Digital Twin-Driven O&M for Telecom Cabinet Communication Power Systems: Cost-Saving via Virtual Debugging & Fault Simulation

Telecom operators often struggle with high costs and technical complexity in maintaining reliable telecom power systems. Digital twin-driven O&M addresses these challenges by enabling virtual debugging and fault simulation, which cut maintenance expenses and improve system reliability. Operators in rural Southeast Asia and Europe have reduced costs and increased uptime by adopting advanced monitoring and hybrid energy solutions.

Challenge | Impact |

|---|---|

Limits upgrades | |

Operational costs | Financial strain |

Maintenance costs | Reliance on old systems |

This shift empowers operators to move from reactive repairs to proactive, data-driven maintenance.

Key Takeaways

Digital twin technology creates a virtual copy of telecom power systems, allowing operators to monitor and fix issues remotely without risking downtime.

Virtual debugging helps engineers test and solve problems in a safe digital environment, reducing maintenance costs and site visits.

Fault simulation predicts failures before they happen, enabling proactive maintenance that lowers downtime and extends equipment life.

Integrating IoT sensors with digital twins provides real-time data, improving fault detection and system optimization.

Adopting digital twin-driven O&M leads to significant cost savings, faster repairs, and higher system reliability for telecom operators.

Digital Twin in Telecom Power Systems

Technology Overview

Digital twin technology creates a virtual replica of physical assets in telecom power systems. This digital model mirrors the real-world system, enabling operators to visualize, analyze, and optimize performance. Leading solutions, such as VIAVI’s Intelligent Digital Twin, emulate thousands of devices and simulate network behaviors across multiple standards, including 4G, 5G, and emerging 6G. These platforms use artificial intelligence and machine learning to enhance modeling accuracy and key performance indicators.

Key components of digital twin technology include:

Data management and analytics for sensor data, historical records, and maintenance logs.

Modeling and simulation to predict and optimize system behavior.

Machine learning for improved predictions and autonomous decisions.

Realistic emulation of network topologies, device characteristics, and traffic profiles.

Operators benefit from a safe environment for testing, optimization, and innovation without risking downtime or service disruption.

Real-Time Monitoring

Digital twins enable real-time monitoring of telecom power systems by integrating data from multiple sensors and IoT devices. This continuous data flow creates a dynamic virtual representation that reflects the current operational state. Machine learning algorithms analyze historical and live data to forecast equipment failures and optimize operations. Real-time alerts and predictive maintenance features allow operators to intervene proactively, reducing downtime and operational costs.

Case studies in energy management show that continuous sensor data—such as temperature, pressure, and equipment health—ensures accurate and reliable system monitoring. Predictive maintenance algorithms detect early signs of wear or malfunction, extending asset lifespan and improving reliability.

IoT Integration

IoT integration enhances digital twin models by providing a constant stream of live data from embedded sensors. These sensors capture metrics like temperature, vibration, and usage, ensuring the digital twin remains an accurate reflection of the physical system. Continuous data ingestion allows for scenario simulation, failure prediction, and process optimization.

Real-time synchronization keeps the digital twin up to date, while two-way connectivity enables remote diagnostics and operational adjustments. This integration supports remote service operations, reducing field service costs and minimizing disruptions. In telecom power systems, IoT acts as the nervous system, delivering the agility and visibility needed for efficient, reliable operations.

O&M Challenges

Maintenance Issues

Telecom cabinet communication power systems face a range of maintenance challenges that impact reliability and operational costs. Common issues include:

Power quality problems, such as voltage fluctuations and harmonic distortions, which degrade equipment performance and increase maintenance expenses.

Physical wear from frequent plugging and unplugging, cable strain due to poor management, and mechanical vibrations that loosen connections.

Environmental factors like temperature extremes, humidity, dust accumulation, and power surges, which can cause overheating, corrosion, and component damage.

Load imbalances that lead to overheating and reduce equipment lifespan.

Communication failures, especially with RS485 systems, including no communication, data upload failures, and intermittent errors. These often result from wiring errors, missing termination resistors, interference, or improper grounding.

Operators often rely on regular cleaning, environmental monitoring, protective enclosures, surge protection, and routine inspections to prevent failures. Maintaining reliable communication and power quality remains critical to avoid downtime, data loss, and equipment malfunction.

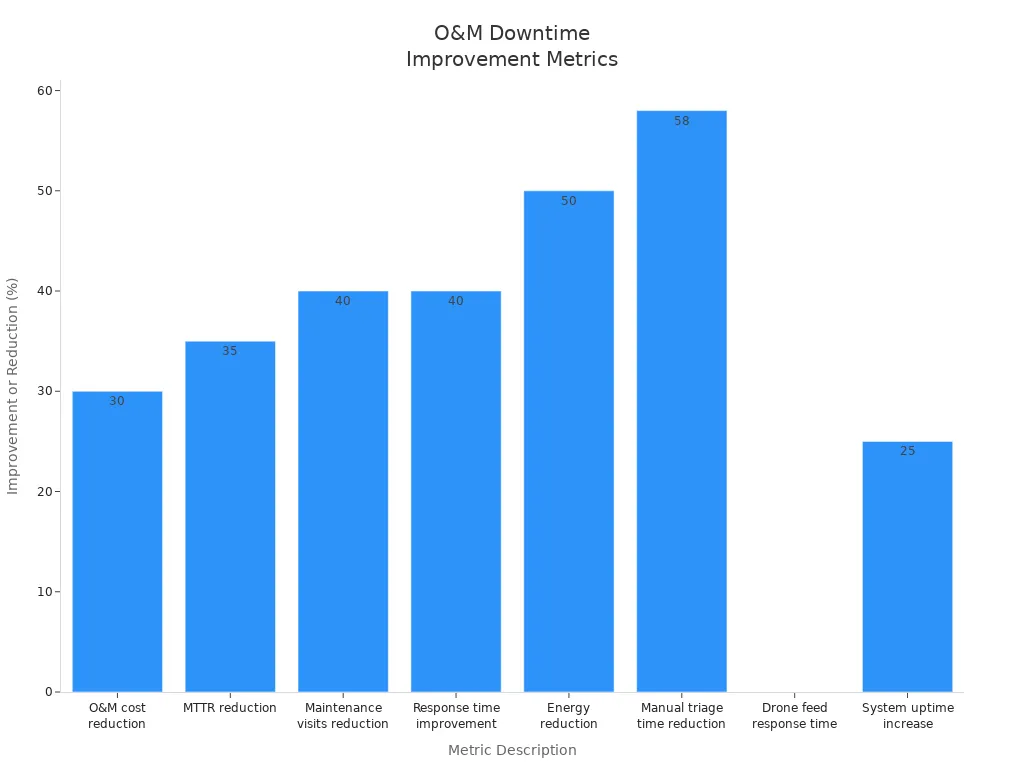

Metric Description | Improvement/Reduction |

|---|---|

O&M cost reduction via high-efficiency modules | |

Mean Time to Repair (MTTR) reduction | From 4.8 hours to 3.1 hours (~35%) |

Maintenance visits reduction through predictive maintenance | Up to 40% |

Maintenance response time improvement via remote monitoring | 40% improvement |

Energy consumption reduction | Up to 50% |

Manual triage time reduction via automated incident categorization | 58% reduction |

Response time reduction from real-time drone feeds | 30 minutes faster |

System uptime increase | 25% increase |

Downtime in telecom cabinet O&M often results from delayed fault detection, slow manual inspections, and communication failures. Smart rectifier modules, remote monitoring, and predictive maintenance help operators detect faults early, reduce site visits, and improve network reliability.

Traditional Methods

Traditional O&M methods in telecom power systems rely heavily on manual inspections, scheduled maintenance, and reactive repairs. These approaches present several limitations:

Day-to-day operations are complex, stressful, and monotonous for network engineers.

Frequent changes in roles and management reduce employee morale and job satisfaction.

Poor working conditions, long hours, and high workloads contribute to burnout.

Outsourcing to managed service partners introduces ambiguity, job insecurity, and adjustment challenges.

Fragmented roles, remote work locations, and frequent travel add to employee stress.

The industry’s cost pressures force operators to cut budgets, impacting employee welfare and training opportunities.

Traditional O&M struggles to adapt to rapid technological changes. It lacks real-time data integration and dynamic simulation, making it difficult to predict failures or optimize maintenance schedules. Digital twin-driven approaches, by contrast, use IoT sensors, AI, and machine learning to enable predictive maintenance and early fault detection. This shift leads to improved efficiency, reduced downtime, and long-term cost savings for telecom power systems.

Virtual Debugging

Process

Virtual debugging uses digital twin technology to create a virtual environment that mirrors the physical telecom power system. Engineers build a digital replica of the cabinet, including all power modules, sensors, and communication links. This model receives real-time data from IoT sensors, which allows the digital twin to reflect the current state of the system.

Operators use this virtual environment to run diagnostic tests, simulate faults, and analyze system behavior without touching the physical equipment. They can identify issues such as voltage drops, communication failures, or overheating by observing the digital twin’s response to simulated scenarios. The process includes:

Connecting live sensor data to the digital twin for accurate modeling.

Running automated scripts to test different fault conditions.

Using analytics dashboards to visualize system health and performance.

Remotely adjusting parameters and observing the impact in real time.

This approach allows teams to troubleshoot problems, validate fixes, and optimize settings before applying changes to the actual telecom cabinet. As a result, they avoid unnecessary site visits and reduce the risk of accidental downtime.

Benefits

Virtual debugging delivers several key benefits for telecom power systems. It reduces operational costs, minimizes downtime, and improves fault detection accuracy. Operators can identify and resolve issues remotely, which leads to faster response times and fewer on-site interventions.

Virtual debugging empowers engineers to test solutions in a risk-free environment, ensuring only proven fixes reach the live system.

Some of the main advantages include:

Cost Savings: By diagnosing and resolving issues remotely, operators cut travel expenses and reduce the need for emergency repairs.

Downtime Reduction: Early fault detection and remote troubleshooting prevent prolonged outages and keep networks running smoothly.

Improved Reliability: Continuous monitoring and simulation help teams catch problems before they escalate, increasing overall system reliability.

Enhanced Safety: Engineers avoid exposure to hazardous environments by performing diagnostics virtually.

Real-world deployments highlight these benefits. For example:

At a remote telecom site in Alaska, engineers deployed a SiteBoss device for power source transfer control.

Integration with network management software and LUA scripting enabled automated control and remote troubleshooting.

The site, located on a mountain top, was difficult to access. Virtual debugging and remote management reduced site visits from four per year to one.

The team improved reliability and lowered operational costs by enabling remote reboot and monitoring of over 85 alarm points.

Redundant wireless routers and dual SiteBoss devices ensured high reliability and robust remote control.

These results show how virtual debugging transforms telecom power systems maintenance. Operators gain the ability to manage complex sites efficiently, even in challenging environments.

Fault Simulation

Predictive Maintenance

Fault simulation plays a crucial role in predictive maintenance for telecom power systems. By leveraging digital twin technology, operators can create high-fidelity virtual models that mirror the real-world behavior of cabinets and their components. This approach allows teams to anticipate failures before they occur, reducing the risk of unexpected outages.

The process for conducting fault simulation in telecom cabinet communication power systems involves several key steps:

Operators initiate fault detection through alarms and visual indicators, both in the physical cabinet and its digital twin.

The system identifies the fault location by pinpointing the specific cabinet and board involved.

Remote testing is performed using tools such as an optical time-domain reflectometer (OTDR) via the digital twin interface.

Engineers conduct virtual operations, including disassembling and replacing boards, within the digital twin environment.

The digital twin synchronizes real-time field data and remote control, enabling a human-in-the-loop hybrid training cycle that covers fault detection, setting, analysis, and repair.

Emergency drills are integrated into the platform, allowing users to select roles—such as chief dispatcher or operation staff—to simulate coordination and fault handling.

Users follow predefined emergency scenarios to coordinate risk investigation and disposal, with the system recording and displaying communication history.

The platform supports multiuser online virtual training, enabling over 100 users to participate simultaneously.

Fault simulation not only prepares teams for real-world emergencies but also ensures that maintenance staff can practice and refine their skills in a safe, controlled environment.

By simulating faults and maintenance scenarios, operators can identify weak points in their systems and develop targeted strategies for improvement. This proactive approach leads to fewer unplanned outages and extends the lifespan of critical infrastructure.

Downtime Reduction

High-fidelity simulations and advanced AI algorithms enable proactive fault diagnosis and system optimization, which are essential for minimizing downtime in telecom power systems. Fault simulation optimizes system performance by enabling rapid and accurate fault detection. Edge computing processes data near the source, filtering anomalies and performing initial assessments locally. This reduces the computational burden on central systems and improves real-time responsiveness.

The central control layer uses advanced models, such as GNN-Transformer fusion, for global fault diagnosis and localization. These models allow for precise fault handling and system optimization, enhancing reliability and operational stability even under fault conditions. Fault simulation also supports the use of optimization algorithms like Improved War Strategy Optimization (IWSO), which improve voltage control and regulator performance. Simulation results show that IWSO outperforms traditional methods in tracking voltage fluctuations and handling varying load conditions, ensuring stable power delivery to telecom base stations.

In addition, fault simulation enables accurate prediction of network performance after faults occur. By modeling adaptive network behavior, operators can anticipate cascading effects and optimize fault handling strategies. The NAB-DQN method, for example, captures dynamic routing and queuing effects, allowing for precise performance prediction with less than 10% error and significant speed improvements over traditional simulators.

These capabilities collectively reduce downtime by:

Enabling faster fault detection and response.

Supporting robust network design and optimization.

Improving energy efficiency and system resilience.

Allowing maintenance teams to practice emergency scenarios and refine their response strategies.

Telecom power systems that integrate fault simulation into their O&M processes experience fewer disruptions, lower maintenance costs, and higher overall reliability.

O&M Comparison

Cost Analysis

Operators face significant differences in cost when comparing traditional and digital twin-driven O&M for telecom power systems. Traditional methods often rely on manual inspections and scheduled maintenance, which can lead to higher operational expenses and slower fault response. Digital twin-driven approaches introduce advanced monitoring, predictive analytics, and remote diagnostics, resulting in notable cost reductions.

Cost Factor | Impact | Explanation |

|---|---|---|

Up to 30% | Achieved through energy savings, modular upgrades, and remote monitoring | |

Annual Energy Savings per Cabinet | Over $600 saved | Nearly 4,000 kWh less electricity used per cabinet each year |

Maintenance Savings | Significant reduction | Hot-swappable modules and remote monitoring reduce site visits and downtime |

~35% faster repair | Automated alerts and diagnostics speed up fault detection and repair |

Digital twin technology requires higher initial investment. Development costs can exceed €1.5 million per asset, with scaling costs reaching €15 million for 100 assets. Most of these expenses come from complex modeling, sensor integration, and AI retraining. Despite these upfront costs, operators benefit from long-term savings through optimized resource allocation and reduced downtime.

Operators who invest in digital twin-driven O&M often see operational costs decrease over time, even though the initial setup is more expensive than traditional methods.

Reliability Gains

Digital twin-driven O&M delivers measurable improvements in reliability for telecom power systems. Predictive maintenance solutions, such as GE Vernova’s APM SmartSignal, use digital twin analytics to detect and prevent equipment failures. This proactive approach reduces unplanned downtime and increases asset availability.

Aspect | Description |

|---|---|

Maintenance Challenge | Traditional maintenance leads to long downtimes and lower reliability |

Digital Twin-Driven Approach | Dynamic, risk-based prioritization of maintenance tasks |

Reliability Improvement | Faster recovery and reduced downtime |

Validation | Case studies show improved reliability under real-world conditions |

Dynamic updates and risk assessments allow operators to focus on critical components and optimize maintenance schedules. These strategies help teams recover quickly from faults and maintain high system reliability. As digital twin maturity increases, operators can implement more advanced features, such as multi-device coordination and AI-driven optimization, further enhancing system performance.

Digital twin-driven O&M delivers significant cost savings for telecom power systems by reducing downtime, optimizing maintenance, and enabling predictive analytics. Telecom operators can take practical steps to adopt these solutions:

Upgrade hardware and software for digital twin compatibility.

Standardize and integrate data across platforms.

Build internal expertise and leverage cloud-powered analytics.

Use virtual environments for employee training and asset management.

Future opportunities include AI-enhanced digital twins, edge computing, and scalable cloud-native platforms. Operators who embrace these innovations gain improved efficiency, reliability, and a clear competitive edge.

FAQ

What is a digital twin in telecom power systems?

A digital twin is a virtual model that mirrors a physical telecom power system. It uses real-time data from sensors to simulate, monitor, and optimize system performance. Operators use digital twins to predict issues and improve maintenance.

How does virtual debugging reduce maintenance costs?

Virtual debugging allows engineers to diagnose and resolve faults remotely. This process reduces the need for site visits and emergency repairs. Operators save money by minimizing travel expenses and downtime.

Can digital twins help prevent unexpected outages?

Yes. Digital twins use predictive analytics and real-time monitoring to detect early warning signs. Operators can address problems before they cause outages, which increases system reliability and uptime.

What skills do operators need to use digital twin-driven O&M?

Operators need basic IT knowledge, familiarity with IoT devices, and an understanding of telecom power systems. Training in digital twin platforms and data analysis helps teams maximize the benefits of this technology.

Is digital twin technology scalable for large telecom networks?

Digital twin solutions scale to support large networks. Cloud-based platforms and modular designs allow operators to manage thousands of assets efficiently. This scalability ensures consistent performance across multiple sites.

See Also

Exploring Various Cooling Techniques Used In Telecom Cabinets

A Comprehensive Guide To The Functions Of Telecom Cabinets

Solar Energy Storage Solutions Designed For Telecom Cabinets

An Overview Of Telecom Cabinet Design And Associated Costs

Strategies To Maintain Consistent Power Supply In Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA