How to Install and Maintain ESTEL Low Voltage Distribution Cabinets

Proper installation and maintenance of electrical equipment ensure safety and optimal performance. When you handle an ESTEL low voltage distribution cabinet correctly, you reduce risks like electrical failures and enhance system reliability. These cabinets are designed to simplify power distribution while offering durability and efficiency. Their compact design and advanced features make them ideal for residential, commercial, and industrial applications. By prioritizing maintenance, you can extend the lifespan of your equipment and prevent costly repairs. Using these cabinets guarantees a balance of safety, functionality, and long-term value.

Key Takeaways

Learn about the parts of the ESTEL cabinet first. Knowing details helps with correct setup and use.

Pick a stable spot with good airflow for installation. This lowers risks and makes the cabinet last longer.

Check and clean the cabinet often to stop dust and damage. This keeps it working well and avoids overheating.

Write down all maintenance in a log. A record helps track problems and plan repairs on time.

Preparing for Installation

Understanding ESTEL low voltage distribution cabinet components

Before installation, you should familiarize yourself with the components of the ESTEL low voltage distribution cabinet. Knowing the specifications ensures proper handling and setup. Below is a table summarizing the key technical details:

Specification | Details |

|---|---|

Model | |

External Size | 750×750×1750mm (W×D×H) |

Internal Space | 650×650×1450mm (W×D×H) |

Material | Galvanized steel |

Ingress Protection | IP55 |

Cooling Capacity | 1500W (Air Conditioner), 150W/k (Heat Exchanger) |

Working Temperature | -40°C to +75°C |

Security Features | Anti-theft three-point locking system |

Rack Units | 32U, standard 19" rack |

These features highlight the cabinet's durability, security, and adaptability to various environments. Understanding these details helps you plan the installation process effectively.

Selecting a safe and ventilated installation site

Choosing the right location is critical for the cabinet's performance and longevity. Select a site that is well-ventilated to prevent overheating. Avoid areas prone to water intrusion or extreme weather conditions. Ensure the surface is stable and level to support the cabinet's weight. Keep the cabinet away from flammable materials and maintain a safe distance from transformers or other high-voltage equipment. A well-chosen site minimizes risks and ensures the cabinet operates efficiently.

Tip: Install the cabinet in a location that allows easy access for maintenance and inspections.

Gathering tools and reviewing safety guidelines

Having the right tools and following safety protocols are essential for a smooth installation. Gather tools such as screwdrivers, wrenches, a sturdy ladder, and a multimeter. Inspect each tool to ensure it is in good condition. Wear safety gear, including gloves and goggles, to protect yourself during the process. Adhere to documented safety measures, as shown in the table below:

Category | Guidelines and Safety Measures |

|---|---|

Stability and Security | Secure the cabinet to the pole with appropriate hardware to prevent movement. Ground the cabinet to protect against electrical hazards. |

Personal Safety Measures | Wear appropriate safety gear, use a sturdy ladder, and inspect tools before use. Avoid working in bad weather. |

Compliance with Regulations | Research local installation rules, obtain necessary permits, and adhere to electrical safety standards. |

Preventing Accidents | Identify potential hazards, maintain safe distances from transformers, and regularly inspect the installation site. |

By preparing thoroughly, you reduce the chances of errors and ensure a safe and efficient installation process.

Step-by-Step Installation Process

Positioning and securing the cabinet

Positioning the cabinet correctly is the first step in ensuring its stability and functionality. Start by placing the low voltage distribution cabinet on a flat, stable surface. Use a level to confirm that the cabinet is perfectly aligned. Uneven placement can lead to operational issues and compromise safety. If the cabinet is mounted on a pole or wall, ensure the mounting brackets are securely fastened.

To secure the cabinet, use bolts or screws that match the material of the mounting surface. Tighten them firmly to prevent movement or vibrations. For outdoor installations, consider using weather-resistant hardware to protect against corrosion.

Tip: Leave enough clearance around the cabinet for ventilation and easy access during maintenance.

Connecting power supply and grounding

Proper electrical connections are crucial for the cabinet's performance and safety. Begin by connecting the power supply to the designated terminals inside the cabinet. Use insulated tools to avoid accidental contact with live wires. Follow the wiring diagram provided by the manufacturer to ensure accuracy.

Grounding the cabinet is equally important. Attach the grounding wire to the grounding terminal and connect it to a reliable earth ground. This step protects the system from electrical surges and reduces the risk of shock. Inspect the grounding connection to confirm it is secure and free of corrosion.

Alert: Never skip grounding. It is a mandatory safety measure for all electrical installations.

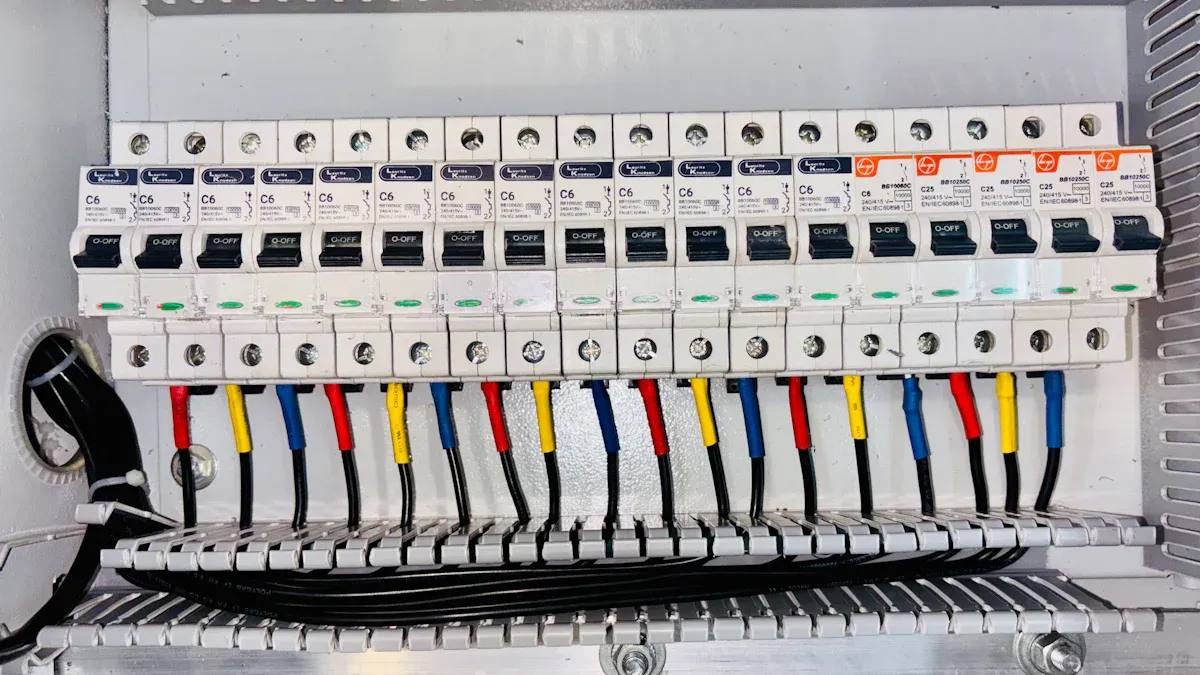

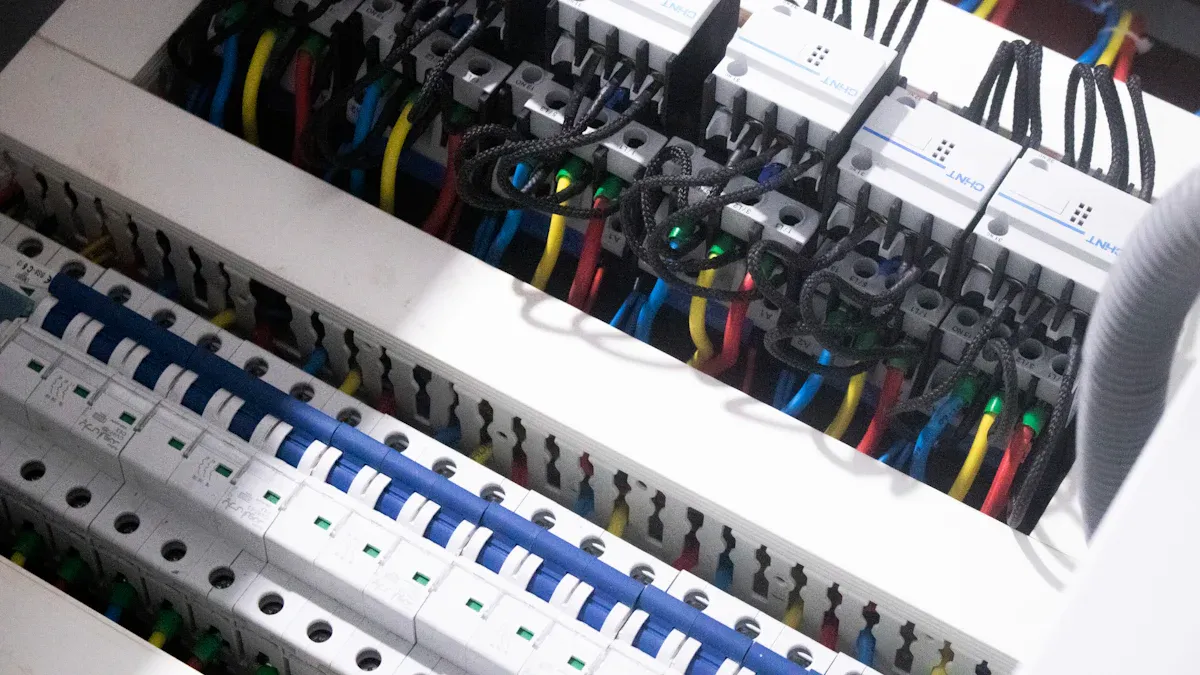

Installing and configuring components

Once the cabinet is positioned and powered, install the internal components. Begin with the main distribution panel, followed by circuit breakers, fuses, and other modules. Secure each component using the provided mounting hardware. Ensure all connections are tight and aligned with the wiring diagram.

After installation, configure the components based on your system's requirements. Adjust settings such as voltage limits, current thresholds, and alarm triggers. Use a multimeter to verify the accuracy of your configurations. Finally, test the system by powering it on and monitoring its performance. Look for any irregularities, such as flickering lights or unusual noises.

Note: Testing is essential to identify and resolve issues before the cabinet becomes operational.

Testing and debugging the system

Testing and debugging ensure your low voltage distribution cabinet operates safely and efficiently. This step helps identify potential issues before the system becomes fully operational. Follow these steps to test and debug your cabinet effectively:

1. Conduct a Visual Inspection

Start by examining the cabinet and its components. Look for loose connections, damaged wires, or improperly installed modules. Ensure all components align with the wiring diagram provided by the manufacturer. Check for signs of physical damage, such as dents or scratches, which could affect performance.

Tip: Use a flashlight to inspect hard-to-see areas inside the cabinet.

2. Verify Electrical Connections

Use a multimeter to test the voltage and current at each connection point. Confirm that the readings match the expected values outlined in the system specifications. Incorrect readings may indicate loose connections or faulty components.

Test the power supply terminals for stable voltage.

Check the grounding connection to ensure it is secure and functioning.

Inspect circuit breakers and fuses for proper operation.

Alert: If you detect irregular readings, disconnect the power supply immediately and recheck the wiring.

3. Perform Functional Tests

Power on the cabinet and observe its behavior. Monitor the system for any unusual noises, flickering lights, or overheating. Test each component individually to confirm it operates as intended. For example:

Activate circuit breakers to ensure they trip correctly under overload conditions.

Test alarm systems to verify they trigger at the configured thresholds.

Check cooling systems, such as air conditioners or heat exchangers, for proper operation.

Note: Keep a record of all test results for future reference.

4. Debugging Common Issues

If you encounter problems during testing, address them systematically:

Loose Connections: Tighten screws and terminals to secure electrical connections.

Faulty Components: Replace damaged modules, such as circuit breakers or fuses, with compatible replacements.

Configuration Errors: Revisit the settings and adjust voltage limits, current thresholds, or alarm triggers as needed.

Tip: Refer to the manufacturer's troubleshooting guide for specific solutions to common issues.

5. Final System Check

After resolving any issues, perform a final test to confirm the cabinet is fully operational. Monitor the system for at least 30 minutes to ensure stability. Verify that all components function correctly and that the cabinet maintains optimal temperature and ventilation.

Emoji Reminder: ✅ A successful test ensures your low voltage distribution cabinet is ready for reliable use.

By following these steps, you can confidently test and debug your cabinet, ensuring it delivers safe and efficient performance.

Maintenance Best Practices

Inspecting for physical damage and wear

Regular inspections are essential to ensure your low voltage distribution cabinet remains in optimal condition. Physical damage or wear can compromise the cabinet's performance and safety. Create a checklist to guide your inspection process and focus on critical areas. The table below outlines key inspection areas and actions you should take:

Inspection Area | Key Actions | Purpose |

|---|---|---|

Flashing | Inspect for rust or damage; ensure proper sealing | Prevent leaks and water intrusion |

Gutters | Examine for clogs, rust, holes; check drainage | Ensure effective water diversion and prevent foundation issues |

Roof Edges | Inspect for damage or gaps; secure loose materials | Maintain structural integrity and prevent water entry |

Signs of Water Damage | Look for stains, mold, or mildew | Identify prolonged moisture exposure and potential structural damage |

Insulation | Assess condition and thickness; check for wet insulation | Ensure energy efficiency and prevent heat loss |

Structural Integrity | Examine rafters and trusses for cracks or sagging | Ensure safety and stability of the structure |

Common Red Flags | Look for leaks, ponding water, missing flashing, and deteriorated gutters | Address issues promptly to prevent further damage |

By following this checklist, you can identify potential problems early and take corrective action before they escalate. Pay close attention to signs of water damage, as moisture can lead to corrosion and electrical failures.

Tip: Schedule inspections at least twice a year, especially after extreme weather conditions, to catch any damage promptly.

Cleaning to prevent dust and debris buildup

Dust and debris can accumulate over time, affecting the performance of your low voltage distribution cabinet. Regular cleaning helps maintain the cabinet's efficiency and prevents long-term damage. Start by inspecting the exterior for dirt, grime, or signs of corrosion. Use a non-abrasive cleaning agent and a soft cloth to clean the surface without damaging the finish.

For the interior, focus on removing dust from sensitive components like circuit breakers and wiring. Use a vacuum cleaner with a soft brush attachment or compressed air to clean hard-to-reach areas. Avoid using water or liquid cleaners inside the cabinet, as they can cause short circuits.

Routine cleaning not only improves the cabinet's appearance but also ensures that dust does not interfere with the functionality of the equipment. Studies show that regular cleaning can significantly reduce the risk of overheating and equipment failure.

Alert: Always disconnect the power supply before cleaning the interior to avoid electrical hazards.

Checking and tightening electrical connections

Loose electrical connections can lead to overheating, arcing, or even system failure. Regularly check all connections inside your low voltage distribution cabinet to ensure they are secure and functioning correctly. Use a torque wrench to tighten screws and terminals to the manufacturer's recommended specifications.

Adhering to technical standards is crucial for maintaining connection quality. Compliance with certifications like UL, RoHS, and ISO ensures that the electrical cables meet safety and performance standards. Proper installation practices and adherence to industry standards, such as ANSI/TIA and IEC, help prevent issues like signal interference and equipment damage.

Evidence Type | Description |

|---|---|

Certifications | Compliance with UL, RoHS, and ISO ensures cables meet safety and quality standards. |

Installation Practices | Proper installation reduces risks and improves system efficiency. |

Industry Standards | Adhering to ANSI/TIA and IEC prevents signal interference and equipment damage. |

Inspect connections for signs of wear, such as discoloration or fraying. Replace any damaged wires immediately to avoid further complications. Testing connections with a multimeter can help verify their integrity and ensure they meet the required voltage and current levels.

Note: Document your findings during each inspection to track the condition of your cabinet over time.

Monitoring for overheating or unusual noises

Monitoring your low voltage distribution cabinet for overheating or unusual noises is essential for maintaining its safety and performance. These issues often indicate underlying problems that, if left unchecked, could lead to equipment failure or even hazardous situations. By staying vigilant, you can address these concerns promptly and avoid costly repairs.

Signs of Overheating

Overheating can damage internal components and compromise the cabinet's functionality. Look for these common signs:

Unusually high temperatures: Use an infrared thermometer to measure the cabinet's surface temperature. Compare the readings to the manufacturer's recommended range.

Discolored or melted parts: Inspect wires, connectors, and other components for discoloration or deformation caused by excessive heat.

Burning smell: A distinct odor often signals overheating or electrical arcing.

Tip: Install temperature sensors inside the cabinet to monitor heat levels continuously. These sensors can alert you to rising temperatures before they become critical.

Identifying Unusual Noises

Unusual noises often point to mechanical or electrical issues. Pay attention to the following:

Buzzing or humming: This could indicate loose connections, overloaded circuits, or faulty transformers.

Clicking sounds: Frequent clicking may suggest a malfunctioning relay or circuit breaker.

Rattling or vibration: Loose screws or improperly secured components can cause these noises.

Alert: If you hear loud or persistent noises, disconnect the power supply immediately and inspect the cabinet for potential issues.

Steps to Address Overheating or Noises

Follow these steps to resolve overheating or unusual noises effectively:

Turn off the power: Always disconnect the cabinet from the power source before performing any inspections or repairs.

Inspect the components: Check for loose connections, damaged wires, or faulty parts. Tighten screws and terminals as needed.

Clean the cabinet: Dust and debris can block ventilation and contribute to overheating. Use a vacuum or compressed air to clean the interior.

Replace damaged parts: Swap out any components showing signs of wear or damage with compatible replacements.

Test the system: After making repairs, power on the cabinet and monitor its performance. Ensure the temperature and noise levels return to normal.

Note: Regular maintenance and inspections can help you detect and prevent these issues early.

By monitoring for overheating and unusual noises, you can ensure your low voltage distribution cabinet operates safely and efficiently. This proactive approach minimizes risks and extends the lifespan of your equipment.

Troubleshooting Common Issues

Addressing water intrusion and moisture

Water intrusion can compromise the performance of your low voltage distribution cabinet. Moisture leads to corrosion, short circuits, and electrical failures. Begin by inspecting the cabinet for signs of water entry, such as rust, stains, or dampness. Pay close attention to seals, gaskets, and ventilation openings.

If you detect moisture, dry the affected areas immediately. Use a cloth or absorbent material to remove water. For persistent dampness, deploy a dehumidifier or silica gel packets inside the cabinet to absorb excess moisture. Replace damaged seals or gaskets to prevent future leaks.

Tip: Apply waterproof coatings or sealants to the cabinet's exterior for added protection against rain and humidity.

Regular inspections and prompt action can safeguard your cabinet from water-related damage.

Replacing damaged or faulty components

Faulty components can disrupt the operation of your low voltage distribution cabinet. Identify damaged parts during routine inspections. Look for signs like discoloration, cracks, or unusual odors. Commonly affected components include circuit breakers, fuses, and wiring.

To replace a damaged part, disconnect the power supply first. Remove the faulty component using appropriate tools. Install a compatible replacement, ensuring it matches the specifications outlined in the manufacturer’s guide. Tighten connections securely and test the new component to confirm proper functionality.

Alert: Always use components approved by the manufacturer to maintain system integrity and safety.

Replacing damaged parts promptly prevents further issues and keeps your cabinet running efficiently.

Resolving circuit breaker or fuse issues

Circuit breakers and fuses protect your cabinet from electrical overloads. When they malfunction, the system becomes vulnerable to damage. Common issues include tripping breakers or blown fuses.

Start by identifying the cause of the problem. Check for overloaded circuits, short circuits, or faulty wiring. Use a multimeter to test the voltage and current levels. Replace blown fuses with ones of the same rating. Reset tripped breakers by switching them off and then back on.

If the issue persists, inspect the wiring and connected devices for faults. Address any underlying problems before replacing the breaker or fuse.

Note: If troubleshooting doesn’t resolve the issue, consult a professional electrician for assistance.

Resolving these issues ensures your cabinet operates safely and reliably.

Knowing when to call a professional

Some issues with your ESTEL low voltage distribution cabinet may require professional expertise. Knowing when to call a licensed electrician or technician can save you time and prevent further damage. Here are situations where professional help becomes essential:

Persistent Electrical Problems

If you notice recurring issues like frequent circuit breaker trips, unexplained power outages, or irregular voltage levels, it’s time to consult a professional. These problems often indicate deeper electrical faults that require advanced diagnostic tools and expertise.Water Damage or Corrosion

Water intrusion can lead to severe damage, including corroded components and short circuits. If you find extensive rust, dampness, or signs of electrical arcing, a professional can assess the damage and recommend repairs or replacements.Overheating or Burning Smell

Overheating components or a burning smell signals a critical issue. These symptoms may result from overloaded circuits, faulty wiring, or damaged parts. A professional can identify the root cause and resolve it safely.Complex Repairs or Upgrades

Tasks like replacing major components, upgrading the system, or integrating new technologies require specialized knowledge. Attempting these on your own could void warranties or lead to improper installations.

Alert: Never attempt repairs if you lack the necessary skills or tools. Electrical systems can be dangerous without proper training.

Compliance with Regulations

Local electrical codes and safety standards often require certified professionals for certain installations or repairs. Hiring a licensed technician ensures compliance and avoids legal complications.

Tip: Keep the contact information of a trusted electrician handy for emergencies. Regular professional inspections can also help identify potential issues before they escalate.

By recognizing these situations, you can protect your equipment and ensure the safety of your electrical system.

Tips for Longevity and Performance

Scheduling regular professional inspections

Regular inspections by professionals help you maintain the efficiency and safety of your low voltage distribution cabinet. Schedule these inspections at least once a year to identify potential issues early. Professionals can detect problems like loose connections, worn components, or signs of overheating that might go unnoticed during routine checks. They also ensure compliance with local electrical codes and standards.

Create a maintenance calendar to track inspection dates. This helps you stay organized and ensures timely evaluations. During inspections, ask the technician to provide a detailed report. Use this report to plan necessary repairs or upgrades. Regular professional assessments reduce the risk of unexpected failures and extend the lifespan of your equipment.

Tip: Choose certified electricians with experience in handling low voltage systems for reliable inspections.

Upgrading components to meet system demands

As your power distribution needs evolve, upgrading components becomes essential. Outdated or undersized parts can limit the performance of your low voltage distribution cabinet. Replace older circuit breakers, fuses, or wiring with modern, high-capacity alternatives. This ensures your system can handle increased loads without compromising safety.

Evaluate your current setup and identify areas for improvement. For example, if your cabinet frequently trips breakers, it may need higher-rated components. Consult the manufacturer’s guide to select compatible upgrades. Upgrading also allows you to integrate advanced features like remote monitoring or energy-efficient modules.

Alert: Always use components approved by the manufacturer to maintain system integrity and avoid voiding warranties.

Ensuring proper ventilation and temperature control

Ventilation and temperature control are critical for the performance of your low voltage distribution cabinet. Poor airflow can lead to overheating, which damages internal components. Ensure the cabinet is installed in a location with adequate ventilation. For enclosed spaces, consider adding cooling systems like fans or air conditioners.

Monitor the cabinet’s temperature regularly using sensors or infrared thermometers. If you notice rising heat levels, clean the ventilation openings to remove dust or debris. For outdoor installations, protect the cabinet from direct sunlight by using shades or heat-resistant coatings.

Note: Maintaining optimal temperature prevents overheating and ensures the cabinet operates efficiently.

Keeping a detailed maintenance log

A detailed maintenance log is essential for tracking the health and performance of your ESTEL low voltage distribution cabinet. By documenting every inspection, repair, and upgrade, you create a reliable record that helps you stay organized and proactive.

Why Keep a Maintenance Log?

A maintenance log serves as a reference point for identifying patterns or recurring issues. It also ensures you don’t overlook critical tasks. For example, if a component frequently malfunctions, your log can help pinpoint the cause. Additionally, a well-maintained log demonstrates compliance with safety standards and regulations.

Tip: A detailed log can also increase the resale value of your equipment by showcasing its maintenance history.

What to Include in Your Log?

Your log should capture all relevant details about the cabinet’s maintenance. Here’s a list of key information to record:

Date and Time: Note when the maintenance occurred.

Tasks Performed: Specify what was inspected, cleaned, repaired, or replaced.

Technician Details: Include the name and contact information of the person who performed the work.

Observations: Record any unusual findings, such as overheating or loose connections.

Next Steps: Outline follow-up actions or the date of the next scheduled inspection.

Example Entry:

Date: October 15, 2023

Task: Tightened electrical connections and cleaned ventilation openings.

Technician: John Doe (Certified Electrician)

Observations: Slight discoloration on wiring near the circuit breaker.

Next Steps: Replace affected wiring during the next inspection.

Benefits of a Maintenance Log

Keeping a log helps you plan future maintenance and avoid unexpected failures. It also simplifies communication with professionals by providing them with a clear history of the cabinet’s condition. Over time, this habit can save you money and extend the lifespan of your equipment.

Emoji Reminder: 📝 Start your maintenance log today to ensure your cabinet stays in top shape!

Proper installation and maintenance of your low voltage distribution cabinet ensure safety and long-term performance. By following the outlined steps, you minimize risks and enhance system reliability. ESTEL cabinets offer durability, efficiency, and advanced features that meet diverse needs. Regular inspections, cleaning, and upgrades keep your equipment in top condition. Adhering to these practices not only extends the cabinet's lifespan but also ensures optimal functionality. Take proactive steps today to safeguard your electrical systems and maximize their value.

FAQ

What tools do you need to install an ESTEL low voltage distribution cabinet?

You need basic tools like screwdrivers, wrenches, a multimeter, and a sturdy ladder. Ensure all tools are in good condition before starting. Wear safety gear, including gloves and goggles, to protect yourself during the installation process.

Tip: Keep a checklist of tools to avoid missing anything important.

How often should you inspect the cabinet for maintenance?

Inspect the cabinet at least twice a year. Focus on physical damage, loose connections, and dust buildup. Schedule additional inspections after extreme weather conditions to catch potential issues early.

Emoji Reminder: 🛠️ Regular inspections prevent costly repairs and ensure safety.

Can you clean the cabinet while it is powered on?

No, always disconnect the power supply before cleaning. This prevents electrical hazards and ensures your safety. Use a vacuum or compressed air for internal cleaning and avoid using water or liquid cleaners inside the cabinet.

Alert: Cleaning while powered on can cause serious accidents.

What should you do if the cabinet overheats?

Check for blocked ventilation or dust buildup. Clean the ventilation openings and ensure proper airflow. If the issue persists, inspect the cooling system or call a professional for assistance.

Note: Overheating can damage components, so act quickly.

When should you call a professional for help?

Call a professional if you notice persistent electrical problems, water damage, or overheating. Complex repairs, upgrades, or compliance with local regulations also require expert assistance.

Tip: Keep the contact details of a licensed electrician handy for emergencies.

See Also

Essential Advice for Caring for Outdoor ESTEL Cabinets

Ensuring Correct Voltage Levels in ESTEL Communication Cabinets

Guidelines for Setting Up ESTEL Cabinets in Tough Environments

Understanding Integration of Supervision Systems in ESTEL Cabinets

Simplifying the Installation Process for ESTEL Outdoor Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA