The Essential Guide to Electrical Cabinets and Their Uses

Electrical cabinets and enclosures are important for protecting electrical systems. They keep parts safe from dust and water damage. This protection helps ensure safety and good performance. The demand for these enclosures is increasing. In 2023, the market was worth $7.91 billion. It is expected to grow by 6.56% each year, reaching $13.95 billion by 2032. In the U.S., the market may grow from $2.10 billion in 2025 to $3.08 billion by 2030. This growth rate is about 7.91% yearly. These numbers show the need for strong electrical protection tools.

Key Takeaways

Electrical cabinets keep systems safe from dust, water, and harm.

There are different types, like wall-mounted, floor-standing, and modular.

Picking the right size, material, and rating (IP or NEMA) is important.

Custom cabinets handle special needs, like bad weather or unique setups.

Checking and fixing cabinets often helps them last and avoids big repairs.

Understanding Electrical Cabinets and Enclosures

What are electrical cabinets and enclosures?

Electrical cabinets and enclosures are protective boxes for electrical parts. They keep equipment safe from dust, water, and other dangers. These boxes help electrical systems work safely by stopping accidents. They also block access to prevent shocks. Rules like IEC 60529 and NEMA set standards for how strong and secure these enclosures must be.

Key differences between an electric cabinet and an electrical enclosure.

Electric cabinets and electrical enclosures are not the same. Electric cabinets hold complex systems like circuit breakers and control panels. They often have doors and locks for safety. Electrical enclosures, however, are a general term for any protective box. They can be small, like junction boxes, or large, like modular enclosures.

Electric Cabinet: Made for holding advanced systems.

Electrical Enclosure: Any box that protects electrical parts.

Importance of electrical cabinets for safety and efficiency.

Electrical cabinets are important for safety and keeping systems working well. They protect equipment from damage, saving money on repairs. By locking parts inside, they stop accidents and keep people safe. For example, Mesa Technologies uses Phoenix Contact enclosures to protect traffic systems. These enclosures have custom designs printed on them, making work easier for technicians.

Electrical cabinets and enclosures help power systems stay safe and efficient. They keep parts working properly, reduce downtime, and improve performance.

Types of Electrical Cabinets and Enclosures

Wall-mounted electrical enclosures

Wall-mounted electrical enclosures are small and flexible boxes for electrical parts. They are attached to walls, saving floor space in tight areas. These enclosures are used in homes, businesses, and factories. They protect systems from dust, water, and accidental touches. Many have doors with hinges for easy access and locks for safety.

They come in different sizes and materials like steel, aluminum, or plastic. For example, NEMA 4 enclosures keep water out, making them great for outdoor use. NEMA 1 enclosures are for indoor spaces where less protection is needed.

Tip: Use wall-mounted enclosures for small setups or to save space.

Floor-standing electrical cabinets

Floor-standing electrical cabinets hold bigger and more complex systems. They are common in factories and industrial places with lots of wiring and panels. These cabinets are strong and built to last in tough conditions.

Important features include size, material, and IP rating. Higher IP ratings mean better protection from dust and water, ideal for outdoor use. Custom options like vents and windows make them more useful. Following safety rules ensures they work well and are reliable.

Metric | Description |

|---|---|

Size and Dimensions | Should fit equipment, allow airflow, and be easy to access. |

Material Type | Affects strength and fit for specific environments. |

IP Rating | Shows how well it blocks dust and water, important for performance. |

Customization Options | Adds features like vents or windows to meet specific needs. |

Access and Security Features | Helps with maintenance and keeps parts safe. |

Junction boxes and modular enclosures

Junction boxes and modular enclosures organize and protect electrical wires. Junction boxes are small and shield wire connections. Modular enclosures are larger and can grow with the system. These are used in industries like energy, IT, and manufacturing.

Recent examples show their usefulness. Rittal LLC made a wall-mounted modular box with cooling for factories. Pratley created a flameproof junction box for risky areas. These designs show how adaptable these enclosures are for different jobs.

Note: Modular enclosures can grow or change to fit new needs.

Custom electrical enclosures for special needs.

Custom electrical enclosures are made for specific tasks. Standard enclosures may not work for all needs. These custom boxes are built with the right size, materials, and features. They are perfect for jobs in industries like aerospace, healthcare, and renewable energy. These industries need to protect delicate equipment in tough conditions.

Why pick custom enclosures?

Custom designs solve problems like extreme heat, corrosion, or tight spaces. For instance, a solar company might need UV-resistant enclosures for complex wiring.

Main advantages of custom electrical enclosures include:

Better Protection: Custom designs guard against environmental dangers.

Higher Efficiency: Special layouts make repairs easier and save time.

Flexibility: They fit unusual equipment sizes and setups.

Custom enclosures are used in many areas:

Medical Equipment: Keeps machines safe in clean environments.

Marine Industry: Protects systems from saltwater damage.

Data Centers: Holds servers with built-in cooling systems.

One example is offshore wind farms using custom enclosures. These boxes handle bad weather and keep power running smoothly. Custom solutions improve safety, performance, and lifespan for electrical systems.

Tip: Work with skilled makers to create enclosures that follow rules and meet your needs.

Key Features of an Electrical Cabinet

Construction materials (steel, aluminum, plastic)

The material of an electric cabinet affects how strong it is. Common materials include steel, aluminum, and plastic. Steel is very strong and resists damage, making it great for factories. Aluminum is light and doesn’t rust, so it works well outdoors. Plastic is cheap and easy to shape but can’t handle high heat or heavy hits.

Feature | Plastic Electrical Enclosures | Metal Electrical Enclosures |

|---|---|---|

Durability | Less durable, breaks under heat or impact | Very durable, resists damage and wear |

Price | Cheaper with lower upfront costs | Costs more but lasts longer |

Customization Options | Easy to customize size, shape, and color | Customizable but at a higher price |

Picking the right material helps protect equipment and match the environment’s needs.

Safety features (locks, seals, ventilation)

Safety features keep equipment and people safe around electric cabinets. Locks stop people from opening them without permission. Seals block dust, water, and dirt from getting inside. Ventilation keeps the cabinet cool, stopping overheating and helping equipment work better.

For example, outdoor cabinets often have weatherproof locks and seals. These protect against rain, dirt, and extreme heat or cold. Such features lower the chance of equipment breaking or needing repairs. Good safety features make systems last longer and work better.

Tip: Look for strong locks and seals when buying outdoor enclosures.

Protection ratings (IP ratings, NEMA classifications)

Protection ratings show how well an electric cabinet guards its contents. IP ratings use numbers to show resistance to dust and water. For example, IP65 means no dust can enter, and it resists water jets. NEMA ratings cover more, like corrosion and harsh conditions.

These ratings help pick the right cabinet for the job. A NEMA 4X cabinet is perfect for outdoor, corrosive areas. An IP54 cabinet works indoors where less protection is needed. Knowing these ratings ensures the cabinet keeps equipment safe.

Note: Choosing the wrong rating can cause damage and safety problems.

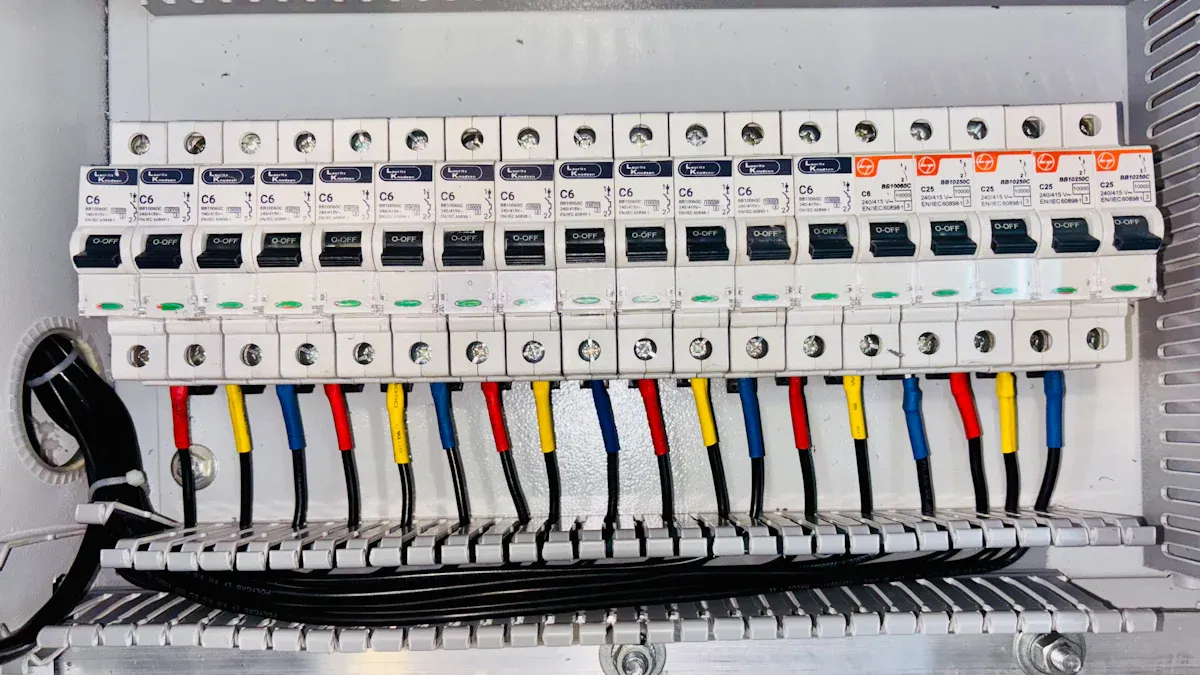

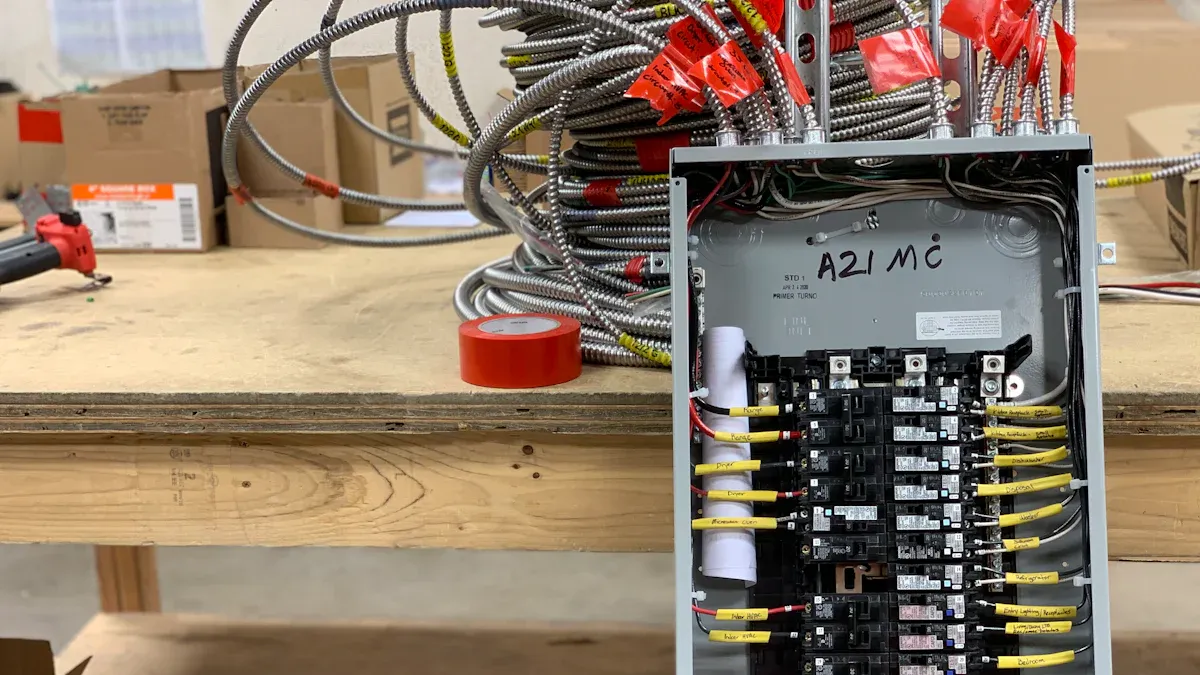

Internal components (panels, wiring, circuit breakers).

The parts inside an electrical cabinet are very important. They help the system work well and stay safe. The main parts—panels, wiring, and circuit breakers—keep things organized, connected, and protected.

Panels are the main support inside the cabinet. They hold devices like switches, relays, and terminal blocks. A good panel design makes repairs and upgrades easier. Neat panels also lower the chance of mistakes during maintenance.

Wiring links all the parts together. Good-quality wires make sure power flows smoothly. Wires with different colors help identify circuits quickly. Keeping wires neat prevents tangles and reduces electrical problems.

Circuit breakers are safety tools. They stop electricity if there’s too much power or a short circuit. This protects equipment and prevents fires. Newer circuit breakers can be monitored and reset remotely, making them more useful.

Following safety rules is key for designing these parts. Two important standards are:

Standard | Description |

|---|---|

NFPA 79 | Covers wiring and grounding for machines and control panels. |

UL 508A | Lists rules for control panels, as per NEC Article 409. |

Meeting these standards keeps cabinets safe and working well. By focusing on quality parts and good layouts, manufacturers make reliable and easy-to-use systems.

Tip: Check panels, wiring, and circuit breakers often to catch problems early and save on repairs.

Applications of Electrical Cabinets and Enclosures

Industrial and manufacturing sectors

Electrical cabinets are crucial in factories and industrial areas. These places have big machines, lots of wires, and high power needs. Cabinets keep electrical parts safe from dust, water, and damage. This helps machines run smoothly and prevents accidents. They also stop people from touching dangerous high-voltage parts.

In factories, cabinets hold control panels, circuit breakers, and wires. These parts manage power and help machines work well. Modular enclosures are often used on assembly lines. They can be adjusted to fit different equipment setups. Their strength and flexibility make them perfect for tough factory conditions.

Tip: Check and maintain cabinets often to avoid delays and boost efficiency.

Energy and utility industries

The energy industry depends on enclosures to protect important systems. These enclosures keep equipment in power plants and substations safe. They block out heat, rain, and dust, ensuring power runs without problems.

Enclosures are also used in utility buildings, chemical plants, and mines. They hold transformers, switchgear, and power boards, which control electricity flow. On streets, enclosures protect things like phone systems and EV chargers from weather.

Common uses in this field include:

New housing and infrastructure projects.

Solar farms and other renewable energy setups.

Oil and gas sites needing explosion-proof enclosures.

These examples show how enclosures keep energy systems safe and working well.

Commercial and residential buildings

In homes and offices, electrical cabinets organize and protect power systems. They hold circuit breakers, fuse boxes, and wires, stopping electrical dangers. Wall-mounted enclosures save space and are easy to access for repairs.

Big commercial buildings use floor-standing cabinets for complex systems. These cabinets often have locks and vents for safety and better performance. In homes, smaller enclosures keep systems safe from dust and accidental touches, making them last longer.

Note: Pick the right enclosure based on size, material, and protection level.

Electrical cabinets are key for keeping power systems safe and reliable in homes and businesses.

Transportation and infrastructure projects.

Electrical cabinets are important for transportation and infrastructure. They protect systems that keep roads, railways, and airports running. By shielding parts from weather, they ensure safety and reliability.

In transportation, these cabinets hold traffic controls, railway signals, and airport lights. For example, traffic signal cabinets protect wires and controllers. Without them, rain, dust, or heat could cause failures and safety issues.

Infrastructure projects also need electrical enclosures for public services. Streetlights, cameras, and EV chargers use weatherproof cabinets. These protect equipment from outdoor conditions, ensuring smooth operation.

Tip: Use cabinets with high IP or NEMA ratings for outdoor use.

Modern systems now include smart technology. Electrical cabinets work with IoT devices for remote monitoring. For example, smart railway systems use sensors to find problems and alert teams. This reduces downtime and improves performance.

Application | Example | Purpose |

|---|---|---|

Traffic Management | Traffic signal cabinets | Protects controllers and wiring |

Railway Systems | Signal control enclosures | Ensures safe and efficient train operations |

EV Charging Stations | Weatherproof charging enclosures | Shields charging units from environmental damage |

Smart Infrastructure | IoT-enabled cabinets | Supports remote monitoring and fault detection |

Electrical cabinets make transportation and infrastructure safer and more efficient. Picking the right enclosures helps systems last longer and need less maintenance.

Choosing the Right Electrical Enclosure

Evaluating environmental factors (dust, moisture, temperature)

Choosing the right electrical enclosure starts with knowing the environment it will be in. Dust, moisture, and temperature are key factors that can affect how well electrical equipment works and lasts. For example, in dusty places like factories or construction sites, enclosures need to resist dust well. In wet areas, like outside or near water, enclosures must protect against moisture to stop rust and electrical problems.

Temperature is also very important. High heat can cause overheating, while cold can make materials break easily. Enclosures with good ventilation or cooling systems help keep the right conditions for the equipment inside. For instance, enclosures with fans or heat exchangers are great for hot areas. Checking these environmental factors makes sure the enclosure protects well and helps the electrical equipment last longer.

Tip: Always check the specific environmental conditions before picking an enclosure to avoid extra repairs or replacements.

Understanding IP and NEMA ratings

IP and NEMA ratings are important for knowing how much protection an enclosure gives. The IP (Ingress Protection) rating, defined by IEC 60529, uses two numbers to show resistance to solids and liquids. For example, an IP65 rating means the enclosure is dust-tight and can handle water jets. NEMA ratings focus on how well the enclosure is built and how it protects against the environment, including corrosion and gasket strength.

Rating Type | Description |

|---|---|

NEMA | Rates protection against corrosion, gasket aging, and material entry. |

IP | Classifies resistance to solid objects and liquids, as per IEC 60529. |

Compliance | UL needs independent testing; NEMA relies on manufacturer compliance. |

Knowing these ratings helps users pick the right enclosure for their needs. For example, a NEMA 4X enclosure is good for outdoor areas with corrosion, while an IP54 enclosure works for indoor and outdoor areas needing moderate protection. This knowledge ensures the enclosure meets safety and performance needs.

Key points to remember:

NEMA ratings focus on environmental protection and quality.

IP ratings focus on resistance to dust and water.

Both systems help users choose enclosures for different situations.

Note: Always check the rating to make sure the enclosure fits the application’s needs.

Selecting the right size and material

The size and material of an enclosure greatly affect how well it works and lasts. Picking the right size makes sure all parts fit well, with enough space for airflow and future upgrades. Crowding an enclosure can cause overheating and maintenance issues. For example, a large electric cabinet is best for power distribution, while smaller enclosures are good for compact setups.

Choosing the right material depends on the environment and use. Steel enclosures are very strong and work well in industrial settings. Aluminum enclosures resist rust and are light, making them great for outdoor use. Plastic enclosures are cheap and easy to customize but may not handle tough conditions well.

Material Type | Strengths | Ideal Applications |

|---|---|---|

Steel | Very durable, impact-resistant | Industrial and manufacturing areas |

Aluminum | Light, rust-resistant | Outdoor and marine environments |

Plastic | Affordable, easy to customize | Indoor setups with few hazards |

Choosing the right size and material makes sure the enclosure protects the equipment well while meeting the specific needs of the job.

Tip: Think about future expansion needs when picking the size of the enclosure.

Balancing customization needs and budget.

Customizing an electrical enclosure helps meet specific needs. But, it’s important to balance customization with costs. This ensures the enclosure is useful without being too expensive. Factors like design, materials, and extra features affect this balance.

Assessing Design Complexity

Complex designs cost more to make. For example, enclosures with many compartments or unique shapes need special tools. Simplifying the design can lower costs while keeping key features. Focus on what the enclosure needs to do, not how it looks.

Choosing Cost-Effective Materials

The material used affects both cost and durability. Steel is strong and great for factories but costs more. Aluminum is light and resists rust, making it good for outdoor use. Plastic is cheap and easy to shape but isn’t as strong. Picking the right material keeps costs low while meeting environmental needs.

Material | Advantages | Cost Considerations |

|---|---|---|

Steel | Strong, impact-resistant | Costs more upfront |

Aluminum | Light, rust-resistant | Moderately priced |

Plastic | Cheap, easy to customize | Less durable |

Evaluating Additional Features

Extra features like locks, seals, and vents improve the enclosure. But, each feature adds to the price. Choose features that are necessary for safety and performance. For example, weatherproof seals are a must for outdoor use. Indoor enclosures may not need advanced locks.

Tip: Only add features that improve safety or performance to save money.

Collaborating with Manufacturers

Working with manufacturers can help save money. Many offer modular designs, so users can add or remove parts as needed. This reduces waste and lowers costs. Manufacturers can also suggest cheaper options, like using standard materials or sizes.

Long-Term Cost Considerations

Spending more upfront on a good electric cabinet can save money later. Strong materials and smart designs mean less maintenance and fewer replacements. Think about the total cost over time, not just the initial price.

Note: A good electric cabinet lasts longer, works better, and saves money in the long run.

Balancing customization and budget takes planning. By simplifying designs, picking affordable materials, and focusing on key features, users can get an enclosure that fits their needs without overspending.

Electrical cabinets and enclosures are crucial for keeping systems safe. They shield equipment from harm, prevent accidents, and keep things running smoothly. For example, lightning causes over 22,000 fires each year. Strong enclosures can stop lightning from damaging systems, avoiding data loss and downtime.

Picking the right enclosures means focusing on safety and strength. Using proper materials and features makes them last longer. By thinking about specific needs and the environment, people can choose enclosures that improve safety and performance.

FAQ

What is the difference between IP and NEMA ratings?

IP ratings show how well something keeps out dust and water. NEMA ratings look at more things like rust and how strong seals are. IP is about keeping stuff out, while NEMA checks how well it works in certain places.

Tip: Use IP ratings for inside systems and NEMA for outside or factory setups.

How do I choose the right material for an electrical enclosure?

Pick based on where it will be used. Steel is strong for factories. Aluminum doesn’t rust, so it’s good outside. Plastic is fine indoors where it’s safer.

Material | Best Use Case |

|---|---|

Steel | Factories, big machines |

Aluminum | Outside, near the sea |

Plastic | Inside, safe places |

Why are ventilation features important in electrical cabinets?

Ventilation stops things from getting too hot by letting air move. This keeps parts cool, so they don’t break or stop working.

Note: Cabinets in hot places need fans or coolers to stay cool.

Can electrical enclosures be customized?

Yes, you can get custom enclosures for special needs. You can change size, material, and add locks or seals. These changes make them safer and better for things like green energy or medical tools.

Example: Wind farms use sun-proof boxes to handle bad weather.

How often should electrical cabinets be inspected?

Check them often to keep them safe and working well. Experts say to look at them every six months. Check for wear, heat problems, or broken seals and locks.

Tip: Do checks during regular fixes to save time and money.

See Also

Essential Tips for Wiring and Choosing Telecom Cabinets

Choosing the Right Outdoor Electrical Cabinet for You

Complete Overview of Outdoor Communication Cabinets for Businesses

Telecom Cabinet Specifications for Effective Communication Equipment

Understanding Outdoor Enclosure Cabinets and Their Advantages

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA