Intelligent Power Distribution for Telecom Cabinet: IoT-Based Real-Time Load Monitoring & Dynamic Circuit Control

You face several power distribution challenges in Telecom Power Systems.

Description | |

|---|---|

Inefficient PDUs | Consume excess energy, raising operational costs and reducing performance. |

Uneven Power Distribution | Can cause overheating and equipment failure. |

Voltage Fluctuations | Lead to malfunctions and higher maintenance costs. |

Environmental Factors | Temperature extremes and dust degrade PDU performance over time. |

Recent trends show a shift toward high-density, modular designs and greater energy efficiency.

AI-powered monitoring now gives you instant alerts for overloads. AT&T improved reliability by 25% and cut costs by 40% using these solutions in their Telecom Power Systems.

Key Takeaways

Intelligent power distribution enhances efficiency and reduces costs. Expect annual savings of over $600 per cabinet and a 20-30% reduction in energy use.

Real-time monitoring with IoT sensors prevents equipment damage. Immediate alerts for temperature spikes and power issues help maintain system reliability.

Follow a clear integration process for IoT systems. Focus on real-time data, predictive maintenance, and scalability to ensure smooth deployment.

Intelligent Power in Telecom Power Systems

Key Benefits

Intelligent power distribution transforms how you manage Telecom Power Systems. You gain advanced features that boost operational efficiency and power management. The table below highlights the main benefits:

Benefit | Description |

|---|---|

Advanced Features | Intelligent PDUs offer advanced features that enhance efficiency and savings. |

Optimization | They optimize power management in dynamic, high-density environments. |

You can expect energy savings of nearly 4,000 kWh per cabinet each year. This leads to over $600 in annual cost savings per cabinet. Many operators also report a 20-30% reduction in energy use and a 20% improvement in network uptime. These improvements help you achieve a quick return on investment and support sustainability goals.

Common Challenges

You may face several challenges in Telecom Power Systems. The most common issues include:

Challenge | Description |

|---|---|

Inadequate Monitoring | Lack of real-time monitoring can delay your response to problems and escalate risks. |

Overheating | Excessive heat damages components, shortens lifespan, and increases fire risk. |

Regular inspections and cleaning prevent dust buildup. Monitoring load balancing helps you avoid overheating and tripped breakers. Replacing worn components promptly maintains system reliability.

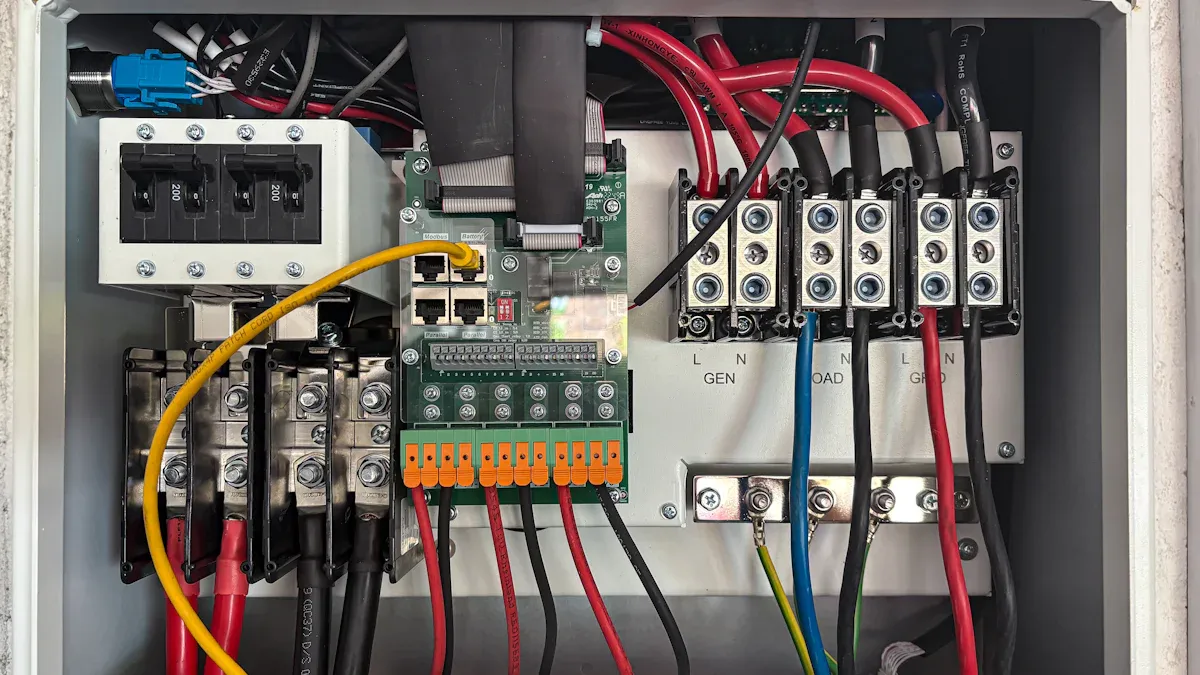

Intelligent PDUs and Remote Monitoring

Intelligent PDUs set themselves apart from traditional units. You can monitor and control power at individual outlets. These units enable remote management, multi-point metering, and environmental monitoring. You receive real-time data on current, voltage, and power usage. This helps you identify inefficiencies and optimize load management.

Remote monitoring enhances operational reliability. You can manage issues without visiting the site. Integrated telemetry provides real-time updates on voltage and breaker status. Predictive maintenance tools alert you to potential problems before they cause downtime. Automation streamlines recovery, reducing human error and speeding up response during failures.

Maintaining a clean and organized workspace improves safety during installation. Proper PDU placement ensures optimal airflow and prevents overheating. Securing the PDU prevents movement that could damage cables or equipment.

Implementing IoT and Dynamic Circuit Control

Core Technologies

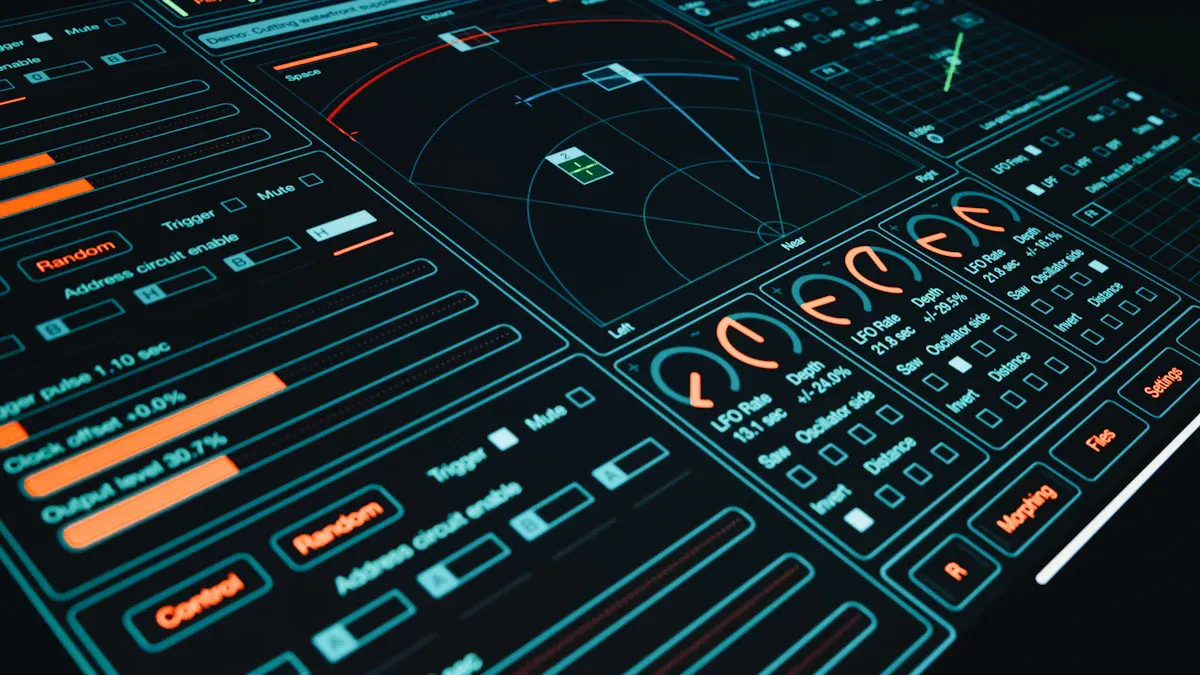

You need to understand the core technologies that drive real-time load monitoring and dynamic circuit control in telecom cabinets. These technologies give you the ability to monitor, analyze, and act on power data instantly. The table below summarizes the primary IoT technologies used for this purpose:

Technology Type | Description |

|---|---|

Embedded IoT Sensors | Monitor temperature, humidity, vibration, and door access in real time, enabling instant alerts. |

AI-Driven Analytics | Analyze real-time data to predict failures and optimize maintenance schedules. |

Intelligent Power Monitoring | Enables immediate adjustments and reduces the need for on-site troubleshooting. |

Dynamic circuit control systems integrate with your existing infrastructure through several key features. Multi-protocol support allows communication with different devices and technologies. Compatibility with legacy systems means you can upgrade without extensive rewiring. Edge computing modules process data locally, which enhances performance and enables immediate actions.

Edge computing modules process data at the source. This local handling allows for immediate analysis and actions, such as dynamic resource allocation and fault detection. These capabilities are crucial for maintaining efficient operations in your telecom cabinets.

Modular designs let you customize solutions for your network needs. You can integrate PDUs, backup batteries, and rectifiers easily. This approach simplifies maintenance and expansion as your network grows.

Integration Steps

Selecting and integrating IoT-based monitoring and dynamic circuit control requires a clear, step-by-step approach. Follow these guidelines to ensure a smooth deployment:

Real-time Data: Choose a monitoring system that provides real-time data. Look for remote access and instant notifications for abnormal conditions.

Predictive Maintenance: Select systems that use predictive maintenance models. These systems leverage historical sensor data to forecast failures and maintain equipment effectively.

Scalability: Ensure your solution can grow with your network. It should handle increased data and devices as your telecom infrastructure expands.

System Compatibility: Pick solutions that integrate seamlessly with your existing infrastructure, regardless of vendor. This minimizes integration challenges.

Cost-effectiveness: Evaluate long-term value. Balance upfront costs with lifecycle savings and performance benefits.

When you integrate dynamic circuit control, look for features like multi-protocol support and compatibility with legacy equipment. Modular designs allow you to tailor the system to your needs. Edge computing modules help you process data locally, which improves response times.

You may encounter some common pitfalls during integration:

Type of Pitfall | Description |

|---|---|

Interoperability issues | Challenges in ensuring different IoT devices and systems can work together effectively. |

Security vulnerabilities | Risks associated with unauthorized access, data interception, and inadequate encryption in IoT deployments. |

Data compatibility and management | Difficulties in managing and ensuring compatibility of data across various IoT devices and systems. |

To avoid these issues, plan for interoperability and data management from the start. Use advanced security protocols and ensure all devices follow the same standards.

Maintenance and Optimization

Ongoing monitoring and predictive maintenance are essential for reliable operation. You should calculate total power needs and plan for future growth. Choose scalable, standards-compliant solutions. Integrate remote monitoring and predictive analytics to stay ahead of potential problems.

Regular audits help you adapt to new technologies. Monitor key parameters such as voltage, current, temperature, humidity, airflow, water leaks, vibration, battery health, and fuse status.

You should install water leak sensors at the base of your cabinet and near any entry points for cables or pipes. These sensors alert you immediately if they detect moisture, giving you time to act before damage occurs.

Predictive maintenance using IoT sensors reduces downtime. As Arunachalam notes, "Data acquisition and the enablement of data analytics is a very powerful tool. We’re not just cooling the site, we’re learning how it behaves and providing meaningful information on preventative maintenance to reduce operational costs and minimize downtime."

Scalability is another critical factor. Your network must handle more IoT devices and increased data as you expand. Consider network capacity, bandwidth optimization, and software infrastructure scalability. Use cloud computing and software-defined networking to support growth. Plan for future scalability to reduce risks and ensure flexibility.

Security remains a top priority. Encrypt communications and use multi-factor authentication. Comply with regional regulations like GDPR. Update software regularly and monitor for threats. IoT devices can introduce new vulnerabilities, so advanced security measures are vital.

Compatibility with legacy systems can present challenges. Older systems may use proprietary protocols or lack the speed to handle real-time data. You may need additional hardware or software to bridge these gaps. Upgrading legacy systems can be costly, so plan carefully.

Safety standards guide the implementation of dynamic circuit control. The table below lists key standards you should follow:

Safety Standard | Description |

|---|---|

ISO 14971 | Risk Management for Medical Devices, focusing on structured risk management in power electronics. |

IEC 61508 | Functional Safety of Electrical, Electronic, and Programmable Electronic Safety-related Systems, emphasizing safety in high voltage operations. |

IEC 61558 | Safety of power transformers, addressing ground fault protection. |

IEC 60364 | Low-voltage electrical installations, outlining requirements for ground fault protection. |

IEC 60601 | Standards for medical electrical equipment, highlighting the importance of electrical isolation. |

IEC 60950 | Safety of information technology equipment, focusing on grounding and isolation for user safety. |

Tip: Always follow industry safety standards and best practices. This ensures the safety of your team and the reliability of your Telecom Power Systems.

Intelligent power distribution in Telecom Power Systems delivers measurable benefits. You gain lower maintenance costs, improved uptime, and enhanced safety.

Feature | Benefit |

|---|---|

IoT Integration | Enables remote monitoring and control |

Predictive Analytics | Reduces downtime and boosts reliability |

Environmental Sensors | Supports proactive maintenance |

Explore resources like virtual power plants and smart metering to future-proof your network.

FAQ

What is an intelligent PDU and how does it help you?

An intelligent PDU lets you monitor and control power remotely. You can track energy use, prevent overloads, and improve uptime.

How does IoT-based real-time monitoring improve telecom cabinet safety?

IoT sensors alert you to temperature spikes, water leaks, or power issues. You can act quickly to prevent equipment damage and reduce downtime.

Can you upgrade existing telecom cabinets with dynamic circuit control?

Yes. Many dynamic circuit control systems support legacy equipment. You can add modules or adapters to enable real-time monitoring and remote management.

See Also

Ensuring Consistent Power Supply For Telecom Cabinet Systems

Solar Energy Storage Solutions For Telecom Cabinet Power

Smart Energy Storage Systems For Telecom Cabinet Integration

Achieving Effective Monitoring For Outdoor Telecom Cabinets

Calculating Power Systems And Battery Needs For Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA