EMC Compliance for 5G Base Station Telecom Cabinet Power: EN 55032 Radiated Emission Testing & Remediation

You face increasing pressure to keep telecom power systems compliant with electromagnetic compatibility (EMC) standards. EN 55032 radiated emission testing plays a critical role in reducing risks from electromagnetic interference, crosstalk, and unstable power distribution. Common challenges include radiated emissions, documentation requirements, and complex regulations. You need practical steps such as using specialized test equipment, troubleshooting emission sources, and ensuring RF-EMF safety.

Electromagnetic interference can disrupt operations.

Crosstalk and power integrity issues threaten reliability.

Radiated emissions often cause compliance failures.

Key Takeaways

Understand EN 55032 to identify which telecom power systems require compliance testing. This knowledge helps you avoid unnecessary delays.

Implement pre-compliance design strategies early in your project. Focus on PCB layout and shielding to prevent costly redesigns later.

Use specialized measurement equipment like spectrum analyzers and near field probes. These tools help you accurately identify and measure radiated emissions.

Document all test setups and results thoroughly. Good documentation supports compliance verification and aids in troubleshooting.

Retest your system after any design or component changes. Regular retesting ensures ongoing compliance with EMC standards.

EN 55032 Requirements

Standard Overview

EN 55032 sets the benchmark for electromagnetic compatibility in multimedia equipment. You will find this standard covers a wide range of devices, including information technology equipment, audio and video products, broadcast receivers, satellite broadcast devices, cable transmission systems, and lighting control equipment. The goal is to ensure that electronic devices do not emit excessive electromagnetic interference. This helps maintain reliable operation in environments with many electronic systems.

Tip: Understanding the scope of EN 55032 helps you identify which equipment in your network needs compliance testing.

Here is a summary of the standard:

Standard | Description |

|---|---|

EN 55032 | Electromagnetic compatibility test standard for multimedia equipment, including information technology equipment, audio, video, broadcast receiver equipment, satellite broadcast, cable transmission, and lighting control equipment. |

Applicability to Telecom Power Systems

You need to apply EN 55032 to telecom power systems because these systems often operate near sensitive communication equipment. Any radiated emissions from power supplies or converters can disrupt network signals. Telecom power systems must meet the same emission limits as other multimedia equipment. This ensures that your base station operates without causing interference to nearby devices. You should always check if your specific power system falls under the scope of EN 55032 before starting compliance testing.

Radiated Emission Limits

EN 55032 defines strict radiated emission limits across different frequency bands. You must measure emissions from your telecom power systems using specialized equipment. The standard specifies maximum allowable emission levels to prevent interference with other devices. You will need to test your equipment in all operational modes to ensure compliance. If your system exceeds these limits, you must take corrective action before deployment.

Testing Telecom Power Systems

Pre-Compliance Design

You can prevent many EMC issues by focusing on pre-compliance design strategies. Early attention to layout and shielding helps you avoid costly redesigns later. Here are some practical steps you should consider:

Review your PCB layout for large loops or poorly grounded areas. These can become sources of unexpected EMI.

Test your design iteratively during development. Early detection of emission problems saves time and resources.

Design your PCB stackup to suppress noise. Proper stackup reduces radiated emissions.

Place ground planes carefully. Good placement ensures low noise and maintains proper impedance.

Route signal traces to minimize return path lengths. Shorter paths help prevent common-mode signal generation.

Use metal enclosures to block external EMI.

Implement shielded cables for high-speed or sensitive signals.

Tip: Early design reviews and iterative testing help you catch emission problems before they reach the final product stage.

Test Setup Essentials

You need a reliable test setup to measure radiated emissions accurately. Start by selecting an appropriate test environment, such as a semi-anechoic chamber or an open area test site. Position your telecom power systems on a non-conductive table at the correct height. Make sure you connect all cables and load the system as it would be in normal operation.

Test your equipment under different conditions. You should measure emissions with radios both enabled and disabled. This approach helps you understand how operational modes affect emission levels. Always test across all modes, including standby, transmit, and receive.

Note: Testing in multiple operational states ensures you capture the full emission profile of your system.

Measurement Equipment

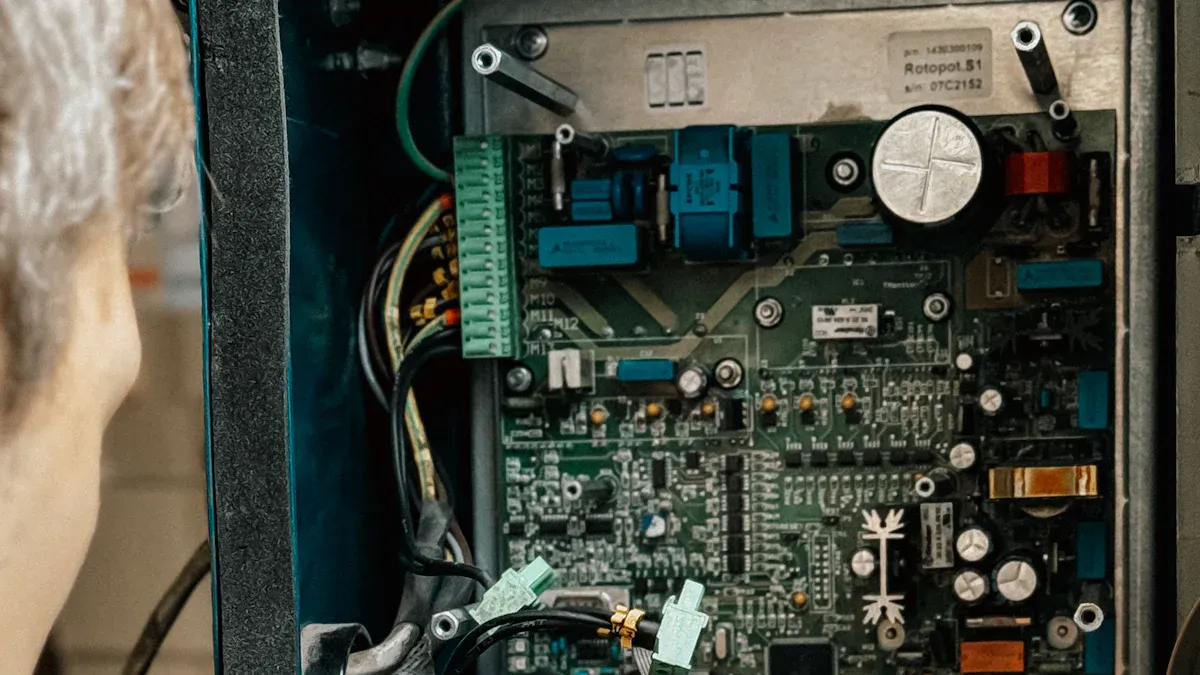

You need specialized equipment to identify and measure sources of radiated emissions. Spectrum analyzers help you visualize the frequency spectrum and pinpoint emission peaks. Near field probes allow you to locate the exact source of EMI on your PCB or within your cabinet.

Here is a quick overview of probe types and their applications:

Probe Type | Function | Application |

|---|---|---|

E-field Probe | Detects electric fields | Finds high voltage sources, high impedance nodes, cables, and un-terminated PCB traces. |

H-field Probe | Detects magnetic fields | Locates high current sources, low-impedance nodes, transmission lines, and power supplies. |

For 5G millimeter wave devices, you should use EMC measurement systems designed for high-frequency testing. These systems provide the sensitivity and bandwidth needed to capture emissions in the 3500–4400 MHz range.

The emission spectrum measurements of 5G transmitters show that they radiate across a wide frequency range with a dynamic range of 80 to 95 decibels. Testing reveals that C-Band radio models filter emissions effectively, transmitting very little above 4 GHz. This reduces unwanted emissions that could interfere with adjacent-band receivers.

Radiated patterns direct more energy toward the ground, where users are located. Airborne measurements show less power. The operational modes of base stations influence the radiated emissions detected in different environments.

You should always document your test setup and results. Consistent documentation helps you track changes and improvements in your telecom power systems.

Radiated Emission Testing

Step-by-Step Process

You can achieve accurate radiated emission results by following a clear process. Start by preparing your test environment. Place your equipment in a semi-anechoic chamber or on an open area test site. Position the device under test on a non-conductive table. Connect all cables and load the system as it would operate in the field.

Next, set up your measurement equipment. Use a spectrum analyzer with the correct frequency range. Attach the appropriate antennas and probes. Calibrate your system before each test. Begin measurements with the radio both enabled and disabled. Record emissions in every operational mode, such as standby, transmit, and receive. Rotate the equipment and adjust antenna height to capture the highest emission levels.

Finally, document your results. Note the test conditions, equipment settings, and any anomalies. This documentation helps you track changes and supports future troubleshooting.

Common Pitfalls

You may encounter several challenges during radiated emission testing, especially with 5G base station power systems:

Conducting spurious emission tests becomes more complex due to 5G technology.

Spectrum analyzers must cover a wider frequency range, which complicates the process.

Multiple antennas and integrated circuits make traditional RF testing methods impractical, so you need over-the-air (OTA) testing.

Notch filters are necessary to suppress the 5G carrier frequency, adding complexity.

Troubleshooting RF emissions requires advanced technology to identify issues.

Tip: Always review your test setup and equipment capabilities before starting. This helps you avoid common mistakes.

Frequency Band Considerations

Different frequency bands affect your test results. The 3.6 GHz band, for example, shows much higher variability in electric field levels than other bands. Active antenna systems and changes in network traffic can cause these fluctuations. The introduction of 5G networks has increased electromagnetic field levels, especially in the 3.6 GHz band. You should pay close attention to these factors when testing telecom power systems, as they can influence compliance outcomes.

Remediation for Telecom Power Systems

Design Modifications

You can often solve EMC issues by making targeted design changes early in your project. Start with your PCB layout. Good layout practices help you control electromagnetic interference and improve overall system performance.

Place signal traces close to a ground plane. This step gives each signal a clear return path and reduces the size of any loops that can radiate EMI.

Use power planes in your design. Power planes lower noise and help filter out high-frequency signals by creating a natural capacitance with the ground plane.

Limit the number of vias on high-speed signal lines. Too many vias add inductance and can disrupt signal integrity.

Add guard traces between high-speed signals. Guard traces help block crosstalk and keep your signals clean.

Choose solid ground planes whenever possible. Solid planes give your signals a stable reference and prevent unwanted emissions.

In multilayer boards, use more than one ground plane. Multiple ground planes boost signal integrity and cut down on noise.

Tip: Review your PCB layout with EMC in mind before you build your first prototype. Early changes cost less and save time.

Many engineers have found success by focusing on these layout and grounding strategies. For example, one team reduced radiated emissions by 40% after adding a solid ground plane and optimizing signal routing. Another project solved persistent EMI problems by minimizing vias and adding guard traces between critical signals.

Shielding and Filtering

Shielding and filtering play a key role in controlling radiated emissions. You can use metal enclosures to block electromagnetic fields from escaping your cabinet. Make sure all seams and joints in the enclosure are tight and well-connected. Even small gaps can let EMI leak out.

Install EMI gaskets or conductive tapes at enclosure openings. These materials help maintain the shield’s effectiveness. For cables, use shielded versions and connect the shield to the enclosure at the entry point. This step prevents cables from acting as antennas.

Filtering is just as important. Place filters on power lines and signal lines entering or leaving your system. Choose filters that target the frequencies where you see the most emissions. For example, common-mode chokes and ferrite beads can block high-frequency noise without affecting normal operation.

Note: Always test your shielding and filtering solutions in the lab. Small changes in installation can make a big difference in performance.

Component Selection

Your choice of components affects EMC performance. Select parts with low emission ratings and good immunity to external noise. Look for switching regulators and converters designed for low EMI. Many manufacturers offer components with built-in filters or shielded packages.

Pay attention to connectors and cables. Use connectors with metal shells and shielded cables for all high-speed or sensitive signals. Choose capacitors and inductors with values that match your filtering needs.

Stay updated with the latest test methods and environmental standards for 5G RAN. New components and materials appear regularly, offering better EMC performance. Align your component choices with current standards to ensure your telecom power systems remain compliant as requirements evolve.

Alert: Component substitutions during production can affect EMC compliance. Always retest your system if you change key parts.

Compliance Verification

Retesting Procedures

You need to verify that your telecom power system meets EMC requirements after making any design changes or component substitutions. Retesting ensures that your remediation efforts work and that your system remains compliant with EN 55032. You should follow a structured approach to retesting:

Prepare your test environment. Use the same chamber, table, and equipment settings as your initial tests.

Repeat all operational modes. Test your system with radios enabled and disabled. Measure emissions during standby, transmit, and receive states.

Compare results. Review your new measurements against previous data and EN 55032 limits.

Document anomalies. Note any unexpected results or emission spikes.

Adjust and retest if needed. If you find issues, make further design changes and repeat the process.

Tip: Always retest after any hardware or firmware update. Even small changes can affect EMC performance.

Documentation Best Practices

You must keep thorough records of your compliance process. Good documentation helps you track changes, support audits, and prove compliance to regulators. You should organize your records in a clear and accessible format.

Document Type | Purpose | Recommended Content |

|---|---|---|

Test Reports | Show compliance results | Test setup, equipment, conditions, data |

Change Logs | Track design and component updates | Date, description, reason for change |

Remediation Records | Detail fixes and improvements | Problem, solution, verification steps |

Compliance Certificates | Prove regulatory approval | Issuing body, date, scope |

You should update your documentation after every test and design change. Store digital copies in a secure location. Share records with your team and regulatory bodies when needed.

Note: Clear documentation saves time during audits and helps you maintain compliance as standards evolve.

You achieve EMC compliance for 5G base station power systems by following a clear process. Test thoroughly, document every step, and address issues as they arise. Proactive compliance strategies, such as Attack Surface Management, help you find vulnerabilities and reduce the risk of regulatory penalties. Stay informed by consulting key industry resources:

Standard | Description | Frequency Range |

|---|---|---|

CISPR 32 | Multimedia Equipment | 150 kHz – 6 GHz |

IEC 61000-4-3 | Radiated RF Immunity | 80 MHz – 6 GHz |

3GPP Specifications | 5G, LTE, and GSM Equipment | Cellular and IoT bands |

Keep learning and adapt your approach as standards evolve.

FAQ

What is the main goal of EN 55032 testing?

You use EN 55032 testing to ensure your telecom power system does not emit electromagnetic interference that could disrupt nearby devices. This testing helps you meet regulatory requirements and maintain reliable network performance.

How often should you retest your telecom power system?

You should retest after any design change, component swap, or firmware update. Regular retesting helps you catch new EMC issues early and keeps your system compliant with current standards.

Which equipment do you need for radiated emission testing?

You need a spectrum analyzer, near field probes, and antennas. For 5G systems, use EMC measurement systems that cover high-frequency bands. Always calibrate your equipment before each test.

What should you do if your system fails EN 55032 limits?

Review your PCB layout, improve grounding, and add shielding or filtering. Test each change. Document your steps and results. If problems continue, consult an EMC specialist for advanced troubleshooting.

See Also

Essential Telecom Cabinet Guidelines for Communication Gear

Specifications for Outdoor Telecom Cabinets and Equipment

Material Specifications for Outdoor Telecom Cabinet Construction

Ensuring Consistent Power Supply for Telecom Cabinets

Design Standards for ESTEL Telecommunication Cabinet Structures

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA