High-Temp Telecom Cabinets: Necessity & Clock Synchronization Solutions for Controller-Monitored Temperature Rise Rate

High-temperature telecom cabinets pose serious risks to your equipment. You face problems such as fried circuit boards, unexpected downtime, and rising repair costs.

Severe damage to electronic components can occur when temperatures climb.

Equipment malfunctions and shortened hardware lifespan become common.

Cooling systems like TEC air conditioning and heat exchangers help you maintain safe conditions.

You need real-time, synchronized data to act quickly. The elecom Cabinet Power Controller lets you monitor temperature and power together, so you can manage cooling and prevent failures. Proactive management keeps your network reliable and efficient.

Key Takeaways

High temperatures in telecom cabinets cause equipment damage, shorten lifespan, and increase downtime; using cooling systems and good ventilation prevents overheating.

Real-time sensors and threshold alerts help detect temperature and humidity changes early, allowing quick action to avoid failures and reduce maintenance costs.

Synchronizing clocks across devices ensures accurate event logging and data correlation, which speeds up troubleshooting and supports better network reliability.

Integrating the elecom Cabinet Power Controller with sensors enables precise temperature and power management, improving energy efficiency and lowering operating costs.

Regular maintenance, proper sensor placement, and security measures keep your monitoring system reliable and protect your telecom cabinets from environmental and cyber risks.

High-Temp Cabinet Challenges

Overheating Risks

You face significant risks when your telecom cabinets operate in high-temperature environments. Outdoor cabinets often endure harsh weather, including direct sunlight, rain, and dust. These conditions, combined with the heat generated by active electronic components, quickly raise internal temperatures. If you rely only on passive cooling, you may find it insufficient during peak heat loads or extreme weather. You need to select cabinets with strong heat dissipation and well-designed ventilation systems. Integrated fan systems, HVAC modules, and advanced climate control solutions help you manage the heat load and prevent overheating.

Tip: Regularly check and clean ventilation paths to keep airflow unobstructed. Dust and debris can block vents, causing temperatures to rise even faster.

Overheating leads to thermal stress, which shortens the lifespan of semiconductors and capacitors. You may notice increased failure rates, especially in outdoor or harsh environments. For example, failure rates can jump from 0.082 to 0.3645 failures per million hours when equipment faces extreme conditions. Operational inefficiencies, higher energy consumption, and increased maintenance costs often follow. You can reduce these risks by using real-time temperature monitoring and predictive analytics to detect anomalies early.

Reliability Concerns

Maintaining reliability in high-temperature telecom cabinets requires proactive management. Excessive heat causes premature component wear, system malfunctions, and reduced network dependability. Temperature fluctuations accelerate wear and tear, further compromising equipment lifespan and functionality. Without proper thermal management, your equipment becomes vulnerable to environmental stresses, which impacts reliability and service quality.

Overheating is the most common reliability issue.

Temperature fluctuations worsen wear and tear.

Lack of cooling increases the risk of system malfunctions.

You can improve reliability by installing insulation, using cooling systems, and performing regular maintenance. Effective cooling reduces failure rates by up to 30%. Maintaining optimal temperature ensures your equipment remains reliable, extends its lifespan, and safeguards network signal stability. Regular inspections and adherence to manufacturer guidelines help you prevent unexpected failures and keep your network running smoothly.

Temperature Rise Monitoring

Real-Time Sensors

You need real-time sensors to keep your telecom cabinets safe from overheating. These sensors give you instant feedback on temperature changes, so you can act before problems start. Place sensors at several points inside your cabinet for the most accurate readings. You can use multisensors that measure temperature, humidity, and even detect water leaks. This helps you monitor all environmental threats at once.

Real-time sensors work with thermostats and cooling systems to adjust temperature automatically.

Smart sensors connect to your network using protocols like Modbus, SNMP, RS485, or Ethernet. You can check readings and receive alerts from anywhere.

IoT-enabled sensors let you make remote adjustments and plan predictive maintenance.

Combining temperature sensors with humidity and airflow sensors gives you a complete picture of your cabinet’s health.

Aspect | Benefit | How It Helps You |

|---|---|---|

Fast Response Time | Sensors detect temperature spikes quickly | You activate cooling systems before damage occurs |

Continuous Monitoring | High-precision sensors provide real-time data | You spot overheating early and prevent outages |

Remote Monitoring & Alerts | Operators receive instant notifications | You reduce downtime and maintenance costs |

Downtime Reduction | Early detection cuts network downtime by up to 25% | Your network stays reliable and efficient |

Tip: Always install sensors near heat sources, air intakes, and exhausts. This gives you the most accurate data and helps you respond faster to temperature changes.

Continuous temperature monitoring helps you catch problems before they grow. You can spot hotspots, take action, and avoid major outages. Real-time alerts let you reduce workloads or schedule inspections, keeping your equipment safe and your network running smoothly.

Threshold Alerts

Threshold alerts are your first line of defense against equipment damage. You set safe temperature limits for your cabinet. When sensors detect a temperature above your threshold, you get an instant alert. This lets you react quickly and prevent overheating.

Use multi-point, high-accuracy sensors with humidity monitoring to catch changes early.

Choose sensors with fast response times and customizable alerts for quick action.

Place sensors near heat sources, air intakes, and exhausts for best results.

Clean and calibrate sensors regularly to keep alerts accurate.

Set up real-time alert systems to notify you of sudden temperature or humidity changes.

For outdoor cabinets, pick sensors that resist moisture, dust, and UV rays.

Sensor Type | Real-Time Alert Capability | Remote Monitoring Feature |

|---|---|---|

Temperature & Humidity | Alerts triggered when readings exceed safe thresholds | Continuous condition tracking with remote notifications |

D-Wire Sensors | Provide real-time data on voltage, temperature, resistance | Aggregate data for detailed remote health checks |

Security Sensors | Immediate alerts for motion, door opening, or disturbances | Instant notifications to security personnel |

Power Independence | Maintain alert function during power outages | Enable continuous remote monitoring despite power failure |

Always choose Telecom Cabinet Sensors that support real-time alerts and remote monitoring. This gives you the best chance to catch problems early and keep your equipment safe.

Continuous monitoring and threshold alerts work together to reduce downtime. You get early warnings, take preventive action, and avoid costly repairs. Automated anomaly detection also helps you cut manual checks and speed up repairs. With these systems in place, you keep your telecom cabinets running efficiently and protect your network from unexpected failures.

Clock Synchronization Benefits

Accurate Event Logging

You need accurate event logging to troubleshoot telecom cabinet issues quickly. Synchronized clocks give you precise timestamps for every event, from temperature spikes to door openings. When you use advanced timing modules, such as Adtran's Enhanced Short-Term Unit (ESTU), you gain short-term frequency stability. This stability ensures that your event logs remain reliable, even during mission-critical operations. The ESTU combines the best features of hydrogen masers and cesium clocks, giving you a highly stable time base for all your monitoring devices.

IEEE-1588 Precision Time Protocol (PTP) helps you synchronize clocks across your network. Devices exchange timestamped messages, calculate delays, and adjust their clocks. This process reduces timing errors and allows you to log each event to a common time base. With accurate timestamps, you can:

Track environmental changes and equipment status in real time.

Pinpoint the exact sequence of events leading to failures.

Respond faster to alerts and minimize downtime.

Tip: Use synchronized event logs to support predictive maintenance. You can spot patterns and address issues before they cause failures.

Data Correlation

You often need to analyze data from multiple sensors and devices. Clock synchronization makes this process simple and effective. When all devices share the same accurate time reference, you can match logs and events across your entire network.

Consistent timestamps let you correlate security events, such as door openings and motion detections.

You can reconstruct incident timelines for forensic analysis.

Matching logs from different systems helps you detect anomalies and related incidents.

Accurate time records help you meet regulatory requirements and support audits.

In telecom networks, precise synchronization is essential for quality of service. You maintain network performance and diagnose errors more effectively. When you synchronize clocks, you enable your devices to provide time services to others, keeping your monitoring system unified and reliable. Accurate data correlation leads to faster troubleshooting and better operational decisions.

Telecom Cabinet Power Controller Integration

Power and Temperature Management

You can achieve precise control over your telecom cabinet environment by integrating the elecom Cabinet Power Controller with real-time sensors. This controller continuously collects temperature and humidity data, allowing you to monitor conditions and respond instantly to any changes. The system uses a 4 to 20mA ambient temperature signal, which ensures accurate readings for both temperature and humidity. You can set your preferred temperature range, typically between 18°C and 50°C, to match your equipment’s needs.

The elecom Cabinet Power Controller supports remote monitoring through its RS485 interface and MODBUS protocol. This lets you check cabinet status and adjust parameters from a central location. You receive instant alerts if the system detects abnormal temperature or humidity levels. The LCD menu, available in English and Chinese, makes it easy for you to set parameters and view alarms.

Here is a summary of the technical specifications that help you manage power and temperature efficiently:

Specification Aspect | Details |

|---|---|

Temperature Control Range | Adjustable between 18°C to 50°C, addressing ventilation and cooling challenges |

Temperature Signal Output | 4 to 20mA ambient temperature signal |

Humidity Control | Heating and dehumidification via temperature and humidity controller; professional dehumidification design |

Condensate Management | Optional automatic evaporation function to efficiently handle condensate discharge |

Communication Interface | RS485 interface supporting MODBUS protocol for remote monitoring |

Alert and Protection Functions | Call-and-call function, alarm dry contact output, various alert and protection features |

User Interface | LCD menu available in English and Chinese for parameter setting and alarm viewing |

Reliability | Designed for continuous operation 365 days/year for over 10 years |

Maintenance | Full frontal maintenance for simplicity and cost reduction |

Protection Level | IP55 protection with strong corrosion resistance |

Tip: Set up regular checks using the remote monitoring feature. This helps you catch small issues before they become big problems.

Cooling System Control

You can use the elecom Cabinet Power Controller to automate and optimize your cooling systems. The controller works with air conditioners, heat exchangers, and dehumidifiers to maintain the ideal temperature inside your cabinet. When the sensors detect rising temperatures, the controller activates the cooling system. If humidity increases, the dehumidification function starts automatically. You can also manage condensate with the optional automatic evaporation feature, which prevents water buildup and reduces maintenance.

For example, if your cabinet temperature rises above your set threshold, the controller will turn on the air conditioner or heat exchanger. Once the temperature drops back to a safe level, the system will switch off to save energy. This smart control reduces unnecessary cooling and extends the life of your equipment.

The elecom Cabinet Power Controller uses advanced power management technologies, such as bridgeless totem-pole PFC topology and high-efficiency semiconductor devices. These features help you minimize power loss and improve thermal performance. You benefit from higher efficiency, less heat generation, and lower electricity costs.

Technical Improvement | Operational Impact | Explanation / Benefit |

|---|---|---|

Bridgeless Totem-Pole PFC Topology | Higher efficiency at high power levels | Reduces power losses, improves power quality, and decreases size of input filters. |

Advanced Semiconductor Devices (GaN, low-RDS(on) MOSFETs) | Reduced conduction and switching losses | Enables higher switching frequencies, smaller components, and better thermal performance. |

Integration of Rectifiers and Converters | Minimized power loss | Enhances overall module efficiency, contributing to energy savings and lower heat generation. |

Efficiency Increase | Directly reduces energy losses, electricity costs, and cooling requirements. |

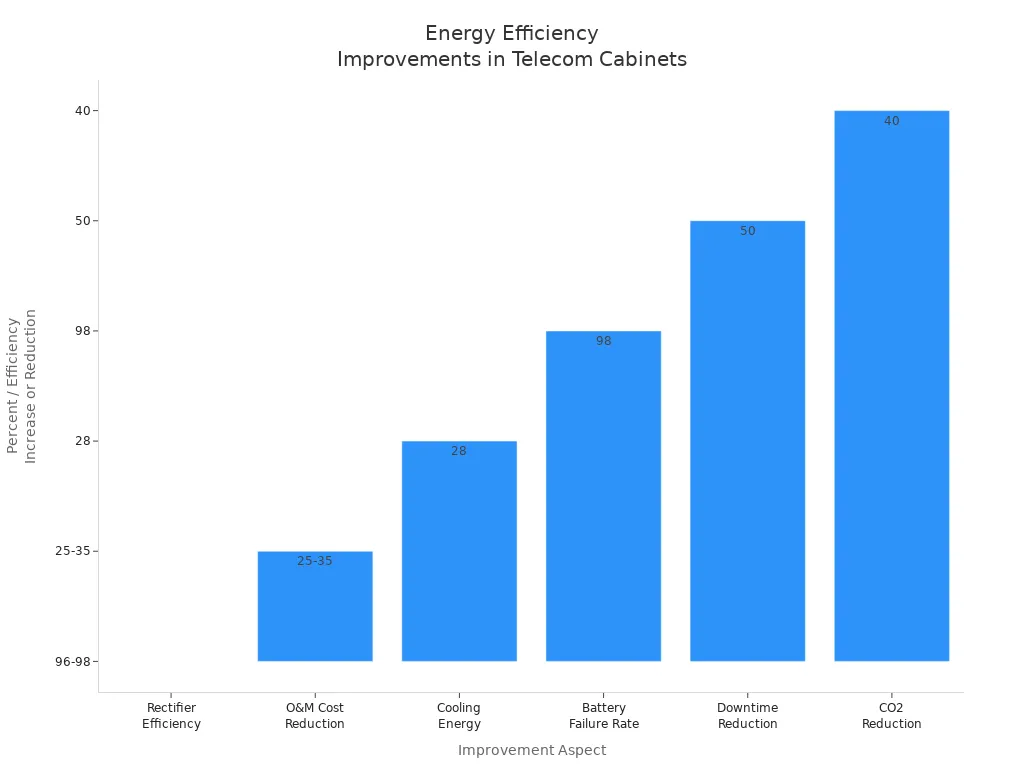

You can see the impact of these improvements in the chart below:

By using the elecom Cabinet Power Controller, you can achieve up to 28% reduction in cooling energy use and increase rectifier efficiency from about 92% to as high as 98%. This translates to annual electricity savings of nearly 4,000 kWh per cabinet, saving you over $600 per year for each cabinet. You also reduce your maintenance costs by up to 35% and cut battery failure rates by 98%. These improvements help you maintain stable operations, reduce downtime, and support your sustainability goals by lowering CO2 emissions.

Note: Smart controllers with predictive maintenance features can reduce unexpected downtime by up to 50%. This keeps your network running smoothly and reliably.

Implementation Steps

Deployment Best Practices

You can achieve a reliable monitoring system by following a structured deployment process. Start with a thorough assessment of your telecom cabinet. Inspect weatherproof sealing, cabinet material, thermal management, power distribution, and security features. Check for compliance with industry standards.

Power down the cabinet before installation. Use a voltage tester to confirm de-energization and apply lockout/tagout procedures for safety.

Select and mount sensors using brackets or adhesive pads. Place temperature and humidity sensors at the front, back, top, middle, and bottom of the cabinet. Avoid direct airflow from fans or vents. Use tamper-proof mounts if needed.

Wire and ground all components according to NEC, NEBS, and ANSI/TIA-607-C standards. Connect everything to a common earth ground. Use shielded cables and organize them with trays and labels.

Manage cables with panels, rings, and conduits. Label each cable to prevent confusion and airflow blockages.

Apply security measures. Install sturdy locks, tamper-proof cabinet designs, and access controls. Consider surveillance cameras for added protection.

Test the system after installation. Verify sensor accuracy, alarm functionality, automated controls, and remote monitoring.

Document sensor locations, wiring, configuration, and test results. Good records help with troubleshooting and compliance.

Tip: Evaluate your existing sites for HVAC operation and monitoring gaps. Obtain a custom application drawing and quote to ensure the solution fits your needs.

Maintenance Tips

Regular maintenance keeps your monitoring system reliable. Monitor power consumption with intelligent PDUs to detect inefficiencies. Balance electrical loads to prevent overheating and reduce cooling demands.

Clean and inspect PDUs to remove dust and debris. Check for physical damage and blocked ventilation.

Protect equipment from temperature extremes, humidity, and power surges. Use climate-controlled enclosures and surge suppressors.

Upgrade to advanced PDUs for better real-time monitoring and power quality management.

Adjust your maintenance routine for each season. In summer, clean outdoor cabinets and control temperature. In fall, clear debris and check weatherproofing. In winter, protect against freezing and maintain heaters. In spring, test backup systems and prevent water damage.

Use strong encryption, role-based access control, and regular audits to protect your system from cyber threats. Enable real-time alerts and maintain redundant power for security systems.

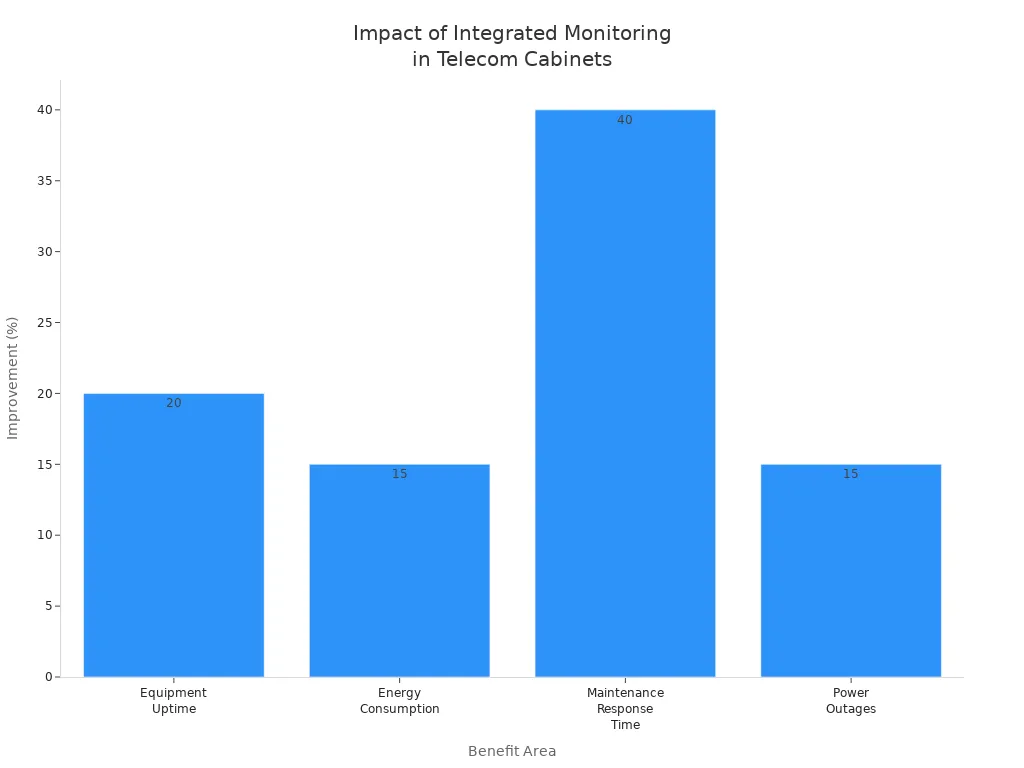

You can boost telecom cabinet reliability and efficiency by integrating temperature monitoring, clock synchronization, and the elecom Cabinet Power Controller. These solutions help you prevent overheating, maintain stable voltage, and enable real-time remote monitoring. Proactive management reduces downtime and energy use, as shown below:

Benefit | Improvement |

|---|---|

Downtime | |

Energy Savings | Up to 30% less |

Maintenance Costs | 30% lower |

Start using these advanced controls to protect your network and cut costs.

FAQ

How do you set up temperature sensors in a telecom cabinet?

Place sensors near heat sources, air intakes, and exhausts. Use brackets or adhesive pads for mounting. Connect sensors to your monitoring system. Test each sensor for accuracy. Clean sensors regularly to maintain reliable readings.

What steps help you maintain optimal cooling in high-temp cabinets?

Check cooling systems weekly. Clean air filters and vents. Inspect fans and heat exchangers for dust buildup. Adjust temperature settings based on seasonal changes. Replace faulty components immediately to prevent overheating.

How can you synchronize clocks for accurate event logging?

Use devices that support IEEE-1588 Precision Time Protocol. Connect all monitoring equipment to a central time server. Verify synchronization through system logs. Update firmware regularly to maintain timing accuracy.

What should you do if you receive a temperature threshold alert?

Respond quickly. Check the cabinet for blocked vents or failed cooling systems. Reduce equipment load if possible. Activate backup cooling. Log the event and schedule a maintenance inspection.

Which maintenance tasks improve telecom cabinet reliability?

Clean sensors and PDUs monthly. Inspect wiring for damage. Test alarm systems. Update software and security settings. Document all maintenance actions for future reference.

See Also

Tips To Maintain Ideal Temperature In Outdoor Telecom Cabinets

Exploring Various Cooling Techniques And Their Uses For Telecom Cabinets

Strategies To Achieve Effective Monitoring Of Outdoor Telecom Cabinets

Selecting The Most Efficient Cooling Solution For ESTEL Telecom Cabinets

Essential Requirements For Outdoor Telecom Cabinets Housing Communication Gear

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA