What is an Outdoor Cabinet Heat Exchanger and How Does It Work

An outdoor cabinet heat exchanger moves heat from inside to outside. This keeps equipment cool and safe. Temperature control stops damage. Studies show heat and humidity can hurt batteries and control modules. Cooling systems keep out dust, water, and rust. This helps electronics work well.

Advanced filters and fan controls help equipment last longer by keeping things steady.

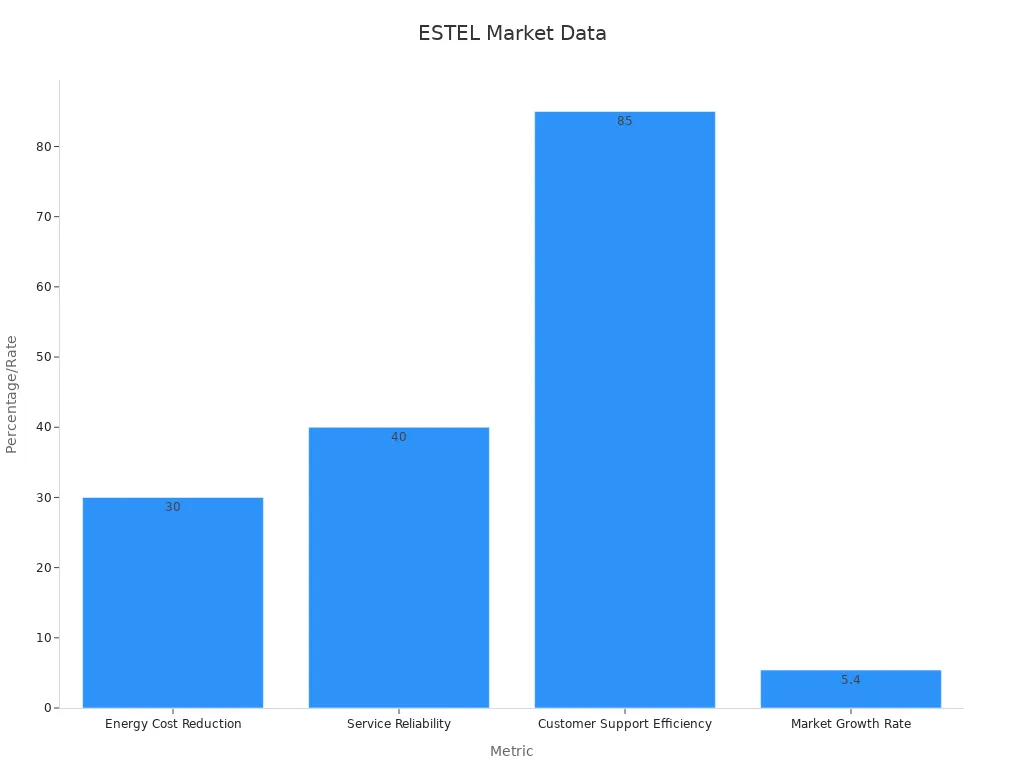

ESTEL’s solutions are top in the market. They give strong support, save energy, and have quick customer service.

Key Takeaways

Outdoor cabinet heat exchangers help keep electronics safe. They move heat from inside to outside. They do this without letting in dust or water.

These devices use a closed-loop system and heat pipes. This cools equipment well and lowers how much care is needed.

Picking the right heat exchanger depends on heat load and environment. It also depends on protection rating, space, and budget.

Air-to-air exchangers save energy and need less care. Air-to-water exchangers cool more but need more maintenance.

Regular checks and good installation help heat exchangers work well. This protects equipment, saves energy, and helps equipment last longer.

Outdoor Cabinet Heat Exchanger Basics

Definition

An outdoor cabinet heat exchanger is a special device. It helps control temperature inside sealed boxes with sensitive electronics. These boxes are often outside. They face tough weather, dust, and water. The heat exchanger moves heat from inside the box to the outside air. This keeps the inside at a safe temperature.

The document 'Thermal Management of Outdoor Enclosures, Part 1' says thermal management needs balance. It depends on how much heat the equipment makes, the sun’s heat, and how well the cooling system works.

Cooling systems fit into three groups:

Fully Active: These use air-conditioning or refrigeration. They keep the inside cooler than the outside air.

Assisted (Semi-Active): These use air-to-air or water-to-air heat exchangers. They keep the temperature steady without letting outside air in. This means less maintenance and helps battery backup.

Passive: These use natural convection or phase change materials. They work for small boxes where higher temperatures are okay.

Heat exchangers help keep electronics cool. They move heat out without letting outside air in. This protects the electronics inside.

Technical guides call the heat exchanger an energy transfer device. It moves heat from the warm air inside to the cooler air outside. It uses conduction and convection. Air-to-air and liquid-to-air exchangers are common types. Fans, blowers, or pumps help move the heat. The design uses special math to pick the right size for the box.

ESTEL is a top brand in this area. The company makes advanced outdoor cabinet heat exchangers. Their products meet strict rules and work well in tough places.

Function

The main job of an outdoor cabinet heat exchanger is to keep electronics safe from heat. It moves heat from inside the box to the outside. It uses a closed-loop system. This stops dust, water, and dirt from getting in. The heat exchanger uses heat pipe technology. A liquid inside the pipe turns to vapor when hot and back to liquid when cool. This lets heat move all the time without extra power. The closed-loop keeps inside air away from outside air. This protects the electronics from getting too hot or damaged by the weather.

Outdoor cabinet heat exchangers help keep the inside temperature steady. They take in heat from inside and push it outside. This stops equipment from failing due to heat. It also helps the equipment last longer. Some models have copper fins and pipes. These lower thermal resistance and save energy. These systems also mean less maintenance and fewer sudden failures.

Note: Outdoor cabinet heat exchangers are great for tough places. Models with NEMA 4 and 4X ratings work well in bad weather and dirty spots. Water-to-air exchangers cool better than air-to-air ones. They also protect equipment from outside dangers.

Many case studies and reports show the benefits of outdoor cabinet heat exchangers:

They stop hardware from breaking down by keeping the temperature safe and lowering stress.

They stop condensation and rust by controlling humidity inside the box.

They help equipment work well in tough weather by giving dust-free cooling and heating.

They make equipment last longer by cutting down on repairs and sudden problems.

They help with lots of equipment in small spaces by managing heat.

They keep networks running by stopping shutdowns and keeping batteries healthy.

They lower maintenance costs with automatic temperature control and early warnings.

They get systems ready for the future with designs that can grow and handle more heat.

They help meet new safety and environmental rules.

The QATS website and other guides give real examples and stories. They show how heat exchangers use heat transfer ideas to work better. They also explain why it is important to match the heat exchanger to the box’s needs and the outside air.

ESTEL’s outdoor cabinet heat exchangers use advanced hvac technology and strong designs. Their products help customers protect their equipment, need less maintenance, and work well anywhere.

How the Heat Exchanger Works

Working Principle

An outdoor cabinet heat exchanger uses a closed-loop system. This system keeps the air inside away from the air outside. It helps protect electronics from dust and water. The heat exchanger can use air-to-air or liquid coolant to move heat out. Engineers add baffles and seals to stop the air from mixing. Some designs use phase change materials, or PCM. PCM takes in heat when it is hot and lets it out when it cools down. The PCM stays in its own container, so the air does not mix. This way, the heat exchanger can cool things without swapping air.

Heat pipes are important in many air-to-air systems. A heat pipe has two parts: the evaporator and the condenser. The evaporator is inside and takes in heat. The condenser is outside and lets the heat go. Baffles and end plates keep the air streams apart. This setup makes sure the closed-loop works well and keeps electronics safe.

Tip: The closed-loop system is very important for outdoor cabinets. It blocks dust and water that could hurt electronics and make them break sooner.

Heat Transfer Process

The heat exchanger uses conduction and convection to move heat. It takes heat from inside and sends it outside. The air inside and outside never mix. In air-to-air exchangers, heat pipes or finned tubes move the heat. The fluid inside the tubes soaks up heat from the air inside. Then it goes outside and lets the heat out. Finned tubes have more surface area, so they work better. Microchannel exchangers use flat tubes with fins. Air moves through these and takes heat away fast.

Some heat exchangers use liquid coolant instead of air. A pump moves the coolant in a loop. The coolant takes heat from inside and brings it to a radiator outside. Fans blow the heat away. The choice between air or liquid depends on what needs cooling and where it is.

The table below shows how well different types work:

Heat Exchanger Type | Heat Exchange Efficiency (%) | Key Factors Influencing Efficiency |

|---|---|---|

Enthalpy Wheel (Air-to-Air) | 88.4 | Large specific surface area, variable heat capacity, avoids flow rate mismatch |

Double Spray Towers (Liquid-Air) | 32–56 | Constant heat capacity of spray water, flow rate mismatch, lower NTU |

The air-to-air enthalpy wheel works better because it has more surface area and matches heat capacity well. Liquid systems like double spray towers do not work as well because of flow problems and less heat capacity.

Studies show that the design changes how well the heat exchanger works. Counter-flow plate exchangers usually move heat better. But if the cabinet is narrow, cross-flow plate exchangers can cool better and have less resistance. The next table shows these differences:

Aspect | Counter-flow Plate Heat Exchanger | Cross-flow Plate Heat Exchanger |

|---|---|---|

Typical Heat Transfer Effectiveness | Higher | Lower |

Cooling Capacity (700 mm width) | ~176.13 W/K | |

Thermal Resistance | Higher at larger widths | Lower at larger widths |

Suitability | Best in unrestricted designs | Best in size-restricted systems |

The heat exchanger keeps electronics cool and safe. The closed-loop stops outside air from getting in. Advanced hvac designs help move heat better. Engineers use math to pick the best fin size and airflow. This helps meet cooling needs, even when the system gets very hot or cold.

Outdoor cabinet heat exchangers use hvac technology for strong cooling. The closed-loop and smart design keep equipment safe for a long time. These systems work well in tough places and keep electronics at safe temperatures.

Key Components and Features

Main Parts

Every outdoor cabinet heat exchanger has important parts. The main part is the heat exchanger unit. It moves heat from inside the cabinet to outside. Fans blow air over the exchanger. This helps take heat away from electronics. Inside, there are coolant pathways or heat pipes. These help move heat fast and well. They use conduction and convection to do this.

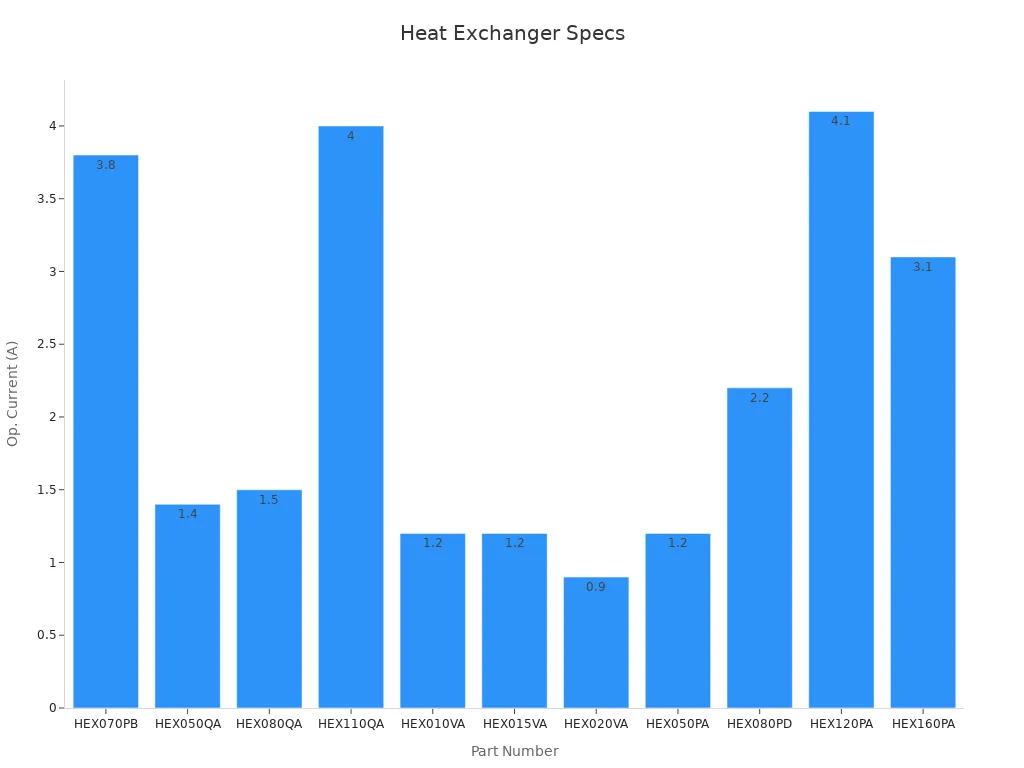

The table below lists technical details for different models. Each model has its own cooling power, size, and ways to mount. This lets people pick the best heat exchanger for their needs.

Part Number | Cooling/Heating Capacity | Dimensions (inch) | Dimensions (mm) | Rated Voltage (VDC) | Operating Current (A) | Noise (dB-A) @1.5M | Weight (lbs/kg) | Approvals | Mount Type |

|---|---|---|---|---|---|---|---|---|---|

HEX070PB | 70 W/K | 37.0H x 19.3W x 3.9D | 940H x 490W x 100D | 48 VAC | 3.8 | 65 | 38.5 / 17.5 | UL Recognized, CE | Outdoor |

HEX050QA | 50 W/°C | 6.1H x 21.7W x 17.0D | 155H x 550W x 434D | 48 | 1.4 | 64 | 19.8 / 9.0 | UL Recognized, CE | Outdoor |

HEX080QA | 80 W/°C | 10.4H x 21.9W x 19.7D | 265H x 555W x 500D | 48 | 1.5 | 64 | 31.1 / 15.0 | UL Recognized, CE | Outdoor |

HEX110QA | 110 W | 21.1H x 17.6W x 8.7D | 536H x 447W x 220D | 48 VAC | 4 | 75 | 33.1 / 15 | UL Recognized, CE | Outdoor |

HEX010VA | 10 W/°C | 16.3H x 10.8W x 2.6D | 415H x 275W x 65D | 24 | 1.2 | 61 | 8.8 / 4.0 | UL Recognized, CE | Outdoor |

HEX015VA | 15 W/K | 23.2 x 5.9 x 3.1 | 510H x 253W x 78D | 24 VAC | 1.2 | 65 | 11 / 5 | UL Recognized, CE | Outdoor |

HEX020VA | 20 W/°C | 23.2H x 11.1W x 3.9D | 590H x 283W x 99D | 24 | 0.9 | 54 | 15.4 / 7.0 | UL Recognized, CE | Outdoor |

HEX050PA | 45 W/°C | 19.7H x 17.5W x 6.0D | 500H x 445W x 152D | 48 | 1.2 | 65 | 22.0 / 10.0 | UL Recognized, CE | Outdoor |

HEX080PD | 80 W/°C | 37.4H x 17.7W x 5.9D | 950H x 450W x 150D | 48 | 2.2 | 65 | 41.9 / 19.0 | UL Recognized, CE | Outdoor |

HEX120PA | 120 W/°C | 45.3H x 18.5W x 7.6D | 1151H x 471W x 193D | 48 VDC | 4.1 | 64 | 72.8 / 33.0 | UL Recognized, CE | Outdoor |

HEX160PA | 160 W/°C | 50.9H x 22.3W x 9.6D | 1294H x 567W x 243D | 48 | 3.1 | 65 | 88.2 / 40.0 | UL Recognized, CE | Outdoor |

Outdoor cabinet heat exchangers can be put in different places. Some go on the roof, some inside, and some outside the cabinet. This makes it easy to install them almost anywhere.

Outdoor Design

Outdoor cabinet heat exchangers must work in bad weather. Makers use special aluminum layers to help move heat and stop rust. The weatherproof build keeps out rain, dust, and bugs. Seals and gaskets keep water from getting inside the cabinet. These things help the heat exchanger work well all year.

ESTEL uses new technology in its heat exchangers. Their products are strong and last a long time. Engineers check each one for safety and how well it works. The company follows strict rules like UL and CE. People trust ESTEL to protect their equipment and lower downtime.

Note: A good heat exchanger keeps electronics safe and helps them work better. Doing regular checks and installing it right helps it work its best.

Cooling Benefits

Energy Efficiency

Outdoor cabinet heat exchangers save a lot of energy. They use advanced hvac technology to move heat outside. The closed-loop design keeps inside and outside air apart. This helps stop energy from being wasted. Many people save over 40% energy with these systems. The table below shows important facts:

Metric / Example | Value / Description |

|---|---|

Energy savings of heat exchangers | Over 40% energy savings compared to traditional cooling systems |

Temperature control | Maintains cabinet internal temperature within 5°F above ambient temperature |

Energy consumption reduction in case study | Heat exchangers consumed 40% less energy than traditional cooling methods |

Operational benefits | Closed-loop design reduces contamination and maintenance needs |

Environmental impact | Significant reduction in electricity consumption and carbon emissions |

Suitability | Effective in harsh or extreme environments, especially for high-density telecom cabinets |

ESTEL’s heat exchangers help people pay less for electricity. They also help the planet by using less power.

Equipment Protection

A heat exchanger keeps electronics safe from heat, dust, and water. The closed-loop system blocks outside air and dirt. This keeps the inside clean and dry. Electronics stay cool and do not overheat. This helps stop equipment from breaking. Many companies use these exchangers in tough weather.

Sealed cabinets with a heat exchanger work better than open ones. Open cabinets let in dust and water that can hurt electronics. The exchanger keeps the cabinet closed, so equipment lasts longer. ESTEL’s hvac technology protects equipment in all kinds of weather.

Tip: Using a heat exchanger in a sealed cabinet helps stop expensive repairs and keeps equipment working.

Maintenance

Heat exchangers need less care than other cooling systems. The closed-loop design has fewer moving parts and fewer leaks. People do not have to clean filters or change coolant often. This saves time and money. ESTEL’s hvac system works well for many years with little work.

Checking the heat exchanger often helps it work its best. Many models have smart alerts to warn if something is wrong. This lets people fix small problems before they get worse. This means equipment lasts longer and there are fewer emergency repairs.

ESTEL’s heat exchangers are known for being reliable, easy to care for, and strong at cooling in any place.

Outdoor Cabinet Heat Exchanger Types

Air-to-Air

Air-to-air heat exchangers use the difference in temperature between inside and outside air to move heat. These systems keep the air inside the cabinet away from the outside air. Fans and heat pipes help move heat from electronics to the outside. This type works well for telecom cabinets, electronics boxes, and cleanrooms. Air-to-air cooling saves energy and needs little care. The best results come when the airflow goes in at a 45° angle. These exchangers are good for medium heat and places where clean air is needed.

Metric / Feature | Air-to-Air Heat Exchangers |

|---|---|

Medium heat loads | |

Energy Efficiency | High; can reduce heating energy use by 76% |

Maintenance Needs | Low |

Environmental Suitability | Clean airflow, electronics, telecom |

Cost | Lower upfront cost |

Note: Air-to-air heat exchangers work best if the cabinet is a little warmer than the outside air.

Air-to-Water

Air-to-water heat exchangers use water to cool things down. Water moves through plates or coils and takes heat from inside the cabinet. A pump sends the water to a radiator or cooler outside. Fans blow away the heat from the water. This type is good for heavy cooling and high heat. Factories, data centers, and big work sites use air-to-water systems. These exchangers work well in tough places. They need more care and cost more because of pumps and water pipes.

Metric / Feature | Air-to-Water Heat Exchangers |

|---|---|

Cooling Capacity | High; excels in heavy cooling applications |

Energy Efficiency | Efficient but higher energy use for pumps |

Maintenance Needs | Regular maintenance needed |

Environmental Suitability | Extreme, industrial, harsh environments |

Cost | Higher upfront cost |

Tip: Air-to-water exchangers are a middle choice between air-to-air units and full air conditioners, especially if clean water is easy to get.

Applications

Outdoor cabinet heat exchangers are used in many fields:

Telecom base stations and 5G networks use both air-to-air and air-to-water cooling to keep working well.

Factories and plants switch old shell-and-tube exchangers for smaller plate models to save money and move heat better.

Electronics boxes use heat pipe technology to get rid of heat fast and help equipment last longer.

Refineries and tough outdoor places pick water-to-air exchangers with NEMA 4 or 4X ratings to protect against rain, snow, and dust.

Case studies show that using nanofluids or spiral coil designs can help move heat and cool better. Cleaning solutions keep the system working without stopping the machines.

Selection Tips

Picking the right heat exchanger depends on a few things:

Key Factor | Consideration |

|---|---|

Heat Load | Match cooling power to the equipment’s wattage |

Environment | Look for dust, humidity, and very hot or cold weather |

Protection Rating | Use NEMA/IP ratings for tough or outdoor places |

Space and Installation | Make sure there is enough room for the system |

Power and Efficiency | Balance energy use with how much cooling is needed |

Maintenance | Plan for easy cleaning and changing parts |

Budget | Think about both starting and long-term costs |

Experts say to know what the process needs and check all types of heat exchangers. Plate models are good for thin or runny fluids. Shell-and-tube types work for thick or dirty fluids. Scraped-surface exchangers handle sticky or messy fluids but cost more.

ESTEL has many outdoor cabinet heat exchangers. Their team helps customers pick the best cooling system for any job. ESTEL gives strong support and reliable products for telecom, factories, and electronics.

Outdoor cabinet heat exchangers help take heat out of boxes. This keeps electronics safe and working well. Experts at Airline Hydraulics and Cytech say these systems control heat and stop dirt from getting in. They also help equipment last longer. More companies want good heat control, so the market is growing. ESTEL’s products work well. People using them have less downtime and better heat control.

Think about future heat needs and check systems often to keep them safe.

Good heat control keeps equipment safe, saves energy, and helps things last longer.

FAQ

What is the main advantage of using a closed-loop heat exchanger?

A closed-loop heat exchanger keeps out air, dust, and water. This helps protect electronics from bad weather. It lowers the chance that equipment will break.

How often should someone maintain an outdoor cabinet heat exchanger?

Most outdoor cabinet heat exchangers need simple checks every few months. People should look at fans, seals, and filters. Doing this helps the system work well and last longer.

Can a heat exchanger work in extreme temperatures?

Yes. Good outdoor cabinet heat exchangers, like ESTEL’s, work in very hot or cold places. Their strong build and special materials help them work well all year.

Which industries use outdoor cabinet heat exchangers the most?

Telecommunications, power companies, and factories use these systems a lot. They keep important electronics safe outside. This helps things run smoothly and stops long breaks.

See Also

Understanding Outdoor Enclosure Cabinets And Their Advantages

Exploring Outdoor Communication Cabinets And Their Practical Uses

Efficient Outdoor Cabinets Providing Cool And Controlled Environments

Key Benefits Of Using Outdoor Communication Cabinets Explained

Essential Features Of Outdoor Communication Cabinets You Should Know

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA