ESTEL Beginner's Guide to Choosing the Perfect Rectifier Module

Rectifier modules are essential components in electrical systems, enabling efficient AC to DC conversion. They transform alternating current into direct current, providing stable power for devices and systems that rely on DC electricity. Without rectifiers, fluctuations in AC power could damage sensitive equipment or lead to inefficiencies in power conversion processes.

Choosing a rectifier tailored to your needs ensures optimal performance and longevity for your system. For example, rectifier modules mitigate voltage spikes and power surges, enhancing the stability of connected components. Their ability to deliver regulated DC power makes them easy to use in industries ranging from telecommunications to renewable energy.

ESTEL’s expertise in rectifier technology ensures you’ll find a solution that aligns with your requirements. Whether you’re a beginner or looking for a buying guide, ESTEL offers reliable rectifier modules designed for efficiency and durability.

Key Takeaways

Rectifier modules change AC power into DC power. They give steady energy for many devices. Picking the right one helps it work well and last longer.

Check the input voltage and current when choosing a rectifier. Make sure these match your system to avoid harm.

Efficiency is very important for rectifiers. Better efficiency saves energy and lowers costs, making it cheaper to run.

Clean and check your rectifier often to make it last longer. This stops it from overheating and finds problems early.

Pick rectifiers made for your specific job or industry. This makes them work better and stay reliable in tough conditions.

Types of Rectifier Modules

Understanding the different types of rectifier modules helps you choose the right one for your application. Each type has unique features and benefits, making it suitable for specific use cases.

Single-Phase Rectifier Modules

Single-phase rectifiers are ideal for low-power applications. They convert AC to DC using one phase of the input supply. You can choose between half-wave and full-wave rectifiers based on your needs:

Half-Wave Rectification: This type of rectifier uses only one half of the AC cycle. It is simple and cost-effective but less efficient.

Full-Wave Rectification: A full wave rectifier utilizes both halves of the AC cycle, providing higher efficiency and smoother DC output.

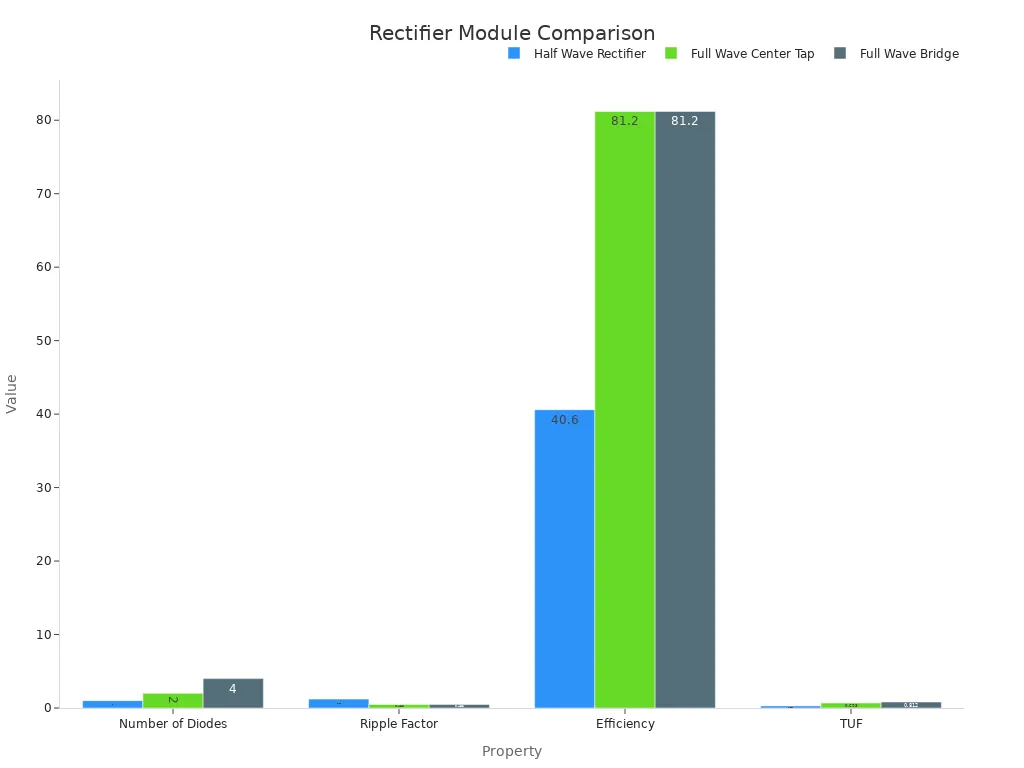

Property | Half Wave Rectifier | Full Wave Rectifier (Center Tap) | Full Wave Rectifier (Bridge) |

|---|---|---|---|

Number of Diodes | 1 | 2 | 4 |

Ripple Factor | 1.21 | 0.482 | 0.482 |

Maximum Efficiency | 40.6% | 81.2% | 81.2% |

The simplicity of single-phase rectifiers makes them a popular choice for small-scale electronics and household devices.

Three-Phase Rectifier Modules

Three-phase rectifiers handle higher power demands and are commonly used in industrial settings. They offer better efficiency and reduced ripple compared to single-phase rectifiers. You can select from several configurations:

Three-Phase Half-Wave Circuit: Uses three diodes, one for each phase.

Three-Phase Full-Wave Circuit: Employs a center-tapped transformer for improved performance.

Three-Phase Bridge Rectifier: Provides the highest efficiency and smoothest output.

Advancements in materials like Silicon Carbide (SiC) and Gallium Nitride (GaN) further enhance the efficiency and reliability of three-phase rectifiers. These modules are perfect for heavy-duty applications like motor drives and power supplies.

Controlled vs. Uncontrolled Rectifier Modules

The choice between controlled and uncontrolled rectifiers depends on your need for output regulation.

Controlled Rectifiers: These use components like SCRs (Silicon Controlled Rectifiers) to adjust the output voltage. They are ideal for applications requiring variable DC output, such as motor speed control.

Uncontrolled Rectifiers: These rely on diodes and provide a fixed DC output. They are simpler and more cost-effective, making them suitable for basic power conversion tasks.

Feature | Controlled Rectifier | Uncontrolled Rectifier |

|---|---|---|

Current Control | Yes, via SCR firing angle | No, uses diodes only |

Output Voltage Regulation | Adjustable | Fixed, no regulation |

Complexity | More complex due to control mechanisms | Simpler design |

Applications | Adjustable power supplies, motor control | Basic rectification for stable DC supply |

Controlled rectifiers offer greater flexibility, while uncontrolled rectifiers excel in simplicity and reliability.

Bridge Rectifier Modules

Bridge rectifier modules are among the most versatile and efficient types of rectifiers. They use four diodes arranged in a bridge configuration to convert AC into DC. This design allows the module to utilize both halves of the AC cycle, resulting in a smoother and more stable DC output. You’ll often find bridge rectifiers in applications requiring high power quality, such as industrial equipment, power supplies, and renewable energy systems.

One of the key advantages of bridge rectifiers is their efficiency. By utilizing the full AC cycle, they minimize power loss and reduce ripple in the output. When paired with filtering circuits, these modules deliver an even smoother DC signal, making them ideal for sensitive electronic devices. Advances in electronics have also made bridge rectifiers more cost-effective, despite their slightly more complex construction.

Feature | Bridge Rectifier | Diode Bridge Module |

|---|---|---|

Construction | Discrete diodes or integrated package | Pre-assembled module with additional components |

Packaging | Compact packages for lower power applications | Larger, robust enclosures for higher power applications |

Applications | General-purpose AC to DC conversion | Industrial and high-power applications |

You can choose between discrete bridge rectifiers or pre-assembled diode bridge modules. Discrete options are compact and suitable for lower power needs, while pre-assembled modules come in robust enclosures for high-power applications. Both options provide reliable performance, but your choice will depend on your specific requirements.

Tip: If your application demands high efficiency and minimal ripple, consider using a bridge rectifier module with a filtering circuit. This combination ensures stable and high-quality DC power.

Bridge rectifier modules are a reliable choice for converting AC to DC in a wide range of applications. Their efficiency and stability make them a cornerstone of modern power systems.

Key Factors to Consider When You Select a Rectifier

Choosing a rectifier involves evaluating several critical factors to ensure it meets your system's requirements. These factors influence the performance, efficiency, and longevity of the rectifier module. Below, we’ll explore the most important considerations to help you make an informed decision.

Input Voltage and Current Rating

The input voltage and current rating are fundamental when selecting a rectifier. These parameters determine whether the rectifier can handle the electrical load without overheating or failing.

Voltage Rating: Ensure the rectifier’s voltage rating matches or exceeds the maximum AC voltage in your system. This prevents damage from voltage spikes or surges.

Current Rating: The current rating indicates the maximum current the rectifier can handle. Always choose a rectifier with a current rating higher than your circuit’s maximum current draw. This provides a safety margin and prevents overheating.

Tip: If your application involves fluctuating loads or inrush currents, select a rectifier with a higher current rating to handle these variations effectively.

Efficiency and Power Loss

Efficiency plays a crucial role in power conversion systems. A more efficient rectifier reduces energy loss, lowers operating costs, and minimizes heat generation.

Benchmark | Description |

|---|---|

Synchronous Rectification | Uses low RDS(ON) MOSFETs to replace diodes, reducing voltage drop and losses. |

Low RDS(ON) MOSFETs | Minimizes conduction losses, improving overall efficiency. |

Quiescent Current | Lower quiescent current enhances performance in power supplies. |

Loss Mechanisms | Understanding and mitigating losses in MOSFETs and diodes is essential. |

Modern rectifiers often achieve efficiencies in the mid to high 90% range. To maximize efficiency:

Use rectifiers with low RDS(ON) MOSFETs for reduced conduction losses.

Opt for designs with synchronous rectification to minimize diode losses.

Evaluate the rectifier’s quiescent current, as lower values improve overall performance.

Note: High-efficiency rectifiers not only save energy but also reduce the need for extensive cooling systems, further lowering operational costs.

Cooling Methods (Air vs. Liquid Cooling)

Cooling is essential for maintaining the rectifier’s performance and preventing overheating. The choice between air and liquid cooling depends on your application’s power requirements and environmental conditions.

Air Cooling: This method uses fans or natural convection to dissipate heat. It is cost-effective and easy to use, making it suitable for low to medium-power applications. However, it may struggle in high-temperature environments or with high-power loads.

Liquid Cooling: This method uses a liquid coolant to transfer heat away from the rectifier. It is more efficient than air cooling and ideal for high-power applications or environments with limited airflow. However, it requires additional components like pumps and heat exchangers, increasing complexity and cost.

Tip: For industrial or high-power applications, liquid cooling provides better thermal management and ensures consistent performance under heavy loads.

When choosing a cooling method, consider the rectifier’s operating temperature range, power density, and the ambient conditions of your installation site. Proper cooling extends the rectifier’s lifespan and ensures reliable operation.

Temperature Range and Environmental Conditions

When selecting the best rectifier for your application, you must consider the temperature range and environmental conditions in which it will operate. Temperature fluctuations can significantly impact the performance and durability of rectifier modules. High temperatures may cause overheating, while extremely low temperatures can reduce efficiency and lead to component failure.

To ensure reliable operation, manufacturers design rectifiers with specific temperature ratings. Always check the operating temperature range of the rectifier and match it to your system's environment. For example, industrial applications often require rectifiers that can withstand extreme conditions, such as high ambient temperatures or exposure to dust and moisture.

Key environmental factors to consider include:

Temperature Effects: Rectifier efficiency decreases at higher temperatures. Effective thermal management, such as heat sinks or cooling fans, is essential to maintain performance.

Durability Testing: Testing rectifiers under maximum load conditions ensures the thermal design can handle operational requirements.

Environmental Protection: In harsh environments, choose rectifiers with protective enclosures to shield them from dust, moisture, and corrosive elements.

Tip: If your application involves fluctuating temperatures, look for rectifiers with advanced thermal management features. These features help maintain efficiency and extend the lifespan of the module.

System Connectivity and Integration

Modern rectifier modules offer advanced connectivity options, making them easy to use and integrate into complex systems. When choosing a rectifier, consider how well it connects with your existing infrastructure and whether it supports features like remote monitoring and control.

Advanced system connectivity provides several benefits:

Real-Time Monitoring: Enables proactive maintenance by identifying issues before they lead to failures.

Scalability: Modular designs allow you to scale power capacity by adding or replacing modules, adapting to changing demands without major overhauls.

Simplified Maintenance: Targeted repairs become possible without disrupting the entire system.

Metric | Description | Benefit to Telecom Systems |

|---|---|---|

Efficiency | Delta rectifiers outperform conventional models in efficiency. | Reduces energy costs and improves operational efficiency. |

Reliability | Their ability to operate across a broad voltage range minimizes downtime. | Ensures continuous operation of telecom systems. |

Scalability | Modular design allows for easy scaling of power capacity. | Adapts to changing power demands without major overhauls. |

Note: For telecommunications or data center applications, rectifiers with advanced connectivity features ensure seamless integration and reliable performance.

Cost and Budget Considerations

Cost is a critical factor when you select a rectifier. While it may be tempting to choose the cheapest option, you should evaluate the total cost of ownership, which includes initial purchase price, operating costs, and maintenance expenses.

Here’s how to balance cost and performance:

Initial Investment: High-quality rectifiers may have a higher upfront cost but often provide better efficiency and durability, reducing long-term expenses.

Energy Efficiency: Efficient rectifiers lower energy consumption, saving money on electricity bills.

Maintenance Costs: Easy-to-use rectifiers with modular designs simplify repairs and reduce downtime, minimizing maintenance expenses.

Tip: When choosing a rectifier, consider its efficiency and reliability alongside its price. A slightly higher investment in a durable and efficient rectifier can save you money in the long run.

Application-Specific Recommendations for Rectifier Modules

Rectifier modules play a vital role in various industries, ensuring efficient power conversion tailored to specific applications. Below, you’ll find recommendations for selecting the right rectifier based on your industry needs.

Industrial Applications

In industrial settings, rectifiers are indispensable for powering manufacturing systems, motor drives, and automation equipment. These systems often demand high reliability and efficiency to maintain productivity and reduce downtime. Rectifier modules designed for industrial use excel in handling high power loads and operating in challenging environments.

Key benefits of using rectifiers in industrial applications include:

High Efficiency: Modern rectifiers achieve over 90% energy efficiency, reducing operational costs.

Durability: Rugged designs withstand harsh conditions, such as high temperatures and dust exposure.

Digital Monitoring: Advanced rectifiers with monitoring capabilities allow you to track performance and address issues proactively.

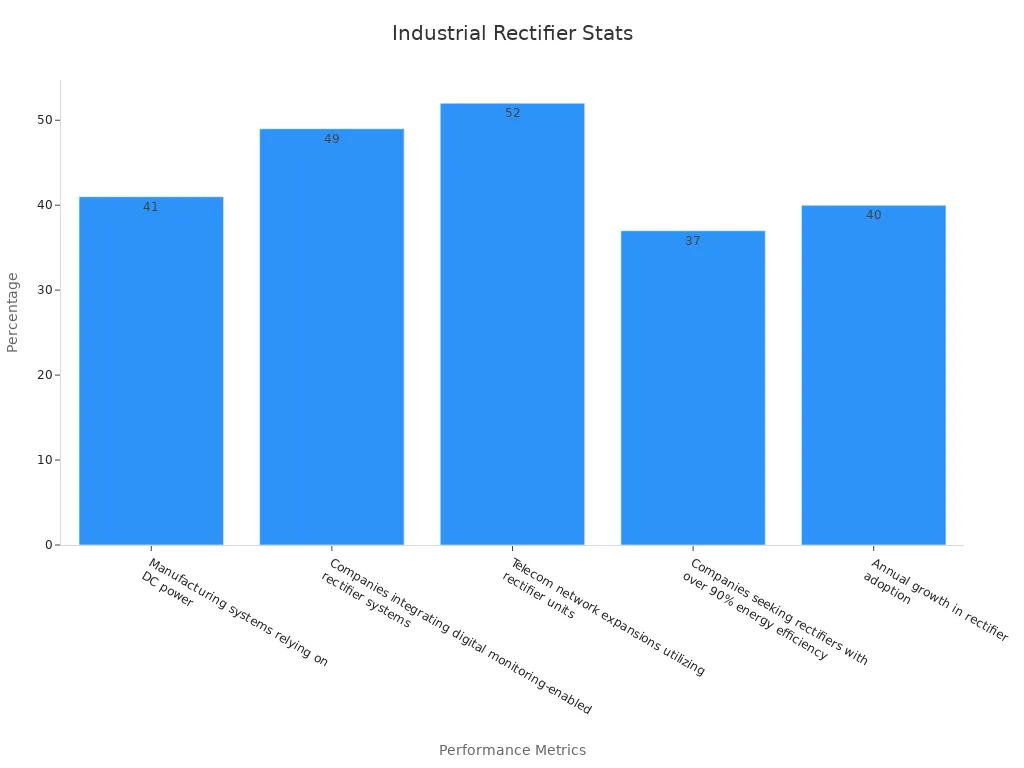

Statistic Description | Value |

|---|---|

Manufacturing systems relying on DC power | 41% |

Companies integrating digital monitoring-enabled rectifier systems | 49% |

Annual growth in rectifier adoption | 40% |

When selecting a rectifier for industrial applications, prioritize models with high current-handling capacity and robust thermal management. These features ensure consistent performance under heavy loads, making them easy to use in demanding environments.

Electroforming and Electroplating

Electroforming and electroplating processes rely heavily on rectifiers to provide the direct current necessary for effective plating. The right rectifier ensures precise voltage control, which is critical for achieving high-quality results.

Rectifiers designed for electroforming offer several advantages:

Steady DC Output: A stable current is essential for uniform plating and minimizing defects.

Adjustable Voltage: Electroforming rectifiers allow you to fine-tune the voltage, ensuring optimal results for different materials and thicknesses.

Reliability: High-quality rectifiers maintain consistent performance, even during prolonged operations.

Did You Know? Rectifiers are essential for electroforming because they convert AC to DC, providing the steady current required for the process. Without a reliable rectifier for electroforming, achieving good plating results becomes challenging.

To maximize efficiency, choose a rectifier for electroforming that offers advanced features like remote monitoring and precise voltage adjustments. These features make the rectifier easy to use and ensure consistent results across various applications.

Telecommunications and Data Centers

Telecommunications and data centers demand rectifiers that deliver uninterrupted power and high efficiency. These environments require reliable power systems to prevent service disruptions and data loss. Rectifier modules designed for these applications offer features tailored to their unique needs.

Performance Data Factor | Description |

|---|---|

Power Stability | Ensures uninterrupted operations in telecommunications and data centers. |

Efficiency | Critical for optimal performance and energy conservation. |

Modular Design | Allows for easy upgrades and maintenance. |

Redundancy Features | Provides backup systems to prevent power failures. |

The expanding telecommunications sector and the rise of data centers have increased the demand for reliable rectifiers. Backup power solutions are critical in these environments. Even a brief power outage can disrupt communication networks or lead to catastrophic data loss in data centers.

When choosing a rectifier for telecommunications or data centers, look for models with modular designs and redundancy features. These characteristics make it easy to use and maintain the system while ensuring continuous operation.

Renewable Energy Systems

Renewable energy systems rely on rectifier modules to convert variable AC power into stable DC power. These systems, including solar panels and wind turbines, generate electricity that fluctuates based on environmental conditions. Rectifiers ensure this power becomes usable for storage or direct consumption.

In solar energy systems, rectifiers play a crucial role in managing the output from photovoltaic (PV) panels. Solar panels produce DC power, but when combined with other components like inverters, rectifiers stabilize the flow of electricity. This stability ensures efficient energy storage in batteries and consistent power delivery to connected devices.

Wind energy systems also benefit from rectifiers. Wind turbines generate AC power, which varies with wind speed. Rectifiers convert this fluctuating AC into DC, making it suitable for storage or grid integration. Without rectifiers, the variability of wind-generated power could lead to inefficiencies or equipment damage.

Tip: When selecting a rectifier for renewable energy systems, prioritize models with high efficiency and durability. These features help maximize energy conversion and reduce long-term costs.

Rectifiers designed for renewable energy applications often include advanced features like remote monitoring and fault detection. These capabilities allow you to track performance and address issues before they escalate. For example, if you use an electroforming rectifier in a renewable energy setup, you can monitor its efficiency and ensure it operates within optimal parameters.

Electroforming rectifiers also find applications in renewable energy systems that require precise voltage control. For instance, in specialized manufacturing processes powered by renewable energy, these rectifiers provide the steady current needed for electroforming. This ensures high-quality results while maintaining energy efficiency.

When choosing a rectifier for electroforming in renewable energy systems, consider its ability to handle fluctuating loads. Renewable energy sources often produce variable power, so a rectifier with robust thermal management and overload protection is essential. These features ensure consistent performance and extend the lifespan of your equipment.

Did You Know? Electroforming rectifiers are not just limited to industrial applications. They can also support renewable energy systems by providing stable DC power for processes like electroforming, which require precise control over current and voltage.

Maintenance and Longevity of Rectifier Modules

Regular Cleaning and Inspection

Maintaining your rectifier starts with regular cleaning and inspection. Dust and debris can block airflow, causing overheating and reducing efficiency. You should inspect the module every three to six months, especially if it operates in dusty or humid environments. Look for signs of wear, such as discoloration or corrosion, which may indicate overheating or electrical faults.

Key Benefits of Regular Maintenance:

Prevent overheating by ensuring unobstructed airflow.

Identify potential issues early, reducing unexpected downtime.

Extend the lifespan of your rectifier by addressing minor problems before they escalate.

Tip: Preventive maintenance not only improves performance but also saves costs by avoiding major repairs.

Monitoring Efficiency and Performance

Monitoring the efficiency and performance of your rectifier ensures it operates at peak capacity. Use real-time monitoring tools to track energy conversion rates and detect anomalies. These tools help you identify inefficiencies, such as increased power loss or irregular voltage output. Addressing these issues promptly prevents long-term damage and keeps your system running smoothly.

Modern modular rectifiers, such as SMR chargers, simplify maintenance. They allow hot-swappable modules, enabling quick replacements without interrupting operations. This feature enhances longevity and reduces maintenance costs compared to traditional SCR chargers.

Note: Regular monitoring ensures your rectifier remains reliable and efficient, even under heavy loads.

Replacing Components When Necessary

Proactive component replacement is essential for maintaining the reliability of your rectifier. Over time, parts like power modules and UPS systems wear out and become obsolete. Replacing them at recommended intervals prevents system failures and ensures consistent performance.

Component Type | Recommended Replacement Interval | Notes |

|---|---|---|

Power Modules | 8-10 years | Modernization services can prolong UPS life but components become obsolete over time. |

3-Phase UPS Systems | 10-12 years | Regular maintenance can extend useful life to 15 years; systems over 15 years should be replaced. |

Tip: Follow replacement schedules to avoid costly downtime and maintain optimal system performance.

Tips for Extending Lifespan

Extending the lifespan of your rectifier module requires consistent care and attention. By following a few practical tips, you can ensure your equipment remains reliable and efficient for years.

Maintain Proper Cooling

Heat is one of the biggest threats to your rectifier. Ensure the cooling system works effectively to prevent overheating. Clean fans and heat sinks regularly to remove dust and debris. If your module uses liquid cooling, check for leaks and maintain the coolant levels.Avoid Overloading

Operating your rectifier beyond its rated capacity can lead to premature failure. Always match the module’s voltage and current ratings to your system’s requirements. If your application involves fluctuating loads, consider using a rectifier with a higher capacity to handle surges safely.Inspect Connections

Loose or corroded connections can disrupt power flow and damage components. Inspect all electrical connections periodically. Tighten loose terminals and replace corroded parts to maintain optimal performance.Use Surge Protection

Voltage spikes can harm your rectifier and connected equipment. Install surge protectors to shield your module from sudden power surges. This simple step can save you from costly repairs.Follow Manufacturer Guidelines

Manufacturers provide detailed instructions for operating and maintaining rectifiers. Adhering to these guidelines ensures your module performs as intended. Keep the user manual handy and refer to it for troubleshooting and maintenance tips.

Tip: Regular maintenance not only extends the lifespan of your rectifier but also improves its efficiency, saving you money in the long run.

By implementing these practices, you can maximize the durability and reliability of your rectifier module, ensuring it serves your system effectively for years.

Understanding rectifier modules is essential for ensuring efficient power conversion and system reliability. By familiarizing yourself with the types of rectifiers and key selection factors, you can confidently choose the best rectifier for your project. This guide simplifies the process for beginners, helping you make informed decisions.

Always consult datasheets and seek expert advice when selecting a rectifier. These resources provide valuable insights into performance and compatibility. If you're looking for a buying guide or tailored solutions, ESTEL offers a wide range of high-quality rectifier modules designed to meet diverse needs.

FAQ

1. What is the primary purpose of a rectifier module?

A rectifier module converts alternating current (AC) into direct current (DC). This ensures stable and reliable power for devices and systems that require DC electricity, such as telecommunications equipment, industrial machinery, and renewable energy systems.

2. How do I determine the right rectifier for my application?

You should evaluate factors like input voltage, current rating, efficiency, cooling method, and environmental conditions. Matching these parameters to your system’s requirements ensures optimal performance and longevity.

Tip: Always consult the rectifier’s datasheet for detailed specifications.

3. Can I use a single-phase rectifier for industrial applications?

Single-phase rectifiers work best for low-power applications. For industrial settings with higher power demands, three-phase rectifiers provide better efficiency and smoother DC output.

4. How often should I maintain my rectifier module?

Inspect and clean your rectifier every three to six months. Regular maintenance prevents overheating, identifies potential issues early, and extends the module’s lifespan.

5. What is the difference between controlled and uncontrolled rectifiers?

Controlled rectifiers allow you to adjust the output voltage using components like SCRs. Uncontrolled rectifiers, on the other hand, provide a fixed DC output using diodes. Controlled rectifiers suit applications requiring variable power, while uncontrolled ones are ideal for basic power conversion.

Note: Choose based on your need for output regulation.

See Also

Essential Insights for Newcomers to Telecom Power Systems

Ensuring Correct Voltage Levels in ESTEL Communication Cabinets

Selecting Optimal Cooling Solutions for ESTEL Telecom Cabinets

Grasping Global Standards for Communication Power Supply Systems

Strategies for Maintaining Reliable Power in Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA