Emerging Trends in ESTEL DC Rectifier Technology for 2025

The world of power electronics is evolving rapidly, and you are witnessing a revolution in how energy is managed. The latest advancements in the dc rectifier system promise groundbreaking improvements in efficiency. These systems now integrate seamlessly with renewable energy sources, helping reduce carbon footprints. Additionally, AI-driven optimization allows smarter energy management and predicts potential issues before they occur. These innovations not only enhance performance but also set new standards for reliability and sustainability.

Key Takeaways

ESTEL DC rectifiers save energy using new tech like better semiconductors and smart AI tools.

They work well with solar and wind power, keeping electricity steady even when input changes.

Smart AI helps predict problems early, cutting repair time and costs while making systems more reliable.

New cooling methods, like liquid cooling and AI tools, make systems work better and last longer.

Using ESTEL DC rectifiers can cut pollution, helping the planet stay green.

Understanding ESTEL DC Rectifier Systems

Role in Modern Power Electronics

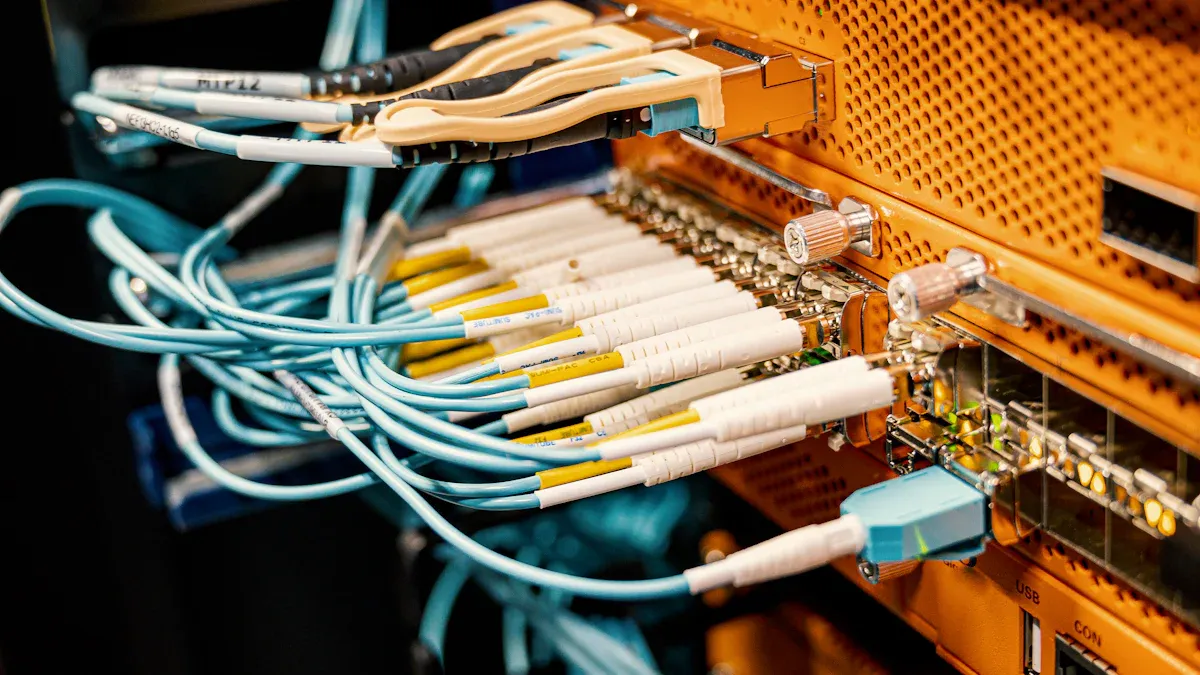

In today’s world, power electronics play a critical role in ensuring efficient energy conversion and distribution. ESTEL DC rectifier systems are at the forefront of this transformation. These systems convert alternating current (AC) into direct current (DC), which is essential for powering modern technologies. For example, ESTEL's TPRS series rectifiers are specifically designed for railway traction substations, enabling smooth and reliable energy delivery.

Modern rectifiers go beyond simple energy conversion. They integrate digital control systems that allow seamless communication with smart grids. This real-time data exchange optimizes power distribution, ensuring energy reaches where it’s needed most. Additionally, intelligent energy management systems adjust power delivery based on demand, reducing waste and improving efficiency.

Metric | Value |

|---|---|

Peak Efficiency | 97.83% |

Voltage for Peak Efficiency | 277 VAC |

Full Load Efficiency (min) | Above target |

These impressive metrics highlight the efficiency of ESTEL DC rectifier systems, making them indispensable in modern power electronics.

🌱 Sustainability Tip: High-efficiency rectifiers not only save energy but also align with global efforts to reduce carbon footprints.

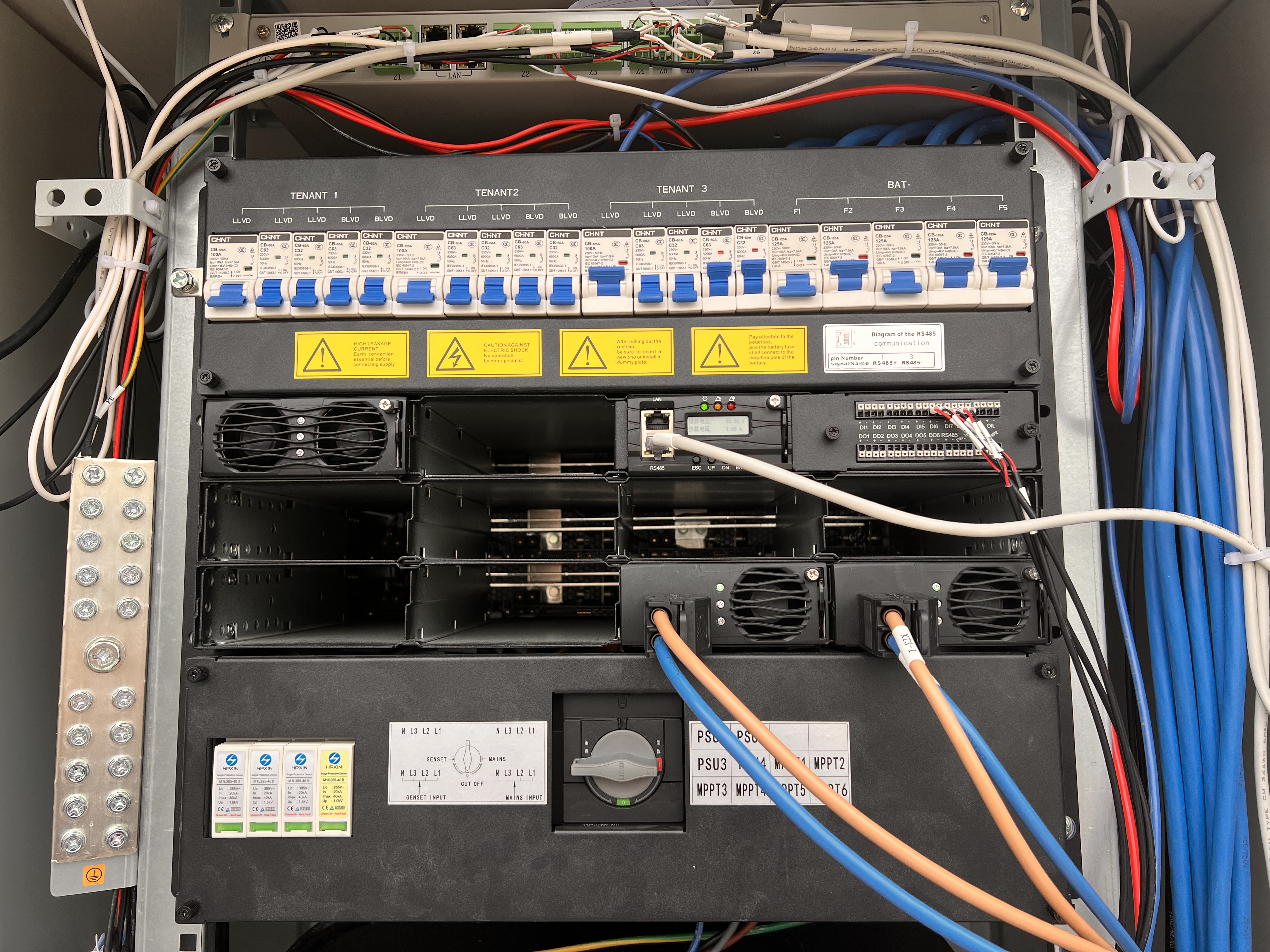

Key Features and Advantages

ESTEL DC rectifier systems offer a range of advanced features that set them apart. These include:

Microprocessor-based protection and diagnostics for enhanced reliability.

An operator panel with an LCD monitor for user-friendly interaction.

Continuous parameter monitoring through an internal oscilloscope, tracking current, voltage, diode temperature, and alarm waveforms.

These features ensure precise operation and quick troubleshooting, minimizing downtime.

Another standout advantage is their ability to integrate with advanced energy storage technologies. For instance:

Supercapacitors: Provide rapid charging and discharging with unlimited cycle life, ideal for voltage stabilization.

Flywheels: Offer long service life and no capacity degradation, ensuring stable power quality.

These technologies enhance grid stability and support renewable energy integration. By storing excess energy during peak production and releasing it during low demand, they ensure a steady power supply.

Key Trends Shaping DC Rectifier Systems in 2025

Advancements in Wide-Bandgap Semiconductors

Wide-bandgap (WBG) semiconductors are transforming the performance of power electronics. These materials, such as silicon carbide (SiC) and gallium nitride (GaN), offer superior efficiency and reliability compared to traditional silicon-based components. You can expect these semiconductors to play a pivotal role in the evolution of dc rectifier systems.

WBG semiconductors enable higher power density, faster switching speeds, and improved thermal management. For example, they allow rectifiers to operate at higher voltages and temperatures, making them ideal for demanding applications like electric vehicles and renewable energy systems.

Parameter | Improvement Description |

|---|---|

Efficiency | Enhanced efficiency in power devices due to better material properties of WBG semiconductors. |

Power Density | Increased power density allows for more compact designs. |

Heat Dissipation | Improved thermal management capabilities, leading to better performance under load. |

Operational Capabilities | Ability to operate at higher voltages and temperatures, expanding application range. |

Switching Speed | Propagation delays reduced to 5 ns, enabling MHz operation in traditional designs. |

System Size and Weight | Overall reductions in system size and weight due to integration of components. |

The growing demand for energy-efficient electronics, electric vehicles, and 5G networks is driving the adoption of WBG semiconductors. However, challenges like high manufacturing costs and supply chain constraints remain. As new materials and fabrication techniques emerge, these barriers will likely diminish, paving the way for widespread adoption.

AI-Driven Optimization and Predictive Maintenance

Artificial intelligence (AI) is revolutionizing how you manage and maintain dc rectifier systems. AI algorithms analyze real-time data to optimize system performance and predict potential failures before they occur. This proactive approach minimizes downtime and reduces maintenance costs.

Predictive maintenance, powered by AI, offers significant benefits:

It saves 8% to 12% over preventive maintenance and up to 40% over reactive maintenance.

It improves equipment reliability by addressing potential failures in advance.

It reduces downtime, ensuring uninterrupted operations.

Statistic Description | Impact |

|---|---|

Cost Savings | Predictive maintenance saves approximately 8% to 12% over preventive maintenance and up to 40% over reactive maintenance. |

Equipment Wear | Only about 10% of industrial equipment actually wears out, indicating that many mechanical failures can be avoided. |

ROI | Predictive analytics can yield a tenfold return on investment, resulting in savings of 30% to 40%. |

Downtime Reduction | Predictive maintenance helps prevent disruptions and minimizes downtime by identifying potential failures in advance. |

Equipment Reliability | It improves equipment reliability by addressing potential failures before they occur. |

By integrating AI into rectifier systems, you can achieve smarter energy management and enhanced reliability. This technology ensures that your systems operate at peak efficiency while reducing operational costs.

Integration with Renewable Energy Sources

The shift toward renewable energy is reshaping the design and functionality of dc rectifier systems. These systems must now handle variable inputs from sources like solar panels and wind turbines. Technologies like SCR (silicon-controlled rectifier) and IGBT (insulated-gate bipolar transistor) rectifiers are well-suited for this task.

SCR rectifiers excel in high-power applications, offering robustness and efficiency in three-phase systems.

IGBT rectifiers provide fast switching and high efficiency, making them ideal for compact power supply units in data centers.

Future developments may include hydrogen fuel cells, where rectifiers will play a crucial role in converting hydrogen energy into stable DC power. This integration ensures a steady power supply, even when renewable energy production fluctuates.

🌍 Sustainability Insight: By adopting rectifiers compatible with renewable energy, you contribute to a greener future while ensuring reliable energy delivery.

The integration of renewable energy sources with advanced rectifier technologies not only supports global sustainability goals but also enhances the resilience of power systems.

Innovations in Thermal Management

Thermal management plays a crucial role in ensuring the efficiency and reliability of modern power electronics, including dc rectifier systems. As devices become more compact and powerful, managing heat effectively becomes increasingly challenging. Recent innovations are addressing these challenges with cutting-edge solutions that improve cooling efficiency and system performance.

Advanced Cooling Simulators

Digital simulation tools are transforming how you approach thermal management. For example, Meta has developed a digital simulator that replicates cooling and thermal behavior in data centers. This simulator allows you to test control policies using AI and model predictive control. It can even predict thermal performance for data centers that have not yet been built.

These simulators use computational fluid dynamics (CFD) to quantify and visualize fluid dynamics. Although CFD simulations require significant computational power, they provide detailed insights into airflow and heat dissipation. Additionally, thermal simulators, often called gray box models, solve thermal balance equations quickly. These models help you understand how systems react to extreme weather conditions, ensuring uninterrupted operation.

💡 Tip: Digital simulators enable proactive thermal management, reducing the risk of overheating and improving energy efficiency.

Liquid Cooling Systems

Liquid cooling is emerging as a preferred solution for high-power applications. Unlike traditional air cooling, liquid cooling uses fluids to transfer heat away from components. This method offers superior heat dissipation and allows devices to operate at higher power densities.

Modern liquid cooling systems use non-conductive fluids to prevent electrical interference. These systems are particularly effective in environments with limited airflow, such as compact data centers or industrial automation setups. By integrating liquid cooling into your dc rectifier system, you can achieve better thermal performance and extend the lifespan of critical components.

AI-Driven Thermal Optimization

Artificial intelligence is revolutionizing thermal management. AI algorithms analyze real-time temperature data and adjust cooling mechanisms dynamically. For example, AI can optimize fan speeds, liquid flow rates, or heat exchanger settings based on current operating conditions.

This approach minimizes energy consumption while maintaining optimal temperatures. AI also enables predictive thermal management by identifying potential overheating risks before they occur. By adopting AI-driven solutions, you can ensure your systems remain efficient and reliable under varying workloads.

Compact and Modular Designs

Innovations in design are also enhancing thermal management. Compact and modular systems reduce heat generation by optimizing component placement and minimizing energy loss. These designs often incorporate advanced materials with high thermal conductivity, such as graphene or aluminum alloys.

Modular systems allow you to scale cooling solutions based on specific requirements. For instance, you can add or remove cooling modules depending on the power density of your dc rectifier system. This flexibility ensures efficient thermal management without over-engineering the solution.

🌱 Sustainability Insight: Efficient thermal management reduces energy waste, contributing to a greener and more sustainable future.

Thermal management innovations are critical for maintaining the performance and reliability of modern power electronics. By leveraging advanced cooling technologies, AI-driven optimization, and modular designs, you can overcome heat-related challenges and unlock the full potential of your systems.

Applications and Challenges of ESTEL DC Rectifier Systems

Applications in Data Centers

Data centers demand reliable and efficient power systems to support their high energy consumption. ESTEL DC rectifier systems excel in meeting these requirements by providing stable and uninterrupted power. These systems ensure that servers, storage devices, and networking equipment operate without disruptions, even during power fluctuations.

One of the key advantages of these rectifiers is their ability to integrate with advanced energy storage solutions. For instance, supercapacitors and flywheels can store excess energy and release it during peak demand. This capability enhances the resilience of data centers, especially in regions prone to power outages.

Additionally, modern dc rectifier systems feature compact designs and high power density. This makes them ideal for space-constrained environments, where maximizing floor space is critical. By adopting these systems, you can achieve energy efficiency while reducing operational costs.

💡 Tip: Upgrading to high-efficiency rectifiers can significantly lower your data center's carbon footprint, aligning with global sustainability goals.

Supporting EV Charging Infrastructure

The rapid adoption of electric vehicles (EVs) has created a pressing need for robust charging infrastructure. ESTEL DC rectifier systems play a pivotal role in supporting this infrastructure by converting AC power from the grid into the DC power required for EV batteries.

Strategically placed high-power charging stations are essential for commercial fleets like taxis and buses. These stations must handle variable charging times and power demands, which require dynamic grid management strategies. ESTEL rectifiers, with their advanced control systems, ensure efficient energy distribution across multiple charging points.

Evidence Description | Numerical Evidence |

|---|---|

Analysis of 1.686 million EVs across seven major Chinese cities | Represents 42.2% of China’s total EV fleet |

Importance of strategically placing high-power charging stations | Supports commercial fleets like taxis and buses |

Variability in charging times and power demands | Indicates need for dynamic grid management strategies |

The EV charging market is projected to exceed $104 billion by 2035, with an annual growth rate of 8%. This growth highlights the importance of investing in scalable and efficient charging solutions. By leveraging ESTEL rectifiers, you can contribute to the development of a sustainable EV ecosystem.

🌍 Sustainability Insight: Supporting EV infrastructure with efficient rectifiers accelerates the transition to clean transportation, reducing greenhouse gas emissions.

Role in Industrial Automation

Industrial automation relies on uninterrupted power to maintain the efficiency of critical machinery and processes. ESTEL DC rectifier systems provide a reliable power source, ensuring smooth operations in automated environments.

These rectifiers offer several advantages:

Compact designs and high power density make them suitable for space-constrained facilities.

Compliance with international safety standards, such as CE and UL certifications, ensures reliability and safety.

Energy efficiency levels exceeding 96%, supported by certifications like Energy Star and ISO 14001, highlight their eco-friendly design.

By integrating these rectifiers into your automation systems, you can achieve higher productivity and lower energy costs. Their ability to operate in harsh industrial conditions further enhances their appeal.

🔧 Note: Regular maintenance of rectifier systems can extend their lifespan and improve overall system performance.

Industrial automation continues to evolve, and ESTEL rectifiers remain at the forefront of this transformation. Their advanced features and robust design make them indispensable in modern manufacturing and production facilities.

Overcoming Challenges: Cost, Scalability, and Adoption Barriers

The adoption of ESTEL DC rectifier systems faces several challenges that could slow their widespread implementation. You need to understand these obstacles to make informed decisions and explore solutions that can overcome them effectively.

Tackling High Costs

Cost remains one of the most significant barriers to adopting advanced rectifier systems. Wide-bandgap semiconductors, AI-driven optimization tools, and renewable energy integration technologies often come with high upfront expenses. These costs can deter smaller businesses or organizations with limited budgets.

To address this challenge, you can explore strategies such as:

Bulk Procurement: Purchasing components in large quantities reduces per-unit costs.

Government Incentives: Many governments offer subsidies or tax breaks for adopting energy-efficient technologies.

Modular Upgrades: Instead of replacing entire systems, you can upgrade specific components to improve performance incrementally.

💡 Tip: Look for partnerships with manufacturers or energy providers to negotiate better pricing and financing options.

Scaling for Large Applications

Scalability is another critical challenge. While ESTEL DC rectifier systems excel in small-scale applications, scaling them for larger systems like industrial plants or extensive EV charging networks can be complex. You may encounter issues such as increased heat generation, higher energy demands, and the need for more robust infrastructure.

To ensure scalability, consider these approaches:

Modular Designs: Modular systems allow you to add capacity as needed without overhauling the entire setup.

Advanced Cooling Solutions: Implementing liquid cooling or AI-driven thermal management ensures efficient operation at higher power densities.

Grid Integration: Collaborate with utility providers to optimize energy distribution across large networks.

Scalability Challenge | Solution |

|---|---|

Increased Heat Generation | Use advanced cooling systems like liquid cooling. |

Higher Energy Demands | Integrate energy storage solutions like supercapacitors or flywheels. |

Infrastructure Limitations | Adopt modular designs for flexible expansion. |

Overcoming Adoption Barriers

Adoption barriers often stem from a lack of awareness or resistance to change. Many organizations hesitate to invest in new technologies due to concerns about compatibility, training requirements, or perceived risks.

You can overcome these barriers by focusing on education and support:

Training Programs: Offer workshops or online courses to help your team understand and operate advanced rectifier systems.

Compatibility Testing: Ensure new systems integrate seamlessly with existing infrastructure to minimize disruptions.

Demonstration Projects: Showcase successful implementations to build confidence and highlight the benefits of adoption.

🌍 Sustainability Insight: Promoting the environmental benefits of ESTEL DC rectifier systems can encourage adoption by aligning with global sustainability goals.

Bridging the Gap

While challenges like cost, scalability, and adoption barriers may seem daunting, they are not insurmountable. By leveraging innovative solutions, fostering collaboration, and prioritizing education, you can pave the way for widespread implementation of ESTEL DC rectifier systems. These efforts will not only enhance energy efficiency but also contribute to a more sustainable future.

The trends shaping ESTEL DC rectifier systems in 2025 highlight a future driven by innovation. Wide-bandgap semiconductors, AI-driven thermal optimization, and hybrid cooling solutions are transforming power electronics. These advancements improve efficiency, reliability, and sustainability. You can expect breakthroughs in areas like electric vehicles, data centers, and renewable energy integration.

🌟 Insight: Future-oriented studies predict that power grids will evolve to support bidirectional energy flow, while cooling innovations will meet the demands of electric aircraft and space exploration.

By embracing these innovations, you contribute to a smarter, greener energy landscape that meets the challenges of tomorrow.

FAQ

What makes ESTEL DC rectifier systems more efficient than traditional rectifiers?

ESTEL DC rectifiers use advanced technologies like wide-bandgap semiconductors and AI-driven optimization. These innovations improve energy conversion efficiency, reduce heat loss, and enable smarter energy management. As a result, you get higher performance with lower energy consumption.

Can ESTEL DC rectifiers integrate with renewable energy systems?

Yes, ESTEL rectifiers are designed to handle variable inputs from renewable sources like solar panels and wind turbines. They stabilize power delivery, ensuring consistent energy output even when renewable generation fluctuates. This makes them ideal for hybrid energy systems.

How does AI improve the reliability of ESTEL DC rectifiers?

AI analyzes real-time data to predict potential failures and optimize performance. It enables predictive maintenance, reducing downtime and repair costs. By addressing issues before they escalate, you can ensure uninterrupted operation and extend the lifespan of your rectifier systems.

Are ESTEL DC rectifiers suitable for small-scale applications?

Absolutely! ESTEL rectifiers come in compact, modular designs that fit space-constrained environments. Whether you’re powering a small data center or an industrial automation setup, these systems provide high efficiency and reliability without requiring extensive infrastructure.

What challenges should you consider before adopting ESTEL DC rectifiers?

Key challenges include high upfront costs, scalability for large systems, and compatibility with existing infrastructure. However, strategies like modular upgrades, government incentives, and training programs can help you overcome these barriers effectively.

💡 Tip: Start with a pilot project to evaluate performance and compatibility before scaling up.

See Also

Innovative Energy Storage Solutions for ESTEL Telecom Cabinets

Latest Developments Shaping Outdoor Telecom Cabinet Designs

Benefits of ESTEL Cooling Solutions for Industrial Use

Exploring Energy Storage Options for ESTEL Telecom Cabinets

Selecting Optimal Cooling Techniques for ESTEL Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA