Step-by-step guide to integrating ESTEL rectifiers into power supply designs

Integrating ESTEL rectifiers into your system requires careful planning and execution. A well-structured approach ensures your rectifier power supply operates efficiently and reliably. Start by understanding your system’s requirements and selecting a compatible model. Next, focus on proper installation and configuration to avoid performance issues. Safety compliance and thorough testing further enhance the system’s longevity. By following a methodical process, you can achieve a seamless integration that supports consistent power delivery and minimizes downtime.

Key Takeaways

Pick the right ESTEL rectifier by checking your system's voltage and current needs. This helps it work properly.

Stay safe by wearing protective gear and making sure the power is off before starting. This lowers the chance of accidents.

Test carefully after setting it up to check voltage and current. This makes sure the rectifier works well with your system.

Plan regular check-ups to watch how it’s working and fix small problems early. This keeps the rectifier lasting longer and avoids surprises.

Use built-in tools to watch how the rectifier works in real-time. This helps find problems before they get worse.

Overview of ESTEL Rectifiers

Purpose in rectifier power supply systems

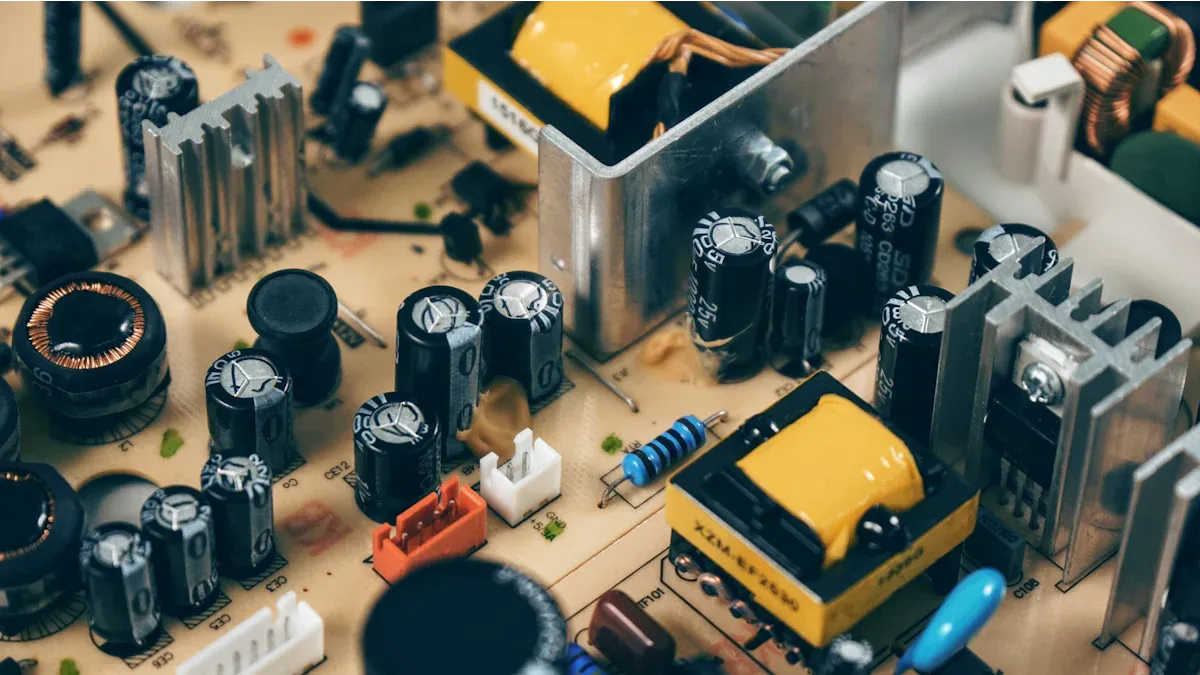

ESTEL rectifiers play a critical role in converting alternating current (AC) to direct current (DC), a process known as rectification. This conversion is essential for powering electronic devices and systems that require a stable DC output. By using advanced diode bridge rectifier technology, ESTEL rectifiers ensure efficient full-wave rectification, which improves the quality of the DC output. These rectifiers are widely used in electronic power supplies, telecommunications, and industrial applications, where reliable ac to dc conversion is crucial for maintaining system performance.

Key features and benefits

ESTEL rectifiers are designed with high efficiency and durability in mind. Their robust construction includes high-quality diodes that resist wear and tear, ensuring a long lifespan with minimal maintenance. The advanced thermal management system prevents overheating, reducing the risk of component failure. Performance metrics highlight their exceptional energy efficiency, with some configurations achieving over 96% efficiency in rectifier mode and over 97% in inverter mode. These rectifiers also support improved dc output stability, making them ideal for applications requiring consistent power delivery.

Configuration | NPV ($M) | Annual Savings ($) | Payback Period (years) | ROI (%) | IRR (%) | LCOE ($/kWh) |

|---|---|---|---|---|---|---|

Config. 1 | 25.5 | 1,200,000 | 0.31 | 339 | 330 | 0.03845 |

Config. 2 | N/A | 1,040,000 | N/A | N/A | N/A | 0.04228 |

Config. 4 | 19.8 | 941,451 | 0.675 | 154 | 155 | 0.3960 |

Advantages for modern designs

Modern power supplies demand compact, efficient, and reliable components. ESTEL rectifiers meet these needs with their innovative designs and advanced diode bridge rectifier technology. Their ability to perform full-wave rectification ensures maximum power conversion efficiency, reducing energy losses. The evolution of ESTEL rectifiers reflects their commitment to innovation. For example:

Year | Milestone Description |

|---|---|

1980 | Introduction of switch mode power supplies, revolutionizing efficiency and power density. |

2005 | Launch of the Flatpack2, introducing a new form factor with improved power density. |

2017 | Flatpack SHE achieves near-theoretical maximum conversion efficiency, setting a benchmark for future innovations. |

These advancements make ESTEL rectifiers a preferred choice for electronic power supplies, offering high efficiency, improved dc output, and reliable performance in diverse applications.

Pre-Integration Checklist

Selecting the right model

Choosing the correct rectifier model is the first step in ensuring a successful integration. You need to evaluate your system's power requirements, including voltage and current ratings. ESTEL offers a variety of models tailored to different applications, so selecting one that aligns with your specific needs is essential. For example, if your system demands high efficiency and compact design, models like the Flatpack2 or Flatpack SHE are excellent options. Always review the technical specifications provided by the manufacturer to confirm compatibility with your rectifier power supply.

Understanding system requirements

Before installation, you must fully understand your system's requirements. This involves analyzing several key factors:

Auxiliary Equipment: Ensure compatibility with switchgear, power factor correction units, and harmonic filters.

Cooling Systems: Decide between air-cooled or water-cooled designs based on your system's size and efficiency needs.

Heat Management: Maintain clean and secure electrical connections to prevent overheating.

Additionally, consider auxiliary circuits for monitoring and protection, as well as transformer adjustment methods for non-standard configurations. Proper planning at this stage minimizes risks and ensures your rectifier operates efficiently within your power supplies.

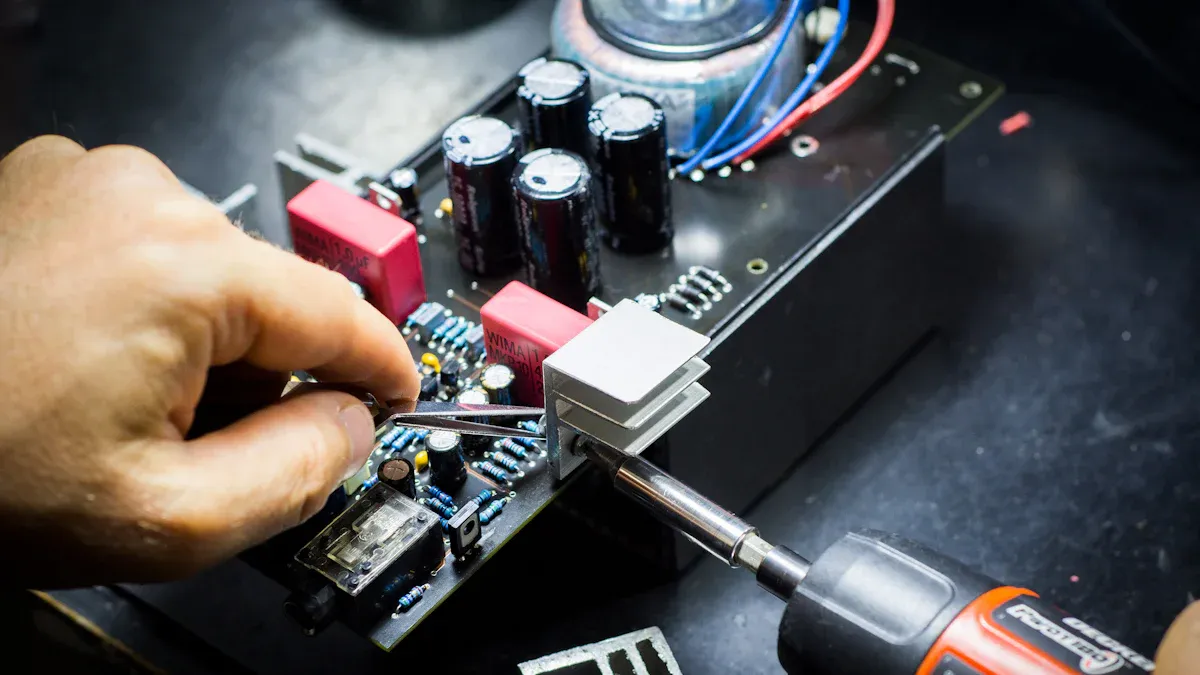

Gathering tools and equipment

Having the right tools and equipment on hand simplifies the installation process. Basic tools like screwdrivers, wrenches, and wire strippers are essential. You may also need specialized equipment, such as multimeters for testing electrical connections and thermal imaging devices for heat management. Keep safety gear, including insulated gloves and goggles, readily available to ensure compliance with safety standards. Organizing these items beforehand saves time and helps you avoid unnecessary delays during the integration process.

Reviewing safety guidelines

Before integrating ESTEL rectifiers into your power supply design, you must prioritize safety. Following proper safety guidelines protects you, your equipment, and your system from potential hazards. Here are the key safety measures to review and implement:

Understand the Manufacturer’s Manual

Carefully read the user manual provided by ESTEL. It contains specific safety instructions tailored to the rectifier model you are using. Pay close attention to warnings about voltage limits, grounding requirements, and handling precautions.Inspect the Work Area

Ensure the installation site is clean, dry, and free from obstructions. Remove any flammable materials nearby. Verify that the workspace has adequate lighting and ventilation to prevent overheating during operation.Wear Appropriate Safety Gear

Equip yourself with insulated gloves, safety goggles, and non-conductive footwear. These items reduce the risk of electrical shock and other injuries. Avoid wearing loose clothing or jewelry that could get caught in equipment.Verify Power Isolation

Disconnect the power supply before starting the installation. Use a multimeter to confirm that no live current flows through the system. This step eliminates the risk of accidental electrocution.

Tip: Always double-check your tools and equipment for damage before use. Faulty tools can compromise safety and lead to errors during installation.

Follow Electrical Codes

Adhere to local and international electrical standards. Proper grounding and circuit protection are essential for preventing short circuits and ensuring compliance with regulations.

By reviewing these safety guidelines, you create a secure environment for integrating ESTEL rectifiers. Taking these precautions minimizes risks and ensures a smooth installation process.

Step-by-Step Integration Process

Preparing the installation site

Before installing the rectifier, you need to prepare the site carefully to ensure optimal performance and longevity. Start by selecting a location that meets the rectifier's spatial and environmental requirements. The site should be clean, dry, and free from dust or debris. Adequate ventilation is essential to prevent overheating. If the rectifier operates in a high-temperature environment, consider installing cooling systems to maintain efficiency.

Proper spatial planning is equally important. Use the following guidelines to optimize the installation site:

Guideline | Description |

|---|---|

Cooling Methods | Effective cooling is essential to prevent overheating, which can lead to module failure and reduced efficiency. |

Input Voltage Matching | Ensuring the rectifier's input voltage matches the system prevents operational issues and maintains performance. |

Temperature Range Considerations | Operating within the recommended temperature range is crucial for optimal performance and longevity of the rectifier. |

System Connectivity | Proper connections enhance system reliability and reduce energy waste, ensuring smooth operation with other components. |

Ensure the rectifier is positioned securely to avoid vibrations or movement during operation. Use mounting brackets or racks designed for the specific model. Double-check the input voltage compatibility with your system to prevent operational issues. By following these steps, you create a stable foundation for the rectifier power supply.

Wiring the rectifier

Wiring the rectifier requires precision and attention to detail. Begin by identifying the input and output terminals on the rectifier. The input terminals connect to the AC power source, while the output terminals deliver DC power to your system. Use high-quality cables to ensure reliable connections and minimize energy loss.

Follow these steps for proper wiring:

Connect the Input Terminals

Attach the AC power source to the input terminals. Ensure the voltage matches the rectifier's specifications to avoid damage. Use a multimeter to verify the voltage before proceeding.Secure the Output Terminals

Connect the output terminals to the DC load. Maintain clean and tight connections to prevent overheating and energy waste. If your system uses auxiliary circuits, integrate them at this stage.Ground the Rectifier

Establish a secure ground connection to protect the rectifier and other components from electrical surges. Use grounding wires that meet local electrical codes.

Tip: Label all wires and terminals during installation. This practice simplifies troubleshooting and maintenance later.

Inspect all connections for signs of wear or damage. Loose or corroded connections can compromise the rectifier's performance and lead to system failures. Once the wiring is complete, proceed to configure the voltage and current settings.

Configuring voltage and current settings

Configuring the rectifier's voltage and current settings ensures it operates within your system's requirements. Begin by accessing the rectifier's control panel or interface. Most ESTEL rectifiers feature user-friendly interfaces that allow you to adjust settings easily.

Follow these steps to configure the settings:

Set the Output Voltage

Adjust the output voltage to match your system's requirements. Use the control panel to input the desired voltage level. For applications requiring full-wave rectification, ensure the voltage remains stable under varying loads.Adjust the Current Limit

Configure the current limit to prevent overloading the rectifier. This setting protects the diode bridge rectifier and other components from damage. Monitor the current during operation to ensure it stays within the configured limit.Enable Monitoring Features

Activate any built-in monitoring features, such as alarms or indicators. These features help you track the rectifier's performance and detect issues early.Test the Settings

Use a multimeter to verify the configured voltage and current levels. Conduct a trial run to ensure the rectifier delivers consistent output under normal operating conditions.

Note: Always refer to the manufacturer's manual for specific instructions on configuring your rectifier model. Incorrect settings can lead to inefficiencies or damage.

By configuring the voltage and current settings accurately, you optimize the rectifier's performance and ensure reliable power delivery to your system.

Verifying connections and safety compliance

After wiring and configuring your rectifier, verifying all connections and ensuring safety compliance is essential. This step guarantees that your system operates reliably and minimizes risks during operation. Follow these guidelines to complete this critical phase effectively.

Inspecting Electrical Connections

Start by examining every connection in your rectifier system. Look for loose wires, frayed insulation, or signs of corrosion. These issues can lead to poor performance or even system failure. Use the following checklist to guide your inspection:

Input and Output Terminals: Ensure all terminals are securely fastened and free from debris. Loose connections can cause overheating or voltage drops.

Grounding Wires: Verify that the rectifier is properly grounded. A secure ground connection protects your system from electrical surges.

Auxiliary Circuits: Check that any additional circuits, such as monitoring or protection systems, are correctly integrated and functional.

Tip: Use a multimeter to test the continuity of each connection. This tool helps you identify hidden issues that may not be visible during a visual inspection.

Testing for Voltage and Current Accuracy

Once the connections are secure, test the rectifier's output to confirm it meets your system's requirements. Use a multimeter or similar device to measure the voltage and current levels. Compare these readings to the values you configured earlier. If discrepancies exist, adjust the settings and retest until the output stabilizes.

Parameter | Ideal Condition | Action if Issue Detected |

|---|---|---|

Output Voltage | Matches configured value | Recheck settings and inspect wiring |

Output Current | Within the specified limit | Adjust current limit or inspect load |

Grounding Resistance | Below the recommended threshold | Improve grounding connection |

Ensuring Compliance with Safety Standards

Adhering to safety standards is non-negotiable when integrating a rectifier. These standards protect both the equipment and the personnel involved. Review the following key areas to ensure compliance:

Electrical Codes: Confirm that your installation meets local and international electrical standards. This includes proper grounding, circuit protection, and wire sizing.

Thermal Management: Check that the rectifier's cooling system functions correctly. Overheating can damage components and compromise safety.

Protective Devices: Install fuses or circuit breakers to safeguard the rectifier and connected equipment from electrical faults.

Note: Always document your compliance checks. Detailed records make future troubleshooting and audits more straightforward.

Final Safety Checks

Before powering up the rectifier, perform a final round of safety checks. Ensure the installation site is clean and free from obstructions. Verify that all tools and equipment have been removed from the area. Double-check that the power supply is isolated before reconnecting it to the system.

Once these steps are complete, you can confidently activate the rectifier. Monitor its performance closely during the initial operation to identify any potential issues early.

Testing and Optimization

Conducting initial tests

After completing the installation and configuration of your rectifier, you need to conduct initial tests to verify its functionality. These tests ensure the rectifier operates as expected and delivers the required output. Begin by powering up the rectifier and observing its startup behavior. Look for any irregularities, such as unusual noises or error indicators on the control panel.

Follow these steps to perform initial tests effectively:

Check the Input Voltage

Use a multimeter to measure the input voltage at the rectifier's terminals. Ensure the voltage matches the specifications provided in the manufacturer's manual. Incorrect input voltage can affect the rectification process and damage the diode bridge rectifier.Verify the Output Voltage

Measure the output voltage using the same multimeter. Confirm that the rectifier delivers stable DC power within the configured range. If the output fluctuates, inspect the wiring and settings for potential issues.Test the Current Flow

Monitor the current flow through the rectifier. Ensure it remains within the configured limit to prevent overloading. Overloaded diodes can lead to overheating and reduced efficiency.Inspect the Diodes

Examine the diodes for signs of wear or damage. Faulty diodes can compromise full-wave rectification and result in inconsistent power delivery.

Tip: Document the results of each test. Keeping detailed records helps you track performance trends and identify issues during future maintenance.

Monitoring output stability

Once the initial tests are complete, focus on monitoring the rectifier's output stability. Stable output is crucial for maintaining the reliability of your rectifier power supply. Begin by observing the rectifier's performance under varying load conditions. Gradually increase the load and monitor how the rectifier responds.

Use the following checklist to ensure output stability:

Voltage Consistency: Verify that the output voltage remains steady, even as the load changes. Fluctuating voltage can disrupt connected power supplies and affect system performance.

Current Regulation: Ensure the rectifier regulates current effectively. Excessive current can damage the diode bridge rectifier and other components.

Thermal Management: Monitor the rectifier's temperature during operation. Overheating can degrade the diodes and compromise rectification efficiency.

Note: Utilize built-in monitoring features, such as alarms or indicators, to track output stability in real time. These features help you detect issues early and take corrective action.

Adjusting for optimal performance

Optimizing your rectifier's performance involves fine-tuning its settings and addressing any issues identified during testing. Start by revisiting the voltage and current configurations. Adjust these settings to align with your system's requirements and ensure efficient full-wave rectification.

Here’s how you can optimize performance:

Refine Voltage Settings

Use the control panel to make precise adjustments to the output voltage. Ensure the voltage remains stable under varying loads. Stable voltage improves the efficiency of connected power supplies.Enhance Current Limits

Reassess the current limit settings. Lower the limit slightly if the rectifier shows signs of overloading. This adjustment protects the diode bridge rectifier and extends its lifespan.Improve Cooling Systems

If the rectifier operates in a high-temperature environment, upgrade its cooling system. Enhanced thermal management prevents overheating and maintains rectification efficiency.Inspect Auxiliary Circuits

Check auxiliary circuits for proper integration. Faulty circuits can affect monitoring and protection features, reducing overall system reliability.

Tip: Conduct periodic performance reviews to identify areas for improvement. Regular optimization ensures your rectifier power supply operates at peak efficiency.

Implementing maintenance practices

Proper maintenance ensures your rectifier operates efficiently and reliably over its lifespan. Neglecting maintenance can lead to performance issues, reduced efficiency, or even system failure. By adopting a structured approach, you can minimize downtime and extend the life of your equipment.

Establishing a Maintenance Schedule

Creating a regular maintenance schedule is the first step. This schedule should include daily, monthly, and annual tasks to keep your rectifier in optimal condition. For example:

Daily Checks: Monitor the rectifier's output voltage and current. Look for any irregularities in performance or error indicators on the control panel.

Monthly Inspections: Conduct visual assessments of the rectifier and its components. Check for loose connections, signs of wear, or overheating.

Annual Maintenance: Perform a comprehensive system review. Test all modules, inspect diodes, and verify the functionality of auxiliary circuits.

Tip: Use a maintenance log to record all activities. This documentation helps track trends and identify recurring issues.

Key Maintenance Practices

Adopting best practices ensures your rectifier remains reliable. Focus on these critical areas:

Periodic Functional Tests: Test low-voltage disconnects (LLVDs) and battery low-voltage disconnects (BLVDs). These components protect battery integrity by preventing over-discharge.

Regular Inspections: Measure voltage and internal resistance during routine checks. These measurements help predict when batteries may reach the end of their life.

Temperature Control: Maintain stable operating temperatures. Ensure adequate airflow around the rectifier to prevent overheating.

Charging Practices: Follow the manufacturer's specifications for charging. Avoid undercharging or overcharging, as both can damage the rectifier and connected batteries.

Performance Checks: Verify the output of rectifier modules and the functionality of control units. Identifying performance drifts early prevents larger issues.

Addressing Common Issues

Even with regular maintenance, issues can arise. Knowing how to address them quickly minimizes disruptions. Here are some common problems and their solutions:

Issue | Cause | Solution |

|---|---|---|

Overheating | Poor ventilation or high ambient temperature | Improve airflow and ensure proper cooling systems are in place. |

Voltage Fluctuations | Loose connections or faulty diodes | Inspect and tighten connections. Replace damaged diodes. |

Reduced Efficiency | Dust accumulation or worn components | Clean the rectifier and replace worn parts. |

Note: Always power down the rectifier before performing any maintenance to ensure safety.

Leveraging Monitoring Tools

Modern rectifiers often include built-in monitoring features. Use these tools to track performance metrics such as voltage, current, and temperature. Alarms and indicators can alert you to potential issues before they escalate. For older models, consider integrating external monitoring systems for real-time data.

Training and Safety

Ensure all personnel involved in maintenance are properly trained. They should understand the rectifier's operation and safety protocols. Equip them with insulated tools and protective gear to reduce the risk of accidents.

Reminder: Always follow the manufacturer's manual for specific maintenance instructions. This ensures compliance with safety standards and protects your equipment.

By implementing these maintenance practices, you can maximize the efficiency and reliability of your rectifier. Regular care not only prevents unexpected failures but also extends the lifespan of your system.

Common Mistakes to Avoid

Choosing incompatible models

Selecting the wrong rectifier model can disrupt your system's performance. You must evaluate your system's voltage and current requirements before making a choice. Each rectifier is designed for specific applications, so using an incompatible model may lead to inefficiencies or even damage. For example, a diode bridge rectifier with insufficient capacity might overheat or fail under heavy loads. Always review the technical specifications and ensure the rectifier supports full-wave rectification if your system demands it. This step guarantees the rectifier power supply operates efficiently and delivers a stable output.

Tip: Consult the manufacturer's manual or technical support team to confirm compatibility with your power supplies.

Skipping safety checks

Neglecting safety checks can result in serious hazards. Before installation, inspect the rectifier and its components for any visible damage. Loose connections or faulty diodes can compromise rectification and lead to system failures. Grounding the rectifier properly is another critical safety measure. Without a secure ground, electrical surges can damage the diode bridge rectifier and connected equipment. Testing the output voltage and current during installation ensures the rectifier operates within safe limits.

Reminder: Always wear protective gear and follow local electrical codes to minimize risks during installation.

Overlooking system requirements

Ignoring your system's specific needs can cause operational issues. You must consider factors like cooling systems, auxiliary circuits, and load capacity. A rectifier operating in a high-temperature environment without adequate cooling may experience reduced efficiency. Similarly, failing to account for auxiliary circuits can disrupt monitoring and protection features. Ensure the rectifier's output matches your system's requirements for voltage and current. Full-wave rectification improves efficiency, but only if the rectifier is configured correctly.

Note: Regularly review your system's performance to identify and address any mismatches early.

Neglecting maintenance

Neglecting maintenance can lead to significant issues in your rectifier system. Regular care ensures the diode bridge rectifier operates efficiently and prevents unexpected failures. Without proper upkeep, the diodes may degrade, causing inconsistent output and reduced performance. Dust accumulation, loose connections, and worn components can also compromise full-wave rectification, leading to energy losses and overheating.

You should establish a maintenance routine to avoid these problems. Start with daily checks. Monitor the rectifier's output for irregularities. Look for voltage fluctuations or signs of overheating. Monthly inspections should focus on the physical condition of the diodes and connections. Tighten any loose wires and clean dust from the rectifier's surface. Annual maintenance should include a comprehensive review of the diode bridge rectifier. Test each diode for wear and verify the stability of the output under varying loads.

Tip: Use a multimeter to measure voltage and current during inspections. This tool helps you identify hidden issues early.

Ignoring maintenance can also shorten the lifespan of your rectifier. Over time, diodes may fail due to excessive heat or electrical stress. Faulty diodes disrupt full-wave rectification, resulting in unstable output. Regularly replacing worn components ensures the rectifier continues to deliver reliable performance.

Proper maintenance also improves safety. Loose connections or damaged diodes increase the risk of electrical surges. These surges can harm the rectifier and connected equipment. By addressing these issues promptly, you protect your system and maintain consistent output.

A well-maintained rectifier supports efficient rectification and reduces downtime. Make maintenance a priority to maximize the performance and longevity of your diode bridge rectifier.

Proper integration and optimization of ESTEL rectifiers ensure your power supply system operates efficiently and reliably. By following the outlined steps, you can confidently achieve a seamless setup that minimizes downtime and maximizes performance. The long-term benefits of using ESTEL rectifiers are significant:

Benefit | Description |

|---|---|

Energy Efficiency | Advanced rectifiers minimize energy loss, leading to lower electricity bills and cost savings. |

Cost-Effectiveness | Initial setup costs are outweighed by long-term savings, making it a financially sound choice. |

Reliability | Ensures uninterrupted power supply, reducing downtime and protecting revenue. |

Investing in ESTEL rectifiers supports consistent power delivery and enhances the overall reliability of your system.

FAQ

1. What makes ESTEL rectifiers suitable for modern power supply designs?

ESTEL rectifiers offer high efficiency, compact designs, and advanced thermal management. Their ability to perform full-wave rectification ensures stable DC output, making them ideal for applications requiring reliable and consistent power delivery.

2. How do I select the right ESTEL rectifier model for my system?

Evaluate your system's voltage and current requirements. Review the technical specifications of ESTEL models like Flatpack2 or Flatpack SHE. Choose a model that aligns with your power supply needs and environmental conditions.

3. Can I install ESTEL rectifiers without professional assistance?

You can install ESTEL rectifiers if you follow the manufacturer’s manual and safety guidelines. Ensure you have the necessary tools, understand system requirements, and prioritize safety checks during installation.

4. How often should I perform maintenance on ESTEL rectifiers?

Perform daily checks for irregularities, monthly inspections for physical wear, and annual comprehensive reviews. Regular maintenance ensures optimal performance, prevents failures, and extends the rectifier's lifespan.

5. What should I do if my rectifier overheats during operation?

Check the ventilation and cooling systems. Improve airflow around the rectifier and ensure the ambient temperature stays within the recommended range. If overheating persists, inspect for loose connections or worn components.

See Also

Ensuring Correct Voltage in ESTEL Communication Cabinets

Telecom Cabinets by ESTEL: The Role of Energy Storage

Understanding the Power System of ESTEL Telecom Cabinets

Explaining Integration of Supervision Systems in ESTEL Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA