ESTEL Beginner's Guide to DC Rectifier Systems

Have you ever wondered how devices like your phone or laptop get the steady power they need? That’s where a dc rectifier system steps in. It’s a device that converts alternating current (AC) into direct current (DC), delivering stable energy for electronics and industrial equipment. Without it, many of the gadgets and systems you rely on daily wouldn’t function properly. From powering telecommunications to ensuring smooth factory operations, this system is the backbone of modern power solutions.

Key Takeaways

DC rectifier systems change AC power into DC power. They give steady energy for electronics and machines.

Good parts like diodes, transformers, and filters make rectifiers work better and last longer.

Picking the right rectifier depends on your power needs, money, and trusted brands.

Controlled rectifiers keep voltage steady, which is great for delicate devices.

Using efficient rectifiers saves money over time on energy and repairs.

Basics of DC Rectifier Systems

Understanding the basics of a DC rectifier system is essential if you want to grasp how it powers modern devices. Let’s break it down step by step.

Working Principle

At its core, a DC rectifier system converts alternating current (AC) into direct current (DC). But how does this happen? It all starts with the nature of AC and DC. AC flows in both directions, while DC flows in just one. The rectifier system uses specific components to "rectify" or correct the flow of electricity, ensuring it moves in a single direction.

Here’s how it works:

AC Input: The system receives AC from the power grid or another source.

Rectification: The rectifier circuits, often made up of diodes, allow current to flow in only one direction. This process eliminates the alternating nature of AC.

Smoothing: After rectification, the current still has ripples. Filters, like capacitors, smooth out these ripples to produce a steady DC output.

Output: The result is a clean, stable DC supply ready to power your devices or industrial equipment.

A study on bridge rectifier circuits highlights how real-world data can improve the performance of these systems. For example, researchers used experimental setups to analyze capacitor behavior in rectifier circuits. They found that models trained on actual data performed better than those relying solely on simulations, achieving prediction accuracy with less than 2% error. This shows how practical insights can enhance the efficiency of rectifier systems.

Key Components: Diodes, Transformers, Filters

Every DC rectifier system relies on three main components: diodes, transformers, and filters. Each plays a unique role in ensuring efficient AC to DC conversion.

1. Diodes

Diodes are the heart of rectifier circuits. They act as one-way gates, allowing current to flow in only one direction. This property is what makes AC to DC conversion possible. Modern diodes are highly reliable, thanks to advancements in semiconductor technology. However, their design must account for factors like inrush currents and ripple current ratings to ensure durability.

2. Transformers

Transformers adjust the voltage of the incoming AC to match the requirements of the rectifier system. For instance, if your device needs a lower voltage, the transformer steps down the AC before it reaches the rectifier. Historically, transformers have evolved significantly. Early systems used rotary converters, but today’s solid-state transformers are far more efficient and compact.

Year/Period | Technology Used | Key Features and Efficiency Improvements |

|---|---|---|

1888 | Rotary Converter | Combined motor and generator functions, higher efficiency than motor-generator sets. |

Early 1900s | Mercury Arc Rectifiers | Transition from rotary converters, improved efficiency in AC to DC conversion. |

Present | Solid-State Rectifiers | Current technology for AC to DC conversion, widely used in modern applications. |

3. Filters

Filters smooth out the DC output by reducing ripples and fluctuations. Capacitors are the most common type of filter used in rectifier circuits. They store energy and release it gradually, ensuring a steady flow of current. Proper filter design is crucial for maintaining voltage stability and protecting sensitive electronic components.

Designing these components requires careful consideration. For example, manufacturers use a K Factor rating system to ensure transformers can handle harmonic load currents. Similarly, filters must be optimized to manage ripple currents effectively. These design choices directly impact the reliability and efficiency of the rectifier system.

Pro Tip: When choosing a rectifier system, always check the specifications of its diodes, transformers, and filters. High-quality components can save you from frequent maintenance and unexpected failures.

Types of DC Rectifier Systems

When it comes to DC rectifier systems, you’ll find several types designed to meet different power needs. Let’s explore the most common ones and how they work.

Single-Phase Systems

Single-phase rectifier circuits are ideal for smaller applications. They’re simple, compact, and often used in household electronics or low-power industrial setups. These systems rely on a single-phase AC input, which makes them easier to design and maintain. However, they’re not as efficient as their three-phase counterparts, especially when handling higher loads.

Single-phase systems typically use bridge rectifier circuits to convert AC to DC. These circuits consist of four diodes arranged in a specific configuration. The diodes ensure that the current flows in one direction, producing a pulsating DC output. To smooth this output, filters are added to reduce ripples and deliver steady energy. While single-phase systems are cost-effective, their efficiency drops when the load increases, making them less suitable for large-scale applications.

Three-Phase Systems

Three-phase rectifier circuits are the go-to choice for industrial environments. They handle higher loads and offer better efficiency compared to single-phase systems. These systems use three-phase AC input, which provides a more stable and continuous DC output. That’s why they’re commonly found in factories, data centers, and other high-power setups.

Here’s what makes three-phase systems stand out:

They reduce harmonic distortion, improving overall efficiency.

Load balancing ensures consistent performance across all phases.

Phasor diagrams help visualize voltage and current relationships, highlighting imbalances and phase shifts.

Technique | Voltage Deviation Reduction | Total Harmonic Distortion (THD) | Response Time (s) |

|---|---|---|---|

Proposed Inverter-based Strategy | 3.75% | 0.1 | |

DSTATCOM-based Compensation | 92.1% | N/A | 0.5 |

Adaptive Reactive Power Control | 88.5% | N/A | 0.3 |

Three-phase systems excel in maintaining power quality. They measure parameters like RMS voltage, true power, and power factor to ensure reliable performance. If you’re looking for a rectifier system for heavy-duty applications, this is your best bet.

Controlled vs. Uncontrolled Rectifiers

Rectifier circuits can be either controlled or uncontrolled, depending on how they regulate the DC output. Uncontrolled rectifiers use diodes to convert AC to DC. They’re straightforward and cost-effective but lack flexibility. Once the AC input is provided, the system produces a fixed DC output, which can’t be adjusted.

Controlled rectifiers, on the other hand, use power converters like thyristors or IGBTs. These components allow you to control the DC output by adjusting the firing angle. This flexibility makes controlled rectifiers ideal for applications requiring precise voltage regulation. For example, industries often use controlled rectifiers to manage energy distribution across multiple machines.

Tip: If you need a rectifier system for sensitive equipment, go for a controlled option. It offers better voltage regulation and reduces power loss.

Output Characteristics of DC Rectifier Systems

When you’re evaluating a DC rectifier system, understanding its output characteristics is key. These characteristics determine how well the system performs in real-world applications. Let’s dive into the details.

DC Waveforms

The output of rectifier circuits isn’t always a perfect, smooth DC signal. Instead, it often starts as a pulsating waveform. This happens because the rectification process converts AC into DC but leaves behind some ripples. Filters, like capacitors, help smooth these ripples, creating a more stable output.

Here’s a breakdown of common waveform types you might encounter:

Waveform Type | Description |

|---|---|

Input Current (Ii) | Shows the characteristics of the input current in the power factor correction (PFC) circuit. |

Diode Current (Id) | Illustrates how the diode behaves during operation. |

Capacitor Current (Ic) | Highlights high-frequency components that can affect harmonic estimation. |

Harmonics Analysis | Focuses on second and fourth harmonics, with potential for future high-frequency measurements. |

These waveforms play a critical role in analyzing the performance of rectifier circuits. For example, harmonics can impact energy efficiency and system stability. By understanding these patterns, you can choose the right system for your needs.

Efficiency and Power Loss

Efficiency is a big deal when it comes to rectifier circuits. It tells you how much of the input energy is successfully converted into usable DC power. High efficiency means less energy is wasted as heat, which is great for both performance and cost savings.

Substation converters can achieve over 97% efficiency in rectifier mode.

Standards like EN 50328 help manufacturers test and optimize efficiency by measuring power losses under specific conditions.

Power loss, on the other hand, is the energy that doesn’t make it to the output. It’s usually lost as heat in components like diodes and transformers. Minimizing these losses not only improves efficiency but also extends the lifespan of your rectifier system.

Voltage Regulation

Voltage regulation ensures that the output voltage remains stable, even when the input or load changes. This is especially important for sensitive equipment that requires a consistent power supply.

Studies show that effective voltage regulation can mitigate faults during system contingencies. For example:

Scenario | Description | Outcome |

|---|---|---|

1 | No system contingencies | Baseline performance |

2 | Contingency introduced at t0=4.0s | Faults effectively mitigated |

3 | Contingency introduced at t0=4.0s | Faults effectively mitigated |

By maintaining stable voltage, rectifier circuits protect your devices and ensure reliable operation. If you’re working with sensitive electronics, this feature is a must-have.

Pro Tip: Look for rectifier systems with advanced power converters. They offer better voltage regulation and reduce power loss, making them ideal for demanding applications.

Practical Considerations for Choosing a DC Rectifier System

When selecting a DC rectifier system, you need to consider several practical factors to ensure it meets your specific needs. Let’s break it down into three key areas: power requirements, cost and budget, and brand reliability.

Power Requirements

The first thing to think about is your power needs. Different applications demand different levels of power, and choosing the wrong system can lead to inefficiencies or even equipment failure. For example, traditional rectifiers typically provide up to 48V DC, which works well for systems like 4G telecommunications. However, if you’re dealing with more advanced setups, such as 5G networks or industrial machinery, you might need a Class 4 rectifier that can deliver up to 450V DC. These systems offer twice the power of traditional ones and come with features like fault management and support for low-voltage wiring.

System Type | Voltage Output | Power Demand Comparison | Key Features |

|---|---|---|---|

Traditional Rectifiers | Up to 48V DC | Adequate for 4G systems | Safe for technicians, limited efficiency |

Class 4 Rectifiers | Up to 450V DC | 2x more power than 4G | Fault-managed, supports low-voltage wiring |

Understanding your power requirements helps you avoid overpaying for unnecessary features or underestimating your energy needs. Always assess the voltage and current demands of your equipment before making a decision.

Tip: If you’re unsure about your power needs, consult with an expert or refer to the equipment’s technical specifications. This can save you from costly mistakes.

Cost and Budget

Budget plays a huge role in choosing the right rectifier system. It’s not just about the upfront cost; you also need to consider operational expenses. Studies show that switching to DC-powered systems can lead to significant savings in the long run. For instance, DC systems are often more efficient than their AC counterparts, reducing energy waste and lowering electricity bills. This makes them a smart investment for businesses looking to cut costs.

Economic appraisals for high-voltage DC (HVDC) systems emphasize the importance of balancing initial investment with operational expenditure. While the upfront cost of a high-quality rectifier might seem steep, the long-term benefits—like reduced maintenance and energy savings—often outweigh the initial expense. A technical analysis comparing DC and AC-powered data centers highlights this point, showing how DC systems can optimize efficiency and reduce overall costs.

When evaluating costs, don’t forget to factor in potential savings from energy efficiency and reduced downtime. A cheaper system might save you money initially, but it could cost more in repairs and inefficiencies over time.

Pro Tip: Think of your rectifier system as a long-term investment. Spending a bit more upfront can save you a lot in operational costs down the road.

Brand Reliability: ESTEL

Finally, let’s talk about reliability. Not all rectifier systems are created equal, and the brand you choose can make a big difference. ESTEL is a trusted name in the industry, known for its high-quality rectifier circuits and power converters. Their systems are designed to handle a wide range of applications, from telecommunications to industrial automation.

Customer performance case studies highlight the importance of choosing a reliable brand. For example:

A case study on performance management shows how ESTEL systems consistently meet technical benchmarks, ensuring smooth operations.

Another study on infrastructure management reveals how ESTEL’s robust designs help reduce project delivery challenges, keeping systems running efficiently.

ESTEL’s commitment to quality and innovation makes it a top choice for businesses and individuals alike. Their systems are built to last, with advanced features that enhance energy efficiency and reduce power loss. Whether you’re powering a small office or a large industrial facility, ESTEL has a solution that fits your needs.

Why ESTEL? Their rectifier circuits are not only reliable but also backed by excellent customer support. This ensures you get the help you need, when you need it.

Choosing the right DC rectifier system doesn’t have to be overwhelming. By considering your power requirements, balancing costs with long-term benefits, and opting for a reliable brand like ESTEL, you can make an informed decision that meets your needs.

DC rectifier systems are the unsung heroes of modern power management. They ensure your devices and industries run smoothly by converting AC to DC efficiently. Whether you're powering a small gadget or a massive industrial setup, these systems play a vital role in delivering reliable energy.

For beginners, here are the key takeaways:

Energy Efficiency: High-power rectifiers are essential for reducing energy waste.

Versatility: They integrate seamlessly with renewable energy systems and electric vehicle technologies.

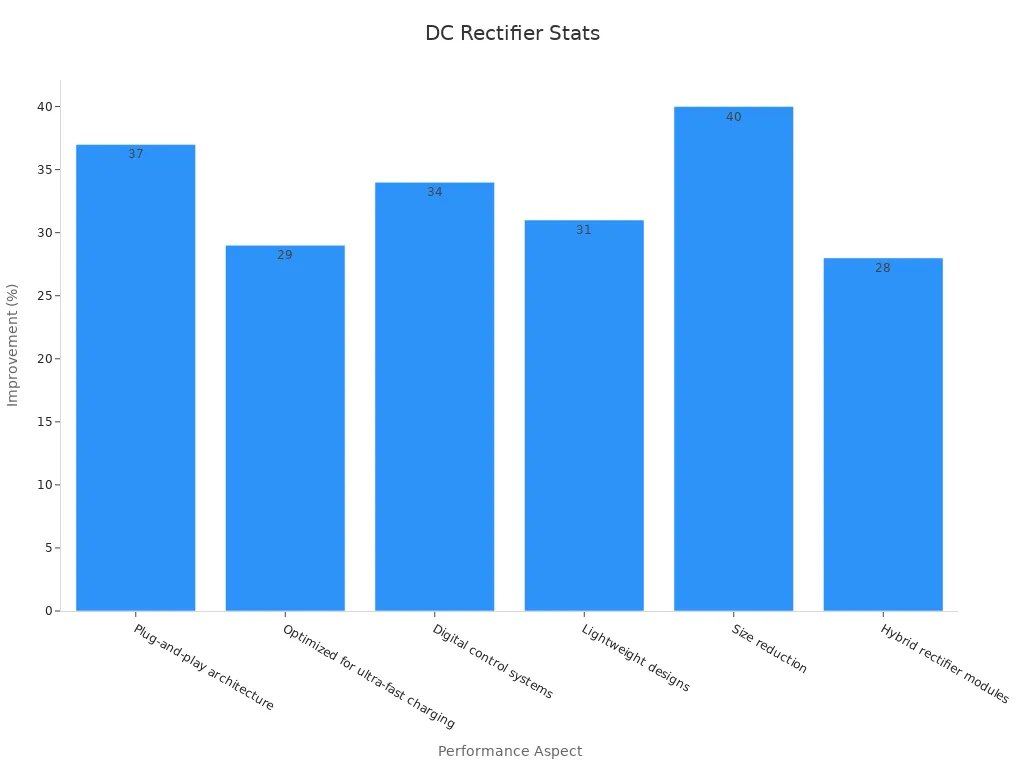

Technological Advancements: Features like plug-and-play architecture and ultra-fast charging optimize performance.

Factor | Description |

|---|---|

Energy Efficiency | High power rectifiers are essential for energy-efficient power management solutions across industries. |

Renewable Energy Integration | Increasing investments in renewable energy projects drive demand for rectifiers in solar and wind systems. |

Electric Vehicle Market Growth | The expansion of the EV market necessitates efficient power conversion systems, boosting rectifier demand. |

If you're looking for a reliable solution, ESTEL offers cutting-edge rectifier systems designed to meet diverse needs. Their focus on quality and innovation ensures you get the best performance and durability. Explore ESTEL’s offerings to find the perfect match for your power requirements.

FAQ

What is the difference between single-phase and three-phase rectifier systems?

Single-phase systems are compact and ideal for low-power applications, like household electronics. Three-phase systems handle higher loads and offer better efficiency, making them perfect for industrial setups. If you need consistent power for heavy-duty equipment, go with three-phase.

How do I know if I need a controlled or uncontrolled rectifier?

Controlled rectifiers let you adjust the DC output, which is great for sensitive equipment. Uncontrolled rectifiers are simpler and cheaper but lack flexibility. If precision matters, choose controlled systems. For basic needs, uncontrolled ones work fine.

Can DC rectifier systems work with renewable energy sources?

Absolutely! DC rectifiers integrate seamlessly with solar panels and wind turbines. They convert the variable AC output from these sources into stable DC power, ensuring efficient energy storage and usage. They're a key component in green energy setups.

How can I improve the efficiency of my rectifier system?

Use high-quality components like diodes and filters. Regular maintenance helps reduce power loss. Also, consider upgrading to systems with advanced voltage regulation features. These steps ensure better performance and lower energy waste.

Why should I choose ESTEL rectifier systems?

ESTEL offers reliable, durable, and energy-efficient solutions. Their systems are backed by excellent customer support and innovative designs. Whether you're powering a small device or a large facility, ESTEL ensures smooth operations and long-term savings.

See Also

Essential Insights for Newcomers on Telecom Power Supplies

Ensuring Correct Voltage Levels in Communication Cabinets by ESTEL

Methods for Calculating Power Systems and Batteries in Telecom

Integrating Solar Inverters and Batteries in Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA