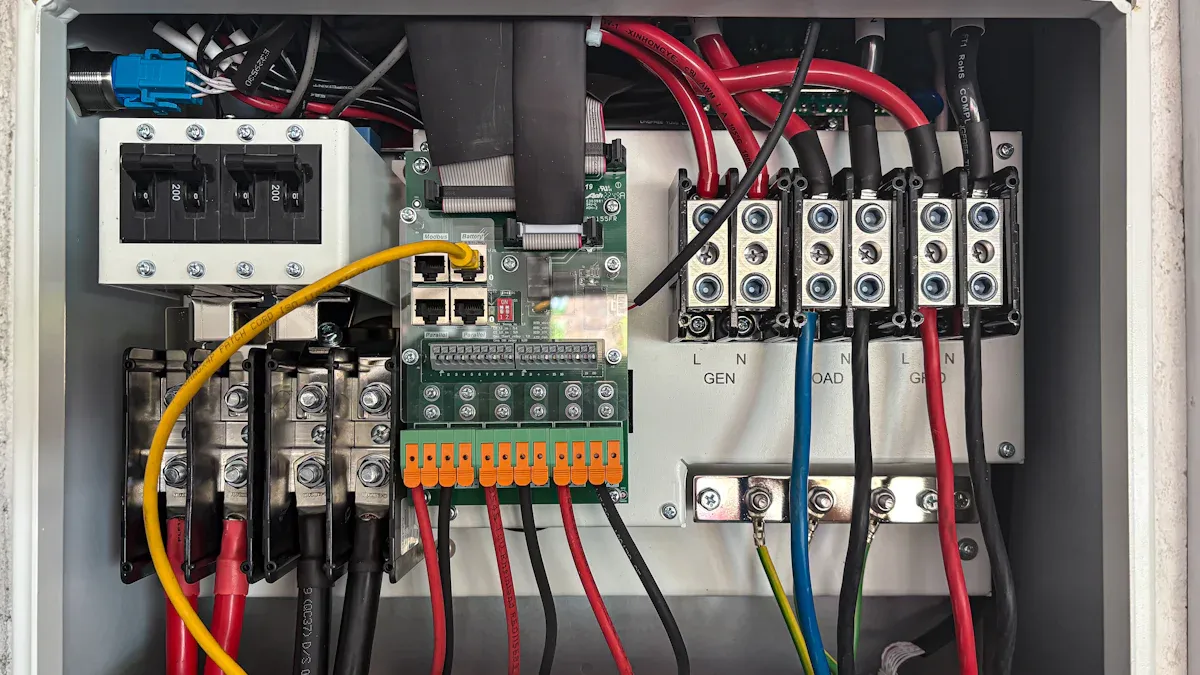

A DC rectifier system is a critical component in industrial power systems. It converts alternating current (AC) into direct current (DC), enabling the operation of equipment that requires stable and consistent DC power. These systems often use configurations like bridge rectifiers, which employ four diodes to achieve efficient AC to DC conversion. The output voltage of a rectifier can be calculated using the formula:V_out = (2V_m)/π - (4V_f)/π, where V_m is the peak voltage and V_f is the forward voltage drop.

Rectifiers are designed to improve efficiency and stability, making them indispensable in high-current applications. Their ability to handle varying input power levels ensures compatibility with three-phase AC systems, which are common in industrial environments.

The role of AC to DC conversion in industrial applications

AC to DC conversion plays a pivotal role in industrial operations by enhancing energy efficiency and reducing power loss. Modern AC/DC converters, especially those using advanced materials like gallium nitride (GaN), achieve up to 95% efficiency at full load. This high efficiency translates to a 5% improvement in energy utilization and a 28% reduction in power loss.

Industries rely on these systems to power critical processes, ensuring uninterrupted operation and minimizing energy waste. By converting three-phase AC systems into usable DC power, rectifiers enable the seamless functioning of industrial power systems, supporting everything from manufacturing to renewable energy applications.

Common industries using high-current applications

High-current applications are prevalent across several industrial sectors. Industries such as electroplating, cathodic protection, and steel production heavily depend on DC rectifier systems. For instance, the steel industry in Europe is a significant user, contributing to a projected market growth of USD 337.4 million by 2030.

These systems are also vital in other sectors, including telecommunications, where they support data centers, and renewable energy, where they facilitate energy storage and distribution. Their versatility and reliability make them a cornerstone of industrial power systems worldwide.

Key Factors for Choosing a DC Rectifier System

Voltage and current requirements

When selecting a DC rectifier system, understanding your voltage and current needs is essential. The rectifier must match the application's load requirements to ensure stable and reliable operation. Start by determining the necessary output voltage and current levels. For instance, sensitive electronics may require precise voltage regulation to maintain optimal performance. Additionally, consider the ripple voltage, as excessive ripples can disrupt the functionality of connected equipment.

Load characteristics also play a significant role. If your application involves transient loads or high inrush currents, ensure the rectifier can handle these demands without compromising efficiency. For industrial applications, rectifiers with robust designs are better suited to manage fluctuating loads and maintain consistent power delivery.

Tip: Always consult manufacturer datasheets to verify the rectifier's voltage rating, current rating, and compatibility with your circuit's operating frequency. This step ensures the rectifier aligns with your specific requirements.

Efficiency and power quality

Efficiency and power quality are critical factors in achieving efficient power rectification. High-efficiency rectifiers minimize power loss, reducing operational costs and environmental impact. Modern rectifiers, such as PWM-based systems, offer superior efficiency compared to traditional designs. They also achieve near-unity power factor, ensuring better energy utilization.

Power quality metrics, including total harmonic distortion (THD) and dynamic response, are equally important. Rectifiers with low THD provide cleaner power, which is crucial for sensitive industrial power systems. For example, PWM rectifiers outperform traditional rectifiers by reducing higher harmonics and delivering stable operation under varying load conditions.

Metric | PWM Rectifiers | Traditional Rectifiers |

|---|---|---|

Power Factor | Achieves unity power factor | Lower power factor |

Total Harmonic Distortion | Reduced higher harmonics | Higher harmonics |

Efficiency | Higher efficiency | Lower efficiency |

Dynamic Response | Better dynamic performance | Poor dynamic performance |

By choosing a rectifier with advanced power quality features, you can enhance the reliability and longevity of your industrial power systems.

Application-specific needs

Every application has unique requirements, and your choice of a DC rectifier system should reflect these needs. For instance, electroplating processes demand high-current rectifiers capable of delivering consistent DC power. In contrast, telecommunications applications prioritize systems with minimal ripple voltage and high reliability to support uninterrupted operations.

Customizable rectifiers offer flexibility for diverse industrial applications. They can be tailored to specific voltage and current needs, ensuring compatibility with your equipment. However, keep in mind that these systems may require a stable DC power supply and additional maintenance. Despite these challenges, their ability to provide less distortion and more stable power quality makes them a preferred choice for many industries.

Note: When evaluating application-specific needs, consider configurations like full-wave or three-phase rectifiers. These designs cater to different operational demands, enhancing overall system performance.

Scalability and future-proofing.

Scalability and future-proofing are essential considerations when selecting a DC rectifier system for industrial applications. These features ensure your power infrastructure can adapt to evolving operational demands while maintaining optimal performance.

Modular Architecture for Growth

A modular architecture provides flexibility to expand your system as your needs grow. This design allows you to add power modules incrementally, ensuring you only invest in capacity when required. For example, a "build as you grow" approach minimizes upfront costs while maintaining the ability to scale efficiently. Modular systems also simplify maintenance, as individual components can be replaced or upgraded without disrupting operations.

Future-Proof Design for Long-Term Viability

Future-proofing involves selecting systems that accommodate emerging technologies and increased power demands. Compact rectifier designs support integration with renewable energy sources, ensuring compatibility with sustainable practices. These systems also offer advanced features like hot plug-in capability, enabling upgrades without downtime. By choosing a future-proof DC rectifier system, you safeguard your investment against obsolescence.

Enhanced Efficiency and Reliability

High-efficiency power modules play a critical role in scalability and future-proofing. These modules reduce operational costs by optimizing energy utilization. Systems with maximum two-minute mean time to repair (MTTR) ensure high availability, minimizing disruptions caused by failures. Comprehensive monitoring features further enhance reliability by providing real-time insights into power infrastructure performance.

Feature | Description |

|---|---|

Modular Architecture | Supports flexibility and scalability, allowing for a 'build as you grow' approach. |

High Efficiency Power Modules | Industry-leading efficiency ensures optimal performance and reduced operational costs. |

Future Proof Design | Compact design that accommodates future power needs and integration of renewable energy sources. |

Hot Plug-in Capability | Modular design allows for easy upgrades and maintenance without system downtime. |

Maximum 2 Minutes MTTR | Ensures high availability and quick recovery from failures. |

Comprehensive Monitoring | Advanced control features for optimizing power infrastructure performance. |

Meeting High-Current Application Demands

Industrial environments often require systems capable of handling high-current applications. Scalable rectifiers ensure consistent voltage regulation and reliable power delivery, even under fluctuating load conditions. This adaptability makes them ideal for industries like manufacturing, telecommunications, and renewable energy, where operational demands frequently change.

By prioritizing scalability and future-proofing, you can ensure your DC rectifier system remains efficient, reliable, and adaptable to future challenges. These features not only enhance performance but also reduce long-term costs, making them indispensable for industrial power systems.

Comparing Rectifier Technologies

Choosing the right rectifier technology is essential for optimizing your industrial power systems. Each type of rectifier offers unique advantages and is suited for specific applications. Below, we explore three key rectifier technologies to help you make an informed decision.

Thyristor-based rectifiers

Thyristor-based rectifiers are a popular choice for high-current applications due to their reliability and cost-effectiveness. These rectifiers use thyristors, also known as silicon-controlled rectifiers (SCRs), to control the flow of electricity. Their robust design makes them ideal for industrial environments requiring consistent performance under demanding conditions.

Advantage | Description |

|---|---|

Safety and Reliability | Thyristor devices have high reliability and robustness, used for over 50 years in high-power applications. |

Harmonic Compliance | Can meet harmonic standards even under low load conditions, improving performance with multiple units. |

Response to Energy Fluctuations | Can handle fluctuations of 5% per second, with a rapid response speed compared to electrolytic cells. |

High Conversion Efficiency | Significant cost savings on electricity, with potential savings of 30.6 million over 20 years. |

Low Equipment Investment | Generally cheaper than IGBT rectifiers, making it a cost-effective choice. |

Small Footprint | Occupies less space compared to IGBT rectifiers, enhancing installation flexibility. |

Long Service Life | Expected lifespan of over 20 years, reducing replacement frequency. |

Low Maintenance Cost | Lower ongoing costs associated with maintenance compared to alternatives. |

Proven Track Record | Over 150 sets of hydrogen production cases in China, demonstrating widespread adoption and reliability. |

Future Adaptability | Easily adaptable for larger electrolyzers, with current supply for 4000Nm³/h systems. |

Thyristor-based rectifiers are particularly effective in applications like electrolysis, where high-performance rectifiers are required to handle fluctuating loads. Their long service life and low maintenance costs make them a reliable and economical choice for industrial operations.

Diode-based rectifiers

Diode-based rectifiers are among the simplest and most widely used rectifier technologies. These rectifiers rely on diodes to convert AC to DC power, making them a fundamental component in many industrial systems. The bridge rectifier configuration, which uses four diodes, is especially common due to its ability to provide full-wave rectification.

Description | |

|---|---|

Conversion Efficiency | Offers moderate efficiency, suitable for applications with steady power demands. |

Cost of Deployment | Low initial cost, making it an economical option for basic power conversion needs. |

Control Delay | Minimal control delay, ensuring quick and straightforward operation. |

Scalability | Limited scalability, best suited for small to medium-scale applications. |

Computational Complexity | Low complexity, simplifying implementation and maintenance. |

Diode-based rectifiers are ideal for applications where simplicity and cost-effectiveness are priorities. For example, they are commonly used in small-scale industrial systems and as part of three-phase rectifiers in larger setups. However, their limited scalability may not meet the demands of high-current or specialized rectifiers.

Active Front-End (AFE) rectifiers

Active Front-End (AFE) rectifiers represent the cutting edge of rectifier technologies. These systems use advanced power electronics to achieve high efficiency and low harmonic distortion, making them suitable for modern industrial applications requiring clean and stable power.

Increased energy efficiency: Reducing harmonics leads to fewer losses in transformers, saving money and extending their lifespan.

Less heat: Minimizing harmonics prevents overheating of transformers, prolonging equipment life.

Proper transformer sizing: Reducing harmonics allows for better sizing of transformers, leading to increased energy efficiency.

Fewer breaker trips: High-quality power reduces the likelihood of faults that can trip breakers, maintaining production.

Low interference: Low harmonics minimize interference with nearby electrical systems.

AFE rectifiers excel in applications where power quality is critical, such as data centers and renewable energy systems. Their ability to reduce harmonic distortion not only improves efficiency but also enhances the reliability of connected equipment. These rectifiers are a forward-looking choice for industries aiming to adopt sustainable and energy-efficient practices.

By understanding the strengths and limitations of these rectifier technologies, you can select the one that best aligns with your operational needs. Whether you prioritize cost, efficiency, or scalability, there is a rectifier solution tailored to your requirements.

Choosing the right rectifier for high-current applications.

Selecting the right rectifier for high-current applications is crucial for ensuring reliable and efficient power delivery. High-current environments demand rectifiers that can handle significant loads while maintaining stability, efficiency, and performance. To make an informed decision, you must evaluate several factors, including the type of rectifier, its performance benchmarks, and its suitability for your specific application.

Key Considerations for High-Current Applications

Load Characteristics

High-current applications often involve fluctuating or transient loads. The rectifier you choose must provide consistent voltage regulation and handle sudden surges without compromising performance. For instance, bridge rectifiers are commonly used in these scenarios due to their ability to deliver full-wave rectification and manage high currents effectively.Efficiency and Power Quality

Efficiency plays a pivotal role in high-current systems. Rectifiers with advanced designs, such as three-phase rectifiers, minimize power loss and improve energy utilization. Additionally, power quality metrics like total harmonic distortion (THD) and dynamic response are critical. Rectifiers with low THD ensure cleaner power, which is essential for sensitive equipment.Scalability and Durability

High-current applications often require systems that can scale with growing demands. Modular rectifier technologies allow you to expand capacity as needed. Durability is equally important, as industrial environments can be harsh. Rectifiers with robust designs and long service lives reduce maintenance costs and downtime.

Comparative Performance Benchmarks

Performance benchmarks provide valuable insights into the capabilities of different rectifier technologies. Below is a comparison of studies highlighting the performance of high-performance rectifiers in high-current applications:

Study Title | Key Findings |

|---|---|

Comparative Analysis of Improved High Performance Direct Power Control of Three Phase PWM Rectifier | Demonstrates the feasibility of the control method in high-current applications. |

Study Title | Performance Metrics |

|---|---|

Direct Power Control of Three-Phase PWM Rectifier Based on New Switching Table | Improved performance in power ripple reduction and dynamic response. |

Simulation and Practical Implementation of Direct Power Control Applied on PWM Rectifier | Achieves grid current close to sinusoidal waveforms (TDH <1.2%) and good DC-bus voltage regulation. |

These studies emphasize the importance of selecting rectifiers with advanced control methods and superior power quality. For example, three-phase rectifiers excel in reducing power ripple and maintaining stable DC output, making them ideal for high-current environments.

Matching Rectifier Technologies to Application Needs

Different rectifier technologies offer unique advantages for high-current applications. Bridge rectifiers, for instance, are widely used due to their simplicity and effectiveness in converting AC to DC power. They are particularly suitable for applications requiring full-wave rectification and high reliability. On the other hand, specialized rectifiers like Active Front-End (AFE) systems provide advanced features such as low harmonic distortion and enhanced energy efficiency, making them a preferred choice for modern industrial setups.

When choosing a rectifier, consider the specific demands of your application. For example:

Electroplating: Requires high-performance rectifiers capable of delivering consistent DC power.

Renewable Energy Systems: Benefit from rectifiers with low THD and high efficiency to support energy storage and distribution.

Manufacturing: Demands robust rectifiers that can handle fluctuating loads and maintain stable operation.

By aligning the rectifier's capabilities with your operational needs, you can ensure optimal performance and long-term reliability.

Practical Tips for Selection

Evaluate Load Requirements: Determine the maximum current and voltage your application requires.

Assess Power Quality Needs: Choose rectifiers with low THD and high dynamic response for sensitive equipment.

Consider Future Growth: Opt for modular designs that allow for scalability.

Prioritize Durability: Select rectifiers with proven track records in industrial environments.

Tip: Always consult technical datasheets and performance benchmarks to verify the rectifier's suitability for your application. This step ensures compatibility and maximizes efficiency.

Choosing the right rectifier for high-current applications involves balancing performance, efficiency, and scalability. By understanding your specific requirements and leveraging advanced rectifier technologies, you can build a power system that meets both current and future demands.

Practical Applications of DC Rectifier Systems

Telecommunications and data centers

Telecommunications and data centers rely heavily on DC rectifier systems to maintain uninterrupted operations. These systems convert AC power into stable DC power, ensuring the reliability of critical infrastructure. You can find rectifiers in telecom network expansions, where over 52% of installations in Asia-Pacific feature units with higher energy conversion efficiency. Modular designs dominate the market, with 47% of rectifier units launched since 2023 offering enhanced control systems and compact configurations.

Data centers benefit from rectifiers with predictive maintenance software, which is included in 44% of units shipped in 2024. This software enables real-time analysis, reducing downtime and improving operational efficiency. By integrating advanced rectifiers, you can achieve better energy utilization and support the growing demand for cloud computing and digital services.

Manufacturing and automation

DC rectifier systems play a pivotal role in manufacturing and automation, where energy efficiency and precision are paramount. Over 41% of manufacturing systems now depend on DC power, driving the adoption of programmable rectifier units. These units provide consistent power delivery, which is essential for automated processes and robotics.

Automation industries increasingly integrate rectifiers with digital monitoring capabilities. Approximately 49% of companies implementing Industry 4.0 use systems equipped with these features. You can leverage these rectifiers to optimize production lines, reduce energy consumption, and enhance productivity. Compact and fanless designs, featured in 45% of product launches in 2023-2024, offer flexibility for installation in space-constrained environments.

Key Benefits for Manufacturing:

Improved energy efficiency with rectifiers rated over 90%.

Enhanced control systems for precise power regulation.

Reduced maintenance costs through predictive monitoring.

Renewable energy systems

Renewable energy systems depend on DC rectifiers to store and distribute power efficiently. These systems convert variable AC power from sources like wind turbines and solar panels into usable DC power. More than 50% of new infrastructure projects in smart grids and transportation incorporate rectifiers to meet energy efficiency standards.

Rectifiers with low harmonic distortion are ideal for renewable energy applications. They minimize interference and ensure clean power delivery, which is crucial for energy storage systems. By adopting advanced rectifiers, you can support sustainable practices and reduce the environmental impact of industrial operations.

Applications in Renewable Energy:

Energy storage systems for solar and wind power.

Smart grid integration for efficient power distribution.

Transportation electrification to reduce carbon emissions.

DC rectifier systems are indispensable across these sectors, offering reliability, efficiency, and scalability. Whether you manage a data center, manufacturing plant, or renewable energy project, these systems provide tailored solutions to meet your operational needs.

Transportation and rail systems.

Transportation and rail systems rely on DC rectifier systems to ensure efficient and reliable power delivery. These systems play a critical role in powering trains, trams, and metro networks, where consistent DC power is essential for smooth operations. By converting AC power into stable DC power, rectifiers enable the seamless functioning of traction motors, signaling equipment, and auxiliary systems.

Energy efficiency is a key advantage of DC rectifier systems in rail applications. Modern rectifiers achieve over 97% efficiency in rectifier mode and 96% in inverter mode. This high efficiency minimizes energy waste, reducing operational costs and environmental impact. For example, a single commuter line can save up to 1 GWh of energy annually by using advanced rectifiers. Additionally, regenerative braking systems, which dissipate approximately 200 kWh of energy per trip, can recover and reuse this energy with the help of rectifiers.

Metric | Value |

|---|---|

Efficiency in rectifier mode | > 97% |

Efficiency in inverter mode | > 96% |

Energy wasted per commuter line | 1 GWh/year |

Energy dissipated during braking | 200 kWh/trip |

Reliability is another critical factor. DC rectifiers ensure uninterrupted power delivery, even under fluctuating load conditions. This reliability enhances passenger safety and reduces downtime, making them indispensable for rail operators. You can also benefit from their compact designs, which save space in crowded urban environments.

By integrating DC rectifier systems into transportation infrastructure, you can achieve significant energy savings, improve operational efficiency, and support sustainable practices. These systems not only enhance performance but also contribute to the long-term viability of modern rail networks.

Financial and Operational Considerations

Initial investment vs. long-term savings

Investing in DC rectifier systems requires careful financial analysis to balance upfront costs against long-term benefits. Cost Benefit Analysis (CBA) is a widely used method for evaluating the economic viability of such investments. It compares total expected costs with total expected benefits, factoring in the time value of money through Discounted Cash Flow (DCF) calculations. This approach yields a Net Present Value (NPV), helping you assess the economic performance of rectifier technologies over time.

Aspect | Description |

|---|---|

Method | Cost Benefit Analysis (CBA) is used to assess the viability of investments or projects. |

Purpose | Compares total expected costs against total expected benefits. |

Time Value of Money | Recognizes that money available now is worth more than the same amount in the future. |

Analysis Method | Discounted Cash Flow (DCF) is used to account for the time value of money. |

Outcome | Yields a Net Present Value (NPV) for the investment, facilitating economic performance comparison. |

DC systems often outperform AC systems in efficiency, especially in transmission applications. For example, overhead DC transmission becomes more cost-effective over distances of 600–800 km, while underground DC transmission achieves efficiency at 50–95 km. These metrics highlight the long-term savings potential of DC rectifier systems in industrial applications.

Transmission Type | Break-Even Distance (km) | Efficiency Comparison |

|---|---|---|

Overhead DC vs AC | 600 - 800 | DC is more efficient |

Underground DC | 50 - 95 | DC is more efficient |

Underwater DC | 24 - 50 | DC is more efficient |

Maintenance and reliability

Maintaining DC rectifier systems involves regular inspections and proactive measures to ensure reliability. Periodic data analysis helps track operational history and identify potential issues before they escalate. Dust isolation devices are essential for preventing dust accumulation, which can lead to malfunctions. Centralized monitoring systems enhance efficiency by enabling timely fault detection and resolution.

IGBT rectifier systems, known for their reliability, benefit from these maintenance practices. By implementing these measures, you can reduce downtime and extend the lifespan of your equipment. Industrial environments often demand robust systems capable of handling fluctuating loads without compromising performance. Regular maintenance ensures your rectifier technologies remain dependable and efficient.

Energy efficiency and sustainability

DC rectifier systems excel in energy efficiency and sustainability, making them ideal for modern industrial applications. These systems achieve a power factor of 0.99, minimizing energy waste and optimizing power utilization. Total Harmonic Distortion (THD) remains low at 1.12%, ensuring clean power delivery for sensitive equipment. With an efficiency rating of 95%, DC rectifiers reduce operational costs and environmental impact.

Metric | Value |

|---|---|

Power Factor | 0.99 |

Total Harmonic Distortion | 1.12% |

Efficiency | 95% |

By adopting energy-efficient rectifier technologies, you contribute to sustainability goals while enhancing operational effectiveness. These systems support renewable energy integration, reduce carbon emissions, and align with global efforts to combat climate change. Their advanced designs ensure compatibility with future energy demands, making them a forward-thinking choice for industrial power systems.

ESTEL's cost-effective solutions.

When it comes to cost-effective DC rectifier systems, ESTEL stands out as a leader in providing solutions that deliver both financial and operational benefits. By focusing on energy efficiency, reliability, and sustainability, ESTEL ensures that your investment yields long-term savings while meeting the demands of modern industrial applications.

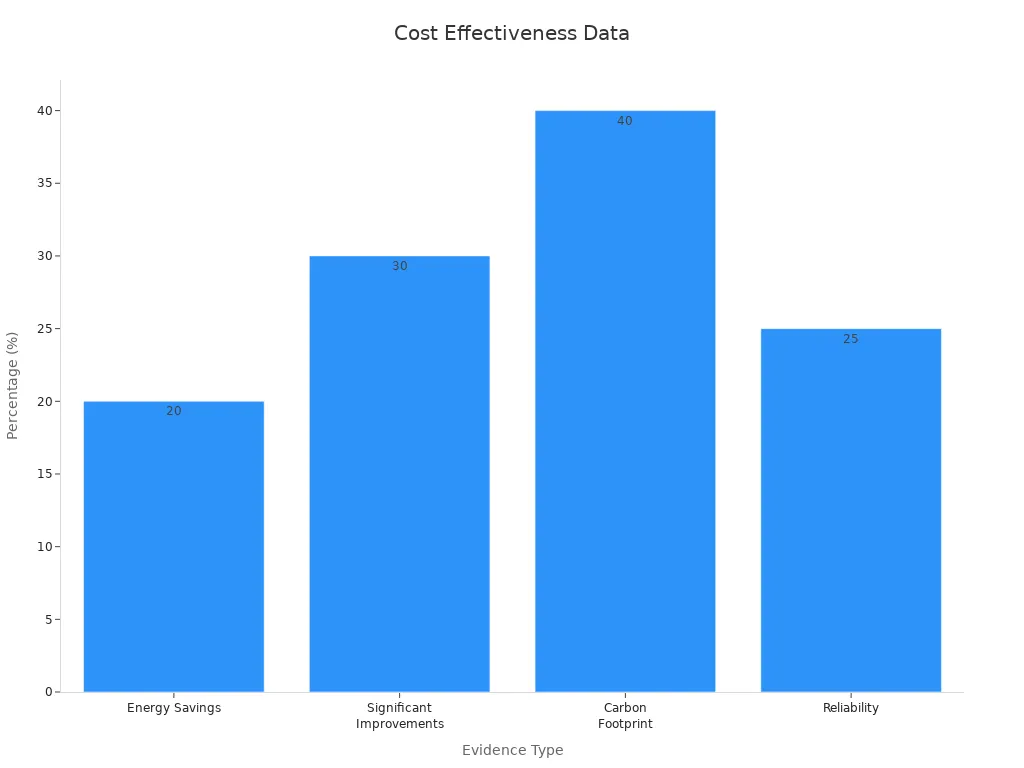

One of the key advantages of ESTEL's rectifier systems is their ability to significantly reduce energy consumption. New-generation rectifiers can save companies up to 20% annually on energy costs. For businesses integrating renewable energy sources, these systems not only lower operational expenses but also contribute to environmental sustainability. For instance, GreenConnect, a major industry player, reported a 30% reduction in energy usage after adopting ESTEL's rectifiers, resulting in millions of dollars in savings.

Reliability is another cornerstone of ESTEL's solutions. Smart rectifier systems minimize downtime by 25%, ensuring uninterrupted operations. This reliability is particularly crucial for industries like telecommunications, where consistent power delivery is essential. Hybrid systems, another innovation by ESTEL, offer telecom companies potential savings of $13-14 billion annually, making them a game-changer in cost management.

The environmental impact of ESTEL's rectifiers is equally impressive. By reducing CO2 emissions by 40%, these systems align with global climate goals, helping your business contribute to a greener future. The combination of energy savings, reduced carbon footprint, and enhanced reliability makes ESTEL's solutions a smart choice for any industrial operation.

Evidence Type | Details |

|---|---|

Energy Savings | New rectifiers save companies up to 20% yearly. |

Cost Reduction with Renewables | Using renewable energy with rectifiers lowers costs and helps the environment. |

Significant Improvements | GreenConnect saw energy use drop by 30%, saving millions of dollars. |

Carbon Footprint Reduction | CO2 emissions fell by 40%, aiding global climate goals. |

Reliability | Smart systems cut downtime by 25%, ensuring steady services. |

Hybrid Systems Savings | Hybrid systems could save $13-14 billion yearly for telecom companies. |

By choosing ESTEL, you gain access to cutting-edge rectifier technologies that optimize costs, enhance reliability, and support sustainable practices. These solutions not only meet your current needs but also prepare your operations for future challenges.

Choosing the right DC rectifier system is vital for optimizing industrial power systems. It ensures efficiency, reliability, and scalability, which are essential for meeting operational demands. Rectifier technologies have evolved significantly, transitioning from vacuum tube designs to advanced semiconductor-based systems.

Type of Rectifier | Key Features | Industrial Application |

|---|---|---|

Vacuum Tube Rectifiers | Obsolete, used in low power applications | Limited use in industrial applications |

Semiconductor Diodes | High efficiency, various types | Widely used for power rectification |

Thyristors | High power handling, controlled switching | Essential for high-voltage DC transmission |

IGBTs | Advanced control, economical for high voltage | Used in medium-power transmission systems |

Modern rectifiers like thyristors and IGBTs enhance performance and reliability, making them indispensable for high-power applications. ESTEL’s tailored solutions leverage these technologies to address your specific needs, ensuring long-term value and sustainability.

Take the next step: Contact ESTEL today for expert guidance and innovative rectifier systems that empower your industrial operations.

FAQ

What is the lifespan of a DC rectifier system?

The lifespan of a DC rectifier system typically ranges from 15 to 20 years. Regular maintenance and monitoring can extend its operational life. You should ensure periodic inspections and timely replacements of components to maximize reliability and efficiency.

How do I determine the right rectifier for my application?

Start by evaluating your voltage, current, and load requirements. Consider factors like efficiency, scalability, and power quality. Consult technical datasheets and performance benchmarks to ensure compatibility with your equipment and operational needs.

Are modular rectifiers more cost-effective than traditional designs?

Yes, modular rectifiers offer scalability and reduce upfront costs. You can expand capacity as needed, minimizing unnecessary investments. Their design simplifies maintenance, reducing downtime and operational expenses over time.

Can DC rectifiers support renewable energy systems?

Absolutely! DC rectifiers convert variable AC power from renewable sources into stable DC power. They enhance energy storage and distribution efficiency, making them ideal for solar panels, wind turbines, and smart grid applications.

What maintenance practices improve rectifier reliability?

Regular inspections, dust isolation devices, and centralized monitoring systems improve reliability. Analyze operational data to identify issues early. Implement proactive measures to reduce downtime and extend the lifespan of your rectifier system.

See Also

Exploring ESTEL's Industrial Cooling Solutions for Cabinets

Selecting the Ideal Cooling Technique for ESTEL Telecom Cabinets

Ensuring Correct Voltage Levels in ESTEL Communication Cabinets

Utilizing Energy Storage Batteries in ESTEL Telecom Cabinets

Choosing the Right Outdoor Electrical Cabinet for Your Requirements

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA