What is an Electrical Control Panel Box and Its Key Components

An electrical control panel box is a container for parts. These parts help manage and control electrical systems. It safely spreads electricity and is important for factories. In 2022, the market for these boxes was worth $6.0 billion. By 2032, it might grow to $10.3 billion. This shows how they help speed up work and reduce mistakes. They also make systems safer and more automatic.

Key Takeaways

An electrical control panel box controls electrical systems for safety and efficiency.

Important parts like circuit breakers and relays stop overloads and automate work.

Picking the right box and back panel keeps things safe and neat.

PLCs and HMIs help make operations easier and improve user control.

Updating and choosing parts like surge arrestors and fuses keeps systems working longer.

Purpose and Importance of an Electrical Control Panel Box

Role in Managing Electrical Systems

An electrical control panel box helps manage electrical systems. It is like the brain of your setup. It connects all parts to work together smoothly. Custom panels are made to fit specific needs. This saves energy and lowers costs. By arranging parts well, these panels improve efficiency and reliability.

Modern panels can track energy use instantly. For example, power meters find problems like old motors using too much power. Fixing these issues early saves time and money. These panels also give useful data. This helps you make better choices and improve performance.

Ensuring Safety and Efficiency in Operations

Safety is a key job of control panel boxes. They protect people and equipment from electrical dangers. Circuit breakers stop power when it gets too high. This prevents fires and damage, keeping workplaces safe.

Efficiency is another big benefit. Variable frequency drives (VFDs) adjust motor speeds to match needs. This saves energy and cuts costs. Real-time motor checks find problems early. Fixing them quickly avoids delays and keeps things running well.

Here’s a simple look at how control panels save energy:

Evidence Type | Description |

|---|---|

Energy Efficiency | VFDs save energy by matching motor speed to needs, lowering costs. |

Real-Time Monitoring | Motor checks find problems early, helping with quick fixes. |

Reducing Downtime | Good panels reduce delays and save energy with early repairs. |

By mixing safety tools with energy-saving tech, control panels keep systems safe, reliable, and cost-friendly.

Structural Parts of an Electrical Control Panel Box

Enclosure and Its Job in Protection

The enclosure is the outer cover of the panel. It protects the inside parts from getting damaged. Think of it as a shield against dust, water, and harmful substances. This keeps the parts safe and helps the system work well.

Enclosures stop people from touching live wires accidentally.

They follow safety rules to lower risks of electrical accidents.

They protect parts from harsh conditions, making them last longer.

Picking the right enclosure keeps your control panel safe and strong.

Back Panel for Holding Components

The back panel is the base inside the enclosure. It holds all the parts securely in place. This keeps everything neat and easy to find. When parts are organized, fixing problems becomes simpler.

A good back panel also helps air move inside the box. This stops parts from overheating and breaking. It is important for keeping the control panel working well.

Door, Hinges, and Easy Access Features

The door and hinges are not just for opening the panel. They make it easier to check and fix things inside. Special hinges let doors open smoothly and stay in place while you work.

Evidence Type | Description |

|---|---|

User-Friendly Design | Modern hinges make doors easier to open and use. |

Maintenance Help | Hinges hold doors open at set angles, helping with repairs and checks. |

Choosing the right door and hinges makes the panel easier to use. These features also help keep the system safe and effective.

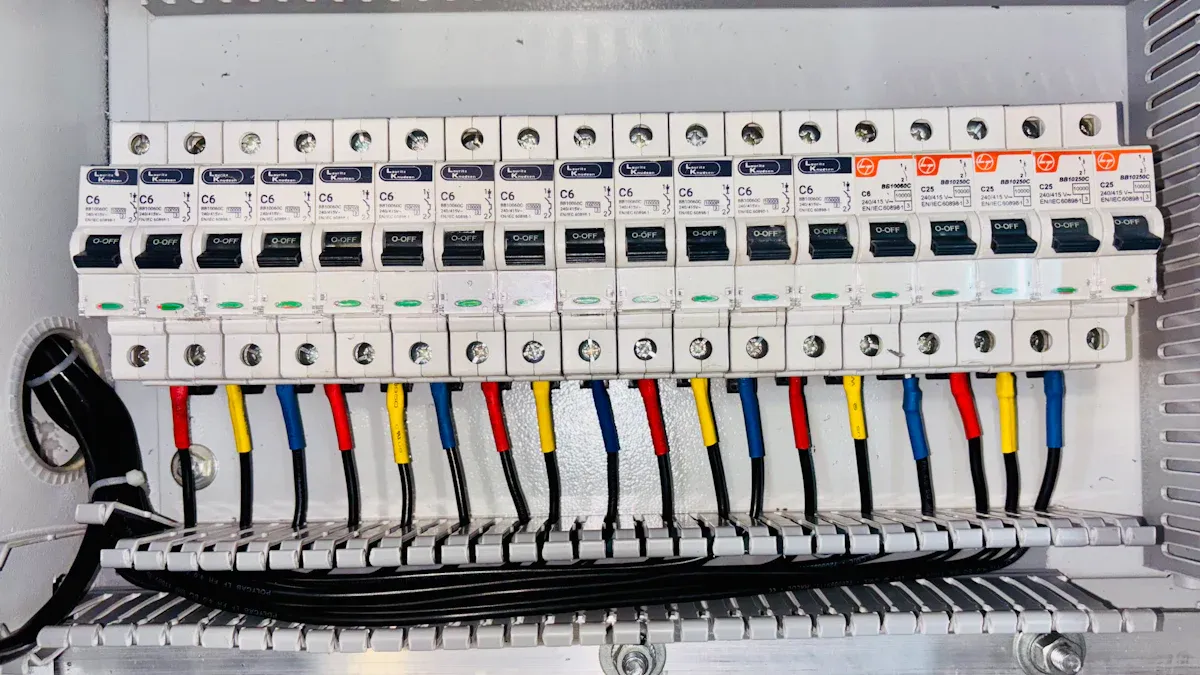

Electrical Components of an Electrical Control Panel

Circuit Breakers for Overload Protection

Circuit breakers are key parts of a control panel. They stop damage from too much electricity or short circuits. If the current gets too high, they cut off the power. This stops overheating, fires, and harm to other parts.

Circuit breakers block power to protect against electrical faults.

They stop wires from overheating when too much current flows.

Switchgear works with circuit breakers to keep power running in safe areas.

In factories, circuit breakers are vital for safety and smooth work. They prevent problems, saving money and avoiding delays.

Relays and Their Role in Switching

Relays are like automatic switches for turning circuits on or off. They let small signals control big electrical systems. This makes them very useful in control panels for factories.

Modern relays use smart tech like digital systems and live tracking. They find problems like overloads fast and shut down unsafe areas. This keeps equipment safe and reduces downtime.

Smart relays make systems safer and more reliable.

They quickly find and fix electrical issues.

Relays isolate problem spots, keeping the rest of the system working.

Relays are crucial for keeping factory systems safe and running smoothly.

Terminal Blocks for Wiring Connections

Terminal blocks help connect wires in an organized way. They make wiring easier to manage and maintain. These blocks are important for keeping systems neat and safe.

Each terminal block connects two or more wires securely. This keeps wires tidy and lowers the chance of mistakes. They also make it simple to find and fix wiring problems.

In factories, terminal blocks save time by organizing wires. They also keep wires in place, stopping accidents like disconnections or short circuits.

Tip: Pick terminal blocks that match your system’s voltage and current needs. This ensures safety and good performance.

Programmable Logic Controllers (PLCs) for Automation

PLCs are important parts of electrical control panels. They work like the "brains" of the system, helping machines run automatically. By following pre-set instructions, PLCs control equipment and keep things running smoothly.

PLCs improve how systems work. For example:

A factory added faster PLCs with better communication tools. This made production quicker and easier to manage.

In a chemical plant, PLCs controlled temperature and pressure accurately. This made the process safer, cheaper, and improved product quality.

PLCs can grow with your needs. You can change or add to their programs as needed. This makes them a smart and affordable choice for long-term use.

Tip: Update your PLC software often to use new features and improve performance.

Human-Machine Interface (HMI) for User Interaction

The HMI is how you interact with the control panel. It shows data on a screen so you can monitor and control systems easily. HMIs make tough tasks simpler and faster.

Modern HMIs have many advantages:

Custom screens show important information quickly.

Real-time controls help you make fast decisions.

Remote access lets you check systems from anywhere.

Predictive tools help you fix problems before they happen.

Easy-to-use designs reduce mistakes and save time.

Adding HMIs to your control panels makes work smoother. They help you solve problems quickly and keep everything running efficiently.

Surge Arrestors and Fuses for Voltage Protection

Surge arrestors and fuses protect control panels from power spikes. Surge arrestors handle sudden increases in electricity, keeping parts safe. Fuses break the circuit if too much power flows through.

Surge devices (SPDs) control extra electricity to protect systems. Fuses back them up by stopping ongoing power problems. Together, they keep your control panels safe and last longer.

Note: Pick surge arrestors and fuses that match your system’s power needs for the best protection.

How Components Work Together in a Control Panel

How Structural and Electrical Parts Work Together

Structural and electrical parts work together to make control panels reliable. The enclosure protects electrical parts from damage outside. The back panel holds parts like relays and terminal blocks in place. These structural parts keep the system safe and organized.

Good design reduces risks like overheating and signal problems. For example, thermal design stops parts from getting too hot and breaking. EMI shielding protects signals from interference, keeping data safe. These steps make the system more dependable.

Problem Example | What Happens |

|---|---|

Electromigration | High currents damage thin wires, causing reliability issues. |

Component Drift | Parts change over time, so circuits need to handle this. |

Too Much Heat | High heat can break parts; good cooling design is important. |

EMI Issues | Signal interference can ruin data; shielding helps prevent this. |

By combining these parts well, control panels work smoothly and handle tough conditions.

Working Together for Safety and Efficiency

Parts must work together to keep the system safe and efficient. Transformers adjust voltage to protect equipment. Wire ducts organize cables to stop short circuits. DIN rails hold parts steady during use. These structural features support electrical parts like relays and PLCs, which control and automate tasks.

For instance, PLCs help devices communicate for smooth operations. Relays and contactors switch power safely, avoiding overloads. When all parts work as a team, the control panel becomes safe and reliable.

Component | What It Does | Why It’s Important |

|---|---|---|

Transformers | Adjust voltage to protect sensitive equipment. | Keeps devices safe and working longer. |

Wire Ducts | Keep wires neat and easy to manage. | Prevents short circuits and improves safety. |

DIN Rails | Hold wires and parts securely. | Helps keep the system organized and safe. |

Relays/Contactors | Control electrical tasks efficiently. | Important for smooth and safe system operation. |

PLC Communication | Helps devices work together for better performance. | Ensures the system runs smoothly and efficiently. |

When parts are coordinated well, the control panel works better and stays safe.

An electrical control panel box helps manage electrical systems. It keeps systems safe, efficient, and reliable by holding key parts like circuit breakers, relays, and PLCs. These parts work together to stop overloads, automate tasks, and give real-time updates.

Knowing these parts helps you fix problems faster and avoid delays. For example:

Switches let you control things by hand.

Indicators show how the system is working.

Transformers change voltage to keep things safe.

Watching important details like downtime and repair costs keeps systems running well.

FAQ

1. What does an electrical control panel box do?

It helps manage and control electrical systems. It spreads electricity safely and makes systems work better. Organized parts lower risks and make fixing problems easier.

2. How do circuit breakers keep your system safe?

Circuit breakers stop electricity when it gets too strong. This avoids overheating, fires, and damage to equipment. They act as a safety shield for your system.

3. Why is the enclosure important?

The enclosure protects parts from dust, water, and damage. It also stops people from touching live wires, keeping everyone safe.

4. Can you improve a control panel later?

Yes, you can upgrade parts like PLCs or HMIs. This lets you make the system better and fit new needs without replacing everything.

5. How does an HMI help manage systems?

An HMI shows live data on a screen. It makes monitoring and controlling systems easier. You can fix problems faster and even check systems from far away.

See Also

Understanding Outdoor Communication Cabinets And Their Main Features

Choosing The Right Outdoor Electrical Cabinet For Your Requirements

Exploring Outdoor Communication Cabinets And Their Applications

The Advantages Of Outdoor Communication Cabinets Explained

Integrating Supervision Systems Within ESTEL Outdoor Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA