Install ESTEL Rectifier Modules Without Stress Today

Installing ESTEL rectifier modules correctly ensures your power systems operate efficiently. Following the proper steps prevents unnecessary downtime and protects your equipment from damage. Regular maintenance plays a crucial role in extending the lifespan of these modules. It also helps you avoid costly repairs by detecting issues early. The process may seem daunting, but it becomes straightforward when you approach it methodically. By taking the right precautions, you can complete the installation with minimal stress and enjoy long-term performance benefits.

Key Takeaways

Collect all tools you need before starting. These include screwdrivers, a multimeter, wire strippers, safety gear, and the manual.

Make sure the rectifier module works with your power system. Check safety rules to prevent problems.

Check the rectifier module for damage before installing. Look for heat marks, voltage changes, or connection issues.

Install step by step. Turn off the system, attach the module tightly, connect wires properly, and set up the system.

Plan regular check-ups to make your rectifier last longer. Check wires, clean off dust, and watch performance levels.

Preparing for Installation

Tools and Equipment Checklist

Before starting the installation, gather all the necessary tools and equipment. Having everything ready ensures a smooth process without interruptions. Here’s a checklist to guide you:

Screwdrivers: Both flathead and Phillips types for securing connections.

Multimeter: To measure voltage and current levels during setup.

Cable Strippers: For preparing wires before connecting them.

Protective Gear: Gloves and safety goggles to protect yourself.

User Manual: The ESTEL rectifier module manual for reference.

Double-check this list to avoid delays. Missing tools can lead to improper installation or safety risks.

Ensuring Compatibility with Your Power System

Compatibility between the rectifier module and your power system is crucial. Using an incompatible module can cause performance issues or even damage your equipment. To ensure compatibility, verify the following criteria:

Compliance Criteria | Description |

|---|---|

International Safety Standards | Compliance with CE and UL ensures safety across diverse applications. |

Regional and Global Regulations | Adherence to NEBS for telecommunications and marine certifications for offshore applications. |

Environmental and Performance Benchmarks | Meeting global standards enhances credibility and reliability of power systems. |

Review these criteria carefully. Confirm that your power system meets the necessary standards before proceeding.

Inspecting the ESTEL Rectifier Module for Damage

Inspect the rectifier module thoroughly before installation. Identifying damage early prevents potential failures. Look for these common indicators:

Code | Description | Action Required |

|---|---|---|

| Overheating detected | Check cooling system and airflow. |

| Voltage fluctuation | Inspect power supply and connections. |

| Fan malfunction | Replace or repair the cooling fan. |

| Communication failure | Verify network or cable connections. |

Additionally, monitor voltage and current levels regularly. Inspect all electrical connections to ensure they are secure and free from corrosion. Check the cooling system for signs of wear or damage. These steps help you identify and address issues before they escalate.

Step-by-Step Installation Guide

Powering Down the System Safely

Before you begin installing the rectifier modules, ensure the power system is completely shut down. This step is critical for your safety and the protection of your equipment. Follow these steps to safely power down the system:

Notify Personnel: Inform everyone in the vicinity about the shutdown to avoid accidental interference.

Disconnect Power Sources: Turn off the main power supply and any backup systems connected to the module.

Verify Power Status: Use a multimeter to confirm there is no residual voltage in the system.

Tip: Always wear protective gear, such as insulated gloves and goggles, when handling electrical systems.

Taking these precautions minimizes the risk of electrical shock and ensures a safe working environment.

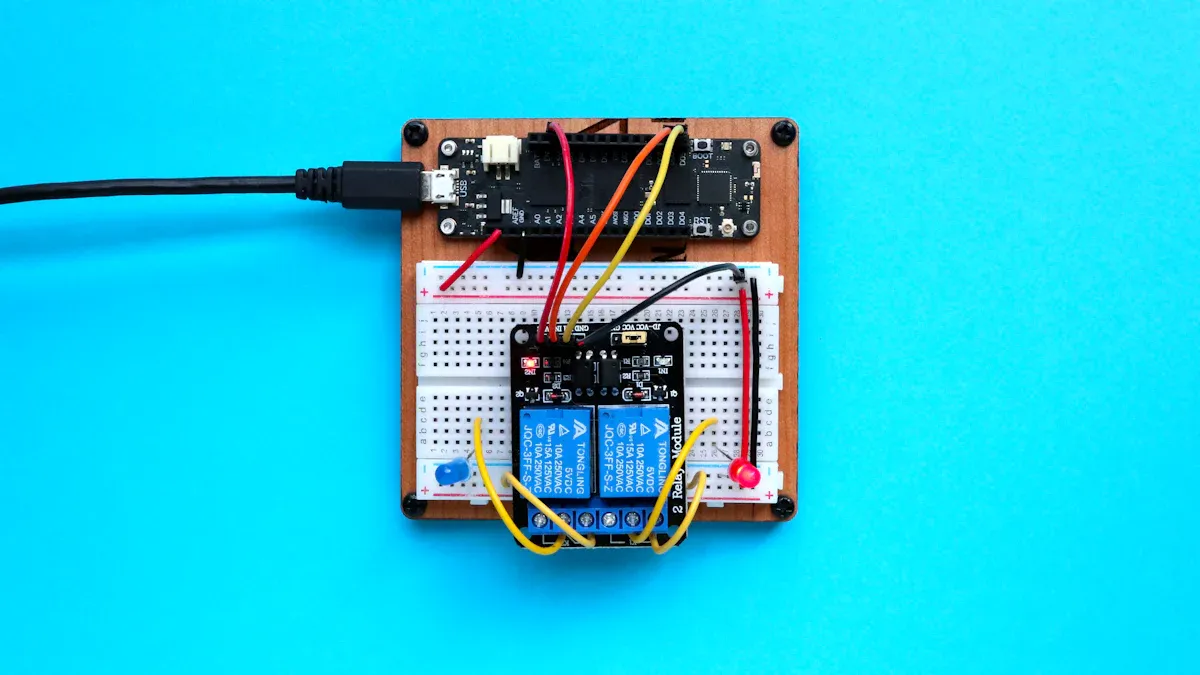

Mounting the Rectifier Module

Proper mounting is essential for the stability and performance of the rectifier modules. Begin by identifying the designated mounting location within your power system. Then, follow these steps:

Position the Module: Align the module with the mounting brackets or slots provided in your system.

Secure the Module: Use screws or clamps to firmly attach the module. Ensure it is level and tightly fixed to prevent vibrations.

Check Clearance: Verify that there is adequate space around the module for airflow and cooling.

Note: Avoid placing the module near heat sources or areas prone to moisture. These conditions can affect its performance and longevity.

A well-mounted module ensures optimal operation and reduces the likelihood of physical damage.

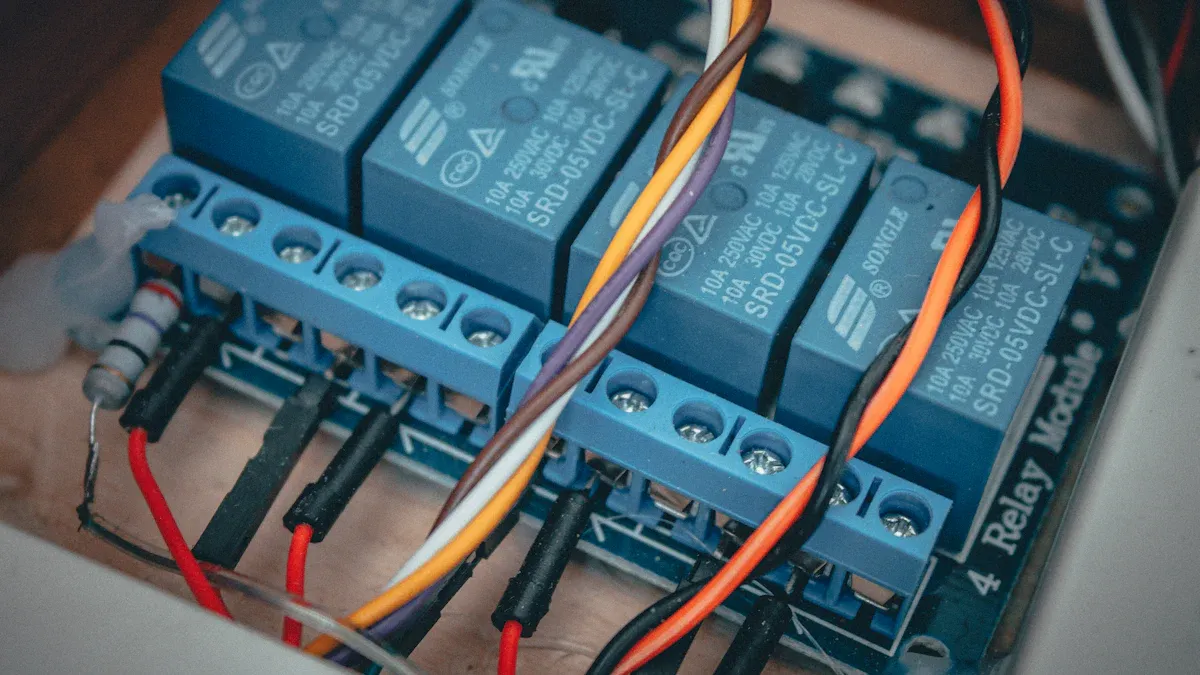

Connecting Input and Output Cables

Connecting the cables correctly is crucial for the functionality of the rectifier modules. Follow these steps to make secure and accurate connections:

Prepare the Cables: Strip the insulation from the ends of the input and output cables using cable strippers.

Connect Input Cables: Attach the input cables to the designated terminals on the module. Ensure the polarity matches the specifications in the user manual.

Connect Output Cables: Secure the output cables to the corresponding terminals. Double-check the connections for tightness.

Inspect Connections: Examine all cable connections for signs of wear or corrosion. Replace any damaged cables immediately.

Alert: Incorrect cable connections can lead to system malfunctions or even permanent damage to the module. Always refer to the user manual for guidance.

By following these steps, you can ensure the module is properly integrated into your power system, ready for configuration and testing.

Configuring System Settings

Once the rectifier module is securely mounted and connected, you need to configure the system settings to ensure optimal performance. This step customizes the module to meet the specific requirements of your power system. Follow these steps to configure the settings effectively:

Access the Control Panel: Locate the control interface on the rectifier module. This may be a physical panel or a software-based interface accessible via a connected device.

Set Voltage and Current Parameters: Adjust the output voltage and current levels to match the specifications of your power system. Refer to the user manual for recommended values.

Enable Safety Features: Activate built-in safety features such as overvoltage protection, short-circuit prevention, and thermal shutdown. These settings safeguard the module and connected equipment.

Synchronize with Existing Systems: If the module is part of a larger power system, ensure it synchronizes with other components. This may involve setting communication protocols or network configurations.

Save and Lock Settings: Once all parameters are configured, save the settings and lock the interface to prevent unauthorized changes.

Tip: Always double-check the configured values before saving. Incorrect settings can lead to inefficiencies or damage to the system.

Proper configuration ensures that the rectifier module operates efficiently and integrates seamlessly with your power system.

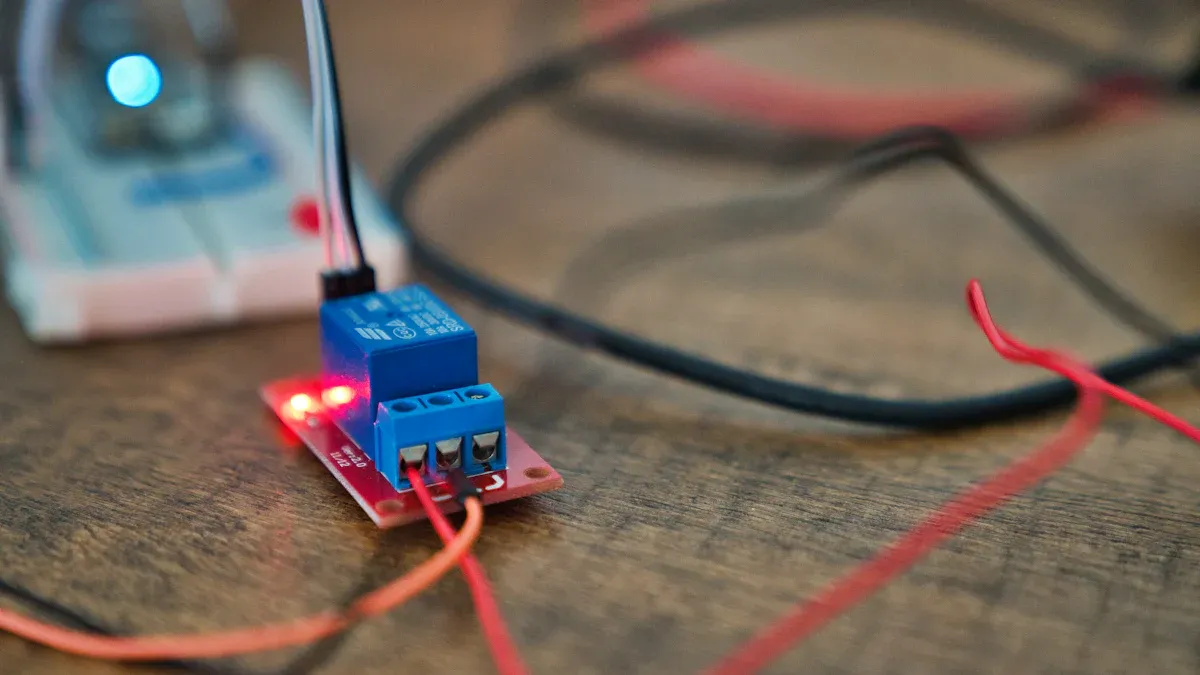

Verifying Installation with a Test Run

After configuring the settings, it’s time to verify the installation with a test run. This step confirms that the rectifier module is functioning correctly and that all connections are secure. Here’s how to conduct a thorough test:

Reconnect Power Sources: Restore power to the system by reconnecting the main supply and any backup sources.

Monitor Initial Startup: Observe the module as it powers up. Look for any error codes or warning lights on the control panel.

Check Output Performance: Use a multimeter to measure the output voltage and current. Ensure the readings match the configured settings.

Test Load Handling: Connect a test load to the system and monitor its performance. The module should handle the load without fluctuations or interruptions.

Inspect for Abnormalities: Listen for unusual noises, check for overheating, and ensure all cables remain secure during operation.

Alert: If you notice any irregularities, power down the system immediately and recheck the installation steps. Address any issues before proceeding.

A successful test run confirms that the rectifier module is ready for regular operation. This step provides peace of mind and ensures long-term reliability.

Avoiding Common Installation Mistakes

Skipping Compatibility Verification

Skipping compatibility checks can lead to serious issues during installation. You must ensure the rectifier modules match your power system's specifications. Incompatible modules may cause performance problems or even damage your equipment. Always verify the voltage, current, and power ratings before installation.

To simplify this process, consult the user manual and compare the module's specifications with your system's requirements. Pay attention to compliance with international safety standards like CE and UL. These standards ensure the module operates safely and efficiently.

Tip: Double-check compatibility before proceeding. This small step can save you from costly repairs and downtime.

Incorrect Cable Connections

Incorrect cable connections are a common mistake that can disrupt the functionality of rectifier modules. Loose or mismatched connections often result in power output instability. To avoid this, carefully follow the wiring diagram provided in the user manual.

Here’s a quick checklist for secure connections:

Strip the cable ends properly to expose clean wire.

Match the polarity of input and output cables with the module's terminals.

Tighten all connections to prevent loose wiring.

Common Installation Mistakes | Description |

|---|---|

Overheating | Caused by poor ventilation; install in a well-ventilated area. |

Power Output Instability | Results from loose connections; monitor voltage and current levels. |

Faulty Cooling Systems | Can lead to overheating; inspect and maintain cooling systems regularly. |

Ignoring Alarm/Error Codes | Can lead to severe damage; understanding codes is essential for maintenance. |

Alert: Incorrect connections can damage the module permanently. Always inspect your work before powering up the system.

Ignoring Safety Protocols

Ignoring safety protocols puts you and your equipment at risk. Electrical systems can be hazardous if handled carelessly. Always wear protective gear, such as insulated gloves and goggles, when working with rectifier modules.

Follow these essential safety measures:

Power down the system completely before starting any work.

Use a multimeter to confirm there is no residual voltage.

Keep the installation area dry and free from clutter.

Note: Safety should always be your top priority. Neglecting it can lead to accidents or equipment failure.

By avoiding these common mistakes, you can ensure a smooth installation process and extend the lifespan of your rectifier modules.

Maintaining ESTEL Rectifier Modules

Scheduling Routine Inspections

Routine inspections are essential for keeping your rectifier modules in top condition. By scheduling regular checks, you can identify potential issues before they escalate into costly repairs. Create a maintenance calendar to stay organized and ensure inspections happen on time.

During each inspection, focus on these key areas:

Electrical Connections: Check for loose or corroded connections. Tighten or replace them as needed.

Cooling Systems: Inspect fans and vents for blockages or damage. Ensure proper airflow to prevent overheating.

Performance Metrics: Use a multimeter to measure voltage and current levels. Compare the readings with the module's specifications.

Tip: Keep a log of your inspection results. This record helps you track trends and spot recurring issues.

Consistent inspections extend the lifespan of your rectifier modules and improve their reliability.

Cleaning and Dust Prevention

Dust and debris can significantly impact the performance of your rectifier modules. Cleaning them regularly ensures optimal operation and prevents overheating. Follow these steps to keep your modules clean:

Power Down the System: Always turn off the power before cleaning to avoid electrical hazards.

Use Compressed Air: Blow out dust from vents and fans using a can of compressed air. Hold the can upright to prevent moisture from entering the system.

Wipe Surfaces: Use a lint-free cloth to clean the exterior of the module. Avoid using water or cleaning agents that could damage the components.

Inspect for Residue: Check for stubborn dirt or residue. If necessary, use a soft brush to gently remove it.

Alert: Never use liquids or abrasive materials when cleaning. These can damage sensitive components and compromise performance.

Preventing dust buildup is equally important. Install your modules in a clean, dry environment. Use dust covers or enclosures if the area is prone to debris.

Monitoring System Performance

Monitoring the performance of your rectifier modules helps you detect inefficiencies early. Regular performance checks ensure the system operates within its optimal range. Here’s how you can monitor effectively:

Track Output Levels: Measure the voltage and current output using a multimeter. Ensure the readings align with the configured settings.

Observe Alarms and Indicators: Pay attention to warning lights or error codes on the control panel. These signals often indicate underlying issues.

Analyze Load Handling: Test the module under different load conditions. Look for signs of instability, such as voltage fluctuations or overheating.

Review Historical Data: If your module supports data logging, review the records for anomalies or trends that require attention.

Note: Address any irregularities immediately. Delaying action can lead to system failures or reduced efficiency.

By actively monitoring performance, you can maintain the reliability and efficiency of your rectifier modules over time.

Replacing Worn-Out Components

Replacing worn-out components is essential for maintaining the efficiency and reliability of your rectifier modules. Over time, components like capacitors, fans, and connectors can degrade due to wear and tear. Ignoring these issues can lead to system failures or reduced performance. By addressing them promptly, you can extend the lifespan of your equipment and avoid costly repairs.

Signs of Worn-Out Components

You should regularly inspect your rectifier modules for signs of wear. Here are some common indicators:

Unusual Noises: A failing fan may produce grinding or rattling sounds.

Overheating: Excessive heat often points to a malfunctioning cooling system.

Voltage Fluctuations: Inconsistent output voltage may indicate capacitor failure.

Physical Damage: Cracks, corrosion, or discoloration on connectors signal the need for replacement.

Tip: Keep a maintenance log to track recurring issues. This helps you identify patterns and plan replacements more effectively.

Steps to Replace Components

Follow these steps to safely and efficiently replace worn-out components:

Power Down the System: Turn off the power supply and disconnect all cables. Use a multimeter to confirm there is no residual voltage.

Identify the Faulty Component: Refer to the user manual to locate the component. Inspect it visually or use diagnostic tools to confirm the issue.

Remove the Component: Use appropriate tools, such as screwdrivers or pliers, to detach the component. Handle it carefully to avoid damaging nearby parts.

Install the Replacement: Align the new component with the designated slot or terminal. Secure it firmly using screws or connectors.

Test the System: Reconnect the power supply and perform a test run. Monitor the system for any irregularities to ensure the replacement was successful.

Alert: Always use manufacturer-approved replacement parts. Generic components may not meet the required specifications and could compromise system performance.

Best Practices for Component Replacement

Adopting best practices ensures a smooth replacement process and minimizes risks:

Stock Spare Parts: Keep essential components like capacitors and fans in stock for quick replacements.

Follow Manufacturer Guidelines: Always refer to the user manual for specific instructions.

Use Proper Tools: Invest in high-quality tools to avoid damaging sensitive components.

Schedule Preventive Maintenance: Replace components proactively based on their expected lifespan, even if they show no immediate signs of failure.

By replacing worn-out components promptly, you can maintain the optimal performance of your rectifier modules and prevent unexpected downtime.

Troubleshooting ESTEL Rectifier Modules

Diagnosing Power Output Issues

Power output issues can disrupt the performance of your rectifier modules. Identifying the root cause quickly ensures your system operates efficiently. Start by checking the output voltage and current using a multimeter. Compare the readings with the configured settings. If the values deviate, inspect the input power supply. A weak or unstable input can lead to inconsistent output.

Next, examine the electrical connections. Loose or corroded terminals often cause voltage drops. Tighten all connections and replace damaged cables. Look for error codes on the control panel. These codes provide clues about potential faults. Refer to the user manual to interpret them accurately.

Tip: Keep a log of recurring power issues. This helps you identify patterns and address underlying problems effectively.

Resolving Overheating Problems

Overheating can damage your rectifier modules and reduce their lifespan. To resolve this issue, begin by inspecting the cooling system. Check the fans for blockages or malfunctions. Clean the vents using compressed air to ensure proper airflow. Replace faulty fans immediately.

Monitor the ambient temperature around the module. High temperatures in the installation area can contribute to overheating. Relocate the module to a cooler environment if necessary. Verify that the module is not overloaded. Excessive load can strain the system and generate heat. Adjust the load to stay within the recommended limits.

Alert: Overheating often triggers warning lights or error codes. Address these warnings promptly to prevent permanent damage.

Fixing Connectivity Errors

Connectivity errors can disrupt communication between your rectifier modules and other system components. Begin troubleshooting by inspecting the network cables. Look for physical damage, such as cuts or frayed ends. Replace damaged cables immediately.

Ensure all connectors are securely attached. Loose connections can interrupt data transmission. Use a diagnostic tool to test the network for signal strength and stability. If the issue persists, check the module's communication settings. Incorrect configurations may block connectivity. Reset the settings to default and reconfigure them as needed.

Note: Always use high-quality cables and connectors to minimize connectivity issues.

Knowing When to Contact Support

Sometimes, troubleshooting rectifier modules can feel overwhelming. Knowing when to contact support ensures you avoid unnecessary delays and prevent further damage to your equipment. Here are situations where reaching out to technical support becomes essential:

Persistent Error Codes: If error codes persist despite following troubleshooting steps, contact support. These codes often indicate deeper issues that require expert intervention.

Unresolved Connectivity Problems: When network errors continue after replacing cables and reconfiguring settings, technical support can help diagnose the root cause.

Overheating Despite Maintenance: If your module overheats even after cleaning vents and replacing fans, it may signal internal component failure. Support teams can guide you through advanced diagnostics.

Performance Degradation: When voltage or current output fluctuates despite proper configuration, it’s time to seek professional assistance.

Tip: Keep a record of all troubleshooting steps you’ve attempted. Sharing this information with support teams helps them pinpoint the issue faster.

How to Prepare Before Contacting Support

Preparation ensures your interaction with support teams is efficient. Follow these steps:

Gather Module Information: Note the model number, serial number, and firmware version of your rectifier module.

Document the Issue: Write down the symptoms, error codes, and any unusual behavior you’ve observed.

List Troubleshooting Steps: Provide details of the actions you’ve already taken to resolve the problem.

Check Warranty Status: Verify if your module is still under warranty. This information determines repair or replacement options.

Alert: Avoid attempting advanced repairs without guidance. Unauthorized modifications can void your warranty and worsen the issue.

Benefits of Contacting Support

Support teams offer expertise that saves you time and resources. They provide detailed instructions, recommend replacement parts, and even schedule on-site assistance if needed. By contacting them promptly, you ensure your rectifier module operates efficiently and avoids prolonged downtime.

Emoji Reminder: 🛠️ Don’t hesitate to reach out! Support exists to help you maintain your system stress-free.

Installing ESTEL rectifier modules becomes a straightforward task when you follow the outlined steps. From preparing your tools to verifying the installation with a test run, each phase ensures safety and efficiency. Regular maintenance, such as cleaning and inspecting components, keeps your system running smoothly and extends its lifespan. By adhering to this guide, you can avoid common mistakes and enjoy reliable performance. Take the time to implement these practices, and you’ll achieve a stress-free installation experience.

FAQ

What should you do if the rectifier module doesn’t power on?

First, check the power source and ensure all cables are securely connected. Use a multimeter to verify input voltage. If the issue persists, inspect the module for physical damage or error codes. Contact technical support if necessary.

Tip: Always verify power compatibility before installation.

How often should you clean the rectifier module?

Clean the module every three to six months, depending on the environment. Dusty or humid areas may require more frequent cleaning. Use compressed air and a lint-free cloth to remove debris.

Alert: Never use water or liquid cleaners to avoid damaging sensitive components.

Can you install the module without professional help?

Yes, you can install it yourself by following the user manual and this guide. Ensure you have the right tools and understand safety protocols. If unsure, consult a professional to avoid mistakes.

Emoji Reminder: 🛠️ Safety first! Always power down the system before starting.

What does an error code on the module mean?

Error codes indicate specific issues, such as overheating or connectivity problems. Refer to the user manual to decode the error and follow the recommended troubleshooting steps.

Note: Persistent error codes may require assistance from technical support.

How can you extend the lifespan of your rectifier module?

Perform regular maintenance, including cleaning, inspecting connections, and replacing worn-out components. Monitor performance metrics and address issues promptly. Keep the module in a clean, dry, and well-ventilated area.

Tip: Create a maintenance schedule to stay consistent.

See Also

Ensuring Correct Voltage Levels in ESTEL Communication Cabinets

Telecom Cabinets by ESTEL: The Role of Energy Storage Batteries

Integrating Smart Microgrid Energy Storage in ESTEL Telecom Cabinets

Essential Maintenance Tips for Outdoor ESTEL Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA