How to Keep Your ESTEL Diesel Generator Running Smoothly in 2025

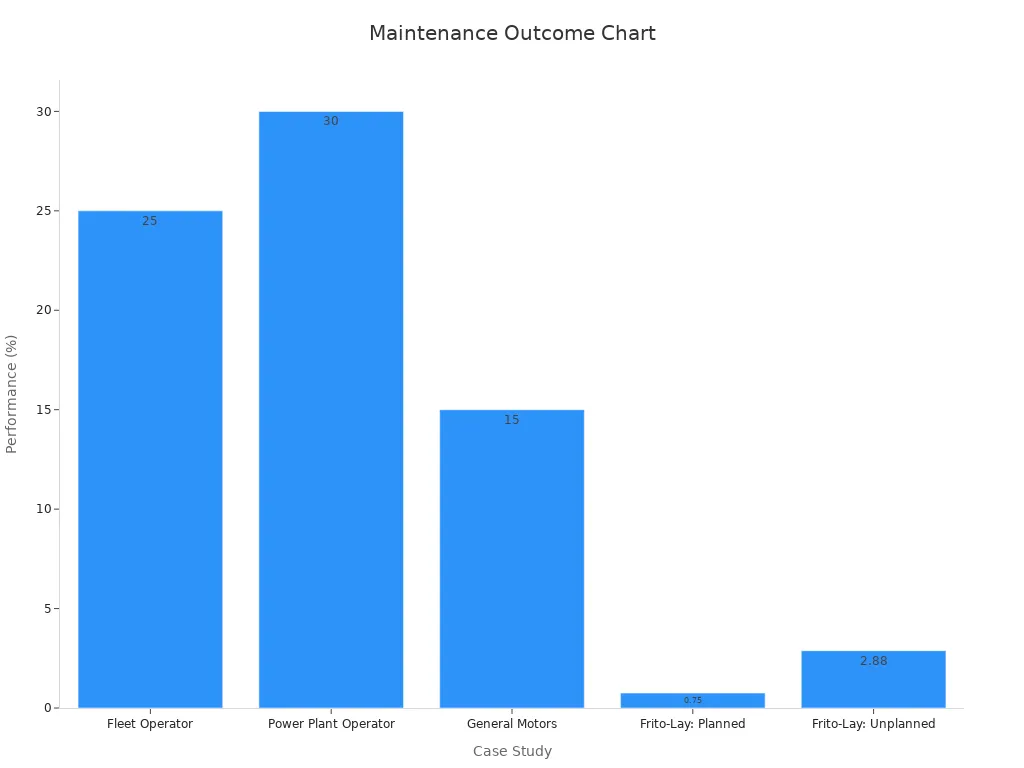

A structured maintenance routine gives your ESTEL diesel generator the best chance for optimal performance and reliability in 2025. You can handle most diesel generator maintenance tasks with basic tools and a little attention. Using the right fuel and following manufacturer guidelines helps you prevent downtime and costly repairs. Studies show that monitoring generator conditions, like temperature and vibration, allows you to act early and reduce downtime by up to 30%. When you stick to a maintenance schedule, you boost the lifespan of your diesel generators and avoid unexpected failures. With the right approach, you can keep your generator running strong and prevent downtime for years to come.

Key Takeaways

Regular inspections catch small problems early, preventing costly repairs and downtime.

Change oil and filters on schedule to keep the engine clean and running efficiently.

Use high-quality diesel fuel and remove water from the fuel system to protect engine parts.

Keep the cooling system, battery, air filter, and electrical connections well maintained for reliable performance.

Follow a consistent maintenance schedule and record all tasks to extend your generator’s life and avoid unexpected failures.

Visual Inspections

Regular inspections form the backbone of effective diesel generator maintenance. When you make visual checks part of your routine, you spot small issues before they become big problems. These inspections help you keep your generator reliable and safe.

Leaks and Corrosion

Start each regular inspection by looking for leaks around the engine, fuel lines, and coolant hoses. Even a small drip can signal a bigger problem. Check for oil, fuel, or coolant pooling under the generator. Examine the exterior for rust, dents, or corrosion, especially on the enclosure and battery terminals. Corrosion on wiring or terminals can lead to electrical failures and power outages. Early detection of leaks and corrosion prevents environmental hazards and costly repairs. According to industry data, regular inspections reduce unexpected downtime by up to 20%.

Tip: Clean away dirt and debris during each inspection. This helps you see leaks and corrosion more easily and keeps the generator running cooler.

Loose Connections

Loose connections can cause your generator to fail when you need it most. Inspect all electrical wiring for frayed or damaged wires. Make sure all terminals are tight and free of corrosion. Check belts for cracks or signs of wear, and tighten any loose bolts or clamps. Routine checks of hoses and clamps prevent overheating, which is a leading cause of engine failure. By tightening connections during thorough inspections, you avoid sudden breakdowns.

Fuel and Exhaust Checks

Inspect fuel lines and filters for cracks, leaks, or signs of wear. Make sure the fuel supply lines are secure and free of damage. Examine the exhaust system for holes, rust, or loose fittings. A damaged exhaust can lead to dangerous fumes and reduced performance. Regular inspections of these areas help prevent fuel wastage, environmental hazards, and ensure safe operation.

Note: Always perform regular inspections with the generator turned off and cooled down for safety.

Oil Change

Oil Change Intervals

You need to pay close attention to oil change intervals to keep your ESTEL diesel generator running smoothly. Most manufacturers recommend changing the oil every 100 to 500 hours of operation. The exact interval depends on how often you use your generator, the environment, and the type of oil you choose. Synthetic oils usually last longer and perform better in extreme temperatures. Always check your owner’s manual for the best advice on oil type and schedule.

Industry experts stress that regular oil changes protect your generator by keeping the engine lubricated, cool, and clean. Oil that stays in the engine too long collects sludge, soot, and other contaminants. These particles can cause engine wear and reduce fuel efficiency. You should also monitor oil quality and level between changes. Many owners use oil analysis or visual checks to decide if an early oil change is needed.

Tip: Keep a log of your generator’s run time and oil changes. This habit helps you stick to a consistent maintenance routine and spot any unusual oil consumption.

Filter Replacement

You should always change oil and filters at the same time. The oil filter traps dirt and debris that could harm your engine. A clogged filter can let contaminants circulate, causing damage. Follow these steps for a smooth oil and filter change:

Turn off the generator and let it cool.

Place a pan under the oil drain plug.

Remove the plug and drain the old oil.

Replace the oil filter with a manufacturer-approved part.

Reinstall the drain plug and fill with fresh oil.

Check the oil level and run the generator briefly to circulate the new oil.

Regular oil changes and filter replacements form the core of good generator maintenance. These steps help you avoid costly repairs and extend the life of your equipment.

Fuel System Care

A reliable generator depends on a well-maintained fuel system. You need to pay close attention to fuel quality, water removal, and regular fuel system checks. These steps help you keep your fuel system clean and your generator running at peak performance.

Fuel Quality

Always use the recommended diesel fuel for your ESTEL generator. Avoid gasoline or low-grade diesel, as these can damage the engine and reduce fuel efficiency. High-quality diesel fuel supports cleaner combustion. This reduces deposits in the fuel injectors and combustion chamber, which helps your generator run smoothly. Clean fuel also means fewer carbon deposits and less wear on engine parts. Proper storage keeps your fuel free from water, dirt, and microorganisms. Fuel additives can further improve fuel stability and prevent microbial growth. When you focus on fuel quality, you protect your investment and ensure your generator delivers reliable power.

Using high-quality diesel fuel:

Promotes cleaner combustion and reduces harmful deposits.

Maintains engine performance and extends generator life.

Prevents filter plugging and erratic engine operation.

Water Removal

Water in the fuel system can cause serious problems. You should check the water separator regularly and drain any collected water. Water can lead to corrosion, poor combustion, and even engine failure. Make this step part of your routine maintenance. If you store your generator for long periods, inspect the fuel tank for condensation. Keeping the fuel system clean and dry helps you avoid costly repairs.

Tip: Drain the water separator after heavy rain or when you notice high humidity. This simple habit keeps your generator safe from water damage.

Fuel Filter Check

Fuel filters trap dirt and debris before they reach the engine. You need to inspect and replace them as part of your fuel system checks. A clogged filter can restrict fuel flow and reduce generator performance. Follow the manufacturer’s schedule for filter changes. If you notice your generator running rough or losing power, check the fuel filter first. Clean filters keep your fuel system clean and support consistent fuel quality.

Cooling System

A healthy cooling system keeps your ESTEL diesel generator running at the right temperature. If you ignore this part of maintenance, you risk engine damage and costly repairs. You need to maintain the cooling system to prevent overheating and keep your generator reliable.

Coolant Check

Check the coolant level before each use. Low coolant can cause your generator to overheat quickly. Use only the coolant type recommended by the manufacturer. Look for signs of rust or discoloration in the coolant. These signs may mean you need to flush the system. Replace coolant at the intervals listed in your manual. This step helps you prevent overheating and keeps the engine safe.

Tip: Always let the engine cool before opening the radiator cap. Hot coolant can spray out and cause burns.

Radiator Cleaning

Dirt and debris can block airflow through the radiator. Blocked airflow reduces cooling and increases the risk of overheating. Inspect the radiator fins for dust, leaves, or bugs. Use a soft brush or compressed air to clean the fins gently. Never use high-pressure water, as it can bend the fins. Clean the radiator as part of your regular cooling system maintenance routine.

Hose Inspection

Hoses carry coolant between the engine and radiator. Check hoses for cracks, leaks, or bulges. Squeeze each hose gently to feel for soft spots. Replace any hose that feels weak or shows damage. Tighten hose clamps if you find any loose connections. Regular inspection helps you spot problems early and keeps your generator running smoothly.

A well-maintained cooling system helps you prevent overheating and extends the life of your generator. Make these checks part of your regular maintenance schedule for the best results.

Battery Maintenance

A healthy battery ensures your ESTEL diesel generator starts when you need it most. You should include battery care as a key part of your maintenance routine. If you ignore the battery, you risk unexpected failures and costly downtime.

Battery Testing

You need to test the battery regularly to guarantee reliable starts. Use a digital multimeter to check the voltage. A fully charged battery should read about 12.6 volts or higher. If the reading drops below 12.4 volts, you should recharge or replace the battery. Many owners test the battery every month, especially during cold weather. Cold temperatures can drain battery power quickly. Regular testing helps you spot weak batteries before they fail.

Tip: Test the battery after the generator has been off for several hours. This gives you the most accurate reading.

Terminal Cleaning

Dirty or corroded terminals can block the flow of electricity. You should inspect the battery terminals for white or green buildup. Use a wire brush and a mixture of baking soda and water to clean the terminals. Make sure the connections are tight after cleaning. Clean terminals help you keep the battery in good condition and support the overall performance of your generator.

Steps for cleaning terminals:

Disconnect the battery cables.

Scrub the terminals with the cleaning solution.

Rinse with clean water and dry.

Reconnect the cables securely.

Replacement Timing

Batteries do not last forever. Most generator batteries need replacement every two to three years. If you notice slow cranking or dim lights, consider replacing the battery soon. Always choose a battery that matches the manufacturer’s specifications. Timely replacement ensures your generator delivers reliable starts and avoids unexpected breakdowns. Add battery checks to your maintenance schedule for peace of mind.

Air Filter and Cleanliness

A clean environment and regular air filter maintenance play a major role in keeping your generator reliable. Dust, dirt, and debris can clog the air filter and reduce airflow. When you keep the air filter and the area around your generator clean, you help ensure optimal performance and prevent unnecessary wear.

Air Filter Change

You should inspect the air filter at regular intervals. Most manufacturers recommend changing the air filter every 500 to 1000 hours of operation. If you use your generator in a dusty or dirty environment, check the filter more often. A clogged air filter restricts airflow, which can cause the engine to work harder and reduce efficiency. When you replace the air filter on schedule, you help your generator run smoothly and avoid performance problems.

Regularly replacing air filters prevents clogging, maintains optimal airflow, and helps your generator operate efficiently without strain. This simple step can extend your generator's lifespan by up to 50% and reduce long-term costs.

You can use a maintenance checklist to track air filter changes. Many owners also keep a log of filter replacements and use load bank testing to confirm that the generator can handle its rated output. These records show that scheduled air filter changes support reliable operation and efficiency.

Maintenance Task | Frequency | Potential Efficiency Gain |

|---|---|---|

Air Filter Replacement | Every 500-1000 hrs | 1-2% |

Keeping Generator Clean

You should keep the area around your generator free from dust, leaves, and debris. Wipe down the exterior surfaces and check for buildup on vents and cooling fins. A clean generator runs cooler and is less likely to overheat. Cleanliness also makes it easier to spot leaks or other issues during inspections.

Tip: Store your generator in a dry, sheltered place to protect it from dirt and moisture.

By making cleanliness and air filter care part of your routine, you help your generator deliver optimal performance and reliable power when you need it most.

Electrical System

A reliable electrical system keeps your generator ready for any situation. You need to check connections and look for faults to prevent unexpected failures. Regular attention to these details helps you avoid costly repairs and downtime.

Connection Tightening

Loose electrical connections can cause your generator to malfunction or stop working. You should inspect all wiring, terminals, and control panels every month. Use a screwdriver to tighten any loose screws or bolts. Look for signs of wear, such as frayed wires or discolored insulation. Replace damaged parts right away.

Monthly inspections help you catch problems early.

Tight connections reduce the risk of voltage drops and blown fuses.

Clean terminals support better electrical flow.

Routine checks and tightening prevent many common issues. Research shows that poor maintenance and substandard installation often lead to wiring faults and blown fuses. Certified installation and regular operator training also lower the risk of electrical failures.

Tip: Always turn off the generator before working on electrical components. This keeps you safe during maintenance.

Fault Checks

You should look for signs of electrical faults during every inspection. Watch for flickering lights, unusual noises, or burning smells. These can signal problems with the wiring or control system. Test the generator’s safety features and alarms to make sure they work.

A study of electrical failures in emergency generators found that most issues came from human errors and poor maintenance. Improved maintenance practices and regular checks can reduce the number of electrical failures. By making fault checks part of your routine, you help keep your generator reliable during every operation.

Check for:

Burn marks or melted insulation

Loose or exposed wires

Faulty switches or relays

If you find any faults, fix them before using the generator again. This habit protects your equipment and ensures safe operation.

Load Testing

Why Load Test

You need to load test the generator to confirm it can handle real-world power demands. This process simulates the electrical loads your equipment will face during actual operation. When you perform load testing, you check if the generator delivers stable voltage and frequency. You also monitor engine oil pressure, coolant temperature, and the ability to reach full operating temperature.

Load testing helps you:

Detect coolant and radiator problems early

Identify wet stacking, which is unburnt fuel buildup in diesel engines

Prevent downtime by catching issues before they cause failures

Validate that your generator meets manufacturer design specifications

Extend engine life and improve reliability

You also ensure compliance with standards like NFPA 110 and EPA emissions requirements. Hospitals, data centers, and other critical facilities rely on regular load testing to confirm operational readiness. By checking these performance metrics, you gain confidence that your generator will work when you need it most.

Regular load testing prevents overheating, shutdowns, and inefficient fuel combustion. It also provides valuable data for maintenance decisions.

How to Load Test

To test the generator, you use a load bank to apply a controlled electrical load. Start by connecting the load bank and gradually increasing the load to about 80% of the generator’s rated capacity. Maintain this load for one to four hours. During the test, monitor key parameters:

Voltage and frequency stability

Engine oil pressure

Coolant temperature

Fuel pressure

AC voltage and current

Responsiveness to load changes

Record all readings and compare them to manufacturer specifications. If you notice voltage drops, overheating, or irregular power output, schedule maintenance right away. Load testing should take place quarterly, semi-annually, or annually, depending on your application and local regulations.

Parameter | What to Watch For |

|---|---|

Voltage/Frequency | Stability |

Oil Pressure | Within safe range |

Coolant Temp | No overheating |

Load Response | Quick and steady |

Tip: Always follow safety procedures and use proper equipment during load testing. Document your results to track performance over time.

Moisture and Storage

Rust Prevention

Moisture is one of the biggest threats to your ESTEL diesel generator. Rust can form quickly on metal surfaces when water or humidity gets inside the generator housing. You need to take steps to keep your generator dry and rust-free.

Inspect the generator regularly for signs of rust or moisture buildup.

Wipe down any damp surfaces with a clean, dry cloth.

Apply a light coat of anti-corrosion spray to exposed metal parts.

Keep the generator in a well-ventilated area to reduce humidity.

Use silica gel packs or moisture-absorbing products inside the enclosure.

Tip: Check the weather seals on your generator’s doors and panels. Replace any damaged seals to keep water out.

If you spot rust, remove it right away with a wire brush. Treat the area with rust inhibitor and repaint if needed. Quick action stops rust from spreading and keeps your generator in top shape.

Storage Tips

Proper storage protects your generator from moisture, dust, and temperature extremes. You should always prepare your generator before putting it away for an extended period.

Clean the generator thoroughly. Remove dirt, oil, and debris from all surfaces.

Drain water from the fuel system and check for any leaks.

Fill the fuel tank to prevent condensation, but add a fuel stabilizer to keep the diesel fresh.

Disconnect the battery and store it in a cool, dry place.

Cover the generator with a breathable, waterproof cover.

Storage Step | Why It Matters |

|---|---|

Clean surfaces | Prevents corrosion and buildup |

Drain water | Stops rust and fuel problems |

Fill tank + stabilizer | Reduces condensation risk |

Disconnect battery | Extends battery life |

Use cover | Shields from dust and moisture |

Note: Store your generator in a location above ground level. Avoid areas prone to flooding or high humidity.

By following these steps, you protect your ESTEL diesel generator from moisture damage and ensure it starts up reliably when you need it.

Diesel Generator Maintenance Schedule

Maintenance Checklist

A structured maintenance checklist helps you keep your diesel generator in top condition. You can prevent most breakdowns by following a preventive maintenance schedule that covers all critical systems. Industry data show that regular checks on oil, fuel, battery, and coolant levels reduce the risk of unexpected failures and costly downtime. You should inspect your generator weekly, monthly, and annually to catch issues early.

Here is a sample maintenance schedule you can follow:

Maintenance Interval | Recommended Tasks |

|---|---|

Weekly | Run generator with no load, check warning lights, fuel levels, and look for leaks |

Monthly | Inspect engine coolant, oil levels, and battery charger |

Twice per year | Inspect enclosure, drive belts, battery, coolant heater, hoses, exhaust, controls |

Annually | Change oil, replace filters, deep clean, check coolant, perform load bank test |

You should also check the air filter, exhaust system, and electrical connections as part of your routine. Replace fuel filters every 300 hours and air filters every 400 hours. Test the battery every 100 hours to ensure reliable starts. Preventive maintenance like this extends the life of diesel generators and keeps them running efficiently.

Setting Reminders

Consistency is key for effective diesel generator maintenance. You can use a maintenance log or digital reminders to track each task. Many owners set calendar alerts on their phones or use maintenance apps to schedule checks and record completed work. This habit helps you stay on track with your preventive maintenance schedule and ensures you never miss a critical inspection.

Tip: Keep a written log near your generator. Record the date, hours run, and each maintenance task you complete. This record helps you spot patterns and plan future service.

Regular reminders and logs make it easier to manage generator maintenance, especially if you operate multiple diesel generators. Following manufacturer guidelines and industry standards ensures your generator stays reliable, reduces emissions, and meets warranty requirements.

When to Call a Professional

Signs for Service

You can handle many maintenance tasks on your ESTEL diesel generator. Sometimes, you need professional servicing to keep your generator safe and reliable. Watch for these signs:

The generator fails to start after several attempts.

You hear loud knocking, grinding, or other unusual noises.

Thick smoke or strange smells come from the exhaust.

Warning lights or error codes appear on the control panel.

You see fuel, oil, or coolant leaks that do not stop.

The generator shuts down unexpectedly during operation.

You notice frequent tripped breakers or electrical faults.

If you see any of these problems, stop using the generator. Call for professional servicing right away. Quick action prevents bigger issues and protects your investment.

What to Expect

When you schedule professional servicing, you get expert help. Trained technicians use special tools and follow strict procedures. They check every part of your generator, including the engine, fuel system, electrical connections, and safety controls. You receive a detailed report with recommendations for repairs or parts replacement.

A typical professional servicing visit includes:

Service Step | What the Technician Does |

|---|---|

Diagnostic Testing | Finds hidden faults |

System Calibration | Adjusts settings for best output |

Deep Cleaning | Removes buildup and debris |

Parts Replacement | Installs new filters or components |

Safety Inspection | Confirms safe operation |

You should expect clear communication from the technician. Ask questions if you do not understand a recommendation. Professional servicing helps you avoid costly breakdowns and keeps your ESTEL diesel generator ready for emergencies.

Generator Maintenance Tips

Best Practices

You can keep diesel generators reliable by following proven maintenance tips. Planned inspections and proactive care help you avoid unexpected failures. Use these best practices to get the most from your equipment:

Maintenance Aspect | Best Practice Description | Interval/Action |

|---|---|---|

Fuel System | Use high-quality diesel fuel; treat with stabilizers if idle | Replace fuel filter as recommended; inspect tank |

Battery Maintenance | Clean terminals; check charge; maintain electrolyte levels | Test and recharge regularly |

Load Testing | Conduct load bank testing to verify performance | Test every 100-250 hours |

Cleanliness | Remove dust, dirt, debris; keep exhaust system clear | Clean regularly |

Consistent data tracking improves preventive maintenance. Many owners use computerized systems to log service dates and performance. This reduces manual errors and helps you spot trends before they become problems.

You should also use advanced diagnostic tools when possible. These tools, such as Generator Health Monitoring systems, help you detect issues early. When you follow these essential maintenance tips, you increase the mean time between failures and reduce downtime.

Common Mistakes

Many owners make mistakes that shorten the life of diesel generators. Skipping inspections or using low-quality fuel can lead to costly repairs. Here are some common errors to avoid:

Ignoring scheduled maintenance tips or delaying oil changes

Using the wrong type of fuel or letting fuel sit too long without stabilizer

Failing to clean battery terminals or check battery charge

Overlooking load testing or only reacting after a breakdown

Field studies show that these mistakes increase downtime and maintenance costs. Relying on reactive repairs instead of preventive maintenance often leads to more frequent failures. You should always keep detailed records of service and repairs. This habit helps you identify patterns and prevent repeat issues.

Remember: Smart, planned maintenance strategies always outperform quick DIY fixes. You protect your investment and ensure your generator is ready when you need it.

Regular maintenance gives you more reliable power and fewer costly surprises. When you follow a schedule, you see real results:

Performance Outcome | Measurable Result |

|---|---|

Average Up-time Percentage | 99.1% |

Reduction in Breakdowns | 25% decrease |

Equipment Lifetime Extension | 20-40% longer |

Proactive care helps you avoid emergency repairs and keeps your ESTEL diesel generator running strong. Start your maintenance plan today for dependable performance in 2025 and beyond.

FAQ

How often should you run your ESTEL diesel generator if not used regularly?

You should run your generator for at least 30 minutes every month. This keeps the engine lubricated and ensures the battery stays charged. Regular exercise helps prevent fuel and oil from degrading.

What type of diesel fuel works best for ESTEL generators?

Use only high-quality, low-sulfur diesel fuel. This type reduces engine deposits and extends the life of your generator. Avoid using old or contaminated fuel to prevent clogs and performance issues.

Can you perform all maintenance tasks yourself?

You can handle basic tasks like oil changes, filter replacements, and visual inspections. For complex repairs or electrical issues, call a certified technician. Always follow the manufacturer’s guidelines for safety.

What should you do if your generator emits black smoke?

Black smoke often means incomplete combustion or a clogged air filter. Check and replace the air filter first. If the problem continues, inspect the fuel system or contact a professional for help.

How do you store your generator during long periods of inactivity?

Clean the generator thoroughly.

Fill the fuel tank and add stabilizer.

Disconnect the battery.

Store in a dry, covered area.

Tip: Use a maintenance log to track storage steps and dates.

See Also

Essential Guidelines For Outdoor Care Of ESTEL Telecom Cabinets

Choosing The Right Energy Storage Batteries For ESTEL Cabinets

Selecting The Optimal Cooling Solution For ESTEL Telecom Cabinets

ESTEL Telecom Cabinets Featuring Smart Microgrid Energy Storage

Smart Maintenance Strategies To Safeguard Outdoor Communication Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA