MPPT+solar Module Combo power optimization for telecom cabinets under light and heavy load scenarios

Reliable power supply remains critical for telecom cabinets, especially in environments with fluctuating load demands. Variable load conditions often lead to increased heat generation, causing thermal stress and raising risks of equipment failure. Operators deploy active cooling systems to stabilize temperatures and prevent issues like condensation and overheating. Smart energy-saving features and remote monitoring further boost operational efficiency by enabling proactive management. The integration of MPPT+solar Module combos in these cabinets optimizes power extraction and system performance. Advanced MPPT algorithms and precise system sizing enhance uptime, reduce maintenance costs, and extend equipment lifespan.

Key Takeaways

MPPT+solar Module combos maximize energy extraction by continuously adjusting to sunlight and temperature changes, ensuring reliable power for telecom cabinets.

Proper solar module sizing, with safety margins and backup planning, prevents energy waste, reduces battery strain, and improves system reliability.

Light load scenarios benefit from energy-saving features like ECO mode and modular rectifiers, which reduce power loss and operational costs.

Heavy load scenarios require advanced MPPT algorithms, multiple trackers, and effective thermal management to maintain efficiency and protect equipment.

Regular monitoring, maintenance, and following a detailed design checklist ensure long-term performance, safety, and reduced downtime for telecom power systems.

Power Demands in Telecom Cabinets

Light Load Scenarios

Telecom cabinets often operate under light load conditions, especially in urban environments with small cells or micro base stations. These scenarios require less power, which allows for efficient energy management and reduced operational costs. Operators deploy cabinets with lower capacity modules to match the minimal demand. The following table illustrates typical power demand ranges for various deployment environments:

Power Demand Range | Typical Capacity (kW) | Typical Deployment Environment |

|---|---|---|

Low Power | Up to 2–3 kW | Small cells, urban micro base stations (urban) |

Medium Power | 3–10 kW | Macro towers, suburban installations (urban/suburban) |

High Power | Above 10 kW | Large macro towers, rural sites, multi-tenant towers (rural and some urban) |

Urban telecom cabinets usually fall within the low to medium power range. These cabinets support smaller cells and suburban macro towers. Operators benefit from lower energy consumption and simplified cooling requirements. Light load scenarios also enable the use of energy-saving features, such as ECO mode, which further reduces power draw and extends equipment lifespan.

Tip: Matching solar module capacity to the actual load prevents energy waste and improves overall system efficiency.

Heavy Load Scenarios

Heavy load scenarios occur in cabinets supporting large macro towers or multi-tenant sites, often found in rural areas. These cabinets must deliver reliable power to multiple high-demand devices. Operators face increased energy consumption and greater cooling needs. Typical equipment in heavy load cabinets includes:

Servers (280–500 W)

Routers (~200 W)

Power supplies (~100 W)

Variable-frequency drives (30–50 W)

PLC units (35–50 W)

Industrial PCs (~300 W)

UPS units (consuming about 20% of rated power)

Power consumption fluctuates with operational load and environmental conditions. Seasonal temperature changes increase cooling or heating demands. During peak traffic periods, GSM 1800 base station cabinets with 12 transceivers can consume between 1.38 kW and 1.91 kW, more than double the usage of GSM 900 or UMTS cabinets. Efficiency improvements in rectifier modules, such as modern SiC modules reaching up to 98%, help reduce power losses and heat output. These advancements are critical for managing energy use and maintaining system reliability during heavy load periods.

MPPT+solar Module Basics

MPPT Functionality

Maximum Power Point Tracking (MPPT) technology plays a vital role in extracting the highest possible energy from solar panels. MPPT controllers continuously adjust the operating point of the solar array to match the maximum power point, which is the optimal combination of voltage and current. This point shifts throughout the day due to changes in sunlight intensity and temperature. The controller acts as a smart DC-DC converter, dynamically matching the load to the solar panel’s optimal voltage and current. This process ensures that the system operates at peak efficiency, regardless of environmental fluctuations.

The principle behind MPPT is straightforward. The maximum power output from a photovoltaic panel occurs at a specific voltage-current pair, not simply at the highest voltage or current. MPPT algorithms constantly search for and track this point, allowing the system to maximize energy extraction. As sunlight and temperature change, the controller adapts, maintaining efficient operation.

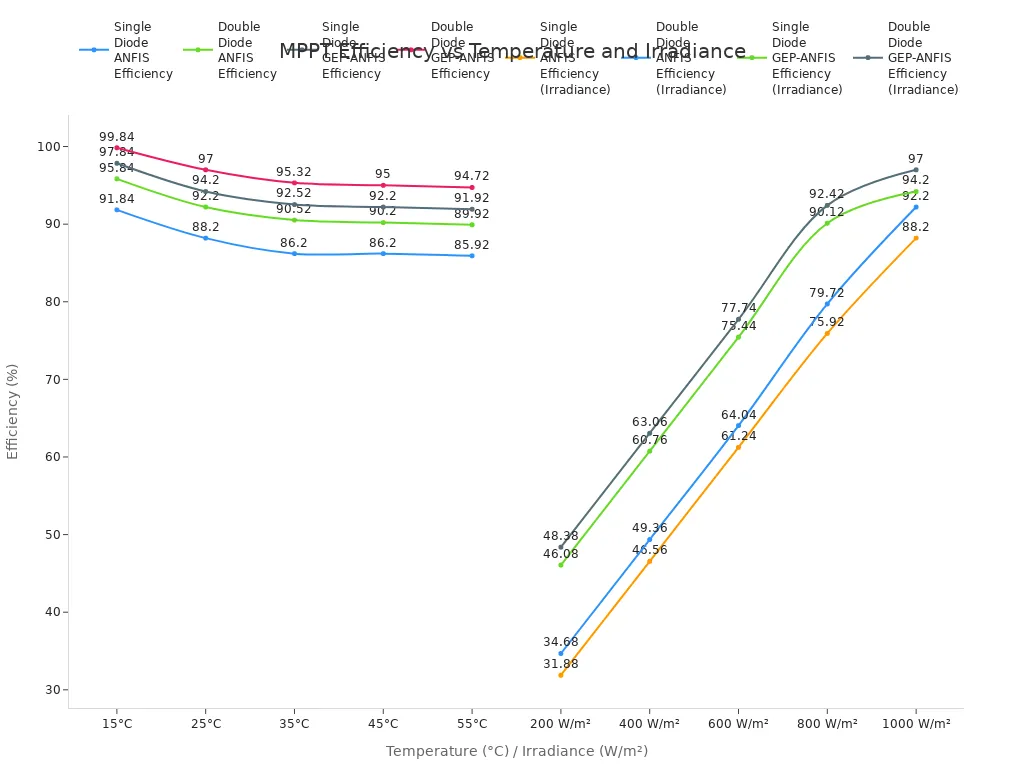

MPPT efficiency varies with environmental conditions. Higher solar irradiance typically increases efficiency, while rising temperatures tend to decrease it. Advanced hybrid MPPT models, such as GEP-ANFIS double diode controllers, demonstrate superior adaptability, achieving nearly 100% efficiency at low temperatures and high irradiance. The following chart illustrates how MPPT efficiency changes with temperature and irradiance for different controller models:

Operators must consider several factors that affect MPPT performance:

Solar cell efficiency drops as temperature rises above 75°C.

Environmental factors such as mist, dust, and air thickness cause solar irradiance to fluctuate.

MPPT algorithms help mitigate efficiency losses caused by these changes.

Weather conditions directly impact inverter output and overall system performance.

Solar Module Sizing

Proper solar module sizing is essential for reliable telecom cabinet operation. Operators must first determine the total daily power consumption of all equipment inside the cabinet. This calculation involves summing the power requirements of each device, using the formula: Current (Amps) × Voltage (Volts). To ensure system resilience, they apply a safety margin—commonly doubling the calculated demand—to account for unexpected energy use or future upgrades.

Two main strategies guide solar panel sizing:

Consumption Strategy:

PV Size [W] = Margin × (Daily Consumption [Wh]) / (Light Exposure [h])Battery Strategy:

PV Size [W] = Margin × (Battery Capacity [Wh]) / (Desired Charge Time [h])

Operators adjust the margin and panel size based on network criticality and local environmental conditions. Geographic and seasonal variations in sunlight exposure also influence sizing decisions. For example, a cabinet consuming 1,500 Wh daily, with 5 hours of sunlight and a 2x margin, requires a 600 W solar array.

Tip: Oversizing the solar system by at least 20% and planning for backup days improves reliability and reduces maintenance costs.

Improper sizing can lead to several issues:

Undersized solar modules fail to meet energy demands, forcing batteries to work harder and wear out faster.

Network uptime decreases, especially during cloudy weather or peak usage periods.

The risk of unexpected outages and costly repairs increases.

Accurate load and site assessments enhance battery longevity and system reliability.

Multiple MPPT Trackers for Variable Conditions

Telecom cabinets often operate in environments with variable shading, panel orientation, and load profiles. Using multiple MPPT trackers within a MPPT+solar Module system offers significant advantages:

Multiple controllers adapt to different panel orientations or shading, increasing energy yield.

They optimize energy harvest by precisely tracking the maximum power point under changing conditions.

Electrical and thermal stress on system components decreases, extending system lifespan.

Real-world deployments show up to a 25% increase in energy output for telecom cabinets using multiple MPPT controllers.

System reliability and efficiency improve, especially in complex solar array setups with shading or misalignment.

Operators benefit from deploying MPPT+solar Module combos with multiple trackers, especially in challenging environments. This approach ensures consistent power delivery, reduces maintenance needs, and supports uninterrupted telecom operations.

Power Optimization

Light Load Optimization

Telecom cabinets operating under light load conditions benefit from targeted energy-saving strategies and advanced control features. Engineers deploy DC rectifier systems to minimize power conversions, which reduces energy loss by approximately 7% and increases efficiency by up to 28% compared to traditional AC systems. Modular rectifiers provide scalability, allowing operators to adjust capacity as demand fluctuates. High-frequency rectifiers offer compactness and efficiency, making them ideal for critical systems with low power requirements.

Operators implement ECO mode to further optimize energy use. ECO mode automatically turns off unused rectifiers when the load drops below 50%, activating additional units only when demand rises. The NetSure Control Unit monitors load levels and manages rectifier rotation, balancing wear and maintaining peak efficiency. By running only the most efficient rectifiers, ECO mode reduces energy loss and operational costs. The system responds quickly to load changes, supported by battery backup and rapid rectifier activation.

Tip: Remote monitoring and smart cabinet features enable real-time tracking of temperature and power anomalies, allowing proactive management and reducing unnecessary energy consumption.

Passive cooling methods such as heat exchangers, ventilation fans, and insulated panels help lower the need for active cooling. Cabinet designs that emphasize thermal management prevent overheating and reduce cooling energy requirements. Modularity in cabinet design allows for scalable deployment, avoiding unnecessary power use during periods of low demand. Power distribution units balance loads and monitor usage, which is crucial for optimizing energy consumption during light load periods.

Advanced MPPT algorithms play a key role in maximizing energy extraction from solar modules. AI-based metaheuristic methods like Particle Swarm Optimization (PSO), Grey Wolf Optimization (GWO), and Genetic Algorithms (GA) effectively track the global maximum power point even under partial shading and rapidly changing environmental conditions. These intelligent controllers adapt to system nonlinearities, temperature fluctuations, and aging effects, maintaining optimal performance and higher overall power output over time. Hybrid algorithms combine strengths of different approaches to achieve faster convergence and more reliable global MPP tracking.

Heavy Load Optimization

Heavy load scenarios in telecom cabinets require robust power optimization strategies to ensure reliability and efficiency. Engineers select advanced MPPT+solar Module systems equipped with multiple trackers to handle variable shading, panel orientation, and fluctuating load profiles. AI-based MPPT algorithms such as Artificial Neural Networks (ANN) and Fuzzy Logic Controllers (FLC) outperform conventional methods by offering nonlinear mapping capabilities, self-learning, adaptive behavior, and high-speed response. These algorithms provide higher tracking accuracy and robustness, which is critical for telecom applications facing dynamic environmental conditions.

Aspect | Conventional MPPT Algorithms (e.g., P&O, INC) | AI-based MPPT Algorithms (e.g., BAT, GWO, IGWO, Hybrid IGWBO, ANN, FLC) |

|---|---|---|

Design Complexity | Simple design and deployment | More complex and costly to implement |

Efficiency under Stable Conditions | Effective, but oscillate around MPP, less suitable for large-scale or fluctuating conditions | Higher tracking accuracy, better global MPP tracking, superior under dynamic and partial shading conditions |

Convergence Speed | Slower, prone to oscillations around MPP | Faster convergence, especially with improved/hybrid metaheuristic algorithms |

Accuracy | Moderate, may fail to track global MPP under partial shading | High accuracy in global optimization and dynamic performance |

Suitability for Telecom Applications | Applicable but less efficient under variable environmental conditions | Favorable due to higher tracking accuracy, faster response, and better handling of nonlinearities |

Implementation Cost | Lower | Higher due to algorithm complexity and hardware/software requirements |

Thermal management becomes essential during peak demand periods. Engineers calculate total heat load and ambient temperature extremes to design appropriate cooling capacity. They use active or passive cooling methods depending on the environment and heat load. Fan cooling manages moderate heat loads by circulating air and maintaining internal temperatures below ambient. TEC air conditioning maintains precise internal temperatures in extreme environments, protecting sensitive equipment. Heat exchangers efficiently transfer heat from inside to outside without contaminant ingress, reducing energy consumption by up to 40% compared to traditional cooling.

PCB-level thermal management techniques include heat sinks made of thermally conductive materials, thermal vias to transfer heat from hot spots, and active cooling methods such as fans and forced air. Liquid cooling systems, though less common at the PCB level, handle extremely high heat densities in advanced telecom applications. Optimized PCB layouts enhance thermal performance, and combining these techniques can reduce peak temperatures by 30-40°C, ensuring reliable operation under continuous heavy loads.

System scaling supports power optimization during heavy load conditions. Modular PDUs allow operators to add outlets or increase capacity without replacing the entire unit, facilitating scalability for future power demands. Advanced monitoring provides real-time power usage data, enabling load balancing and energy optimization. Remote management reduces on-site interventions, improving operational efficiency. Redundancy ensures continuous operation during power failures, maintaining system reliability. Environmental monitoring prevents efficiency loss by alerting to adverse conditions, protecting equipment performance.

Note: Modular designs in telecom cabinets allow adding or removing rectifier modules to match power demands, improving efficiency by concentrating loads on fewer modules and reducing energy losses. Hot-swappable modules enable maintenance or replacement without shutting down the system, ensuring continuous operation during heavy loads.

MPPT+solar Module systems must withstand harsh environmental conditions such as dust, debris, salt spray, and humidity. Dust and debris block sunlight and increase panel temperature, reducing efficiency. Rain and high humidity can cause insulation failures and accelerate material aging. Engineers select corrosion-resistant materials and weatherproof designs to protect equipment. Regular cleaning and inspection prevent dust buildup and corrosion, ensuring reliable solar energy delivery. Thermal insulation and active cooling systems help maintain stable temperatures, improving efficiency and extending equipment life.

Implementation and Results

Design Checklist

A robust MPPT+solar Module system in telecom cabinets depends on careful design and integration. Key checklist items include:

Select enclosures with high IP ratings (IP55 or IP66) to protect against water and dust.

Separate battery and equipment compartments to prevent acid mist damage.

Implement ventilation and thermal management, using fans and sensors to keep battery temperatures below 25°C.

Install hydrogen discharge devices for safe venting of battery gases.

Use mechanical supports and latching connectors to minimize vibration and accidental disconnections.

Choose MPPT charge controllers for higher efficiency, especially in variable weather.

Match voltage and current ratings across all components for compatibility.

Integrate advanced Battery Management Systems (BMS) with monitoring and safety features.

Enable real-time monitoring and remote alarms for battery health and power status.

Schedule regular maintenance, including inspection and cleaning of ventilation systems and seals.

Arrange cabinet layout with equipment on top and batteries at the bottom for easier access.

Leave adequate spacing between batteries for air circulation and swelling.

Use corrosion-resistant materials and weatherproof sealing for durability.

Incorporate surge protection and redundancy to enhance system resilience.

🛠️ Tip: Following this checklist ensures optimal performance, safety, and longevity for telecom power systems.

Monitoring and Maintenance

Effective monitoring and maintenance practices keep MPPT+solar Module systems running efficiently. Operators use smart monitoring features with real-time diagnostics to track performance and identify issues early. Automated alerts notify when cleaning or repairs are needed. Regular maintenance, performed every six months, includes cleaning solar panels, inspecting wiring, and checking battery health. Technicians manage vegetation to prevent shading and use temperature compensation features in cold environments. Remote monitoring systems provide real-time data on energy production, battery status, and inverter efficiency, with alerts for anomalies. Annual professional inspections and firmware updates further extend system life and reliability.

Performance Metrics

Performance Metric | Description / Typical Values |

|---|---|

Maximum Efficiency | Up to 98.6% (e.g., Sunny Tripower CORE1, Sungrow SG60CX) |

CEC Efficiency | 96.5% to 99.0% depending on model |

Operating Voltage Range | 16-65 V (small inverters), 200-1000 V (large inverters) |

Number of MPPTs | 2 to 6 per inverter |

Maximum Input Voltage | 65 V to 1000 V |

Maximum Input Current | Up to 45 A per MPPT |

Power Factor | Adjustable, nominal 1.0 |

Total Harmonic Distortion | Less than 3% at nominal power |

Protection Features | DC reverse polarity, AC short circuit, AFCI, overvoltage, rapid shutdown, UL certifications |

Module-Level Monitoring | Supported by power optimizers for granular data and fault detection |

System Management & Monitoring | Cloud-based platforms enable remote diagnostics, performance tracking, and alerts |

Additional Features | Battery integration, DC oversizing, rapid shutdown, integrated switches, UL compliance |

📊 These metrics help operators evaluate system efficiency, reliability, and safety, ensuring optimal performance for telecom applications.

Operators optimize telecom cabinet power by selecting MPPT+solar Module systems, sizing solar arrays accurately, and implementing advanced MPPT algorithms.

MPPT controllers boost energy harvest, support oversized arrays, and reduce installation costs for both light and heavy loads.

Proper system design, including modular layouts and effective thermal management, ensures long-term reliability.

Advanced MPPT solutions, such as AI-driven controllers, maintain stable power delivery and extend equipment lifespan, making them essential for reliable telecom operations.

FAQ

What is the main advantage of using MPPT+solar Module combos in telecom cabinets?

MPPT+solar Module combos maximize energy extraction from solar panels. They adapt to changing sunlight and temperature. This approach increases system efficiency and ensures reliable power for telecom equipment.

How often should operators perform maintenance on MPPT+solar Module systems?

Operators should inspect and clean solar panels every six months. Regular checks on wiring, batteries, and cooling systems help prevent failures. Remote monitoring tools provide real-time alerts for faster response.

Can MPPT controllers handle partial shading on solar panels?

Yes. Advanced MPPT controllers use algorithms that track the maximum power point even when shading affects some panels. This feature helps maintain high energy output in challenging environments.

Why is proper solar module sizing important for telecom cabinets?

Proper sizing ensures the solar system meets power demands. Undersized modules cause battery strain and outages. Oversized systems improve reliability and reduce maintenance costs.

What role does remote monitoring play in telecom cabinet power systems?

Remote monitoring enables operators to track performance, detect faults, and receive alerts. This capability reduces downtime and supports proactive maintenance, ensuring continuous operation.

See Also

Solar Energy Storage Solutions Designed For Telecom Cabinets

Methods To Calculate Power Systems And Batteries For Telecom

Telecom Cabinets Using Grid-Tied Solar Inverters And Batteries

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA