What is Hot-Dip Galvanizing and Why It Is the Corrosion Protection Lifeline for Steel Structure for PV Panel

Hot-dip galvanizing covers steel with a layer of zinc by dipping it into molten zinc. This process helps shield the steel structure for PV panel from rust and damage. Solar installations face rain, sun, and wind every day. Without a strong barrier, steel can weaken fast. Galvanizing gives the steel a tough coat that fights corrosion and keeps the structure strong for years.

Key Takeaways

Hot-dip galvanizing keeps steel safe by adding a thick zinc layer. This layer stops rust and damage. It helps steel last longer outside.

The zinc layer is like a strong shield. It also gives itself up to protect steel. It still works even if the steel gets scratched or hurt.

This process covers every part of the steel. It even covers corners and hidden places. This gives full protection to PV panel supports.

Hot-dip galvanizing saves money over time. It lowers the need for fixing and taking care of steel. It lasts longer than paint or other coatings.

The zinc used in galvanizing can be recycled. It is good for the environment. This makes it a smart choice for solar projects.

What Is Hot-Dip Galvanizing?

Process Overview

Hot-dip galvanizing is a way to protect steel using zinc. First, workers clean the steel to get rid of oil and dirt. They use a special cleaner for this step. Then, they put the steel in a hot acid bath to remove rust. After that, the steel goes into a flux solution. This stops the steel from rusting before the next step.

The main part is dipping the steel in melted zinc. The zinc bath is very hot, about 860°F (460°C). The zinc sticks to the steel and makes a strong layer. When the steel comes out, it cools down and gets a shiny coat. Inspectors check the steel to make sure the zinc covers everything.

Tip: Hot-dip galvanizing works well for tricky shapes. It covers all parts, even corners and hidden spots. This is great for PV panel support structures that need full protection.

Here are the main steps:

Clean the steel with a special cleaner.

Put the steel in a hot acid bath.

Use flux to stop rust before coating.

Dip the steel in hot zinc.

Check the steel to see if it is fully coated.

The zinc layer makes a pattern called “spangle.” This shows good hot-dip galvanizing. The process is quick, saves money, and gives a tough coat that lasts outside.

Zinc Coating Science

The science of hot-dip galvanizing is about the zinc layer and how it protects. When steel goes into the melted zinc, a reaction happens. Zinc and iron mix and make several layers. These layers stick tightly to the steel and are hard to take off.

A pure zinc layer forms on top. This layer reacts with air and makes zinc oxide and zinc carbonate. These new layers block water and air from touching the steel. If the coat gets scratched, zinc still protects the steel by rusting first. This is called sacrificial or cathodic protection.

The table below shows how hot-dip galvanizing keeps steel safe:

Aspect | Explanation |

|---|---|

Process | Steel goes in melted zinc, making a thick, strong zinc layer |

Mechanical Protection | The zinc layer blocks things that cause rust from touching steel |

Electrochemical Protection | Zinc rusts first to protect steel, even if scratched |

Protective Compounds | Zinc makes ZnO, Zn(OH)₂, and zinc carbonate layers that slow rust and fix themselves if hurt |

Coating Thickness | Hot-dip galvanizing makes a thick coat, thicker than electroplating |

Coverage | The coat covers all parts, even corners and hidden spots |

Durability | The strong bond and tough coat stop damage |

Cost and Efficiency | Hot-dip galvanizing saves money, is faster than painting, and lasts a long time |

Additional Benefits | Makes steel harder to scratch, easier to weld, and better for recycling in PV panel structures |

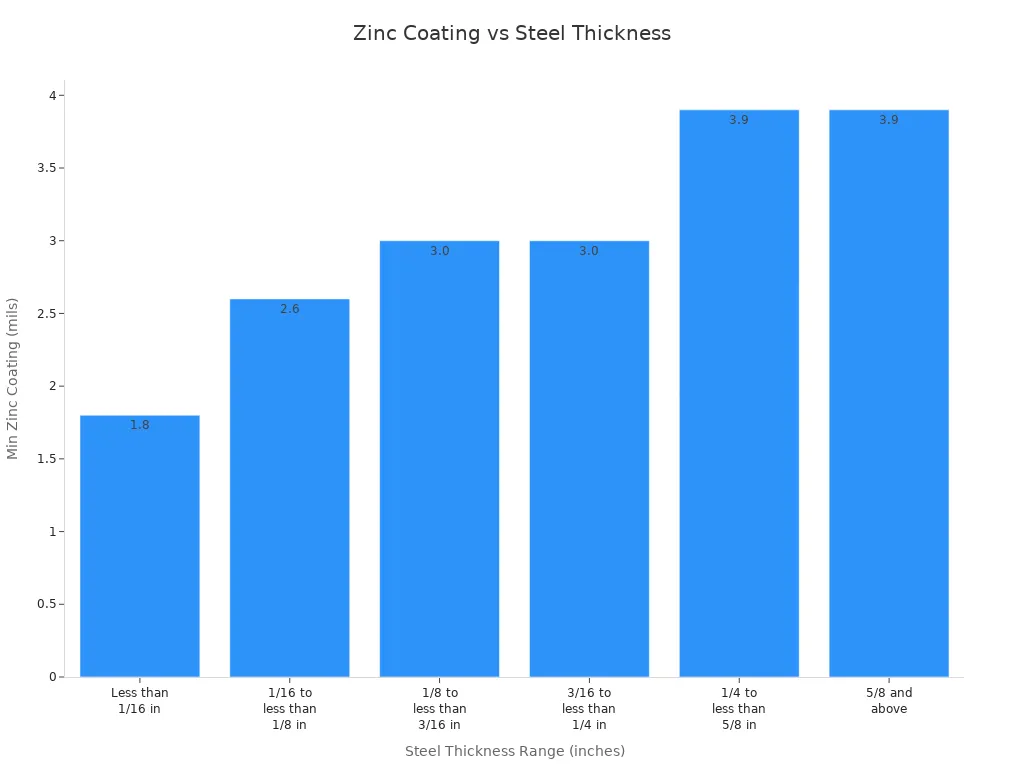

The thickness of the zinc coat is very important. Hot-dip galvanizing usually makes a coat between 43 and 86 microns thick. This is much thicker than other ways like electro-galvanizing. Thicker coats mean longer-lasting protection, sometimes over 50 years in the countryside. The chart below shows the least zinc coat thickness for different steel sizes in PV panel structures:

The zinc coat acts as a shield and also gives sacrificial protection. Even if the coat is damaged, zinc will rust before steel does. This double protection keeps steel strong and free from rust for a long time. That is why hot-dip galvanizing is the best choice for PV panel support structures.

Corrosion Protection Mechanisms

Barrier Protection

Hot-dip galvanizing creates a strong shield on steel. This shield blocks water, oxygen, and other harmful things from reaching the steel surface. The zinc coating forms several layers, including special intermetallic phases called delta and zeta. These layers bond tightly to the steel and make it hard for rust to start.

Scientific studies show that this zinc coating acts as both a physical and sacrificial barrier. The zinc layer stands up to scratches and bumps. Even if the surface gets damaged, the coating still protects the steel underneath. The quality of this barrier depends on how the steel is cleaned, the temperature of the zinc bath, and how long the steel stays in the bath. When these steps are done right, the coating lasts for decades, even outdoors.

Note: The barrier from hot-dip galvanizing can keep steel safe for over 50 years, even in tough weather.

The zinc layer blocks moisture and air.

The coating covers all parts, including corners and edges.

The bond between zinc and steel makes the shield extra tough.

Cathodic Protection

Zinc does more than just block rust. It also acts as a sacrificial anode. This means zinc will corrode first, saving the steel from damage. When the coating gets scratched, zinc gives up its electrons to protect the steel. This process is called cathodic protection.

Zinc sacrifices itself to keep steel safe.

The steel stays strong, even if the coating has small breaks.

This protection works as long as any zinc remains.

The zinc-iron alloy layers formed during galvanizing make this effect even stronger. These layers help the steel last longer, which is important for PV panel structures that face sun, rain, and wind every day.

Zinc Patina

Over time, the zinc surface reacts with air and water. This reaction forms a thin, dull layer called zinc patina. The patina acts as a second shield. It slows down corrosion and keeps the steel safe for many years.

Zinc patina forms naturally and does not need extra care. It blocks harmful chemicals and stops rust from spreading. Real-world data and tools like the Zinc Coating Life Predictor show that this patina can extend the life of steel structures, even in places with pollution or harsh weather.

The zinc patina helps PV panel supports stay maintenance-free and reliable, even after many years outside.

Benefits for Steel Structure for PV Panel

UV and Weather Resistance

Hot-dip galvanizing gives steel structures for PV panel a strong shield. The zinc coating blocks sunlight, rain, wind, and big temperature changes. This keeps the steel safe from breaking down outside for many years.

Solar farms often face very hot days and cold nights. The zinc layer does not crack or peel when it gets hot or cold. It also stands up to salt spray and pollution, which can make steel rust faster. In places with lots of sun and rain, zinc patina forms fast and adds more protection.

Note: The Roadrunner Solar Field in Texas uses lots of hot-dip galvanized steel. After many years, the steel structures for PV panel are still strong and have no rust, even in tough weather.

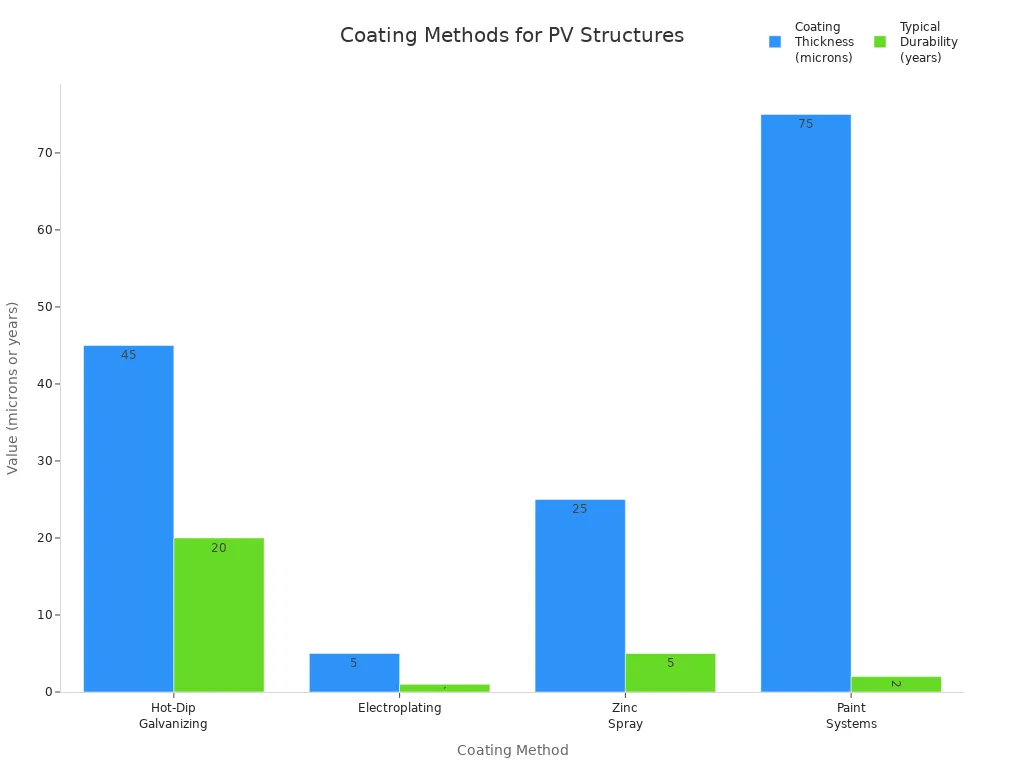

The chart below shows how hot-dip galvanizing is thicker and stronger than other coatings:

Coating Method | Coating Thickness (microns) | Adhesion Type | Application Method | Typical Durability (years) |

|---|---|---|---|---|

Hot-Dip Galvanizing | 45-200 | Metallurgical bond | Immersion | 20-100+ |

Electroplating | 5-25 | Electrodeposition | Electrical current | 1-5 |

Zinc Spray | 25-100 | Mechanical bond | Spray application | 5-15 |

Paint Systems | 75-250 | Adhesive | Brush/spray | 2-10 |

This table shows hot-dip galvanizing makes a thicker, stronger coat. The zinc layer bonds to the steel, so it does not flake off. This matters for steel structure for PV panel that must last in all weather.

Maintenance and Cost Savings

Hot-dip galvanized steel structures for PV panel need little care. The zinc coating protects the steel for many years, so owners do not spend much on repairs or checks.

Hot-dip galvanized steel posts can last over 75 years in most soils, much longer than most solar farms.

The corrosion rate is much lower than bare steel, and pitting is also much less. This means less rust and fewer problems underground.

The thick zinc layer resists scratches and damage from wind or moving during shipping and setup.

The coating stays strong in very hot or cold places, so it works in deserts, mountains, and cold areas.

Owners save money over time because they do not need to fix or replace the steel structure for PV panel as often.

Characteristic | Hot-Dip Galvanizing (HDG) | Electro-Galvanizing (EG) |

|---|---|---|

Initial Cost | Significantly higher (up to 5x) | Lower |

Whole-Life Cost | Lower due to minimal maintenance | Higher due to frequent maintenance |

Maintenance Needs | Minimal to none over decades | Regular and frequent maintenance |

Typical Lifespan | 25-50+ years | Shorter lifespan |

Tip: Hot-dip galvanizing costs more at first, but saves money later. Owners do not have to pay a lot to fix or replace steel that rusts.

Most care for hot-dip galvanized steel is simple checks. If workers see small bare spots or scratches, they can use zinc-rich paint to fix them. Big problems are rare, but thermal spraying or zinc-alloy soldering can repair them. These easy fixes keep the steel structure for PV panel working without big stops.

Long-Term Durability

Hot-dip galvanizing gives steel structures for PV panel a long, strong life. The zinc coating stops rust, even in soil or near water. The service life can be over 75 years, which is longer than most solar projects.

Aspect | Hot-Dip Galvanized (HDG) Steel | Uncoated (Bare) Steel |

|---|---|---|

Corrosion Protection | Strong above and below ground; lasts in tough spots | Rusts easily, especially near pollution and in soil |

Corrosion Rate Reduction | Much lower average corrosion and pitting rates | Higher corrosion and pitting rates |

Service Life in Soil | Over 75 years in most soils | Shorter, not always predictable |

Abrasion Resistance | Hard coating makes it tougher | Softer, easier to damage |

Temperature Resistance | Works from -40°F to 392°F | Not as good in extreme heat or cold |

Inspection | Easy to check the coating | Harder to spot rust |

Cost Consideration | Higher at first, lower over time | Cheaper at first, costs more later |

The zinc coating also helps the steel handle stress, so it is less likely to crack or break under heavy loads. The patina that forms over time adds more protection, even if the surface gets scratched. This means the steel structure for PV panel stays strong and safe, even in deserts, near the ocean, or in cities with lots of pollution.

Hot-dip galvanizing is the best way to protect steel in PV panel systems. It keeps the structure safe from rust, weather, and damage, so owners do not have to worry for many years.

Comparison with Other Methods

Paint and Coatings

Paint and powder coatings put a simple layer on steel. People use brushes, sprays, or powder to cover the steel. These coatings can look nice and come in many colors. But paint and powder coatings break down fast outside. Sun, rain, and wind can damage the coating. When paint cracks or peels, water and air touch the steel. This makes the steel start to rust.

Hot-dip galvanizing lasts much longer than paint. The zinc layer sticks to the steel and does not peel off. Paint needs to be fixed and replaced often. This means more money and work over time. Hot-dip galvanizing keeps the steel structure for PV panel safe for many years with little care.

Paint and powder coatings may look good at first, but they do not protect as long as hot-dip galvanizing.

Method | Durability (years) | Maintenance Needs | Environmental Impact | Cost Over Time |

|---|---|---|---|---|

Paint/Powder | 2-10 | High | Higher (repaints) | High |

Hot-Dip Galvanize | 20-100+ | Low | Low (recyclable) | Low |

Other Galvanizing Techniques

Other ways to galvanize steel are electro-galvanizing, pre-galvanizing, and metallizing. Electro-galvanizing uses electricity to put a thin zinc layer on steel. Pre-galvanizing coats steel before it is made into parts. Metallizing sprays zinc onto the steel.

Hot-dip galvanizing is different because it makes a thick, strong zinc coat. This coat forms when steel is dipped in melted zinc. It is tough and lasts a long time. Other ways make thinner coats that wear off faster. For example, electro-galvanized steel needs more fixing and does not protect cut edges well. Metallizing is good for fixing spots but does not last as long and needs careful work.

Hot-dip galvanizing saves money because it needs less fixing.

The zinc in hot-dip galvanizing can be recycled and is safe for nature.

Hot-dip galvanizing covers all parts, even corners and hidden places, so it gives full protection.

Hot-dip galvanizing is the best way to protect steel structure for PV panel in solar projects. It gives the strongest shield against rust, needs the least care, and is the best deal for the life of the structure.

Hot-dip galvanizing is the top way to protect steel structure for PV panel. Experts say it stops rust for a long time and saves money. It works well in bad weather like rain and wind. Many solar projects use hot-dip galvanizing because it follows tough environmental rules. It also helps the planet by being good for sustainability.

Experts also say to use stainless steel fasteners and keep parts apart for best results.

When you pick hot-dip galvanizing, solar projects last longer and need fewer repairs.

FAQ

What makes hot-dip galvanizing different from regular paint for steel?

Hot-dip galvanizing puts a thick zinc layer on steel. This layer sticks tightly to the steel. Paint just covers the outside and can peel off. The zinc layer keeps steel safe much longer than paint, especially outside.

What happens if the galvanized coating gets scratched?

The zinc layer still works if it gets scratched. Zinc will rust first and protect the steel. This means the steel stays safe under the zinc.

What is the expected lifespan of hot-dip galvanized steel in solar projects?

Hot-dip galvanized steel can last 20 to 75 years. How long it lasts depends on where it is used. In most solar farms, the steel lasts longer than the panels.

What are the main benefits of hot-dip galvanizing for PV panel structures?

Stops rust for a long time

Needs little care or fixing

Stands up to weather and sunlight

Covers all parts, even edges and corners

What is the environmental impact of using hot-dip galvanizing?

Hot-dip galvanizing uses zinc, which can be recycled. The process does not make much waste. Most of the steel and zinc can be used again, so it is good for the environment.

See Also

Solar Energy Storage Solutions Designed For Telecom Cabinets

Telecom Cabinet Battery And Solar Inverter Grid Connection

Understanding Outdoor Enclosure Cabinets And Their Advantages

Effective Ways To Safeguard Equipment Using Outdoor Cabinets

Exploring Outdoor Communication Cabinets And Their Key Benefits

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA