ESTEL Tips for Maintaining Rectifier Modules in Outdoor Telecom Cabinets

Maintaining rectifier modules for outdoor telecom cabinet systems is vital for ensuring reliable power conversion and uninterrupted telecom operations. These modules achieve peak efficiency levels of up to 97.83%, minimizing power losses and maximizing energy utilization. Proactive maintenance not only reduces downtime but also enhances equipment reliability by addressing potential failures before they occur. Predictive strategies save 8% to 12% more compared to preventive measures, while offering up to 40% cost savings over reactive approaches. By investing in regular care for these components, you safeguard both system performance and financial resources.

Key Takeaways

Check rectifier modules often to find problems early. This avoids expensive fixes and delays.

Clean rectifier modules to keep them working well. Use soft brushes or air to remove dust.

Use tools to predict problems before they get worse. This saves time and money on repairs.

Make sure telecom cabinets have good airflow. This stops overheating and protects important parts.

Update firmware often to improve how modules work and stay secure. This adds new features to the modules.

Regular Inspection and Monitoring

Visual Checks for Rectifier Modules

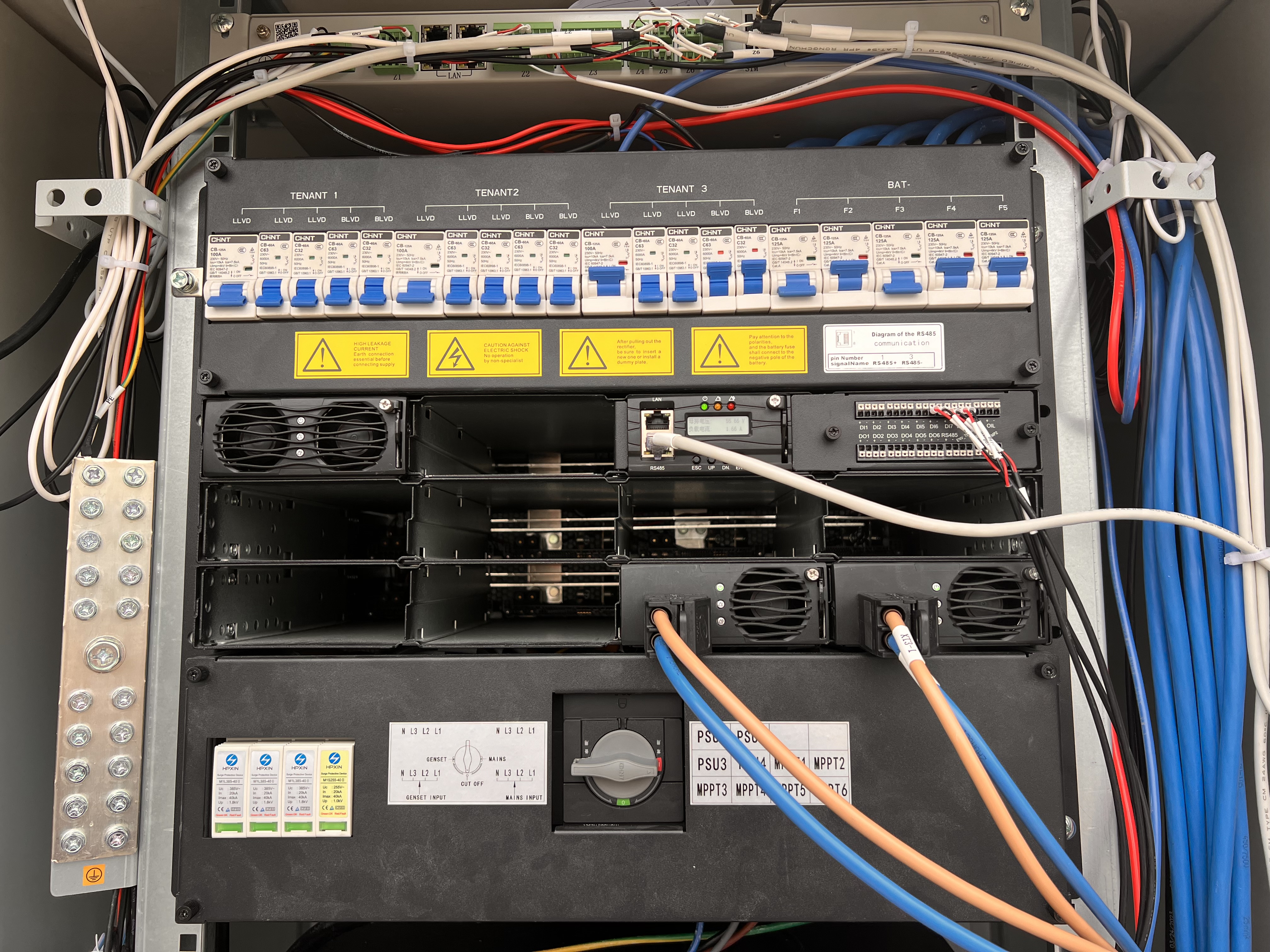

Regular visual inspections help you identify potential issues before they escalate. Begin by examining the rectifier modules for outdoor telecom cabinet systems for signs of physical damage, such as cracks, dents, or discoloration. These indicators often point to overheating or external impacts.

Pay close attention to the connectors and terminals. Loose or corroded connections can disrupt power flow, reducing efficiency. If you notice any corrosion, clean the affected areas immediately to prevent further degradation.

Inspect the cooling systems integrated into the cabinet. Dust accumulation or blocked vents can hinder airflow, leading to overheating. Ensure the cooling fans are operational and free from obstructions.

Tip: Use a flashlight during inspections to spot hidden damage or debris in hard-to-reach areas.

Monitoring System Performance and Alarms

Monitoring the performance of rectifier modules ensures they operate at optimal efficiency. Check the output voltage, current, and efficiency of each module regularly. These metrics reveal whether the modules are converting AC power to DC power effectively.

Control units play a critical role in maintaining system balance. Verify that the site controller is functioning properly. It should log events accurately and distribute loads evenly across the modules.

Keep an eye on system alarms. These alerts often signal issues like power supply failures or overheating. Address alarms promptly to prevent downtime.

Key Performance Indicator | Description |

|---|---|

Module Outputs | Regularly check each rectifier module’s output voltage, current, and efficiency. |

Control Unit Verification | Ensure the site controller is functioning properly, balancing loads and logging events accurately. |

Rectifier Modules: Convert AC power to DC power for telecom equipment.

Control Units: Monitor and adjust the rectifier for efficiency.

Cooling Systems: Prevent overheating to extend the rectifier's lifespan.

Note: Many modern systems allow remote monitoring, enabling you to track performance and alarms without visiting the site.

Cleaning and Dust Removal

Dust-Free Maintenance for Rectifier Modules

Keeping rectifier modules clean is essential for maintaining their performance. Dust buildup can impair the efficiency of these components and shorten their lifespan. You should regularly remove dust from the modules to prevent resinous deposits from forming. These deposits attract airborne particles, leading to significant accumulation over time.

Focus on areas prone to dust collection, such as connectors, terminals, and cooling vents. Use a soft brush or compressed air to dislodge particles without damaging sensitive components. Avoid using water or liquid cleaners, as they can cause electrical shorts.

Tip: Increase exhaust rates in the cabinet to reduce condensation and limit dust buildup. Longer vestibules can also help minimize resinous material accumulation.

A dust-free environment ensures that rectifier modules for outdoor telecom cabinet systems operate efficiently. Regular cleaning prevents overheating and extends the lifespan of your equipment.

Air Filter Cleaning and Replacement

Air filters play a critical role in maintaining clean airflow within outdoor telecom cabinets. Dirty filters restrict airflow, causing cooling systems to work harder and increasing the risk of overheating. You should inspect air filters periodically and clean or replace them as needed.

To clean reusable filters, remove them from the cabinet and gently wash them with water. Allow them to dry completely before reinstalling. For disposable filters, replace them with new ones to ensure optimal performance.

Note: Always check the filter specifications provided by the manufacturer to avoid using incompatible replacements.

Regular maintenance of air filters not only protects rectifier modules but also improves the overall efficiency of the cooling system. Clean filters reduce energy consumption and help maintain stable operating temperatures.

Cooling System Maintenance

Ensuring Proper Ventilation in Outdoor Cabinets

Proper ventilation is essential for maintaining the performance and longevity of rectifier modules for outdoor telecom cabinet systems. Without adequate airflow, heat builds up inside the cabinet, leading to overheating and potential damage to internal components. You can prevent this by ensuring the cabinet meets ventilation standards designed to optimize cooling performance.

Overheating damages sensitive components, reducing their lifespan.

Passive cooling systems use natural airflow through strategically placed vents, ideal for moderate climates.

Active cooling systems, such as fans and air conditioning, manage heat more effectively, preventing hotspots.

A well-designed ventilation system promotes consistent airflow, reducing the risk of thermal damage.

To enhance ventilation, inspect the cabinet for blocked vents or obstructions. Clear any debris that may hinder airflow. If the cabinet operates in a high-temperature environment, consider upgrading to active cooling systems for better heat management.

Tip: Install customizable airflow patterns to target areas prone to overheating. This reduces the risk of thermal damage and ensures even temperature distribution.

Inspecting and Maintaining Cooling Fans

Cooling fans play a critical role in regulating the temperature inside outdoor telecom cabinets. Regular inspection and maintenance of these fans ensure they operate efficiently, preventing overheating and extending the lifespan of rectifier modules.

Begin by checking the fan blades for dust or debris. Clean them using a soft brush or compressed air to maintain optimal airflow. Inspect the fan motors for wear and tear. Lubricate them periodically to reduce friction and improve performance.

Condition | Efficiency (kW/ton) | Energy Cost Increase |

|---|---|---|

Well-Maintained | 0.55 to 0.60 | N/A |

Neglected | 0.90 to 1.0 | 20–25% |

Maintenance Task | Impact on Efficiency |

|---|---|

Cleaning and replacing filters | Significant increase |

Inspecting and cleaning coils | Significant increase |

Lubricating fan motors | Significant increase |

Regular fan maintenance not only improves cooling efficiency but also reduces energy costs. Neglected fans consume more power and increase operational expenses. By keeping fans in top condition, you ensure consistent cooling performance and protect your equipment from heat-related failures.

Electrical Connections and Cabling

Tightening and Securing Electrical Connections

Securing electrical connections is crucial for maintaining the performance and safety of rectifier modules for outdoor telecom cabinet systems. Loose connections can lead to power interruptions, overheating, or even equipment failure. You should regularly inspect and tighten all electrical connections to ensure they remain stable and secure.

Start by checking the connectors and terminals for signs of looseness or wear. Use appropriate tools to tighten screws and clamps. Avoid over-tightening, as this can damage the components. Ensure that all connections are properly aligned to prevent electrical resistance, which can reduce efficiency.

To protect the cabinet from external elements, seal any gaps with weatherproof materials. This prevents water ingress and keeps pests from damaging the wiring. Proper sealing also reduces the risk of corrosion, which can compromise the integrity of the connections.

Tip: Use high-quality hardware and connectors designed for outdoor environments. These materials resist corrosion and provide long-lasting stability.

Inspecting Cabling for Corrosion or Damage

Damaged or corroded cabling can disrupt power flow and compromise the efficiency of your telecom system. Regular inspections help you identify issues early and prevent costly repairs. Begin by visually examining the cables for cracks, fraying, or discoloration. These signs often indicate wear or exposure to harsh conditions.

Check for corrosion on metal connectors and terminals. Corrosion can weaken the connection and increase electrical resistance. If you find corroded areas, clean them with a non-abrasive brush and apply a protective coating to prevent further damage.

Inspect the cable insulation for signs of deterioration. Damaged insulation exposes the wires to moisture and contaminants, increasing the risk of short circuits. Replace any cables with compromised insulation immediately.

Key Inspection Steps:

Examine cables for physical damage, such as cracks or fraying.

Clean corroded connectors and apply protective coatings.

Replace cables with damaged insulation to prevent short circuits.

Note: Always use cables that meet the manufacturer’s specifications for outdoor telecom cabinets. This ensures compatibility and reliability under varying environmental conditions.

Firmware and Software Updates

Updating Firmware for Rectifier Modules

Keeping firmware up to date is essential for optimizing the performance of rectifier modules for outdoor telecom cabinet systems. Firmware updates often include bug fixes, security enhancements, and new features that improve efficiency. You should check for updates regularly to ensure your modules operate with the latest capabilities.

Start by identifying the current firmware version installed on your rectifier modules. Compare it with the latest version provided by the manufacturer. If an update is available, download it from the official website or authorized sources.

Before proceeding, back up the existing firmware and system settings. This precaution protects your data in case the update encounters issues. Follow the manufacturer’s instructions carefully during installation to avoid errors.

Tip: Schedule firmware updates during low-traffic periods to minimize disruptions to telecom operations.

Safe Software Update Practices

Software updates require careful planning to prevent system downtime or data loss. You should always verify the compatibility of the update with your rectifier modules and other connected systems. Incompatible software can cause malfunctions or reduce efficiency.

Begin by reviewing the update documentation provided by the manufacturer. This information outlines the changes and requirements for successful installation. Use secure methods to download the update, such as encrypted connections or trusted networks.

During installation, monitor the process closely. Avoid interrupting the update, as this can corrupt the software and lead to system failures. Once the update is complete, test the modules to ensure they function correctly.

Note: Keep a log of all updates, including the date, version, and any observed changes. This record helps you track system performance over time.

By following safe practices, you maintain the reliability of rectifier modules for outdoor telecom cabinet systems while reducing risks associated with software updates.

Troubleshooting Common Issues

Resolving Power Supply Failures

Power supply failures in rectifier modules can disrupt telecom operations. Identifying and addressing these issues promptly ensures system reliability. Begin by checking for electromagnetic interference (EMI), a common cause of power supply disruptions. EMI arises from high-frequency switching actions within the modules. It can manifest as conducted interference or radiated interference, with the former being easier to diagnose.

To mitigate EMI, inspect the module's printed circuit boards (PCBs). Poor design or improper component placement can amplify interference. Ensure that the layout minimizes noise and optimizes signal flow. High-quality filter capacitors can also reduce differential mode interference, improving power stability.

Noise from switching power supplies often includes peak and harmonic interference. Address these by using shielding techniques and grounding methods. Regularly monitor the system for unusual noise patterns, as they may indicate underlying issues.

Tip: Use diagnostic tools to measure EMI levels and identify the source of interference. This helps you implement targeted solutions effectively.

Addressing Overheating in Rectifier Modules

Overheating is another frequent issue that affects rectifier modules. Excessive heat can damage components and reduce efficiency. Start by inspecting the cooling system. Ensure that fans and vents are free from obstructions. Dust and debris can block airflow, causing heat to build up inside the cabinet.

Check the thermal paste on heat sinks. Over time, it can degrade, reducing its ability to transfer heat away from critical components. Replace it if necessary. Monitor the module's temperature regularly. Sudden spikes may indicate a failing cooling system or excessive load.

Common Causes of Overheating:

Blocked airflow due to dust or debris.

Malfunctioning cooling fans.

Excessive power loads on the module.

Note: Install temperature sensors to track heat levels in real-time. This allows you to take immediate action if overheating occurs.

By addressing these common issues, you can maintain the performance and longevity of rectifier modules in outdoor telecom cabinets.

Preventive Maintenance Scheduling

Establishing Routine Maintenance for Rectifier Modules

Routine maintenance ensures the consistent performance of rectifier modules for outdoor telecom cabinet systems. By establishing a structured schedule, you can prevent unexpected failures and extend the lifespan of your equipment. A well-planned maintenance routine focuses on efficiency, resource optimization, and adherence to manufacturer guidelines.

Start by setting clear goals for your maintenance activities. These goals may include reducing downtime, improving energy efficiency, or minimizing repair costs. Once you define your objectives, consider the logistics. Evaluate the timing, resources, and staffing required to execute the maintenance tasks effectively.

Use the manufacturer’s checklists as a guide. These checklists provide detailed instructions tailored to the specific requirements of your rectifier modules. Additionally, gather useful data about your equipment, such as performance metrics and historical maintenance records. This information helps you identify patterns and prioritize tasks.

Break down your goals into manageable tasks and assign them to your team. For example, you can schedule regular inspections, clean the hardware, and review system logs. These smaller tasks contribute to the overall success of your maintenance strategy.

Strategy | Purpose |

|---|---|

Set Your Goals | Increase efficiency, prevent downtime, etc. |

Consider the Logistics | Optimize timing, resources, and staffing. |

Use OEM Checklists As a Guide | Follow manufacturer recommendations. |

Gather Useful Data | Compile equipment data for efficient repairs. |

Assign the Tasks | Break down goals into manageable tasks. |

Tip: Regularly inspect server logs and evaluate system security to identify potential vulnerabilities early.

By following a structured routine, you can maintain the reliability of rectifier modules and ensure uninterrupted telecom operations.

Leveraging Predictive Maintenance Tools

Predictive maintenance tools use advanced technologies to monitor the condition of rectifier modules for outdoor telecom cabinet systems. These tools analyze real-time data to detect potential issues before they escalate, allowing you to address them proactively. This approach not only reduces downtime but also lowers maintenance costs.

Case studies highlight the effectiveness of predictive maintenance in telecom operations. For instance, a leading telecom provider achieved energy efficiency levels of up to 97.8% by using predictive tools. They also detected issues early, preventing service disruptions and enabling seamless network expansion. Similarly, GreenConnect reduced energy use by 30% and downtime by 25%, while also cutting CO2 emissions by 40%.

Case Study | Key Outcomes |

|---|---|

Leading Telecom Provider | - Improved Efficiency: Energy efficiency levels of up to 97.8%. |

- Enhanced Reliability: Issues detected before impacting service. | |

- Scalability: Seamless network expansion without disruption. | |

GreenConnect | - Energy Savings: 30% reduction in energy use. |

- Environmental Benefits: 40% decrease in CO2 emissions. | |

- Improved Reliability: 25% reduction in downtime. |

To implement predictive maintenance, start by integrating sensors and monitoring devices into your telecom cabinets. These devices collect data on temperature, voltage, and other critical parameters. Use software platforms to analyze this data and generate actionable insights. For example, temperature sensors can alert you to overheating, while voltage monitors can detect power fluctuations.

Note: Predictive maintenance tools require an initial investment, but the long-term savings and improved reliability make them a worthwhile addition to your maintenance strategy.

By leveraging predictive maintenance tools, you can optimize the performance of rectifier modules and ensure the seamless operation of your telecom systems.

Training and Safety Protocols

Technical Training for Maintenance Teams

Comprehensive technical training equips your maintenance team with the skills needed to handle rectifier modules effectively. A well-trained team can identify issues faster, perform repairs accurately, and reduce downtime. Training programs should focus on both technical and soft skills to ensure well-rounded development.

For technical skills, prioritize hands-on exercises that simulate real-world scenarios. For example, practicing fault diagnosis on rectifier modules helps your team build confidence in troubleshooting. Additionally, training on the latest firmware updates ensures your team stays current with technological advancements.

Soft skills are equally important. Effective communication, teamwork, and problem-solving enhance collaboration during maintenance tasks. The table below highlights methodologies that improve these skills:

Training Methodology | Description |

|---|---|

Listening Skills | Exercises like the Goldilocks challenge develop attentive listening and critical thinking. |

Business Networking | Prepares employees to build professional relationships for lasting connections. |

Media Ambush | High-pressure simulations teach composure in critical situations. |

Sales Pitching | Refines approaches through practice and immediate feedback. |

Eye Contact and Body Language | Improves non-verbal communication for customer service and teamwork. |

Sexual Harassment Prevention | Immersive simulations raise awareness and teach appropriate responses. |

By combining technical expertise with soft skills, your team becomes more efficient and adaptable.

Safety Standards for Rectifier Module Maintenance

Safety should always be your top priority during maintenance. Working with rectifier modules involves electrical hazards, so following strict safety protocols is essential. Begin by equipping your team with personal protective equipment (PPE) such as insulated gloves, safety goggles, and non-conductive footwear.

Before starting any task, ensure the power supply is disconnected. Use lockout/tagout (LOTO) procedures to prevent accidental re-energization. Inspect tools and equipment for damage to avoid malfunctions during use. Always maintain a clean and organized workspace to minimize risks.

Tip: Conduct regular safety drills to reinforce emergency response procedures. This prepares your team for unexpected situations.

Adhering to safety standards not only protects your team but also ensures the longevity of your rectifier modules. A safe work environment fosters productivity and builds trust within your organization.

Maintaining rectifier modules for outdoor telecom cabinet systems requires a structured approach. Regular inspections, cleaning, and firmware updates ensure optimal performance. Proactive maintenance prevents costly failures and extends equipment lifespan.

Tip: Establish a routine schedule and use predictive tools to identify issues early.

Leverage ESTEL’s expertise to simplify maintenance tasks and enhance system reliability. Their solutions help you achieve uninterrupted telecom operations with minimal effort.

FAQ

What is the ideal frequency for maintaining rectifier modules?

You should perform maintenance every 3 to 6 months. This schedule ensures optimal performance and prevents unexpected failures. Adjust the frequency based on environmental conditions and equipment usage.

How can you identify overheating in rectifier modules?

Monitor temperature sensors and look for system alarms. Overheating often causes physical signs like discoloration or a burning smell. Regular inspections help you detect these issues early.

Can you clean rectifier modules without professional tools?

Yes, you can use a soft brush or compressed air to remove dust. Avoid water or liquid cleaners to prevent electrical shorts. Always follow the manufacturer’s cleaning guidelines.

What are the benefits of predictive maintenance tools?

Predictive tools help you detect issues early, reduce downtime, and lower maintenance costs. They also improve energy efficiency and extend the lifespan of rectifier modules.

Why is firmware updating important for rectifier modules?

Firmware updates improve performance, fix bugs, and enhance security. Keeping your modules updated ensures they operate with the latest features and capabilities.

Tip: Always back up your system before performing firmware updates to avoid data loss.

See Also

Essential Strategies for Caring for Outdoor Telecom Cabinets

Requirements for Ensuring Longevity of Outdoor Telecom Cabinets

Necessary Materials for Durable Outdoor Telecom Cabinet Construction

Safeguarding Equipment Using Outdoor Telecom Cabinet Solutions

Effective Maintenance Tips for Outdoor Communication Cabinet Protection

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA