Tips for Picking the Perfect Power Supply for Harsh Environments

Operating in tough places can be challenging. Very hot or cold weather, water, and shaking can harm machines. This can cause expensive delays. Picking strong industrial power supplies helps keep systems working well. Bad power choices can break machines, cause dangers, and lower efficiency. You need industrial power supplies built to handle tough conditions and work steadily. Smart choices improve safety and help your systems last longer.

Key Takeaways

Pick power supplies that work in very hot or cold places. Choose ones rated from -40°C to +85°C for best use.

Check the IP rating to see if they block dust and water. IP67 or IP68 are great for wet or dusty areas.

Get power supplies with safety features like overvoltage and overcurrent protection. These keep them safe and working well.

Think about having backup power supplies to avoid losing power. This is important where power loss can cause big problems.

Do regular checks and cleaning to keep power supplies working longer. Remove dust and check wires to avoid issues.

Key Considerations for Harsh Environments

Choosing industrial power supplies for tough places needs careful thought. These choices help your machines work well in hard conditions. Below are the most important things to check.

Temperature Range and Thermal Management

Extreme temperatures can affect how long power supplies last. Check if the power supply works in your temperature range.

Regular power supplies work between -25°C and 50°C. Some need a wider range, like -40°C to +85°C.

Hot temperatures can wear out parts faster. Cold ones may cause problems.

At 70°C, many power supplies give only half their full power.

Cooling is also key. Pick power supplies with fans or heat sinks to stop overheating. Good airflow in your setup helps them work better.

Tip: For very hot or cold places, pick power supplies made for those conditions to avoid breakdowns.

Humidity and Moisture Resistance

Water in the air can harm power supplies without proper protection. High humidity can cause rust and make machines fail. Even small amounts of moisture can be risky.

Check the IP rating to see how well the power supply handles water. Below are two common IP ratings for wet places:

IP Rating | Description |

|---|---|

IP67 | Keeps out dust and water up to 1 meter deep for 30 minutes. Good for damp areas. |

IP68 | Keeps out dust and water deeper than 1 meter for long periods. Great for very wet places. |

These ratings show the power supply can handle wet conditions, making them good for outdoor or water-heavy jobs.

Note: Always match the IP rating to your environment to avoid damage.

Dust, Dirt, and Particle Protection

Dust and dirt can block vents and harm parts inside. In places with lots of particles, you need strong protection.

Choose power supplies with sealed cases or high IP ratings to keep out dust. An IP6X rating means no dust can get inside. This is useful for jobs like mining or construction where dust is everywhere.

Tip: Clean your power supply often to stop dust buildup and keep it working well.

Vibration and Shock Resistance

Tough places often have shaking or sudden impacts. These can harm power supplies by loosening parts or breaking circuits. If your machines work in busy areas like factories, trains, or building sites, you need power supplies that can handle these stresses.

Strong power supplies resist shaking and impacts to work well. Makers build them with tough cases, secure mounts, and strong parts inside. Pick power supplies tested in hard conditions to ensure they last.

Common Testing Methods for Vibration and Shock Resistance

To check if power supplies can handle shaking, makers use special tests. Here are two common ones:

Testing Method | Description |

|---|---|

Highly Accelerated Stress Screen (HASS) | A test that uses strong shaking to find hidden problems. It shows if the power supply can handle real-world stress. |

Burn-in Testing | A test that puts power supplies in tough conditions, like shaking, to find weak parts early. |

These tests copy real-life tough conditions. They help you pick power supplies that last longer and work better.

Tip: Always make sure the power supply passed vibration and shock tests. This proves it can handle tough jobs.

Features to Look For

When choosing power supplies for shaking and impacts, look for these features:

Reinforced Housing: Strong cases keep the inside parts safe.

Secure Mounting Options: Good mounts lower the effects of shaking.

Shock-Absorbing Materials: Soft materials inside protect parts from sudden hits.

By picking these features, you can avoid breakdowns and make your machines last longer. Good power supplies keep your work running, even in hard conditions.

Note: Check mounts and clean cases often to improve resistance to shaking and impacts.

Technical Specifications for Industrial Power Supplies

When picking an industrial power supply, knowing its specs is important. These details make sure it works well for your needs and stays reliable in tough conditions. Below are the main things to check.

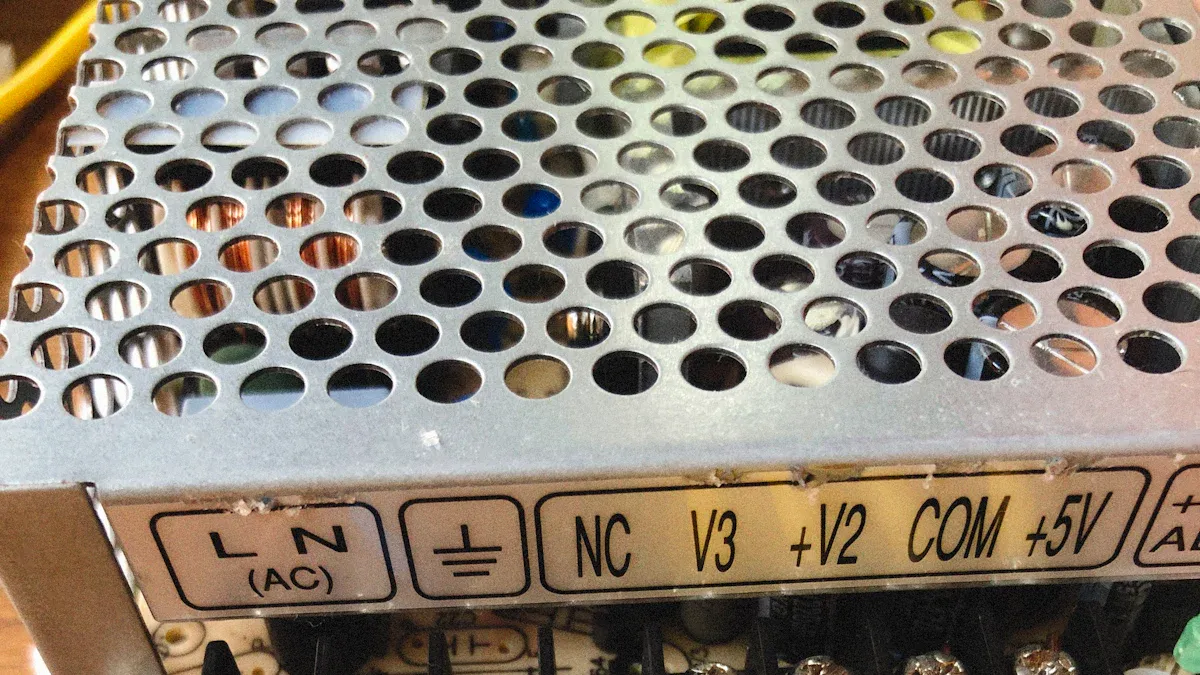

Voltage and Current Needs

It’s important to match the voltage and current to your equipment. Most industrial power supplies use one DC input, like 12 VDC, linked to AC mains. Also, check the maximum current. Make sure it can handle all your devices and extra parts.

Specification Type | Details |

|---|---|

Input Voltage | Needs a single DC input, like 12 VDC, connected to AC mains. |

Maximum Current | Must handle total current for devices and extras, e.g., 2 A for 24 Watts. |

Full-load Power Output | Should work well at full load without overheating. |

For AC-DC power supplies, the input range is usually 85~264 Vac. This works for most low or medium-power tasks. Common output voltages are 5, 12, 24, or 48 VDC. Custom designs or DC-DC converters can meet special needs.

Tip: Always check the output voltage and current to match your devices.

Power Efficiency and Energy Savings

Good energy efficiency lowers costs and saves power. Newer power supplies are small but very efficient. For example, AC-DC power supplies with 1 W to 49 W output meet strict efficiency rules. They work well while using less energy.

Power Supply Type | Output Power Range (Pout) | Minimum Average Efficiency in Active Mode | Maximum Power in No-Load Mode |

|---|---|---|---|

AC-AC External Power Supplies | Pout ≤ 1 W | ≥ 0.5 x Pout/1W + 0.160 | ≤ 0.21 |

AC-DC External Power Supplies | 1 W < Pout ≤ 49 W | ≥ 0.071 x ln(Pout/1W) - 0.0014 x Pout/1W + 0.67 | ≤ 0.10 |

Low Voltage External Power Supplies | 49 W < Pout ≤ 250 W | ≥ 0.880 | ≤ 0.21 |

Efficient power supplies cut electricity bills and make devices last longer. They create less heat, which is helpful for steady performance in critical tasks.

Note: Look for certified power supplies to meet energy-saving standards.

Load Capacity and Scalability

Power supplies for industry need to handle changing demands. They should work well at full load without overheating. They also need to grow with your business.

Key Feature | Description |

|---|---|

Scalability and Flexibility | Can adjust to more power needs as businesses expand. |

Modular Design | Lets you add or remove parts to fit system needs, saving resources. |

Energy Efficiency | Saves energy and cuts costs, boosting productivity. |

Modular designs are great for growth. You can add or remove parts to match your system’s needs. This saves money and avoids waste.

Tip: Pick a power supply with a boost feature, like 120% power for up to 50 °C. This helps with high power demands without losing performance.

By checking these specs, you can choose a power supply that fits your needs, saves energy, and grows with your business.

Stable Output and Low Ripple

Picking a power supply with steady output and low ripple is important. These features help your equipment work well and last longer. This is especially true for tasks like testing, calibration, or using precise electronics.

Why Stable Output is Important

Steady output gives your devices constant power without changes. Power changes can cause problems, lower efficiency, or even damage your equipment. Precise power supplies are better because they give accurate voltage. This makes them great for jobs like factory machines or medical tools.

For example, power supplies with top stability keep output steady. This improves data quality and lowers mistakes in important tasks. Whether you’re running a DC motor or lab equipment, steady power is a must.

Tip: Always check the power supply’s voltage range to match your devices.

Why Low Ripple Matters

Ripple means small, unwanted changes in the power supply’s output. Even small ripples can hurt how sensitive electronics work. Low ripple gives clean, quiet power, which is key for accurate testing and calibration.

Power supplies with less ripple are great for delicate electronics. They keep signals clear in communication systems and ensure exact readings in labs. Lower noise and better resolution make these power supplies essential for good power quality.

Features You Should Look For

When choosing power supplies for steady output and low ripple, check these:

Voltage Accuracy: Pick power supplies that keep voltage steady to avoid changes.

Ripple Ratings: Choose ones with very low ripple for clean power.

Noise Filtering: Get power supplies with noise blockers for better performance.

These features make your equipment more reliable and last longer. A good power supply prevents costly problems and keeps things running smoothly.

Note: Power supplies with advanced filters and controls are best for places needing high power quality.

Real-Life Uses

Steady output and low ripple are needed in many fields. For example:

Medical Tools: Helps diagnostic machines give accurate results.

Telecom Systems: Keeps signals clear in communication networks.

Factory Automation: Ensures machines work smoothly and reliably.

By focusing on these features, you can pick a power supply that fits your needs and works well for a long time.

Safety and Protection Features

Overvoltage and Undervoltage Protection

Power supplies in tough places can face voltage problems. Too much voltage can harm parts, while too little can stop devices from working. To avoid these problems, pick power supplies with built-in safety features.

These protections keep power systems safe and reliable.

New designs include these features to save space and money.

Advanced chips monitor systems and improve overall safety.

These features are very useful in industries where voltage changes happen often. Choosing a power supply with these protections helps keep your equipment safe and working well.

Tip: Make sure the power supply has both overvoltage and undervoltage protection to avoid expensive fixes.

Overcurrent and Short-Circuit Protection

Too much current or short circuits can cause overheating or fires. Power supplies with these protections can spot problems and shut down before damage happens.

Overcurrent protection stops extra current to prevent overheating.

Short-circuit protection blocks faults to protect the whole system.

Built-in solutions make systems safer and cut costs.

These features are key for keeping equipment and workers safe. They also help power supplies last longer by stopping damage from electrical issues.

Note: Choose power supplies with automatic reset options for easier and safer use.

Thermal Shutdown and Overheating Prevention

High heat can hurt power supplies and shorten their life. Thermal shutdown features turn off the power supply if it gets too hot. This stops damage and keeps things safe.

Safety rules now focus more on heat risks in solar systems.

Some connectors and devices can cause heat problems, showing the need for good heat control.

Studies show thermal shutdown features lower the chance of heat-related issues.

In hot places, pick power supplies with good heat control. These often have fans, heat sinks, or sensors to keep temperatures safe.

Tip: Check your power supply often for dust or dirt that could block airflow and cause overheating.

Noise Reduction for Sensitive Uses

In certain tasks, electrical noise can cause problems and mistakes. You need a power supply that reduces noise to keep your equipment working well. Noise, caused by EMI or RFI, can harm devices like medical tools, communication systems, and testing machines.

To lower noise, choose power supplies with built-in filters. EMI and RFI filters block unwanted signals, giving clean and steady power. These filters are important in places where clear signals matter. For example, in labs, low-noise power supplies help keep readings correct and data safe.

Shielding is also important for cutting noise. Power supplies with metal cases or electromagnetic shields stop outside interference from reaching sensitive parts. This is helpful in busy industrial areas with lots of electrical activity.

Grounding is another key factor. Good grounding stops stray currents from affecting your equipment. Always check if the power supply has strong grounding options to improve noise control.

When picking a power supply, look at its ripple and noise ratings. A low ripple rating means better performance for sensitive tasks. Makers usually list these details in the product datasheet, so read it carefully before buying.

Also, think about power supplies with advanced safety features. These not only protect your equipment from electrical issues but also help reduce noise by keeping output steady under different conditions.

Tip: Test the power supply in your real work setting to make sure its noise control meets your needs.

By focusing on noise reduction, you can protect your equipment and ensure it works well in tough situations.

Compliance with Standards and Certifications

Why Industry Standards Matter (e.g., UL, CE, RoHS)

Industry standards make sure power supplies are safe and reliable. Choosing a power supply with certifications like UL, CE, or RoHS shows it meets strict rules. These certifications prove the product passed tough tests and follows global safety laws.

To get certified, manufacturers follow these steps:

Find the right standards for the product.

Design the product to meet safety rules.

Test prototypes for safety and EMI/EMC issues.

Use third-party labs for certification.

Submit paperwork for approval.

Get certified and keep following the rules.

For example, UL certification checks for safety, while RoHS ensures no harmful materials are used. Certified power supplies protect your devices and meet industry rules.

Tip: Look for certification marks like UL or CE on the label to confirm compliance.

Environmental and Safety Certifications

These certifications show a product is safe and eco-friendly. Labels like Environmental Product Declarations (EPDs) explain a product’s impact on the environment. Businesses now care more about buying green products and following rules.

Feature | What It Means |

|---|---|

Credibility | EPDs show clear details about a product’s environmental effects. |

Market Demand | Buyers want products with environmental certifications. |

Competitive Advantage | EPDs make companies stand out as eco-friendly suppliers. |

Regulatory Compliance | Some areas require EPDs to meet local laws. |

Green Building Credits | Products with EPDs can earn points in programs like LEED. |

Sustainability Goals | EPDs help measure and improve a product’s environmental impact. |

Using certified power supplies helps meet eco-friendly goals and boosts your market position.

Note: Check for EPDs or similar labels to meet green goals and legal rules.

Regional and Application-Specific Rules

Different places and industries have their own rules. For example, medical devices need stricter safety checks than regular machines. Regional rules like CE in Europe or UL in North America ensure products meet local safety needs.

To follow these rules:

Learn the standards for your area and use.

Confirm the power supply meets these rules with documents.

Pick products tested by trusted labs.

Knowing and following these rules avoids legal trouble and keeps your equipment safe.

Tip: Ask experts or certification groups to confirm your power supply meets all needed rules.

Picking the Right IP Rating

When picking a power supply for tough places, know about IP ratings. IP (Ingress Protection) ratings show how well a device blocks dust and water. This helps you pick a power supply that fits your environment.

An IP rating has two numbers. The first shows how it blocks solids like dust. The second shows how it handles liquids like water. For example:

IP65: Blocks all dust and resists water jets.

IP67: Blocks dust and handles water up to 1 meter deep for 30 minutes.

IP68: Blocks dust and works in water deeper than 1 meter for long times.

To choose the right IP rating, think about your environment. For dusty places like building sites, pick a high first number, like IP6X. For wet areas, like outdoor setups, focus on the second number. IP67 or higher is good for these conditions.

Always check if the product meets industry rules. Certified IP ratings mean the power supply passed strict tests. This avoids failures and ensures it works well for a long time.

Tip: If your area has both dust and water, pick a power supply with high ratings for both, like IP68.

By learning about IP ratings, you can pick a power supply that works well in tough conditions.

Reliability and Redundancy in Power Supply Selection

Why Redundant Power Supplies Matter

Redundant power supplies keep systems running if one fails. This is very important where downtime can cause big problems or risks. Using redundancy ensures constant power, which is crucial for industrial power supplies in tough conditions. For instance, a UPS often has redundancy to handle sudden power cuts.

Redundancy also spreads the load across multiple sources. If one stops working, others take over smoothly. This is helpful in places like data centers, hospitals, and factories where power must not stop.

Tip: Check your power needs and environment to decide the right redundancy level.

Understanding MTBF and Equipment Lifespan

MTBF tells how reliable a power supply is. It shows the average time between failures, helping you know how long it will work without problems. A higher MTBF means better reliability and longer use, which is key for smooth operations.

MTBF shows the average time between failures for reliability.

It helps plan maintenance and predict how long it will last.

Higher MTBF often comes with longer warranties, showing product trust.

For example, power supplies with high MTBF reduce unexpected downtime. This is critical for jobs needing nonstop power, like telecom or vital systems.

Note: Always consider MTBF when choosing a power supply for long-term use.

Backup Systems and Safety Features

Backup systems and safety features ensure power stays on in critical jobs. A backup, like a UPS, gives temporary power during outages. This lets you safely shut down or switch to another source. Safety features shut down equipment automatically in unsafe conditions.

To boost reliability, follow a regular maintenance plan. Check, clean, and adjust equipment to find problems early. Predictive maintenance, using past data, can also prevent sudden failures.

Tip: Use a CMMS to plan and track maintenance tasks. This helps meet industry rules.

By focusing on redundancy, MTBF, and backups, you can build a strong power supply system. This ensures it fits your needs and works reliably for a long time.

Regular Inspections and Maintenance

Regular checks and care keep your power supply systems working well. By looking at your equipment often, you can spot problems early. This helps avoid expensive fixes or downtime. It also makes sure your systems stay strong in tough places.

Make a plan for maintenance. Add tasks like cleaning and testing parts. Dust can block vents and cause overheating. Use a soft brush or air spray to clean surfaces. Look for loose wires or broken connections that might stop power.

Testing is very important. Use tools to check voltage, current, and heat levels. Match the results with the maker’s guidelines. Strange changes may mean something is wrong and needs fixing fast. For backup systems like UPS, testing ensures they work when needed.

Watch for worn-out parts. Over time, things like fans and capacitors wear down. Replace them as the maker suggests. Old parts can lower performance and increase failure risks.

Write down every check and repair. Keeping records helps you track equipment health and plan fixes. Logs are useful for solving repeated problems.

Tip: Teach your team to notice signs of trouble early. This can stop small issues from becoming big problems.

By focusing on regular checks and care, you can make your power supplies last longer and work better in hard conditions.

Additional Features for Enhanced Performance

Remote Monitoring and Control Capabilities

Remote monitoring lets you check your power supply systems from anywhere. This is helpful in industries where downtime costs a lot. Watching power systems can stop outages, which often cause failures in data centers. These failures get more expensive every year. Using remote monitoring saves money and improves how systems work.

These systems show real-time data like voltage, current, and temperature. Alerts warn you about problems so you can fix them fast. For example, if an AC power supply gets too hot, the system can shut it off or adjust it. This keeps your equipment safe and working well.

Tip: Pick custom power supplies with remote monitoring to improve performance and meet your needs.

EMI/RFI Filtering for Signal Integrity

Electromagnetic interference (EMI) and radio frequency interference (RFI) can harm sensitive devices. Filters for EMI/RFI lower unwanted noise and keep signals clear. These filters are placed where power enters to block high-frequency noise.

They stop interference, which is key for automation and critical systems.

Errors from EMI can cause costly downtime in robots and sensors.

Filters meet global EMI rules, making systems more reliable.

For example, in robotic systems, EMI filters help robots move correctly and avoid mistakes. Adding these filters boosts efficiency and lowers repair costs.

Note: Always check filter details to ensure they work for your setup.

Compact Design and Mounting Options

Small power supplies save space and are easy to install. In tight industrial spaces, compact designs fit without losing performance. Many power supplies offer flexible mounts, like DIN rails or wall mounts, for easy setup.

A small design also makes moving equipment easier. For example, in mobile AC-powered tools, lightweight power supplies reduce the load. These designs often include features like vibration resistance, making them tough for harsh conditions.

Tip: Choose modular power supplies to save space and adjust to future needs.

Programmable Features for Precision and Adaptability

Modern industrial power supplies often have programmable features. These features let you adjust settings to fit your needs. They are great for changing environments.

Why Programmable Features Matter

Programmable power supplies let you control voltage, current, and timing. This helps your equipment work better, even if conditions change. For example, you can set voltage limits to protect delicate devices or change output for different tasks.

Tip: Choose power supplies with easy-to-use software for simple programming.

Key Programmable Features to Consider

Adjustable Voltage and Current Settings

Change the output to match your equipment’s needs. This saves energy and prevents damage.Remote Programming Options

Some power supplies let you adjust settings from far away. Use tools like RS-232, USB, or Ethernet to save time.Sequencing and Timing Control

Program the order and timing of power delivery. This avoids power surges and ensures smooth startups.Data Logging and Monitoring

Track performance data like efficiency and load. This helps you make smarter decisions.

Real-World Applications

Programmable power supplies are used in labs, factories, and telecoms. In labs, they provide exact voltage for testing electronics. In factories, they automate tasks, improving accuracy and saving time.

Note: Check if the programmable features work with your current systems to avoid problems.

By picking a power supply with programmable features, you can adapt to changes while keeping things efficient and precise.

Picking the right industrial power supplies needs careful planning. Think about how well it fits your environment, its technical details, safety features, and if it meets rules. Key things to check include output voltage, maximum current, and temperature range. These ensure it works reliably. For example, if your equipment needs changing power levels, choose a supply with strong output control and good cooling.

It’s important to balance strength, dependability, and performance. A power supply that fits your needs and follows industry rules will work safely and last longer. To choose wisely, talk to experts, study your power needs, and test supplies in real conditions. This helps lower risks and improve success.

Tip: Make a checklist to match power supply features to your needs.

FAQ

What is the most important feature to consider for power supplies in harsh environments?

Strength is key. The power supply must handle tough conditions like heat, cold, water, dust, and shaking. Pick one with high IP ratings, strong cases, and certifications like UL or CE for dependable use.

Tip: Match the power supply's features to your environment's challenges.

How do I determine the right IP rating for my application?

The IP rating depends on where you’ll use it. For dusty places, pick IP6X. For wet areas, choose IP67 or higher. If both dust and water are issues, IP68 gives the best protection.

IP Rating | Dust Protection | Water Protection |

|---|---|---|

IP65 | Full | Blocks water jets |

IP67 | Full | Works underwater up to 1 meter |

IP68 | Full | Works underwater beyond 1 meter |

Can I use a standard power supply in extreme temperatures?

No, regular power supplies can fail in very hot or cold weather. Use industrial ones made for wide temperature ranges, like -40°C to +85°C. These have cooling tools like fans or heat sinks to stop overheating.

Note: Always check the temperature range in the product details before buying.

How do I ensure my power supply is energy-efficient?

Choose power supplies with high efficiency ratings and certifications like Energy Star. These save energy, cut costs, and make less heat. Modular designs also help by adjusting power output to match what’s needed.

Tip: Pick power supplies with low ripple and noise for better energy savings.

Why is redundancy important in power supply systems?

Redundancy keeps power running if one unit stops working. This prevents downtime, which is crucial in industries like healthcare, telecom, and factories. Power loss in these areas can cause big problems or costs.

Tip: Use a backup power system with automatic switching for better reliability.

See Also

Best 10 Durable Outdoor Cabinets for Extreme Weather

Ensuring Consistent Power Supply for Telecom Enclosures

Choosing the Ideal Outdoor Electrical Cabinet for You

Enhancing Outdoor Cabinets with Power, Cooling, and Monitoring

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA