How to Choose the Right Telecom Cable for Your Project

Have you ever faced confusion when picking the right telecom cable for your project? You need to think about your project’s goals, the work environment, and what you might need in the future. If you match the wrong cable type or ignore key cabling factors, you risk project delays and extra costs. The right cabling can make a huge difference—projects that choose the best telecom cable see up to 75% faster cabling installation and up to 30% less cable preparation time. Check out these real-world improvements:

Cabling Feature | Project Benefit |

|---|---|

Faster cabling installation | Up to 75% time saved |

Smaller cable outside diameter | 60% reduction, easier cabling |

Quicker cable preparation | 30% faster cabling setup |

By following a clear, step-by-step process, you can confidently select the best cabling for your needs.

Key Takeaways

Start by understanding your project's speed, bandwidth, and device needs to pick the right cable type.

Choose cables with proper insulation and shielding to protect against interference and harsh environments.

Keep cable lengths within recommended limits to maintain strong, clear signals and avoid data loss.

Select cables and connectors that meet industry standards for safety, performance, and future upgrades.

Plan for future growth by choosing scalable cables like fiber optics that support new technologies and higher speeds.

Project Requirements

Speed & Bandwidth

You need to start by considering the speed and bandwidth your project demands. Modern cabling must handle much higher data transmission rates than in the past. For example, fiber optic cables can support multi-terabit capacities, which is up to 1,000 times more bandwidth than copper cables. This means you can move large amounts of data quickly and with less signal loss. The table below shows how cable broadband speeds have increased over the years:

Year | Downstream Capacity | Upstream Capacity |

|---|---|---|

1997 | 40 Mbps | 10 Mbps |

2008 | 1 Gbps | 100 Mbps |

2016 | 10 Gbps | 1-2 Gbps |

Today’s applications, like streaming and virtual reality, require more bandwidth than ever. Even though Netflix streaming needs less than 4 Mbps, gigabit speeds are now common, giving you plenty of room for future growth. High-quality cabling ensures your network can handle both current and future data transmission needs.

Devices & Applications

Think about the devices you plan to connect and the type of application and environment you expect. Different devices, such as IoT sensors, Wi-Fi access points, and smart lighting, have unique requirements for cabling. The table below highlights how cable categories support various needs:

Cable Category | Bandwidth (MHz) | Max Distance for 1G (meters) | Max Distance for 10G (meters) | PoE Power Support |

|---|---|---|---|---|

Cat 5e | 100 | 100 | N/A | Up to 25.5W |

Cat 6 | 250 | 100 | 37 | Up to 25.5W |

Cat 6A | 500 | 100 | 100 | >25.5W |

You should choose cabling that matches your devices’ data transmission and power needs. Certified cables help prevent signal loss and network failures, making sure your system runs smoothly.

Environment

Your installation environment plays a big role in cable selection. Moisture, chemicals, extreme temperatures, and electromagnetic interference can all affect cabling performance. For outdoor or industrial settings, you need cables with strong insulation and shielding to protect the signal. Always check for compliance with safety and regulatory standards like NEC, NFPA, RoHS, and FCC. These steps help you select telecom cable that will last and perform well, no matter the application and environment.

Telecom Cable Types

Choosing the right type of network cable starts with understanding the main cable categories used in telecom projects. Each type of cabling offers unique benefits for different environments and applications. You will often see three main types of data communication cables: Ethernet network cables, fiber-optic cables, and coaxial cables.

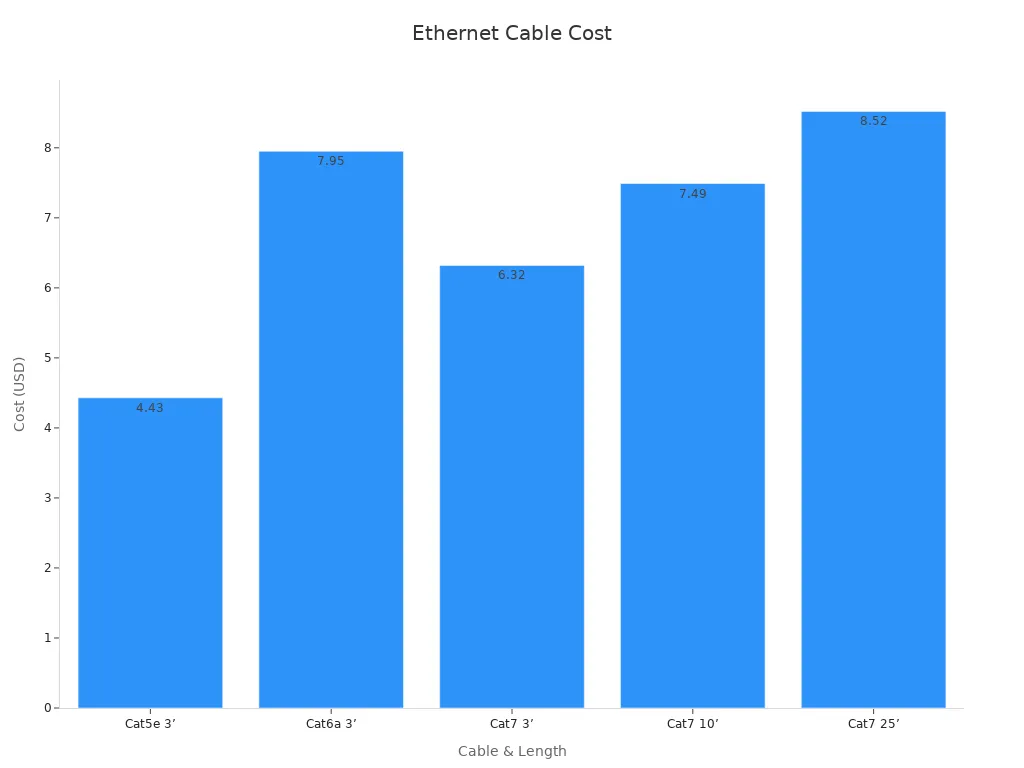

Ethernet Network Cables

Ethernet network cables remain the most common choice for connecting computers, switches, and routers. You can select from several cable categories, such as Cat5e, Cat6, Cat6a, Cat7, and Cat8. These best ethernet cables differ in speed, shielding, and cost. For example, Cat5e supports up to 100 MHz bandwidth and 100 Mbps speeds, making it suitable for basic home networks. Cat6 and Cat6a provide higher speeds, with Cat6a maintaining 10 Gbps over 100 meters. Cat7 and Cat8 are the best ethernet cables for data centers, offering even higher speeds and better shielding.

Feature | Cat5e | Cat6 | Cat6a | Cat7 | Cat8 |

|---|---|---|---|---|---|

Max Bandwidth | 100 MHz | 250 MHz | 500 MHz | 600 MHz | 2000 MHz |

Max Speed | 1 Gbps | 10 Gbps (55 m) | 10 Gbps (100 m) | 40 Gbps (50 m) | 40 Gbps (30 m) |

Shielding | UTP/STP | UTP/STP | UTP/STP | S/FTP | S/FTP |

Typical Use | Home/office | Office/enterprise | Enterprise | Data center | Data center |

You should keep cable length under 100 meters to avoid signal loss. The best ethernet cables use copper conductors, which provide reliable performance and easy installation. Cat6a and Cat7 cables maintain more consistent impedance, which helps reduce interference.

Fiber Optic Cables

Fiber-optic cables use light to transmit data, making them the top choice for high-speed and long-distance cabling. You will find these cables in backbone networks, data centers, and telecom infrastructure. Fiber-optic cables deliver much higher speeds and bandwidth than copper cables. They also offer low latency and strong resistance to electromagnetic interference. The telecom cable market shows that fiber-optic cables outperform copper for high-speed internet and data services. As network complexity grows, fiber-optic cabling ensures reliable performance and future scalability.

Coaxial Cables

Coaxial cables remain a practical option for TV, internet, and legacy systems. You will see these types of cables in environments where moderate interference exists. Coaxial cabling uses a copper conductor, insulation, a metallic shield, and an outer sheath. This design protects signals from external noise. Coaxial cables support bandwidths over 1 GHz and can deliver internet speeds up to 10 Gbps with DOCSIS standards. They are cost-effective and easy to install, making them suitable for areas without fiber-optic infrastructure. You should consider coaxial cables for legacy systems or when budget is a concern, but remember that fiber-optic cables can support higher speeds and lower latency.

Tip: Always match your cabling choice to your project’s speed, distance, and interference requirements. The right type of network cable ensures your telecom cable installation meets both current and future needs.

Cable Selection Factors

Selecting the right cabling for your project means understanding the key factors in choosing the best network cable. Each factor affects performance, reliability, and long-term value. Let’s break down the most important considerations for cable selection.

Cable Gauge & Size

Cable gauge, measured in American Wire Gauge (AWG), determines the thickness of the conductor inside your cabling. The gauge directly impacts insertion loss, resistance, and how far you can run a cable without losing signal quality. Lower AWG numbers mean thicker conductors, which reduce resistance and improve performance for longer distances and higher power delivery, such as with poe applications.

22 AWG and 23 AWG cables offer lower resistance and better performance for extended runs or high-power poe.

24 AWG is common for standard installations and provides a balance between cost and performance.

Industry standards like ANSI/TIA-568.2-D set a maximum dc loop resistance of 25 ohms for Cat 5e, Cat 6, and Cat 6A cables to ensure safe and efficient poe delivery.

Cat 6A cables use larger conductors, resulting in lower insertion loss and improved signal-to-noise ratio, which is ideal for longer cable runs and advanced poe needs.

Trade-offs exist between conductor size, cost, and performance, so you should match the gauge to your project’s requirements.

Tip: For longer cable runs or high-power poe, choose a thicker cable (lower AWG) to maintain performance and reliability.

Conductor Material

The material used for the conductor inside your cabling plays a major role in electrical performance and durability. Copper remains the industry standard for most telecom cable installations due to its excellent conductivity and flexibility. However, new materials like graphene are emerging, offering even higher conductivity and strength.

Property | Copper | Graphene |

|---|---|---|

Electrical Conductivity | 57-59 MS/m | Up to 100 MS/m |

Charge Carrier Mobility | ~4.5 cm² V⁻¹ s⁻¹ | ~15,000 cm² V⁻¹ s⁻¹ |

Tensile Strength | 200-400 MPa | 130,000 MPa |

Young's Modulus | 120 GPa | 1000 GPa |

Thermal Conductivity | 400 W m⁻¹ K⁻¹ | ~5300 W m⁻¹ K⁻¹ |

Melting Point | ~1085 °C | >2300 °C |

Copper provides reliable poe support and is easy to terminate. While graphene offers superior properties, it is not yet widely used in mainstream cabling. Experimental studies show that copper-silver alloys can increase mechanical strength but may reduce electrical performance due to electron scattering at the grain boundaries. For most poe and data applications, pure copper remains the best choice.

Insulation & Shielding

Insulation and shielding protect your cabling from physical damage, moisture, and electromagnetic interference (EMI). The right insulation material ensures safety and durability, especially in harsh environments. Shielding, such as foil or braided layers, blocks external noise and maintains signal integrity, which is critical for poe and high-speed data transmission.

Cable Type | Shield Layers | Shield Termination Method | Insulation/Shielding Features | Frequency Range Tested | Key Findings on Shielding Effectiveness (SE) |

|---|---|---|---|---|---|

Single overbraid | 1 | 360° clamp | Baseline insulation | 100 MHz - 2.8 GHz | Low noise, reference standard |

Unshielded TP | 0 | N/A | No shield | 100 MHz - 2.8 GHz | Used for comparison |

Single braid + overbraid | 2 | 360° soldering vs. pigtail | Insulated braid | 100 MHz - 2.8 GHz | 360° soldering improves SE; pigtails reduce SE |

Double braid + double overbraid | 4 | 360° clamp | Double insulation | 100 MHz - 2.8 GHz | Best SE with direct contact, no pigtails |

Multiple shielding layers and proper 360° termination provide the best protection against EMI. Pigtail terminations can cause fluctuations and reduce shielding effectiveness. Insulating films between shield layers may also lower performance. For poe and sensitive data lines, always select cabling with robust insulation and shielding.

Note: Environmental conditions like moisture, chemicals, and UV exposure demand weather-resistant insulation and UV protection. Mechanical strength is also vital for outdoor or industrial cabling.

Voltage & Current Rating

Voltage and current ratings define how much electrical power your cabling can safely carry. These ratings are especially important for poe systems, where cables deliver both data and power to devices like cameras, access points, and lighting.

Technical reports show that current carrying capacity (CCC) and power shutdown duration (PSD) directly affect cable risk and performance. For example, a cable with a CCC of 260 A and a PSD of 50 minutes has a moderate risk level. Exceeding these ratings can lead to overheating, signal loss, or even fire hazards. Always check the manufacturer’s specifications and ensure your cabling matches the poe requirements of your devices.

Compliance & Standards

Compliance with industry standards guarantees that your cabling meets performance, safety, and interoperability requirements. Standards like ISO/IEC 11801, ANSI/TIA-568, and EN-50173 define cable categories, performance benchmarks, and test methods.

ISO/IEC 11801 sets global requirements for telecom cable performance, including categories, connectors, and testing.

TSB-67 provides field testing methods and pass/fail criteria for 4-pair, 100-ohm UTP cabling, supporting poe and high-speed data.

EN-50173 adapts ISO/IEC 11801 for European markets and is mandatory for public projects.

Amendments to these standards introduce new cabling classes and improved measurement methods for advanced applications.

Following these standards ensures your cabling supports poe, high-speed data, and future upgrades. It also helps you avoid compatibility issues and ensures long-term reliability.

Remember: Environmental factors, insulation type, and compliance with standards all work together to influence network reliability. Studies show that insulation type and environmental conditions have the greatest impact on repair rates and network robustness, while conductor material and cable age play a smaller role.

By understanding these factors in finding the best network cable, you can make informed decisions for your telecom cable project. Careful cable selection based on these key factors in choosing will maximize performance, reliability, and value for your investment.

Choosing the Right Cable

Length & Signal Quality

When choosing the right cable, you must pay close attention to cable length. The distance your signals travel affects their strength and clarity. Longer cables cause more signal loss, which can lead to poor performance or even data errors. This loss, called insertion loss, increases as the cable gets longer. You also see a drop in the signal-to-noise ratio, which means noise can overpower your signals more easily. Crosstalk, or unwanted signals from nearby cables, becomes a bigger problem as length increases. Impedance mismatches between cables and connectors can add to this loss and create bit errors.

Insertion loss rises with cable length, reducing signal quality.

Signal-to-noise ratio drops as cables get longer, making signals less clear.

Crosstalk, especially power-sum NEXT, increases with length and affects signal integrity.

Impedance mismatches cause more noise and signal loss.

Bandwidth drops if you exceed length limits or use poor installation practices.

Environmental factors like temperature can require you to shorten cable runs.

You should always follow recommended length limits for each cable type. For example, most Ethernet cables have a maximum length of 100 meters. If you need longer runs, consider fiber optic cabling, which handles distance much better. Good cable installation practices, such as using high-quality connectors and avoiding sharp bends, help maintain signal quality.

Tip: Always measure your cable runs before installation. Staying within length limits ensures your signals remain strong and reliable.

EMI & Interference

Electromagnetic interference (EMI) can disrupt your signals and cause network problems. EMI comes from many sources, such as power lines, motors, and wireless devices. When you install cables near these sources, signals can pick up unwanted noise. This interference can lower signal strength, increase delay, and cause packet loss.

Empirical studies show that EMI affects communication systems by reducing signal strength and throughput. For example, in rail transit environments, researchers found that signal strength varied based on the environment and system. Throughput dropped slightly when trains passed by, and packet loss increased, though usually by less than 1%. These results show that EMI can impact your network, especially in complex or industrial settings.

You can reduce EMI by choosing the right cable shielding. Shielded cables block outside noise and protect your signals. Proper grounding and separation from power cables also help. When choosing the right cable, always consider the level of interference in your environment.

EMI Source | Impact on Signals | Solution |

|---|---|---|

Power lines | Signal loss, noise | Use shielded cables |

Motors/machinery | Crosstalk, packet loss | Separate cable routes |

Wireless devices | Bandwidth reduction | Proper grounding |

Note: Shielded cables and careful routing protect your signals from EMI. Always check your environment before starting cable installation.

Flexibility & Installation

Flexibility and installation needs play a big role in choosing the right cable. You must decide between stranded and solid cables. Stranded cables use many thin wires twisted together. They bend easily and work well for patch cables or areas where you move cables often. Solid cables use a single thick wire per conductor. They provide better performance for long runs and fixed installations.

Stranded cables: Flexible, best for short runs and movable connections.

Solid cables: Rigid, best for permanent installations and longer distances.

You should also consider the installation environment. Tight spaces, frequent movement, or harsh conditions may require more flexible cabling. Outdoor or industrial areas need cables with tough jackets and extra protection. Good planning makes cable installation easier and helps maintain signal quality.

Tip: Match cable type to your installation needs. Flexible cables make moves and changes easier, while solid cables deliver better performance for fixed runs.

When choosing the right cable, always balance length, interference, and installation needs. This approach ensures your signals stay strong and your network runs smoothly.

Best Network Cable for Future-Proofing

Scalability

When you plan for future network demands, you need to think about scalability. Scalability means your network can grow without major redesigns or expensive upgrades. The best network cable for future proofing supports more users, devices, and higher speeds as your needs change. Fiber optic cables stand out because they handle huge amounts of data and work well with new technologies. You can use the same fiber infrastructure for many years by upgrading the equipment at each end, which saves you from digging up and replacing cables.

Industry forecasts show strong growth in fiber optic and advanced copper cables. For example, the global network cable market is expected to grow from USD 22.5 billion in 2024 to USD 35.7 billion by 2033. This growth comes from digital transformation, 5G expansion, and smart city projects. You see more data centers and smart buildings using fiber optic and shielded twisted pair cables for high-density connections. The table below highlights key market trends:

Aspect | Details |

|---|---|

Market Size (2033) | USD 35.7 Billion |

Growth Drivers | 5G, smart cities, digital transformation |

Cable Types Preferred | Fiber optic, Cat 6A/7/8 |

Sustainability | Eco-friendly, recyclable materials |

By choosing the best network cable now, you avoid costly upgrades later. You also support futureproofing by selecting cables that meet new standards and higher speeds.

Supporting New Technologies

You want your network to support new technologies as they arrive. The best network cable for future proofing must handle faster speeds, more devices, and advanced applications like IoT and AI networking. Fiber optic cables have proven their value in real-world tests. In Chicago, a single pair of fibers carried hundreds of phone calls, and later upgrades increased capacity even more. Today, fiber optics support technologies like Dense Wavelength Division Multiplexing (DWDM), which lets you send multiple signals over one cable.

Copper cables also keep improving. Category 6A, 7, and 8 cables now support higher bandwidths and power delivery for devices like smart sensors and wireless access points. Testing services check these cables for performance, electromagnetic compatibility, and durability. You can trust cables with certifications from organizations like UL, which means they meet strict safety and performance standards.

To achieve futureproofing, look for cables that pass industry tests and support new protocols. This approach ensures your network can adapt to changes in technology and user needs. You also help the environment by choosing cables made with halogen-free and recyclable materials, which are becoming more common in smart city and IoT deployments.

Tip: Select cables that support both current and next-generation technologies. This strategy gives you flexibility and protects your investment as your network grows.

Cost & Quality Balance

Price vs. Performance

You face many choices when you compare telecom cables. Price often stands out, but performance matters just as much. Many people choose cables made with copper because they offer a good balance between cost and performance. Copper cables deliver strong data speeds and power, making them a popular choice for both homes and businesses. You might see cheaper cables that use less copper or lower-grade materials. These options can save money at first, but they often lead to problems later.

High-quality network cabling uses pure copper conductors. This type of cable gives you better signal strength, less data loss, and longer life. You also get more reliable Power over Ethernet (PoE) support. If you pick cables with less copper, you risk poor connections and more downtime. You should always check the cable’s specifications and look for trusted brands. A small increase in price can give you much better reliability and fewer repairs.

Tip: Investing in cables with more copper content pays off over time. You avoid frequent replacements and enjoy stable network performance.

Total Ownership Cost

You need to look beyond the sticker price when you plan your project. The total ownership cost covers every phase of your cable’s life. This includes design, installation, operation, maintenance, and even disposal. The Life-cycle Cost Analysis (LCCA) method helps you compare different cable options over their full lifespan. LCCA lets you see how choices like copper content, cable tray design, and installation methods affect long-term costs.

LCCA breaks down costs into categories such as materials, labor, and ongoing maintenance. You can use a decision matrix to focus on the most important factors for your project. For example, you might compare the cost of copper cables with alternatives, then weigh the benefits of better performance and reliability. During construction, you align contract documents with LCCA findings and review value engineering options. At project closeout, you receive training and documentation to help you manage costs. In the ownership phase, you monitor utility use and maintenance expenses to check if your choices deliver the expected savings.

Cost Phase | What to Consider |

|---|---|

Design | Cable type, copper content, layout |

Construction | Labor, installation, cable trays |

Operation | Energy use, network reliability |

Maintenance | Repairs, upgrades, downtime |

Ownership | Monitoring, documentation, disposal |

By using LCCA, you make informed decisions that save money and boost reliability. You also ensure your network stays strong and efficient for years.

Network Cables: Connectors & Accessories

Connector Compatibility

You need to pay close attention to connector compatibility when working with network cables. Using the right connectors ensures your cables deliver reliable performance and prevent costly errors. Industry-standard connectors like LC, SC, and MPO support a wide range of telecom applications. For example, the Waterproof Outdoor Drop Cable LC Connector works with LC duplex SFP transceivers, making it easy to integrate with systems such as WiMax, LTE, and 5G. Its IP67 rating protects against water and dust, so you can trust it in harsh outdoor environments.

Connector standards set important parameters like insertion loss and return loss. These standards help you avoid problems like high electrical resistance or overheating, which can happen if you use the wrong size or type. Technical studies show that using compatibility charts and proper assembly methods prevents connection errors. For instance, over-compression or incorrect lug sizing can lead to increased resistance and even fire hazards. You should always check compatibility charts and follow manufacturer guidelines to keep your network safe and efficient.

Tip: Choose connectors that match both your cable type and your equipment. This step reduces installation errors and keeps your network running smoothly.

Accessories

Accessories play a key role in the performance and longevity of network cables. You will find items like cable management clips, dust caps, and waterproof boots essential for protecting connections and organizing your setup. Accessories designed for outdoor use often feature waterproof, dustproof, and corrosion-resistant materials. These features help maintain uninterrupted data transmission, even in tough conditions.

You should also look for accessories that comply with industry standards such as ITU-T, IEC, TIA, and EIA. Standardized accessories ensure your network cables remain compatible and durable. Using the right accessories lowers maintenance costs and supports future upgrades. Real-world testing confirms that high-quality accessories help maintain bandwidth and reduce signal loss, which is vital for high-speed telecom networks.

Remember: Investing in proper accessories extends the life of your network cables and supports reliable network performance.

Cable Selection Checklist

Step-by-Step Guide

You can simplify cable selection by following a clear checklist. This approach helps you avoid mistakes and ensures your project meets technical and safety standards. Many successful projects, such as those in the UK rail sector, used step-by-step processes to improve efficiency and reduce costs. For example, engineers designed cables with better rodent protection and tested for insulation thickness, tensile strength, and compliance. These steps led to certified, cost-effective solutions.

Here is a practical checklist you can use:

Identify your project’s environment and application (indoor, outdoor, industrial, public space).

Choose the right conductor material, such as copper for most telecom needs.

Select insulation and shielding based on exposure to heat, oil, fire, or electromagnetic interference.

Check cable ratings for voltage, current, and temperature.

Match cable type to your devices and required bandwidth.

Plan cable routing to avoid sharp bends and interference sources.

Test cables for insulation resistance (at least 500 Mega Ohm per km at 20°C).

Record all installation parameters, including depth, width, and distances.

Use cable markers and maintain clear documentation for future reference.

Tip: Tailored training on cable specification, testing, and logistics can help you make better procurement and engineering decisions.

Quick Reference Table

You can use this table to quickly review the main points for cable selection:

Step | What to Check or Do |

|---|---|

Project Environment | Indoor, outdoor, industrial, public space |

Conductor Material | Copper, aluminum |

Insulation & Shielding | Heat, oil, fire, EMI protection |

Voltage & Current Rating | Meets device and safety requirements |

Bandwidth & Application | Supports network speed and device needs |

Connector Compatibility | Matches cable and equipment |

Routing & Installation | Avoids sharp bends, interference, and hazards |

Testing & Compliance | Insulation resistance, RoHS, and other standards |

Documentation | Record all parameters and use cable markers |

This checklist helps you select the right cable for your project and ensures reliable, safe performance.

Choosing the right telecom cable starts with understanding your project’s needs. You should focus on factors like network speed, bandwidth, cost, and environment. A checklist helps you avoid mistakes and ensures you cover every detail.

Tailor your cable choice to your application and environment

Consider long-term reliability and maintenance

Review commercial and industrial requirements separately

Factor in physical and chemical challenges

Always review your project specs and consult standards or experts when needed. The right cable choice gives you a reliable, cost-effective network that supports your goals. 🚀

FAQ

What is the maximum length for Ethernet cables?

You should keep Ethernet cables under 100 meters (328 feet) for best performance. Longer cables can cause signal loss and slower speeds. For longer distances, use fiber optic cables.

How do you protect cables from electromagnetic interference (EMI)?

Use shielded cables and keep them away from power lines or heavy machinery. Proper grounding also helps reduce EMI. Shielded cables block outside noise and keep your signals clear.

Can you mix different cable categories in one network?

You can mix cable categories, but your network will only perform as well as the lowest-rated cable. For example, if you use Cat5e and Cat6 together, your network speed will match Cat5e.

What is the difference between stranded and solid cables?

Stranded cables bend easily and work well for patch cords or movable connections.

Solid cables provide better performance for long, fixed runs inside walls or ceilings.

How do you know if a cable meets safety standards?

Check the cable jacket for markings like UL, RoHS, or ISO/IEC codes. These labels show the cable passed safety and performance tests. Always buy from trusted brands to ensure compliance.

See Also

Complete Handbook For Wiring And Choosing Telecom Cabinet Cables

Steps To Find The Perfect Size For Telecom Cabinets

Selecting The Optimal Mount For Outdoor Telecom Cabinets

Understanding The Distinction Between Wires And Cables In Telecom

Guide To Installing Telecom Cabinets On Poles With Safety Tips

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA