Energy Efficiency in Telecom: How Modern Rectifiers Reduce OPEX for DC Power Plants

Modern rectifiers deliver up to 98% energy efficiency, immediately lowering operating expenses for telecom DC power plants. Telecom operators face urgent financial and operational challenges as energy costs rise. Many transition from older rectifiers to advanced models like those from ESTEL, seeking substantial savings and reliability.

Modern rectifiers achieve efficiencies over 97%.

Some models reach 98%, offering up to 30% cost reduction compared to outdated designs.

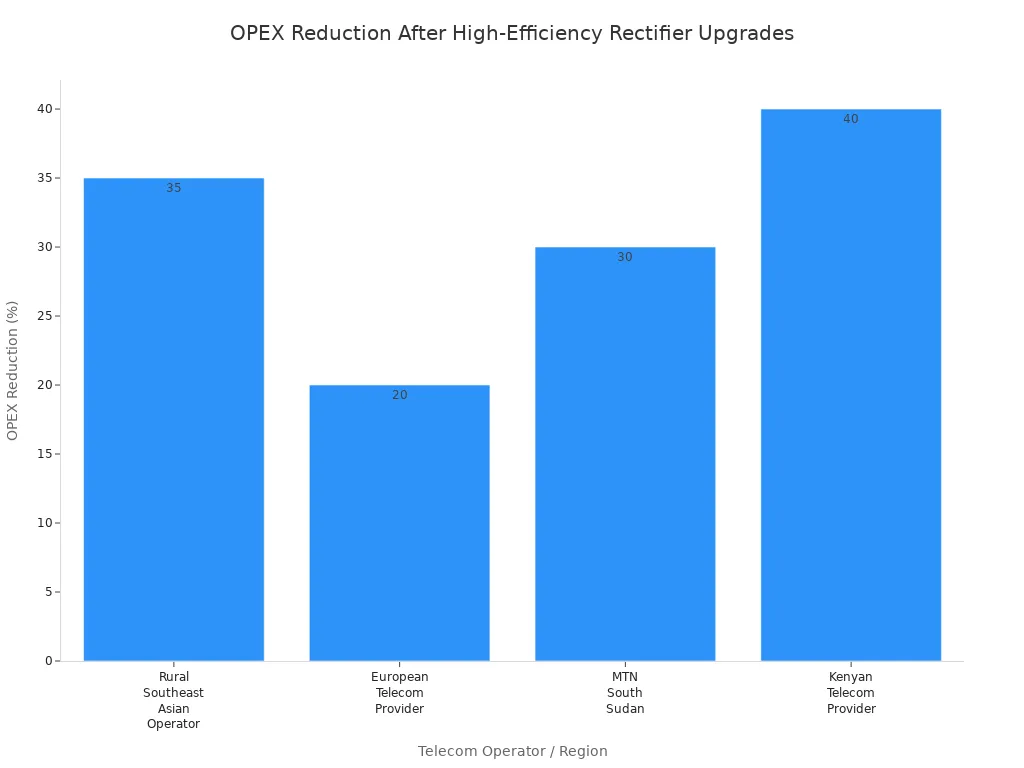

Telecom Operator / Region | Operational Benefit | Financial Benefit | Additional Notes |

|---|---|---|---|

Rural Southeast Asian Operator | Ensured uninterrupted mobile connectivity | 35% reduction in operational costs | Deployment of ESTEL’s hybrid solar power systems |

European Telecom Provider | Enhanced energy efficiency and reduced downtime | 20% improvement in network uptime | Infrastructure upgrade supporting 5G technology with ESTEL solutions |

MTN South Sudan | Improved operational efficiency | 30% reduction in fuel costs | Solar energy shields from energy price volatility |

Kenyan Telecom Provider | Enhanced service reliability in remote areas | 40% reduction in energy expenses | Solar-powered towers deployed in off-grid locations |

Key Takeaways

Modern rectifiers can achieve up to 98% energy efficiency, significantly lowering operating expenses for telecom operators.

Upgrading to high-efficiency rectifiers can reduce energy costs by 15% to 30%, freeing up capital for network improvements.

Operators can extend battery life to 10 years with modern rectifiers, compared to just 2 years with traditional systems.

Implementing regular maintenance and monitoring can prevent failures and ensure optimal performance of rectifier systems.

Integrating solar power with modern rectifiers supports sustainability goals and further reduces reliance on grid energy.

Lowering OPEX with Modern Rectifiers

Financial Benefits for Telecom Operators

Telecom operators can achieve significant financial gains by upgrading to modern rectifiers. These advanced systems reach up to 98% efficiency, which translates into direct energy cost savings. Operators often report reductions in utility bills ranging from 15% to 30% after replacing outdated rectifiers.

Operators save on energy costs due to higher conversion efficiency.

Lower utility bills free up capital for network expansion or technology upgrades.

Leasing options for modern rectifiers help optimize capital expenditure budgets.

The following table summarizes the impact of modern rectifiers on operational costs and investment returns:

Evidence Type | Details |

|---|---|

Maintenance Cost Reduction | Operators reported maintenance costs dropping to 7% of those for traditional systems. |

Energy Consumption | Advancements in rectifier technology lead to lower energy consumption. |

Payback Period | Many operators realized payback periods between 6 months and 3 years. |

Battery Life | Battery life extended to 10 years, compared to the typical 2-year lifespan of lead-acid batteries. |

Operational Reliability | Pilot sites maintained reliable operation under extreme temperatures ranging from 20°F to 110°F. |

ESTEL’s Delta Rectifier Modules stand out in the market for their ultra-modular designs and advanced AI integration. These features enable predictive analytics and self-optimization, which further reduce operational expenses. Compared to competitors, ESTEL modules offer conversion efficiency above 98%, while others typically range from 94% to 96%.

Feature | ESTEL’s Delta Rectifier Modules | Competitors’ Modules |

|---|---|---|

Modularity | Ultra-modular designs | Limited modular options |

AI Integration | Predictive analytics & self-optimization | Basic AI capabilities |

Conversion Efficiency | >98% | 94–96% |

Applications | Automotive, hybrid vehicles, industrial automation solutions | Primarily automotive |

Tip: Operators who prioritize high-efficiency rectifiers can realize a return on investment in as little as six months, especially in regions with high energy costs.

Operational Improvements with High-Efficiency Models

High-efficiency rectifiers deliver more than just cost savings. They also drive operational improvements that enhance the reliability and sustainability of telecom networks.

Energy cost savings can reach up to 75% due to reduced energy losses.

Lower energy consumption leads to a significant reduction in carbon emissions, supporting environmental goals.

Enhanced reliability of power delivery ensures business continuity, even during peak demand or extreme weather.

Modern rectifiers, such as those used in about 70% of new telecom setups like 5G networks, ensure smooth communication and stable DC power supply. Their advanced designs and modular architectures allow for real-time monitoring and maintenance without service interruption. This stability is critical for maintaining continuous operations in telecom environments.

Operators benefit from reduced downtime and improved reliability.

Modular rectifier systems enable quick replacement or upgrades, minimizing service disruptions.

Stable DC power supply supports essential infrastructure, such as base stations and data centers.

ESTEL’s technology leads the industry by combining high energy efficiency with robust operational features. Their rectifiers help operators maintain consistent service, reduce downtime, and extend battery life, which can now reach up to 10 years. These improvements contribute to lower maintenance costs and greater network reliability.

Note: By investing in high-efficiency rectifiers, telecom operators not only lower their OPEX but also future-proof their networks for evolving technologies and sustainability requirements.

Energy Efficiency Impact in DC Power Plants

Role of Rectifiers in Power Conversion

Rectifiers serve as the backbone of telecom DC power plants. They convert alternating current (AC) from the grid, usually at 220V or 380V, into direct current (DC) at 48V. This voltage matches the requirements of most telecom equipment. Rectifiers also support backup battery systems by supplying the DC power needed to charge batteries. This process ensures that telecom networks continue to operate during power outages. Reliable power conversion helps maintain uninterrupted service, which is critical for both urban and remote telecom sites.

Note: Operators who understand the function of rectifiers can better plan upgrades and maintenance, leading to improved network stability.

Efficiency and Energy Consumption

Rectifiers account for more than 25% of the total energy use in a typical telecom DC power plant. Improving their efficiency has a direct effect on operational expenses (OPEX). High-efficiency rectifiers, which reach up to 98% efficiency, minimize energy loss as heat. This reduction in wasted energy lowers both electricity bills and cooling costs.

Operators can follow these steps to maximize energy efficiency and reduce OPEX:

Assess the current rectifier efficiency and identify outdated units.

Upgrade to high-efficiency rectifiers to reduce energy loss.

Monitor energy consumption and cooling needs after the upgrade.

Track reductions in utility bills and maintenance costs.

High-efficiency rectifiers minimize energy loss during conversion, which leads to lower operational costs and improved system performance.

A 62% reduction in wasted energy per site can result in significant savings on grid and diesel expenses.

Lower heat output means less demand on cooling systems, which further reduces costs.

Regulatory standards also play a role. They set benchmarks for energy efficiency, encouraging manufacturers to innovate. Government incentives for clean energy make it easier for operators to invest in advanced rectifier solutions.

Tip: Operators who prioritize energy efficiency not only cut costs but also support sustainability goals and comply with industry regulations.

Cost Reduction Strategies for Telecom Operators

Minimizing Energy Losses

Telecom operators can reduce energy losses in DC power plants by adopting several practical strategies:

Install thermal management systems, such as air conditioning, heat exchangers, or fans, to regulate internal temperatures.

Use protective enclosures with high IP ratings to shield equipment from dust and moisture.

Deploy humidity control measures, including dehumidifiers or silica gel packs, to lower moisture levels inside enclosures.

Conduct regular maintenance to inspect and clean equipment, preventing dust buildup and corrosion.

Balance electrical loads between phases to optimize system performance.

Select efficient components and solutions to minimize technical losses.

Track and analyze energy consumption using data management tools.

Operators who focus on these steps can achieve continuous optimization and improve overall system performance.

Reducing Cooling and Maintenance Needs

Operators can further cut costs by implementing both passive and active cooling strategies. Free cooling uses outside air to lower internal temperatures, reducing reliance on energy-intensive air conditioning. Advanced algorithms, such as Artificial Neural Networks, help manage energy use by adjusting cooling systems in real time. These methods lower energy consumption and extend equipment life. Regular maintenance also prevents unexpected failures and reduces repair costs.

Extending Battery Life and Reliability

Modern rectifiers play a key role in extending battery life and improving reliability. The following table highlights important features:

Feature | Benefit |

|---|---|

High Efficiency | Reduces energy loss and operational costs while supporting sustainability |

Modular Design | Allows easy expansion and quick part replacement, minimizing downtime |

Advanced Protection | Lowers risk of equipment damage and service interruptions |

Operators who upgrade to high-efficiency rectifiers can see battery life extend up to 10 years, compared to traditional systems.

Supporting Sustainability Goals

Operators support sustainability goals by choosing energy-efficient rectifiers with smart designs. Many companies now share network equipment, which saves energy and reduces manufacturing needs. New rectifiers work well with solar panels and wind turbines, making it easier to use clean energy. Compact designs use fewer materials, lowering waste and environmental impact. Transitioning to high-efficiency rectifiers can save over $7,000 annually for every 1000A at $0.3/kwhr.

ESTEL stands out as a recommended brand for upgrades. Their rectifier systems meet international standards, offer modular designs, and include advanced monitoring features. Operators benefit from comprehensive support and continuous innovation, making ESTEL a reliable choice for cost reduction and improved Energy Efficiency.

Upgrading to ESTEL Rectifiers

Assessing Current System Efficiency

Telecom operators should begin by evaluating the current state of their rectifier systems. Regular assessments help identify inefficiencies and prevent unexpected failures. Operators can follow these steps:

Inspect rectifier modules for physical damage, corrosion, or signs of overheating.

Monitor output voltage, current, and efficiency to confirm proper power conversion.

Use predictive maintenance tools and sensors to detect abnormal temperature changes or voltage fluctuations.

Check cooling systems and airflow to avoid overheating.

Secure all electrical connections and cabling.

Clean dust and replace air filters to maintain optimal conditions.

Update firmware to improve performance and security.

Review system alarms and logs to address issues before they cause downtime.

Routine checks ensure that the system operates at peak performance and supports future upgrades.

Integrating High-Efficiency Rectifiers

When integrating high-efficiency rectifiers, operators must consider several factors to ensure a smooth transition. The following table outlines key considerations:

Consideration | Description |

|---|---|

Efficiency | Evaluate the efficiency rating to achieve optimal power conversion. |

Reliability | Choose rectifiers with high reliability for continuous operation. |

Scalability | Select systems that can expand as network demands grow. |

Remote Monitoring | Use features that allow real-time performance tracking and rapid response to issues. |

System Integration | Ensure all components work together for stable power supply and operational efficiency. |

Operators who focus on these factors can maximize the benefits of new rectifier technology.

Calculating ROI and Savings

Upgrading to ESTEL rectifiers requires an initial investment, but the long-term savings are significant. Operators can calculate return on investment by considering these points:

The payback period for solar systems with ESTEL rectifiers usually ranges from three to six years, depending on system size and local energy prices.

Solar solutions reduce energy bills and maintenance costs over time.

High-efficiency rectifiers minimize fuel consumption and extend equipment life.

Many operators report greater long-term savings compared to traditional diesel generators.

Reliable rectifiers justify the investment by reducing downtime and protecting sensitive equipment.

Operators who invest in Energy Efficiency see lower operational costs and improved network reliability.

Implementation Best Practices

To achieve the best results, operators should follow these practices:

Improve power factor to reduce energy losses in AC systems.

Use Class 4 power systems, which operate above 50V DC and can reach up to 450V DC, for enhanced safety and efficiency.

Monitor cabling and shut off power in case of faults to prevent damage.

Consider that implementing a Class 4 telecom rectifier reduces cabling costs and voltage drop, leading to further savings.

Operators who follow these best practices can ensure a smooth upgrade process and maximize the benefits of high-efficiency rectifiers.

Telecom operators face growing demands for reliable and efficient power. Modern rectifiers offer several advantages:

They convert AC to DC power with minimal loss, which reduces energy consumption and operating costs.

They support high-density power needs for 5G networks and data centers.

They enhance reliability for critical equipment.

New designs use advanced materials and eco-friendly production methods. These changes lower operational expenses, improve Energy Efficiency, and support sustainability. Operators can achieve immediate and lasting results by auditing power systems, upgrading rectifiers, and monitoring performance.

FAQ

What steps should operators take before upgrading rectifiers?

Operators should inspect current rectifier systems, check for inefficiencies, and review maintenance records. They should also consult with technical experts to assess compatibility with new models. This process helps ensure a smooth upgrade and maximizes energy savings.

How do high-efficiency rectifiers reduce operating expenses?

High-efficiency rectifiers convert more AC power into usable DC power. This process reduces energy loss and lowers electricity bills. Operators also spend less on cooling and maintenance, which further decreases operating expenses.

Can operators integrate solar power with modern rectifiers?

Yes. Many modern rectifiers, including ESTEL models, support solar and hybrid energy sources. Operators can connect solar panels directly to the system. This integration reduces reliance on grid or diesel power and supports sustainability goals.

How quickly can operators see a return on investment?

Operators often see a return on investment within six months to three years. The exact period depends on energy prices, system size, and usage patterns. High energy costs and large networks usually lead to faster payback.

What maintenance practices extend rectifier lifespan?

Operators should clean equipment regularly, monitor system performance, and update firmware. They should also replace air filters and check for overheating. These practices help prevent failures and extend the lifespan of rectifiers.

See Also

Essential Insights Into Telecom Power Supply Characteristics

Integrated Solar Inverter And Battery Solutions For Telecom Cabinets

Calculating Power Systems And Battery Needs For Telecom Cabinets

Solar Energy Storage Solutions For Telecom Cabinet Power

Ensuring Consistent Power Supply For Telecom Cabinet Operations

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA