Electrostatic Discharge (ESD) Protection for Telecom Cabinet Power Systems: Impact on Power Chips & Protective Circuit Design

Electrostatic discharge (ESD) can strike without warning and cause serious harm to power chips inside Telecom Power Systems. You may notice unexpected failures or erratic behavior when ESD bypasses weak protection. Strong ESD safeguards help you maintain equipment reliability and prevent costly downtime. Understanding how ESD impacts your electronics prepares you to defend your systems from these invisible threats.

Key Takeaways

Understand ESD events and their risks. Common occurrences include direct contact, air discharge, and cable discharge. Ground yourself before handling sensitive components to prevent damage.

Identify vulnerable points in your telecom systems. Focus on power distribution boards, control circuits, and connectors. Apply extra ESD safeguards in these areas to enhance protection.

Implement a multi-layer protection strategy. Use devices like TVS diodes and polymer suppressors close to entry points. This approach effectively diverts surges away from critical components.

Maintain your ESD protection regularly. Inspect grounding connections, clean surfaces, and test protection devices. Consistent maintenance helps catch issues early and ensures reliability.

Follow established ESD standards. Adhering to guidelines like IEC 61000-4-2 and ANSI/ESD S20.20 ensures your systems meet industry expectations and remain protected against ESD threats.

ESD Impact on Power Chips

Common ESD Events

You face ESD events in many forms when working with Telecom Power Systems. These events can occur during installation, maintenance, or even routine operation. Static electricity builds up on your body or tools. When you touch sensitive components, the charge discharges rapidly. This sudden flow of electricity can reach thousands of volts in a fraction of a second.

Some common ESD events include:

Direct Contact Discharge: You touch a power chip or connector, releasing static directly into the device.

Air Discharge: Static jumps through the air from your finger or tool to a component, even without direct contact.

Cable Discharge: You connect or disconnect cables, and the stored charge in the cable releases into the system.

Field-Induced Discharge: A charged object near a circuit board induces a voltage, causing a discharge when you ground the board.

Tip: Always ground yourself before handling any circuit boards in Telecom Power Systems. This simple step can prevent most ESD events.

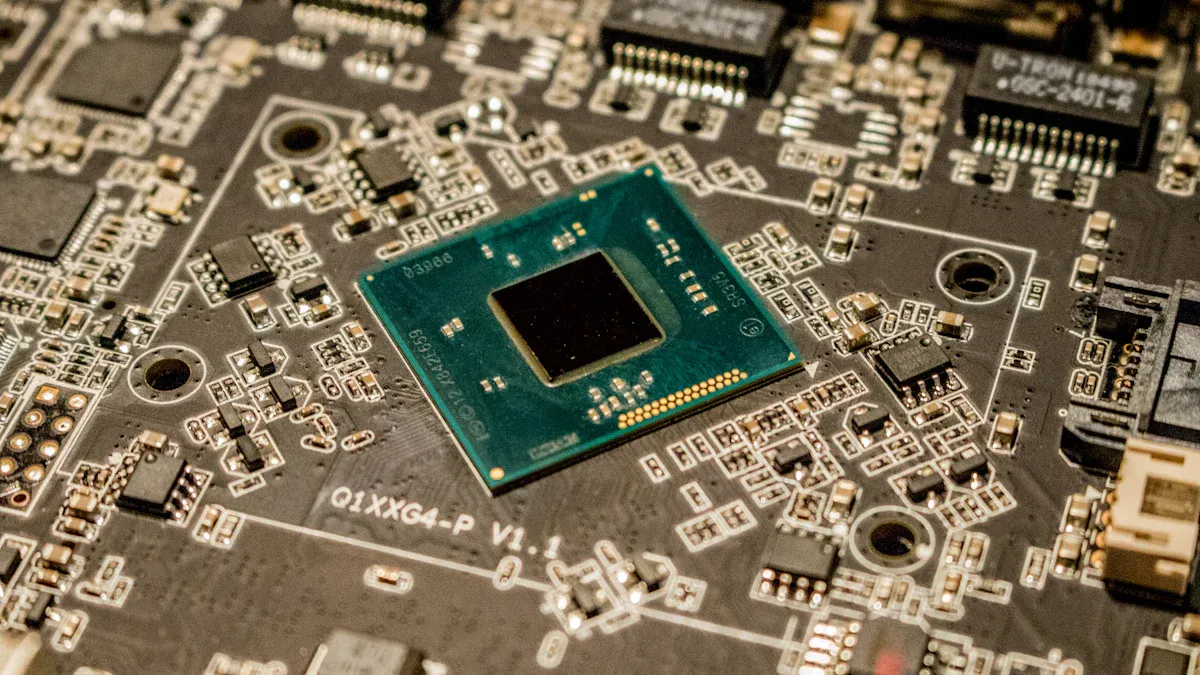

Power Chip Failures

When ESD strikes, power chips in Telecom Power Systems can suffer immediate or delayed failures. You might see a device stop working right away, or you might notice problems weeks later. ESD can damage the thin layers inside a chip, creating tiny holes or short circuits.

Here are some ways ESD can cause power chip failures:

Failure Mode | What You Might Notice | Long-Term Impact |

|---|---|---|

Gate Oxide Breakdown | Chip stops responding | Permanent device failure |

Junction Damage | Increased leakage current | Reduced efficiency |

Latch-Up | Sudden high current, device heats up | Catastrophic chip destruction |

Parametric Shift | Unstable voltage regulation | Unpredictable system behavior |

You may also see intermittent faults. These faults make troubleshooting difficult. A chip might work fine during testing, then fail in the field. ESD can weaken a chip without causing immediate failure. Over time, normal operation stresses the damaged area until it fails completely.

Note: Even a single ESD event can reduce the lifespan of power chips in Telecom Power Systems. You protect your investment by using proper ESD safeguards.

ESD Threats in Telecom Power Systems

Environmental Risks

You face several environmental risks when you work with Telecom Power Systems. Static electricity builds up more easily in dry air. Low humidity inside telecom cabinets increases the chance of ESD events. If you do not control the climate, you create a perfect environment for static buildup. Dust and debris also collect on surfaces and act as insulators. These materials hold static charges and release them when you touch equipment.

You should pay attention to the ESD Protected Area (EPA) in your workspace. If you do not follow EPA guidelines, you increase the risk of ESD. You need to use antistatic mats, wrist straps, and proper footwear. These tools help you discharge static safely. You also need to monitor temperature and humidity. A simple humidity sensor can alert you when the air gets too dry.

Tip: Keep humidity between 40% and 60% in your telecom cabinet. This range reduces static buildup and lowers ESD risk.

Vulnerable Points

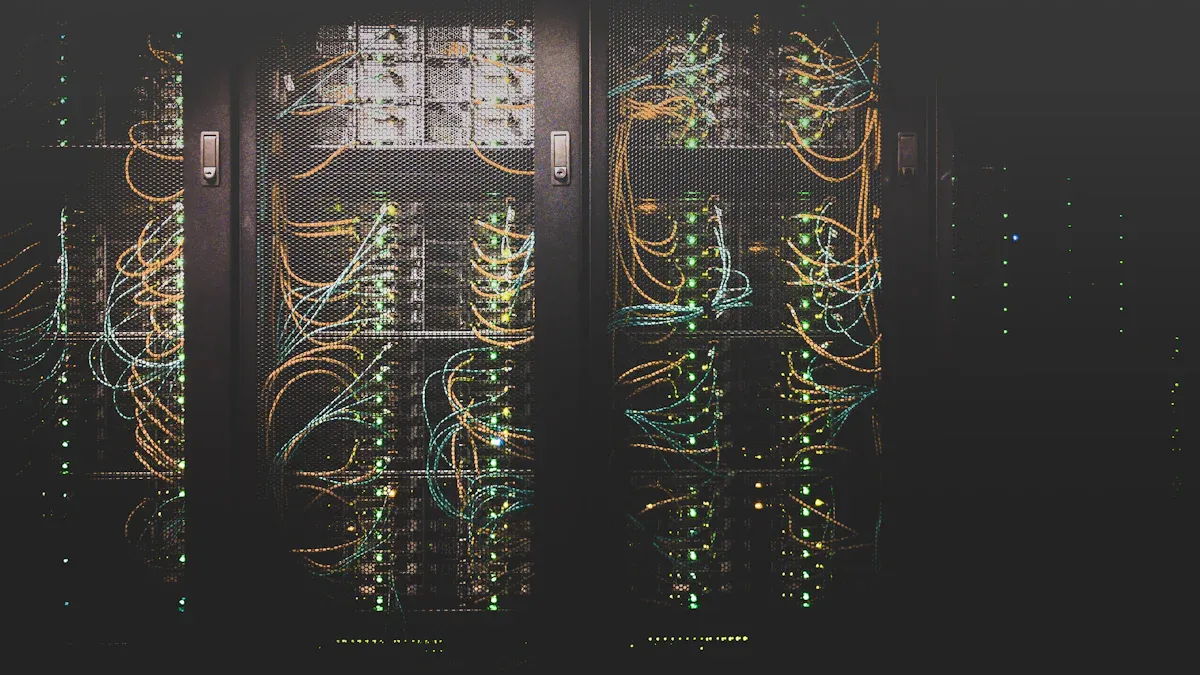

Some parts of Telecom Power Systems are more vulnerable to ESD than others. Power distribution boards handle high currents and often have exposed connectors. When you plug or unplug cables, you can discharge static directly into sensitive circuits. Control circuits, which manage voltage and current, use chips that are very sensitive to ESD.

You should also watch out for front-panel interfaces and test points. These areas see frequent human contact. Even a small static charge can damage chips connected to these points. Pay special attention to grounding paths. If you have poor grounding, ESD can travel through unexpected routes and damage multiple components.

Most vulnerable points include:

Power distribution boards

Control circuits

Front-panel connectors

Test points

Grounding connections

You protect your system by identifying these weak spots and applying extra ESD safeguards.

ESD Circuit Design

Protection Devices

You need to select the right protection devices to defend your circuits from ESD. In Telecom Power Systems, you often use transient voltage suppression (TVS) diodes. These diodes react quickly to voltage spikes. When ESD strikes, a TVS diode clamps the voltage and diverts the surge away from sensitive chips. You can also use polymer ESD suppressors. These devices absorb and dissipate static charges. They work well for repeated ESD events and help protect connectors and data lines.

A multi-layer protection strategy gives you the best results. You combine TVS diodes, polymer suppressors, and sometimes metal oxide varistors (MOVs). Each device responds to different types of surges. This layered approach covers a wider range of threats. You protect both high-speed data lines and power rails in Telecom Power Systems.

Tip: Place protection devices as close as possible to the entry points of your circuit. This placement stops ESD before it reaches critical components.

PCB Layout

Your printed circuit board (PCB) layout plays a big role in ESD protection. You want to keep traces short and direct. Long traces act like antennas and pick up static charges. Route sensitive signal lines away from connectors and exposed edges. Use ground planes under critical areas. This design shields your circuits and provides a low-resistance path for ESD to flow safely to ground.

You can also add guard traces. These traces run alongside sensitive lines and connect to ground. They catch stray charges before they reach your chips. Avoid sharp corners in your PCB layout. Sharp angles concentrate electric fields and increase ESD risk.

Here is a quick checklist for ESD-safe PCB layout:

Keep traces short and direct.

Use ground planes under sensitive circuits.

Add guard traces next to critical lines.

Avoid sharp corners and right angles.

Place protection devices near connectors.

Grounding Methods

Grounding forms the backbone of ESD protection in Telecom Power Systems. You need to create a low-impedance path from your equipment to earth ground. Use wide, short ground straps or copper bars. Thin wires add resistance and reduce the effectiveness of your grounding system.

You should connect all metal parts of your cabinet to a common ground point. This practice prevents voltage differences that can cause ESD currents to flow through your circuits. For materials that cannot be grounded, such as plastic panels or isolated conductors, ionization techniques offer extra protection. Air or nitrogen ionizers neutralize static charges on these surfaces. Ionization works alongside grounding to safeguard your equipment. This dual strategy ensures that even non-conductive materials do not become sources of ESD.

Note: Regularly inspect your grounding connections. Loose or corroded joints weaken your ESD protection and put your Telecom Power Systems at risk.

Best Practices for Telecom Power Systems

Device Placement

You improve ESD protection by placing devices thoughtfully inside your cabinet. Position sensitive chips and control circuits away from entry points, such as connectors and front panels. You reduce the risk of ESD reaching these components when you keep them distant from areas with frequent human contact. Arrange protection devices, like TVS diodes, close to connectors and exposed lines. This placement stops surges before they travel deeper into your system. You also benefit from grouping similar components together. When you organize your layout, you simplify maintenance and inspection.

Tip: Place ESD protection devices at every cable entry and near high-risk connectors. This strategy blocks static before it can damage your equipment.

Impedance Reduction

You lower ESD risk by minimizing impedance in your grounding paths. Use wide copper straps or bars for ground connections. Thin wires add resistance and weaken your protection. You should keep ground paths short and direct. Avoid unnecessary bends or loops. When you connect multiple cabinets, link their grounds to a single point. This method prevents voltage differences that can cause ESD currents to flow through your circuits. You also improve safety by using conductive materials for mounting and support structures.

Method | Benefit |

|---|---|

Wide ground straps | Lower resistance |

Short ground paths | Faster ESD dissipation |

Single-point grounding | Prevents ground loops |

Maintenance

You maintain strong ESD protection by inspecting your system regularly. Check all grounding connections for corrosion or looseness. Replace damaged straps or wires immediately. Clean dust and debris from surfaces, as these materials hold static charges. You should test your ESD protection devices during scheduled maintenance. Use an ESD simulator to verify that TVS diodes and suppressors respond correctly. Upgrade your protection devices when you add new equipment or change your cabinet layout. Keep records of inspections and repairs. This habit helps you track trends and spot recurring issues.

Note: Regular maintenance ensures that your Telecom Power Systems stay protected against ESD threats year-round.

Standards and Testing

ESD Standards

You need to follow established ESD standards to protect telecom power systems. These standards set clear requirements for ESD protection levels and testing procedures. The most widely recognized standards include:

IEC 61000-4-2: This standard defines ESD immunity testing for electronic equipment. It specifies test voltages, discharge methods, and acceptance criteria.

ANSI/ESD S20.20: This standard provides guidelines for developing an ESD control program. It covers grounding, personnel training, and protective equipment.

Telcordia GR-1089-CORE: This standard addresses ESD requirements for telecom network equipment. It includes both test methods and performance criteria.

You should review these standards when designing or upgrading your telecom cabinet. They help you select the right protection devices and layout strategies. Compliance with these standards also ensures your equipment meets industry expectations.

Tip: Always check for updates to ESD standards. New revisions may introduce stricter requirements or improved testing methods.

Testing Methods

You must verify that your ESD protection works as intended. ESD testing uses controlled discharges to simulate real-world events. You can use the following methods:

Contact Discharge Test: You apply a probe directly to exposed points, such as connectors or metal surfaces. This test checks how well your system handles direct ESD strikes.

Air Discharge Test: You bring a charged probe close to the device without touching it. This method simulates ESD events that jump through the air.

System-Level Testing: You test the entire cabinet or subsystem under realistic conditions. This approach reveals weaknesses that may not appear in component-level tests.

You should document all test results. Use a table to track compliance:

Test Type | Pass/Fail | Notes |

|---|---|---|

Contact Discharge | ||

Air Discharge | ||

System-Level |

Note: Regular ESD testing helps you catch problems early. You maintain system reliability and meet industry standards by following a strict testing schedule.

You protect your telecom power systems and power chips by using strong ESD safeguards. Layered protection, smart circuit design, and regular validation all play key roles. Regular checks help you catch problems early and keep your equipment reliable.

Regular validation prevents both sudden and hidden damage.

Advanced tools like Synopsys PrimeESD help you spot and fix ESD issues before they cause failures.

Exhaustive analysis boosts long-term reliability.

Stay updated on standards and always follow best practices. Take steps now to strengthen your ESD protection.

FAQ

What is the most common cause of ESD in telecom cabinets?

You often see ESD caused by human contact. Static builds up on your body or clothing. When you touch connectors or boards, the charge discharges into sensitive components. Dry air and dust increase this risk.

How do TVS diodes protect power chips?

TVS diodes react quickly to voltage spikes. When ESD strikes, the diode clamps the voltage and diverts the surge away from your power chip. This action prevents permanent damage.

How often should you test ESD protection systems?

You should test ESD protection during every scheduled maintenance. Use an ESD simulator to check devices like TVS diodes. Regular testing helps you catch weak points before failures occur.

Can you use regular cleaning products on ESD-protected areas?

Avoid regular cleaners. Many contain chemicals that leave residues and increase static buildup. Use only antistatic cleaning solutions and lint-free cloths. This practice keeps your ESD-protected areas safe.

See Also

Ensuring Consistent Power Supply for Telecom Equipment

Safeguarding Equipment Using Outdoor Telecom Cabinets

Ensuring Correct Voltage Levels in ESTEL Communication Cabinets

Understanding the Power System of ESTEL Telecom Cabinets

Design Specifications for ESTEL Telecommunication Cabinet Structures

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA