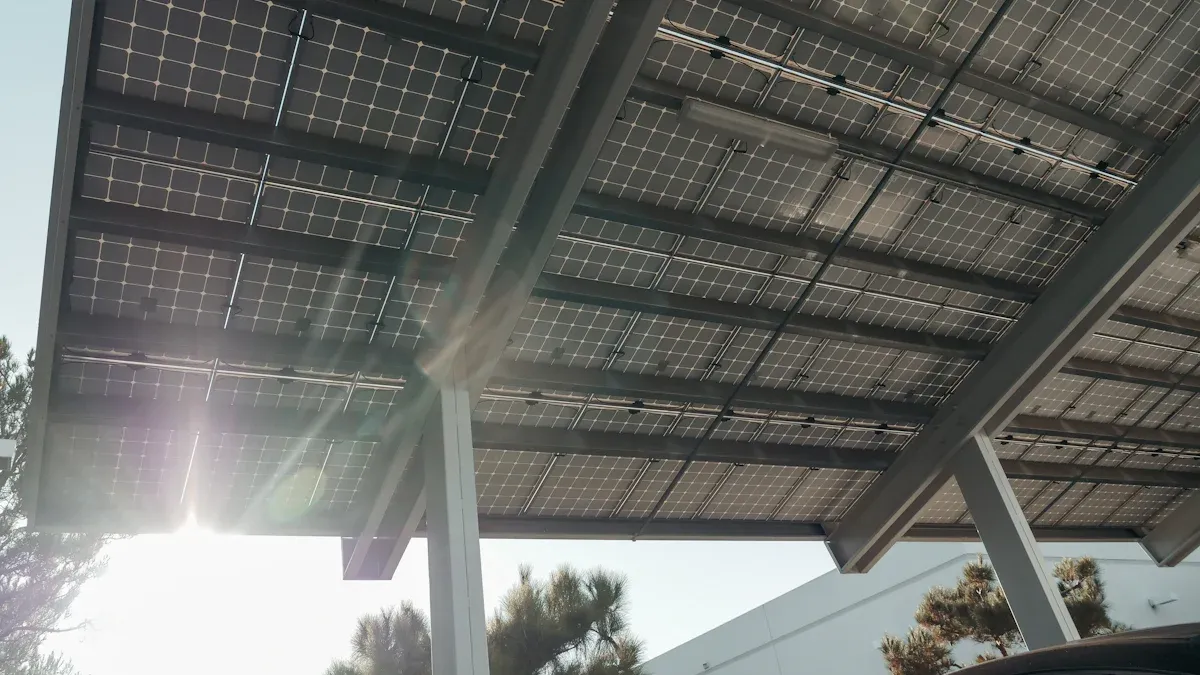

How to Choose a Steel Structure That Withstands Harsh Weather for PV Panels

Choosing the right Steel Structure for PV Panel installations protects your investment in areas with harsh weather. You need to match the structure to your local climate and environment. Galvanized steel works well in most places, offering good corrosion resistance at a lower cost. Stainless steel handles coastal or high-humidity regions, delivering superior durability and long-term savings. When you select quality materials and ensure proper installation, you maximize the lifespan and performance of your solar system.

Key Takeaways

Match your steel structure to your local weather and environment to prevent damage and extend your solar system's life.

Choose corrosion-resistant materials like galvanized or stainless steel based on your climate to protect against rust and wear.

Ensure your steel structure can handle wind, snow, and other loads by following local building codes and using proper thickness and design.

Hire professional installers to guarantee safe mounting, roof compatibility, and proper grounding for long-term system reliability.

Perform regular inspections and maintenance to catch issues early, keep your system efficient, and save money on repairs.

Key Factors for Steel Structure for PV Panel

Location and Environment

When you choose a Steel Structure for PV Panel, you must first look at your local environment. Climate, geography, and weather patterns all play a major role in how your solar system will perform over time. For example, high temperatures in places like the Middle East can stress both the panels and the steel frame. In coastal areas, saltwater exposure increases the risk of corrosion, which can weaken the structure if you do not select the right materials. Humidity, ultraviolet rays, and sand storms also affect the lifespan and reliability of your installation.

Tip: Always match your steel structure to your region’s unique environmental challenges. This step helps you avoid costly repairs and ensures your solar panels last longer.

Here is a table that shows how different environmental factors impact steel structures for PV panels and which steel properties help address these challenges:

Environmental Factor | Impact on PV Steel Structures | Steel Property Addressing Factor |

|---|---|---|

High Temperature | Reduces PV efficiency; stresses structure | Steel maintains strength under thermal stress |

Heavy Snow and Strong Winds | Adds heavy load and stress | High strength and load-bearing capacity |

Saltwater Exposure | Causes corrosion and degradation | Advanced anti-corrosion coatings |

Corrosion Risk | Can reduce load capacity by over 50% | Stainless steel and anti-corrosion treatments |

Lifecycle Cost and Maintenance | Increases maintenance needs and costs | Durability and corrosion resistance |

Extreme Weather Conditions | Threatens structural reliability | Robustness and adaptability |

Large-Scale Installations | Requires handling immense loads | Strength, adaptability, and recyclability |

You need to assess your site’s climate and geography before making any decisions. For example, if you live in a region with frequent sand storms, you should choose steel with a protective coating to prevent abrasion and corrosion. In humid or rainy areas, prioritize corrosion-resistant materials to avoid structural weakening.

Wind and Snow Loads

Wind and snow loads are two of the most important factors when designing a Steel Structure for PV Panel. Wind can create strong uplift forces, especially in open or elevated locations. Snow adds extra weight, which can stress the mounting system and even cause failure if not properly accounted for.

PV modules must meet strict standards for wind and snow resistance. Most panels are tested to withstand at least 2400 Pa (about 50 pounds per square foot), but in areas with hurricanes or heavy snow, you should look for systems rated up to 5400 Pa (about 75 pounds per square foot). Some manufacturers go even higher to ensure safety and durability.

Here is a quick reference for typical load ratings by building type and region:

Building Type | Snow Load Rating (psf) | Wind Speed Rating (mph) |

|---|---|---|

Metal Garages | 30 to 60 | 90 to 140 (up to 150) |

Metal Barns | 40 to 70 | 100 to 150 |

Metal Carports | 20 to 40 | 80 to 120 (up to 130+) |

Commercial Metal Buildings | 50 to 100+ | 120 to 180 |

Regional Snow Load Categories | Snow Load Range (psf) |

|---|---|

High Snow Load States | 60 to 100+ |

Moderate Snow Load States | 30 to 50 |

Low Snow Load States | 0 to 20 |

Mountainous/Transition Zones | 20 to 80+ |

PV modules should be certified for at least 2400 Pa (~50 psf) load rating. In heavy snow regions, look for modules rated up to 5000 Pa (~104 psf).

Use a tilt angle of 30–35° or higher to help snow slide off the panels.

Increase the number of attachment points and supports to improve snow load resistance.

In cold climates, consider frost heave effects on foundations to keep the structure stable.

For hurricane-prone areas, select systems with higher wind speed ratings and reinforced anchoring.

You must always check local building codes and weather data before finalizing your design. Regional differences in wind and snow loads mean that a structure suitable for one area may not work in another. Using joint wind-snow hazard data helps you design a system that stands up to both forces at once.

Panel Size and Orientation

Panel size and orientation have a direct impact on the structural requirements for your steel mounting system. Larger panels or higher tilt angles increase wind uplift forces. For example, a 30° tilt angle can create up to 2.5 times more wind uplift than a 10° tilt. This means you need stronger anchoring and possibly more robust steel supports.

The way you arrange your panels—whether in landscape or portrait orientation—also affects wind and snow loads. Tighter row spacing can increase turbulence and uplift, so you may need to adjust anchor placement or add reinforcements. Proper spacing also helps reduce shading and allows for better ventilation, which improves both energy output and structural safety.

Note: If you install panels on a roof, make sure the roof can handle the extra weight. Tilt-up systems usually require stronger support than flush-mounted systems.

Ground-mounted systems give you more flexibility with tilt and orientation, but they often need more complex structural designs. Adjustable or tracking systems can boost energy production but also increase the demands on your steel structure.

When you plan your PV system, always balance energy performance with structural safety. Choose a Steel Structure for PV Panel that matches your panel size, tilt, and orientation to ensure long-term stability and efficiency.

Material and Corrosion Resistance

Material Options

You need to choose the right material for your PV panel mounting system. The most common options include galvanized steel, stainless steel, and cold-formed steel. Each material offers different benefits for strength, cost, and weather resistance.

Here is a table to help you compare these materials:

Property | Galvanized Steel | Stainless Steel | Cold-Formed Steel |

|---|---|---|---|

Cost | Affordable, budget-friendly option | Higher upfront cost, premium price | Cost-effective and durable |

Corrosion Resistance | Moderate; zinc coating protects well | Excellent; ideal for extreme conditions like coastal areas | Good resistance to harsh environments |

Durability | Good; suitable for most climates | Exceptional; long lifespan in harsh environments | Strong and reliable structural integrity |

Environmental Impact | Lower CO₂ emissions compared to aluminum | Slightly higher CO₂ emissions | Growing affordability and eco-friendly due to manufacturing advances |

Suitability | Best for moderate climates and large-scale projects | Best for extreme climates, high humidity, and high wind areas | Versatile for various installations balancing cost and strength |

Galvanized steel works well for most outdoor environments. The zinc coating helps prevent rust and keeps costs low. Stainless steel gives you the best protection in harsh or coastal areas, but it costs more. Cold-formed steel offers a good balance between strength and price, making it a smart choice for many projects.

You may also see materials like AL-6005-T5 anodized aluminum and Q235B steel in PV mounting systems. AL-6005-T5 resists corrosion and works well for ground screws and mounting hardware. Q235B, when hot-dip galvanized, stands up to tough weather and lasts longer outdoors. Always check if the material meets ASTM or EN standards for quality and safety.

Tip: Match your material choice to your local climate and project budget. This step helps you get the best value and durability from your Steel Structure for PV Panel.

Corrosion Protection

Corrosion can shorten the life of your PV mounting system. You need to protect your steel structure from rust, especially in areas with saltwater, high humidity, or chemical exposure. The right coating or treatment makes a big difference.

Some of the most effective corrosion protection methods include:

Using marine-grade steel for superior resistance to saltwater and moisture.

Applying advanced coatings like marine-grade epoxy or UV-resistant paint to create a barrier against rust.

Choosing Zinc-Aluminum-Magnesium (ZAM) coatings for extreme environments. ZAM lasts two to four times longer than standard hot-dip galvanizing, especially in coastal or chemical areas.

Selecting Magnelis®-coated steel, which reduces corrosion in soil and offers at least 25 years of durability without extra protection.

Regular maintenance also helps. Inspect your structure for rust and reapply coatings as needed. This keeps your system strong and safe for years.

Feature | Zinc-Aluminum-Magnesium (ZAM) | Hot-Dip Galvanizing (HDG) |

|---|---|---|

Corrosion Resistance | Superior, especially in harsh/coastal/chemical environments | Good, but less effective in aggressive settings |

Durability & Lifespan | Lasts 2 to 4 times longer than HDG in harsh environments | Moderate lifespan, shorter in harsh conditions |

Applications | Coastal areas, chemical plants, solar panel mounts | General outdoor infrastructure, agriculture |

Cost | Higher initial cost, justified by longer service life | Lower initial cost, suitable for mild environments |

Environmental Impact | Lower emissions and waste during production | Higher emissions and waste |

Aesthetic Appearance | Matte gray, smooth, uniform finish | Shiny or dull metallic finish |

Ease of Processing | More challenging to weld and process | Easier to weld and process |

Note: ZAM and Magnelis® coatings provide self-healing properties and protect even cut edges from rust. This makes them ideal for PV panel structures in harsh weather.

Steel Thickness

Steel thickness plays a key role in the strength and durability of your PV mounting system. Thicker steel components handle heavy wind and snow loads better. They also resist bending and damage from impacts.

Thicker gauge steel and strong cross-bracing improve performance in extreme weather.

Systems with thicker steel need less frequent maintenance because they are less likely to deform or corrode quickly.

Clamp types with larger bearing surfaces and bolts that require more turns to release also add to the system’s durability.

You should always follow engineering guidelines for minimum steel thickness based on your local wind and snow loads. This ensures your structure stays safe and stable for many years.

Tip: Do not cut corners on steel thickness. Investing in stronger materials up front saves you money on repairs and replacements later.

Structural Design and Safety

Load Capacity

You must ensure your steel structure can handle all expected loads. Start by considering the different types of loads your PV system will face:

Dead load: This includes the weight of the steel structure, panels, and mounting hardware.

Live load: Temporary weights such as maintenance workers or equipment.

Snow load: Varies by region and roof slope.

Wind load: Depends on wind pressure, roof area, and shape.

Seismic load: Important in earthquake-prone areas.

Structural engineers use these factors to calculate the total load capacity. You should always follow local building codes like the International Building Code (IBC) and standards such as ASCE 7-16. These codes require you to document all loads and ensure your roof or ground system can support them. Lightweight, corrosion-resistant materials like aluminum alloys or stainless steel help reduce the burden on your structure. Even weight distribution prevents stress points and maintains integrity. Always work with a qualified engineer to verify your design meets safety standards.

Roof Compatibility

Check your roof’s condition before installing PV panels. The roof must be free from rust, leaks, or damage. Roof orientation and slope affect both energy output and structural needs. Different roof types require specific mounting systems:

Standing seam metal roofs: Use clamp mounts that do not penetrate the roof.

Corrugated metal roofs: Need penetrating mounts with waterproofing.

Metal tile roofs: Require custom solutions to avoid damage.

Older or fragile roofs may need reinforcement. Always use materials compatible with your roof to prevent corrosion. Consider thermal expansion and local weather when choosing mounting hardware. Professional installers help you select the right system and preserve your roof’s integrity.

Grounding and Bonding

Proper grounding and bonding protect you from electrical hazards. Follow the National Electrical Code (NEC) for all installations. You must bond all metal parts—panels, frames, and steel supports—to create a continuous, low-impedance path. Ground these bonded parts to safely discharge fault currents and lightning strikes. Use certified equipment and hire qualified installers. Install disconnects and emergency shut-offs for safety. Regular inspections help you catch and fix grounding issues early.

Improper grounding can cause shock hazards, fires, and equipment damage. Always ensure continuous bonding and grounding of all metal parts in your PV system.

Outdoor systems need grounding components rated for weather exposure. Pay attention to thermal cycling and material compatibility to prevent loose connections and corrosion. This keeps your PV system safe and reliable for years.

Installation and Maintenance

Professional Installation

You should always choose professional installation for your steel PV mounting system. Experts understand how to match mounting systems to different roof types without causing leaks or damaging warranties. They perform structural studies and wind load assessments to ensure your system stays safe and secure. Many installers provide structural certificates and guarantees, which support long-term durability.

Solar mounting systems work best when installed by professionals who avoid roof perforations, protecting your building from water damage.

Steel roofs offer a strong, lasting surface for solar panels, but you must account for the extra weight during manufacturing.

Professional consultation helps you check compatibility and keeps your roof warranty valid.

The durability of steel roofs, combined with expert installation, maximizes your solar investment.

Tip: Always ask for documentation and guarantees from your installer to ensure your system meets safety standards.

Site Adaptation

Every site presents unique challenges. You need to adapt your steel structure to local conditions for the best results. Start with a thorough site study. Check the ground support, slope, and drainage. Prepare the land by clearing vegetation and leveling the surface. Make sure your mounting system can handle wind, snow, and seismic loads.

Soil/Topography Condition | Impact on Structure Choice | Suitable Solutions |

|---|---|---|

Acidic soil | Corrosion risk | Use protective coatings |

Rocky terrain | Hard to anchor | Ballasted mounts, drilled piers |

Uneven/sloped ground | Installation complexity | Adjustable racking, tracking mounts |

You must also follow local permits and zoning laws. Plan for easy access to your panels for cleaning and repairs. Consider wind mitigation techniques, such as ballast design or wind deflectors, to keep your system stable.

Regular Inspection

Regular inspection keeps your steel structure safe and efficient. You should inspect your mounting equipment at least twice a year.

Check for loose bolts, rust, or corrosion.

Clean panels and remove debris to maintain performance.

Increase inspection frequency in areas with harsh weather or heavy snowfall.

Tighten fasteners and replace damaged parts as needed.

Adjust your maintenance schedule based on local conditions, such as dust or bird activity.

Routine checks and cleaning help prevent common issues like corrosion, structural fatigue, and electrical failures, especially in coastal or high-humidity regions.

Cost, Longevity, and Sustainability

Budget vs. Durability

When you choose a steel structure for your PV panels, you need to balance your budget with long-term durability. The initial cost for steel structures usually ranges from $37 to $38 per square foot. This price covers materials, labor, foundation, and any custom features. While this may seem high at first, you gain significant value over time.

Steel structures often last 25 to 30 years, matching the lifespan of most solar panels. You can expect annual maintenance costs between $150 and $700, depending on your system size and location. Regular cleaning and inspections, which cost around $300 to $700 each year, help keep your system running efficiently. These low ongoing costs make your investment cost-effective over the system’s lifetime.

If you invest in higher-quality steel, such as hot-dip galvanized (HDG) steel, you benefit from even greater savings. HDG steel can last over 75 years in many soil conditions. It resists corrosion and damage from harsh weather, which means you spend less on repairs and replacements. You also save money because HDG steel is easy to inspect and can be reused or re-galvanized during upgrades.

Choosing quality steel up front helps you avoid unexpected expenses and ensures your solar system stays reliable for decades.

Environmental Impact

You also need to consider the environmental impact of your steel structure. Steel stands out as one of the most sustainable materials for PV panel mounting systems. You can recycle steel frames easily, which reduces waste and conserves natural resources. When you recycle steel, you lower carbon emissions and support a circular economy. Many solar projects now redesign components for longer life and easier recycling, which helps protect the environment.

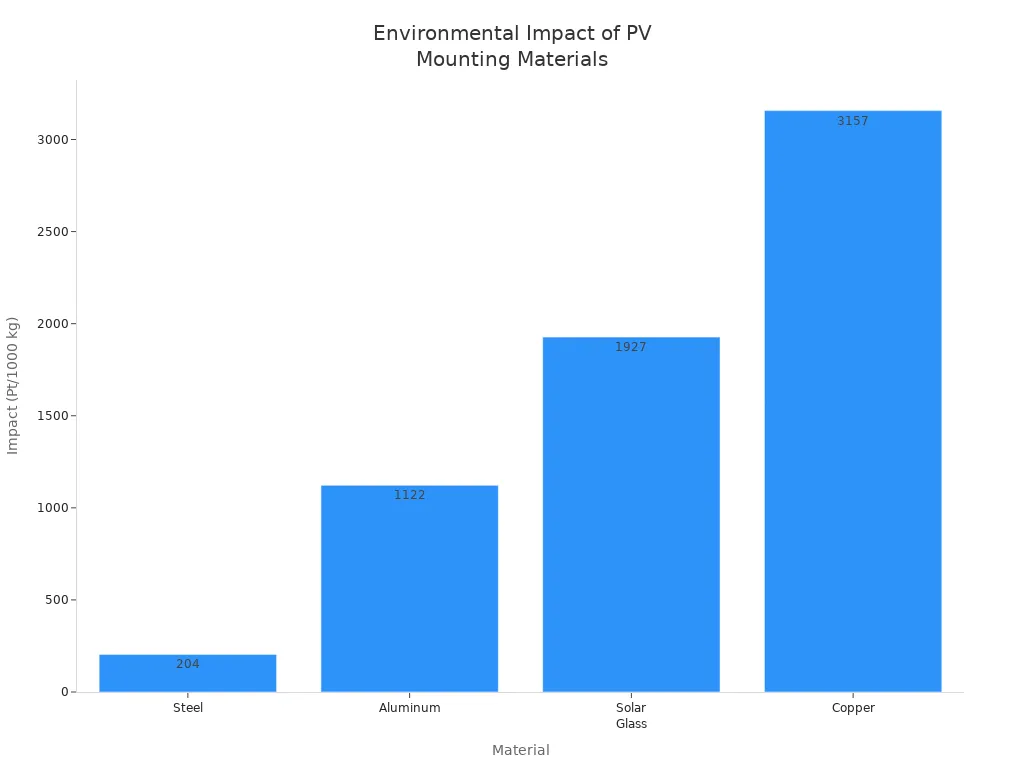

Steel and aluminum both have low environmental impacts compared to other materials used in solar installations. The table below shows how steel compares to other common materials:

Material | Environmental Impact (Pt/1000 kg) | Notes on Lifecycle Impact and Recycling |

|---|---|---|

Steel | 204 | Lowest impact among support structure materials; easily recycled and reused, reducing environmental footprint |

Aluminum | 1122 | Also used in support structures; relatively low impact and recyclable |

Solar Glass | 1927 | High impact due to energy/material intensive production |

Copper | 3157 | Highest impact; used mainly in electrical installations |

When you select steel for your PV structure, you help reduce landfill waste and energy use. Recycling steel components from retired solar panels creates new products and supports jobs in recycling and material recovery. By making smart choices, you not only save money but also help build a more sustainable future.

You can choose the right Steel Structure for PV Panel by following a few essential steps. First, assess your local weather and environment. Next, select high-quality materials and ensure your structure meets all safety standards. Always hire professionals for installation. Remember to balance your budget with long-term durability and sustainability. By taking these actions, you protect your solar investment and help your system last for decades.

Tip: Regular inspections keep your structure strong and efficient.

FAQ

What is the best way to protect steel structures from corrosion?

You should choose steel with advanced coatings like hot-dip galvanizing or ZAM. Regularly inspect and clean your structure. Apply touch-up paint to scratches. In coastal areas, select stainless steel for maximum protection.

How do I know if my roof can support a PV steel structure?

Check your roof’s age and condition. Hire a professional to assess load capacity. Reinforce weak areas before installation. Always follow local building codes for safety.

Can I install a steel PV structure myself?

For best results, hire a certified installer. Professionals ensure correct mounting, grounding, and weatherproofing. DIY installation can void warranties and lead to safety risks.

How often should I inspect my steel PV mounting system?

Inspect your system at least twice a year. After storms or heavy snow, check for loose bolts, rust, or damage. Regular maintenance helps you catch problems early and extend system life.

See Also

Assessing Material Options for Outdoor Telecom Enclosures

Selecting The Ideal Mount For Outdoor Telecom Cabinets

Essential Requirements For Long-Lasting Outdoor Telecom Cabinets

Important Guidelines To Maintain ESTEL Cabinets Outdoors

Comparing Durability Of Various Outdoor Communication Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA