How to choose the right outdoor cabinet heat exchanger for your needs

Choosing the right outdoor cabinet heat exchanger starts with knowing your cabinet’s environment, heat load, and what it needs to do. The best way to manage heat is to match the heat exchanger to these things. Studies show that if you calculate heat load correctly, you can stop overheating and keep systems working well. This means you must count both the power used inside and outside things like sunlight. Industry data says using a heat exchanger made for your site can lower energy use by up to 15%. The heat exchanger you pick changes how long your system lasts, how much work it needs, and how much it costs. Picking the right heat exchanger helps your system work well for a long time.

Key Takeaways

Learn about your cabinet’s area and heat before picking a heat exchanger. This helps stop overheating and saves energy.

Find out the hottest outside temperature and how much heat your equipment makes. This helps you choose the right cooling system.

Pick materials and protection ratings that match your site’s weather and dirt. This keeps your cabinet strong and working well.

Choose a heat exchanger type that fits your space and how easy it is to take care of. Make sure it meets your cooling needs for good, long use.

Think about future needs by making your cooling system a bit bigger than you need now. Do not forget to check maintenance and protection ratings to avoid mistakes.

Application & Environment

When you pick a heat exchanger, look at what you need it for and where it will go. Each use is different. You must match the heat exchanger to the job and the place. This helps it work well and last longer.

Ambient Temperature

Ambient temperature is very important for cooling. Always check the hottest temperature at your site. Heat exchangers work best with medium heat. They cannot cool things below the outside temperature. If you need cooler air, you might need an air conditioner. Use a good thermometer to check the real air temperature, not the cabinet’s surface. Think about the hottest days of the year. Outdoor cabinets usually see temperatures from -30°C to 55°C. Inside, it can get up to 85°C. The best battery temperature is 25°C. Knowing these numbers helps you choose the right heat exchanger.

Parameter | Value / Description |

|---|---|

Typical External Ambient Temp | -30°C to 55°C across all latitudes and longitudes |

Equipment Chamber Temp Range | 20/30°C to 65/85°C |

Optimum Battery Temp | 25°C |

Contaminants & Weather

Outdoor cabinets face many problems from the weather. Dust, rain, and wet soil can hurt how well your heat exchanger works. Rain and frozen ground can change how your system cools. Wet soil can help cooling, but frost makes it worse. Sunlight also makes the cabinet hotter. Pick materials that do not rust or break easily. Aluminum, copper, and stainless steel protect in different ways. Stainless steel is best for dirty or harsh places. Copper cools well but does not last long in salty air. Always pick the right material for your job and the weather.

Site Challenges

Every place has its own problems. You might have little space, lots of water in the air, or strong sun. Some places have more dust or chemicals. These things can make your heat exchanger work less well. Think about how easy it is to put in and take care of the system. Check if your site needs special things, like extra covers or easy cleaning. Picking the right heat exchanger for your job and place helps you avoid trouble and keeps your system working well.

Heat Load & Cabinet Size

When you pick a heat exchanger, you need to know two things. First, find out how much heat your cabinet makes. Second, check how big your cabinet is. These help you choose the best cooling system. This stops your cabinet from getting too hot.

Internal Heat Sources

All the devices inside your cabinet make heat. You must count every piece of equipment. This includes power supplies, batteries, and electronics. All this heat adds up. It changes how well your heat exchanger works.

Calculating Heat Load

Here are steps to find your cabinet’s total heat load:

Measure the cabinet’s surface area that touches air. Use this formula: (Height × Width × 2) + (Height × Depth × 2) + (Depth × Width).

Find the difference between the hottest outside temperature and your target inside temperature.

Use a conversion factor (Btu/hr/ft²) to turn this difference into an external heat load.

Add the heat from your equipment. Change the watts lost by your devices into Btu/hr (multiply by 3.41).

Add both the internal and external heat loads.

Include extra heat from fans or sunlight if needed.

Make sure your cooling system can handle the total heat load.

Example Scenario: Calculating Heat Load for a Telecom Cabinet

Let’s say you have a telecom cabinet with a surface area of 20 ft². The temperature difference is 20°F. Your equipment loses 500 watts. The external heat load is about 400 Btu/hr. The internal heat load is 500 × 3.41 = 1,705 Btu/hr. The total heat load is 2,105 Btu/hr. Pick a heat exchanger that can handle at least this much.

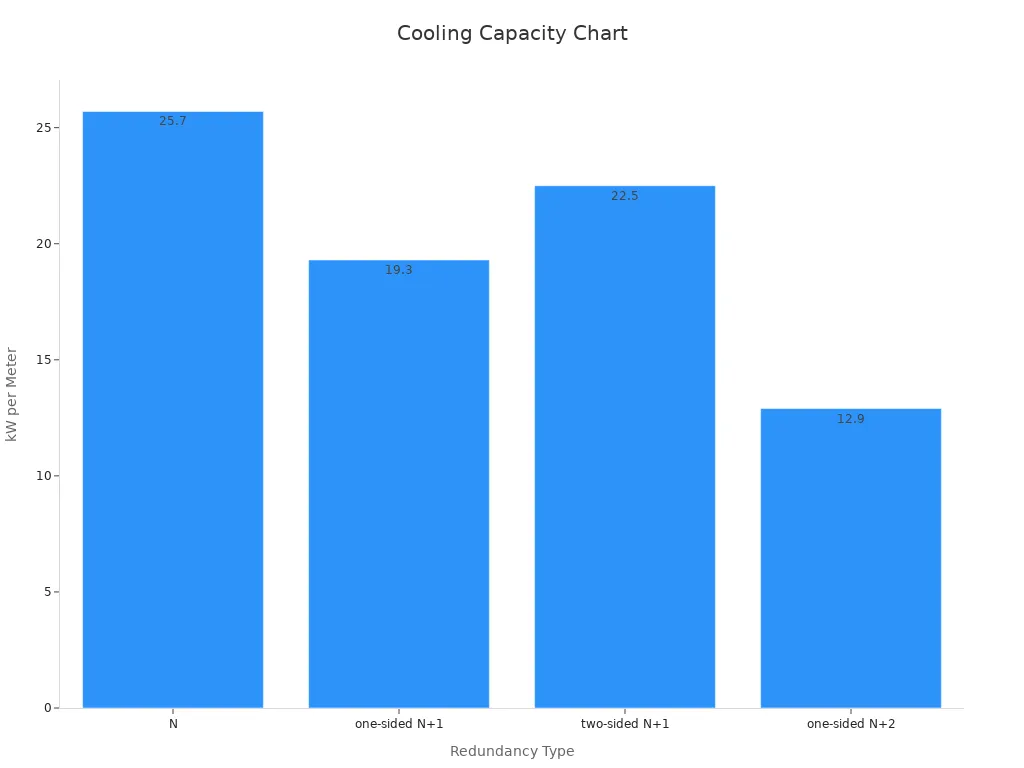

Cabinet Cooling System Sizing

Your cooling system should be 1.5 to 2 times bigger than needed. This gives you a safety margin for hot days or more equipment. The table below shows some formulas and tips for sizing:

Metric / Formula | Description | Formula / Value | Notes |

|---|---|---|---|

CRAC Capacity Formula | Relates CRAC capacity to number of cabinets and load per cabinet | CRAC Capacity = Number of IT cabinets × kW per cabinet | Excludes lighting and solar gains |

Cabinet Capacity to Footprint Factor (C2F) | Measures IT capacity relative to space used | (kW per cabinet) / C2C | Higher C2F means more efficient use |

Future Expansion

Always think about adding more devices later. Pick a heat exchanger and cooling system that can handle extra heat. Use the same steps as before, but add the power of new equipment to your numbers. This keeps your system safe and cool as you grow.

Outdoor Cabinet Heat Exchanger Types

When you pick an outdoor cabinet heat exchanger, you should know the main types. Each type works differently and needs different care. Some are better for certain jobs than others. Let’s check out the most common choices.

Air-to-Air

Pros & Cons

Air-to-air heat exchangers use air to move heat outside the cabinet. They save energy and work well with medium airflow. These units are simple and easy to take care of. You do not need water or extra pipes. But they might not cool very hot cabinets.

Application Scenarios

Air-to-air heat exchangers are good for telecom cabinets and battery boxes. They work best in places with medium heat. They are great if you want low care and good energy savings.

Maintenance Difficulty

You only need to clean the filters and check the fans. Taking care of them is easy and quick.

Tip: To get the best results, keep the air inlet at a 45° angle. This helps move heat better and saves energy.

Metric | Observation |

|---|---|

Best Energy Efficiency Ratio | |

Lowest EER | 7.2 at 25 L/s airflow |

Cooling Capacity | Increases with airflow |

Air-to-Water

Pros & Cons

Air-to-water heat exchangers use water to cool the cabinet. They can handle more heat than air cooling. They work well but need water pipes and pumps. You have to do more care, and leaks can happen.

Application Scenarios

Air-to-water heat exchangers are best for places with lots of heat. Data centers and big telecom sites use this type.

Maintenance Difficulty

You must check the water pipes, pumps, and filters. Taking care of them takes more time than air-to-air units.

Metric / Aspect | Value / Description |

|---|---|

Average Seasonal Performance | 2.59 (field studies) |

Typical Product Rated COP | 4.12 |

Field vs Rated Performance |

Plate Heat Exchangers

Pros & Cons

Plate heat exchangers use thin plates to move heat. They are small and work very well. They fit in tight spaces and can stop hot spots by up to 95.7%. But they may have more pressure drop and need careful design.

Application Scenarios

Plate heat exchangers are good for outdoor cabinet heat exchanger systems with little space. They are great for telecom and power cabinets.

Maintenance Difficulty

You need to look for blockages and clean the plates. Taking care of them is not too hard.

Performance Metric | Value |

|---|---|

Max Temperature Drop | |

Cooling Efficiency Increase | 15% |

Highest Local Heat Transfer Coefficient | 21.96 W/m²·K |

Reduction in Localized Overheating | Up to 95.7% |

ESTEL’s Innovations and Market Performance

ESTEL is a leader with new outdoor cabinet heat exchanger ideas. Their cabinets use strong materials that do not rust. They have high IP ratings for tough weather. ESTEL’s telecom cabinets save over 96% energy and cut energy use by up to 20%. Their heat exchanger design has models like HE06-190SEH/01, which cools 1900W and has IP55 protection. ESTEL meets world rules like ISO 9001 and IEC 60529. Customers trust ESTEL for good performance and long-lasting products. The world market for heat exchangers keeps growing, and ESTEL stays ahead with strong ideas and good results.

Making the Right Choice

Product Features

When you pick a heat exchanger, match its features to your job. First, check the NEMA or IP rating. These ratings show how well it keeps out dust and water. For example, NEMA 4X means it can handle water sprays and does not rust. This is good for outdoor or marine places. IP65 or IP67 ratings mean strong dust and water protection. The table below helps you see what each NEMA rating does:

NEMA Rating | Protection Focus | Protection Details | Typical Use Cases |

|---|---|---|---|

NEMA 3R | Outdoor Weather | Rain, sleet, snow | Exterior panels |

NEMA 4 | Indoor/Outdoor | Watertight, dustproof | Industrial washdown |

NEMA 4X | Indoor/Outdoor | Corrosion resistant | Marine, food processing |

NEMA 12 | Indoor Industrial | Dust, dripping liquids | Warehouses |

NEMA 6/6P | Submersion | Temporary/prolonged submersion | Special environments |

Think about expandability too. If you want to add more equipment later, pick a heat exchanger that can handle more heat. This helps you avoid trouble as your needs grow.

Features like airflow, cooling power, and material type change how well it works. Studies show that higher outside temperatures and heavy loads make more frost and longer recovery. Opening the door and high humidity also use more energy. Pick a heat exchanger that matches your site’s temperature, humidity, and load. This keeps your system working well and saves energy.

Maintenance & Cost

Pick a heat exchanger that is easy to put in and take care of. Some only need filter cleaning. Others need checks on pumps or water lines. Think about how much time you can spend on care. If your site is hard to reach, choose a model that needs less work.

Cost is important, but do not just look at the price. The best heat exchanger will save money by using less energy and needing fewer repairs. Plate heat exchangers are good for low-to-medium thick fluids and high flow. They cost less to run and fix than other types. If you have thick or dirty fluids, you may need a pricier model, but it will last longer and work better.

Real case studies show that matching the heat exchanger to the job gives better results and lower costs. In one oil refinery, engineers saved 8% energy by moving heat exchangers to fit the process. Another plant made coolers smaller and saved money by picking the right design.

Common Mistakes

Many people make mistakes when picking a heat exchanger. Avoid these errors to make a good choice:

Do not forget about the outside temperature. If your unit cannot handle hot days, it may overheat.

Do not pick a heat exchanger that is too small or too big. Too small will not cool enough. Too big wastes money and energy.

Do not forget about future growth. If you plan to add more devices, pick a model that can handle more heat.

Do not ignore protection ratings. If your site has dust, water, or chemicals, pick a heat exchanger with the right NEMA or IP rating.

Do not skip regular care. Even the best unit needs cleaning to work well.

Tip: Use this checklist to help pick your heat exchanger:

What is the hottest outside temperature at your site?

What is your total heat load, including future needs?

What NEMA or IP rating do you need?

How much space do you have?

How often can you do maintenance?

What is your budget for buying and running it?

If you pick carefully, you will avoid costly problems and keep your system working well. When you match product features to your job, think about care and cost, and avoid mistakes, you will make a good choice for long-term use.

You can choose the right outdoor cabinet heat exchanger by following a few simple steps. First, look at your application and environment. Next, calculate your heat load. Then, match product features to your needs. Use the checklist to guide your decision. If you have a complex setup, talk to ESTEL or another expert. You will keep your system safe and efficient with the right heat exchanger.

For more help, check out guides or ask a supplier for support.

FAQ

How often should you clean your outdoor cabinet heat exchanger?

You should check and clean filters every three months. In dusty areas, clean more often. Regular cleaning keeps your system working well and helps prevent overheating.

What is the best material for harsh outdoor environments?

Stainless steel works best for harsh or dirty places. It resists rust and damage from chemicals. You can trust it to last longer in tough weather.

Can you use an air-to-air heat exchanger in very hot climates?

Air-to-air heat exchangers work well in mild to warm climates. In very hot places, you may need extra cooling, like an air conditioner, to keep your equipment safe.

How do you know if your heat exchanger is too small?

If your cabinet gets too hot or equipment shuts down, your heat exchanger may be too small. Always check the total heat load before you choose a model.

See Also

Choosing The Ideal Outdoor Electrical Cabinet For You

Tips For Selecting The Perfect Outdoor Telecom Cabinet Mount

Selecting The Most Effective Cooling Solution For ESTEL Cabinets

Benefits Of ESTEL Cooling Systems In Industrial Settings

Reliable Outdoor Cabinets Providing Efficient Cooling And Control

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA