What Outdoor Cabinet Heat Exchangers Do That Air Conditioners Don’t

You gain more than just cooling with an Outdoor Cabinet Heat Exchanger. This technology protects sensitive outdoor equipment by transferring heat directly, keeping internal conditions stable. You experience lower energy use and higher reliability, as seen in studies that report significant power savings and performance gains:

Source | Key Finding |

|---|---|

WattsKit (2017) | Improved energy efficiency |

Flash disk opportunity | Breakthroughs in power savings |

R* optimizer validation | Enhanced reliability and performance |

ESTEL delivers solutions trusted by telecom and industrial professionals for their low maintenance and robust performance.

Key Takeaways

Outdoor cabinet heat exchangers save energy by transferring heat directly without using compressors or refrigerants, cutting energy use by up to 40%.

These systems need less maintenance than air conditioners because they have fewer moving parts and do not require filter changes or refrigerant refills.

Heat exchangers protect equipment better by keeping dust, moisture, and contaminants out with a closed-loop design, increasing equipment lifespan by up to 30%.

They help the environment by avoiding harmful refrigerants and reducing carbon emissions, supporting cleaner and safer outdoor cooling solutions.

Heat exchangers work well in telecom, industrial, and electronics cabinets, offering reliable and cost-effective cooling for outdoor equipment in many climates.

How Outdoor Cabinet Heat Exchangers Work

Passive and Active Cooling

You can choose between passive and active cooling methods when you use an Outdoor Cabinet Heat Exchanger. Passive cooling uses natural airflow or temperature differences to move heat away from your equipment. This method works well in mild climates or for cabinets with low heat loads. You do not need extra power for fans or pumps, so you save energy and reduce costs.

Active cooling uses fans, pumps, or other mechanical devices to boost heat transfer. This method helps when your cabinet faces higher heat loads or sits in a hot environment. Research shows that heat exchangers can deliver over 40% energy savings and up to 22% cost reduction compared to traditional cooling. You also see up to a 30% increase in equipment lifespan because the closed-loop design keeps out dust and moisture. The table below compares different cooling methods:

Cooling Method | Energy Savings (%) | Cost Reduction (%) | Equipment Lifespan Increase (%) | Maintenance Requirements and Notes |

|---|---|---|---|---|

Heat Exchangers | Over 40% energy savings | 18-22% cost reduction | Up to 30% lifespan increase | Closed-loop design reduces contamination and maintenance; minimal cleaning needed; reliable in harsh environments |

DAC Thermal Cooling | Up to 75% energy savings | Significant electricity cost savings over time | Not specified | Long-term cost-effective; reduces operational expenses |

TEC Air Conditioning | Not specified | Higher initial investment | Precise temperature control; maintains 25°C internal temp at 40°C ambient | Closed-loop design; reduced maintenance; protects sensitive equipment |

Fan Cooling | Moderate energy efficiency | Cost-effective for moderate heat loads | Not specified | Requires regular cleaning of fan blades and filters; less effective for high-density setups |

Natural Cooling | Passive, minimal energy use | Minimal installation cost | Not suitable for high heat loads | Limited to low-heat scenarios and moderate climates; minimal maintenance |

You can see that heat exchangers offer a strong balance of energy savings, cost reduction, and reliability. Many telecom cabinets in temperate climates use passive cooling, while high-density data centers often rely on active heat exchangers for stable performance.

Closed-Loop Operation

You benefit from closed-loop operation when you install an Outdoor Cabinet Heat Exchanger. This system keeps the inside air separate from the outside environment. You protect your sensitive electronics from dust, dirt, and moisture. Closed-loop systems come in two main types: air-to-air and air-to-water.

Air-to-air systems use two separate airflows. One loop circulates air inside the cabinet, while the other loop moves outside air across a heat exchanger surface. Heat transfers between the two loops without mixing the air.

Air-to-water systems use water or coolant to carry heat away from the cabinet. This method works well for cabinets with high heat loads or in places where water cooling is available.

You can find Outdoor Cabinet Heat Exchanger models with NEMA and IP ratings. These ratings show how well the enclosure resists dust and water. For example, a NEMA 4 or IP66 rating means your cabinet stays protected in harsh weather.

Many systems run on 48 VDC power, which matches telecom and industrial standards. You also get ROHS compliance, which means the system avoids hazardous materials. These features make heat exchangers a safe and reliable choice for your outdoor equipment.

You can measure the efficiency of a closed-loop system using the formula η = q/qopt, where η is efficiency, q is the actual heat transfer rate, and qopt is the optimal rate. This formula helps you compare different systems and choose the best one for your needs. Deep closed-loop systems can reach temperatures from 40°C to 100°C, depending on the design and environment. You get stable cooling even when outside temperatures change.

Direct Heat Transfer

You get direct heat transfer with an Outdoor Cabinet Heat Exchanger. This means the system moves heat straight from your equipment to the outside air or water, without using refrigerants or compressors. You avoid the energy losses that come with traditional air conditioners.

Tests show that a flat-plate liquid-cooling and air-cooling system can improve cooling efficiency by about 60% compared to standard air-cooled cabinets. The system can remove over 19,000 kJ of heat and reach a peak efficiency close to 89%. In real-world use, cabinet heat exchangers can supply up to 80% of the total heat demand for nearby buildings. This approach cuts annual operating costs by 67% and lowers CO2 emissions by up to 90% compared to traditional heating and cooling.

You also gain the option to reuse waste heat for other purposes, such as water heating or desiccant regeneration. This makes your cooling system more sustainable and cost-effective.

Outdoor Cabinet Heat Exchanger Benefits

Energy Efficiency

You achieve significant energy savings when you use an Outdoor Cabinet Heat Exchanger. Unlike air conditioners, these systems do not rely on compressors or refrigerants, which consume more electricity. Instead, they transfer heat directly, making the process much more efficient.

In many cities, you can reduce energy use by about 30% with wickless Heat Pipe Heat Exchangers. For example, in Changsha, natural cooling is possible for over 3,800 hours each year, which covers nearly 44% of the year. This means you can keep your equipment cool for long periods without extra energy costs.

Metric Description | Value | Context |

|---|---|---|

Energy reduction due to HPHX | ~30% | Wickless Heat Pipe Heat Exchangers |

Annual energy saving ratio | Over 30% | 74.2% of Chinese cities |

Hours below 16˚C in Changsha | 3818 hours | Natural cooling potential (43.58%/year) |

You see these savings because the Outdoor Cabinet Heat Exchanger uses the outside air’s natural temperature difference to remove heat. This approach works best in mild climates, but even in warmer areas, you still use less energy than with traditional air conditioning.

Low Maintenance

You spend less time and money on maintenance when you choose an Outdoor Cabinet Heat Exchanger. These systems have fewer moving parts than air conditioners, so they break down less often. You do not need to replace filters or refill refrigerants regularly. This simple design means you face fewer unexpected repairs and less downtime.

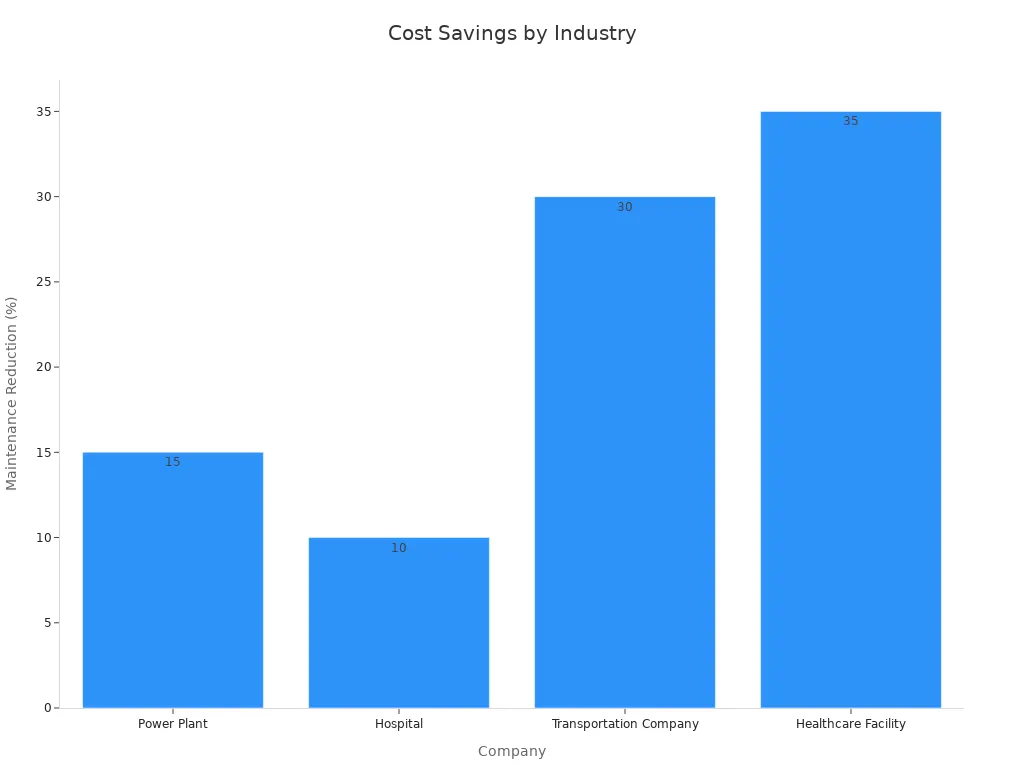

Many companies have reported big drops in maintenance costs after switching to preventive strategies with heat exchangers. For example, Toyota Motor Corporation saw a 30% reduction in maintenance costs and a 40% increase in equipment availability by using proactive maintenance methods.

Industry/Company | Maintenance Strategy | Cost Savings / Impact |

|---|---|---|

Company XYZ | Preventive maintenance & monitoring | 30% reduction in unplanned downtime; 20% cost reduction |

Manufacturing Company 1 | Preventive maintenance + CMMS | 20-25% cost reduction |

Toyota Motor Corporation | Total Productive Maintenance (TPM) | 30% cost reduction; 40% more equipment availability |

You benefit from lower operational costs and longer equipment life. You also avoid the hassle of frequent service visits, which keeps your systems running smoothly.

Environmental Impact

You help protect the environment when you use an Outdoor Cabinet Heat Exchanger. These systems do not use refrigerants, which can harm the ozone layer or contribute to global warming. Many models meet RoHS and REACH standards, which means they avoid hazardous substances like mercury and lead.

Manufacturers now focus on sustainability by using recycled materials and reducing water use in production. Some heat exchangers even use natural refrigerants or none at all, which lowers their global warming potential to zero. You support a cleaner and safer environment by choosing these solutions.

You also reduce your carbon footprint because you use less energy and avoid chemicals that can leak into the air or soil.

Reliability

You gain peace of mind with the rugged design and proven reliability of Outdoor Cabinet Heat Exchangers. These systems use corrosion-resistant materials such as stainless steel and aluminum, which help them last longer in harsh outdoor conditions. Strong seals keep out water, dirt, and pests, so your equipment stays protected.

You benefit from special coatings that resist salty air and industrial pollution.

Manufacturers test these systems for durability using fatigue, corrosion, and tensile tests.

Weatherproof covers and advanced alloys add extra protection against rust and wear.

You also see fewer failures because closed-loop systems keep dust and moisture away from sensitive electronics. Telecom companies have reported up to a 30% drop in failure rates after switching to closed-loop cooling. You can trust these systems to keep your equipment running, even in tough environments.

Applications

Telecom Cabinets

You often see outdoor cooling solutions in telecom cabinets that support wireless communication, 5G, and smart city infrastructure. These cabinets use high-quality galvanized steel and achieve IP55 ratings, which means they resist dust and water. You benefit from reliable network performance because these cabinets keep equipment at the right temperature. For example, a telecom provider improved network reliability by upgrading to modern outdoor cabinets. A data center reduced cooling costs by adding advanced heat exchanger systems. You find these cabinets in many places:

5G small cells and urban nodes use compact cabinets with thermal management and surge protection.

Rural broadband and fiber nodes rely on weather-resistant cabinets powered by solar or generators.

Backhaul and data aggregation points use tamper-proof enclosures to protect critical networking equipment.

Edge computing and IoT hubs need advanced airflow and surge protection for sensitive devices.

Industrial Enclosures

You use industrial enclosures to protect control panels and sensitive electronics in harsh environments. These enclosures often sit near hot equipment, such as kilns or furnaces. For example, in a steelmaking plant, control cabinets stand next to a kiln operating at 2800°F. The cabinets use water-cooled heat exchangers and air conditioners to keep internal temperatures safe, between 41°F and 86°F. The enclosures have NEMA 4/IP56 ratings and powder-coated steel construction. You can trust these systems because they pass strict tests for durability and safety, including UL, CE, RoHS, and Telcordia GR-487 certifications. You keep your equipment running smoothly, even in extreme conditions.

Electronics Panels

You find electronics panels in outdoor cabinets that manage power, batteries, and communication systems. These panels generate heat loads from 500 to 10,000 W. You need effective cooling to keep equipment within safe temperature limits. Air-to-air heat exchangers work well for battery compartments when cooling loads are moderate. You balance heat from equipment, solar exposure, and cooling system capacity to maintain thermal equilibrium. The FieldSmart Fiber Active Cabinet 400 shows how you can use a door-mounted integrated air-to-air heat exchanger with DC-powered fans. This cabinet operates in harsh environments, from -40°C to +46°C, and meets industry standards for safety and reliability. You ensure safe and efficient thermal management for your electronics panels in real-world conditions.

Air Conditioner Limitations

High Energy Use

You often see air conditioners using more energy than outdoor cabinet heat exchangers. Most air conditioners rely on compressors and refrigerants, which require a lot of electricity. When you use a standard AC unit, you may notice higher utility bills, especially during hot weather or when the system runs constantly. The Energy Efficiency Ratio (EER) helps you measure this. Typical industrial air conditioners have EER values between 9 and 12. Higher EER means better efficiency, but many older or basic models fall short.

Many studies show that single-speed air conditioners waste energy during low cooling demand. Refrigerant faults and dust buildup can increase energy use by 3% to 10%. In contrast, heat exchangers transfer heat directly and avoid these losses.

Aspect | AC Air Conditioners | Outdoor Cabinet Heat Exchangers |

|---|---|---|

Energy Consumption | High, especially with fixed-speed compressors and refrigerant faults | Low, due to direct heat transfer |

Energy Savings | Up to 55% less efficient than advanced DC or inverter systems | Up to 40% energy savings |

Maintenance Needs

You face higher maintenance demands with air conditioners. These systems need regular filter cleaning, refrigerant checks, and coil cleaning. If you skip maintenance, you risk breakdowns and expensive repairs. Neglecting HVAC maintenance can increase energy use by up to 25%. About 85% of HVAC repairs link to poor maintenance. Well-maintained systems last longer and use less energy, but many users fall behind on upkeep.

You must schedule routine inspections to avoid emergency repairs.

Proactive maintenance can extend system life by up to 50%.

The global HVAC maintenance market keeps growing, showing how much attention these systems need.

Routine care reduces breakdown risk by up to 95%, but missing even a few steps can shorten service life by five to ten years.

Environmental Concerns

You encounter strict regulations when you use air conditioners because of their refrigerants. The EPA and international agreements require you to manage refrigerants carefully. These chemicals can harm the ozone layer and contribute to global warming if they leak. You must follow rules for leak monitoring, recovery, and disposal. The 2021 AIM Act now requires an 85% phasedown of hydrofluorocarbons (HFCs) over 15 years.

Technicians need certification to handle refrigerants.

You must keep records of refrigerant use and disposal.

New rules allow safer, low-flammability refrigerants, but you still need to track and manage them.

By choosing systems that avoid refrigerants, such as heat exchangers, you help reduce your environmental impact and simplify compliance.

Choosing the Right Solution

Decision Criteria

When you select a cooling solution, you need to consider several important factors. You look at the cooling load, the climate where your equipment operates, and the temperature requirements of your devices. You also check if your application can tolerate temperatures slightly above ambient. If your equipment needs strict temperature control, you may lean toward air conditioning. If your priority is enclosure isolation and moderate cooling, a heat exchanger often fits best. You should always follow industry standards for sizing and installation, such as those outlined by the Building America Solution Center and ACCA Manual S. These guidelines help you match the right system to your needs and ensure compliance with certification standards.

Cost Factors

You want to balance performance and budget. You compare the initial investment, installation costs, and long-term operating expenses. Heat exchangers usually offer a lower upfront cost and reduced energy bills over time. Air conditioners may require a higher initial investment and ongoing maintenance. You also factor in the cost of compliance with environmental regulations, especially if refrigerants are involved. Some companies use decision-making tools or software, like UniSuite SHELL SELECT, to document and compare options based on cost and performance. This structured approach helps you make informed choices that align with your financial goals.

Performance Needs

You assess what level of performance your application demands. You review technical specifications, such as cooling capacity and efficiency ratings. Advanced testing methods, like those using virtual building models, provide more accurate seasonal performance ratings. These tests show that variable-speed systems often deliver better part-load efficiency than single-stage units. You also consider how well the system maintains stable temperatures under real-world conditions. ESTEL recommends choosing a solution that meets your specific performance needs, whether you require high reliability in harsh environments or precise temperature control for sensitive electronics.

You now understand what sets heat exchangers apart. You get direct heat transfer, energy savings, and low maintenance. Choose a heat exchanger when you need reliable, efficient cooling for outdoor equipment. Air conditioners work best for strict temperature control, but heat exchangers offer a simpler, greener solution. ESTEL gives you proven products and expert support for your toughest environments.

FAQ

What makes an outdoor cabinet heat exchanger different from an air conditioner?

You use a heat exchanger to transfer heat directly without refrigerants or compressors. This method saves energy and reduces maintenance. Air conditioners use more electricity and require regular servicing. Heat exchangers work best for moderate cooling needs in outdoor environments.

What types of outdoor cabinets benefit most from heat exchangers?

You see the best results in telecom cabinets, industrial enclosures, and electronics panels. These cabinets need reliable cooling and protection from dust and moisture. Heat exchangers help you maintain stable temperatures and extend equipment life.

What maintenance do outdoor cabinet heat exchangers require?

You perform minimal maintenance. You may need to check for dust buildup and clean surfaces occasionally. Most systems do not need filter changes or refrigerant refills.

You save time and reduce unexpected repairs with this simple upkeep.

What environmental benefits do heat exchangers offer?

You avoid refrigerants, which can harm the environment. Many models meet RoHS and REACH standards.

Benefit | Description |

|---|---|

No refrigerants | Lower global warming impact |

Energy savings | Reduced carbon footprint |

See Also

The Importance Of Cooling For Outdoor Communication Cabinets

Efficient Cooling Solutions For Reliable Outdoor Cabinets

Benefits Of ESTEL Cooling Systems In Industrial Cabinets

Air Conditioning Systems Built For Outdoor Telecom Cabinets

Understanding Outdoor Enclosure Cabinets And Their Advantages

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA