Outdoor enclosure cooling systems: Outdoor Cabinet Air Conditioner vs Cabinet Fan

Comparing Cooling Solutions for Outdoor Enclosures

Explore key differences between outdoor cabinet air conditioners and cabinet fans.

Features | Outdoor Cabinet Air Conditioner | |

|---|---|---|

Cooling Precision | Provides precise temperature and humidity control. | Offers moderate cooling by moving ambient air. |

Environmental Protection | Sealed system blocks dust and moisture ingress. | Allows outside air, less protection from contaminants. |

Energy Consumption | Consumes more energy due to refrigeration cycle. | Uses less energy, efficient in mild climates. |

Maintenance Requirements | Needs regular filter, coil, and refrigerant checks. | Simple cleaning or replacement of fans and filters. |

Initial Cost | Higher upfront cost, $3,000 to $15,000+ range. | Lower upfront cost, more affordable installation. |

Suitability for Environment | Ideal for harsh, dusty, humid, or extreme climates. | Best for mild, clean, and stable environments. |

Cooling Capacity | Can cool below ambient temperature effectively. | Cannot cool below outside air temperature. |

Longevity and Reliability | Extends equipment life by preventing moisture damage. | May wear faster in harsh or dusty conditions. |

When you choose between outdoor enclosure cooling systems, your environment and needs determine which option performs best. Selecting the right system protects sensitive equipment and helps you avoid costly outages—39% of data center failures link to cooling problems, with damages reaching over $600,000. You should consider performance, cost, energy efficiency, maintenance, and how well the system fits your environment. Some systems, especially those with advanced cooling technologies, can reduce energy use by up to 20% and offer significant operational savings.

Key Takeaways

Choose cabinet fans for mild climates with low heat and clean air to save energy and reduce costs.

Use outdoor cabinet air conditioners in harsh environments to protect equipment from heat, moisture, and dust.

Fans are easier and cheaper to maintain, but air conditioners offer precise temperature and humidity control.

Consider your enclosure's heat load and local weather to pick the best cooling system for long-term reliability.

Regular maintenance keeps both systems running well and prevents costly equipment failures.

Why Cooling Matters

Overheating Risks

You face serious risks when your equipment overheats inside outdoor enclosures. Excessive heat can shorten the life of critical control devices like PLCs, HMIs, and AC drives. You may notice nuisance faults, such as unexpected overload trips or erratic performance from circuit breakers and fuses. These problems often start when internal heat sources combine with high outdoor temperatures, solar radiation, or nearby heat-producing equipment. Smaller, sealed enclosures make things worse because they trap heat and limit natural airflow. Without proper cooling, hot spots develop and damage sensitive electronics.

⚠️ Tip: Always monitor the temperature inside your enclosures. Even a small rise can lead to big problems over time.

When you compare cabinet fans and air conditioners, you see that both aim to prevent these issues, but they do so in different ways. Fans move air to reduce hot spots, while air conditioners provide precise temperature control and keep the enclosure sealed from outside contaminants.

Environmental Factors

Your local environment plays a huge role in how well your cooling system works. High temperatures and humidity can push your equipment to its limits. For example, studies show that when temperature and humidity rise, electronic components lose signal strength and network switches drop more data packets. In one test, a soaked sample at 80°C lost up to 36% more signal than a dry one. Network switches exposed to fluctuating heat and humidity dropped data up to 14 times more often than those in stable, air-conditioned spaces.

You need to manage not just temperature, but also humidity and airflow. Sensors placed throughout your enclosure help you spot trouble before it causes damage. Keeping humidity near 60% helps prevent condensation, corrosion, and electrical shorts. Good airflow management stops hot spots and keeps cooling efficient.

When you compare cooling options, consider how each system handles these environmental challenges. Air conditioners excel in extreme conditions, while fans work best in milder climates with lower humidity.

Cabinet Fan Overview

How Fans Work

Cabinet fans use forced convection to move air through your enclosure. You install these fans to draw cooler outside air in and push warmer air out. This process helps balance the temperature inside the enclosure with the environment outside. You can control airflow by adjusting fan speed or using variable frequency drives. When you use thermal modeling, you can optimize fan placement and airflow paths for the best cooling results.

Fan Advantages

You benefit from several advantages when you choose cabinet fans for your cooling needs:

Energy Efficiency: Cabinet fans with variable frequency control can save you up to 10% in energy use. For example, a hospital saved about 55.8 MWh of electricity per year and reduced CO2 emissions by 34 tonnes by running fans 14 hours a day, 300 days a year.

Lower Initial Cost: Fans usually cost less to purchase and install than air conditioners.

Simple Maintenance: You can easily clean or replace fans, which keeps maintenance straightforward.

Flexible Design: You can use thermal modeling to select the right number and type of fans for your specific enclosure.

💡 Tip: Use fans with variable speed control to match cooling output to your actual heat load and save more energy.

Fan Disadvantages

Cabinet fans have some limitations, especially when you compare them to more advanced cooling systems. The main drawback is cooling precision. Fans that use non-PWM (Pulse Width Modulation) technology cannot provide fine-tuned temperature control. The table below shows how PWM fans compare to non-PWM fans:

Feature | PWM Fans | Non-PWM Fans |

|---|---|---|

Cooling Precision | High precision with fine-tuned control | Lower precision with a higher minimum speed threshold |

Fans also struggle in environments with high humidity, dust, or extreme temperatures, since they rely on exchanging air with the outside.

Best Uses

You get the best results from cabinet fans in moderate climates and clean environments. They work well for enclosures with low to moderate heat loads. For example, engineers used eight fans and three heat sinks to cool a 1U switch cabinet after 30 rounds of thermal modeling. In another case, fans cooled a device with over 100 circuit boards, keeping temperatures within safe limits. You should select fans based on airflow and pressure requirements, using thermal modeling or CFD simulations to guide your choices. Cabinet fans offer a practical solution for many industrial and electronics enclosures, especially when you need reliable, cost-effective cooling.

Outdoor Cabinet Air Conditioner

How Air Conditioners Work

You use outdoor cabinet air conditioners to keep your equipment safe from heat, moisture, and dust. These systems use a sealed refrigeration cycle. The refrigerant absorbs heat from inside the enclosure and releases it outside. This process keeps the inside cool and dry. Unlike fans, air conditioners do not bring in outside air. You get a sealed environment that blocks dust, moisture, and other contaminants. This feature protects sensitive electronics and extends their lifespan.

Air Conditioner Advantages

Outdoor cabinet air conditioners offer several advantages over fan cooling systems. You gain precise control over both temperature and humidity. This is important when you need to protect equipment in harsh or unpredictable environments. The table below compares key features:

Feature | Outdoor Cabinet Air Conditioner | Fan Cooling System |

|---|---|---|

Cooling Efficiency | Precise control of temperature and humidity; suitable for extreme heat and humidity | Effective mainly in mild weather; less control over humidity |

Humidity Control | Effectively removes excess moisture, preventing rust and corrosion | Does not manage humidity well; can introduce moisture |

Sealed Environment | Uses sealed cooling systems that block dust and moisture ingress | Relies on airflow, which can bring in dust and moisture |

Maintenance | Requires regular filter and component checks to maintain performance | Easier maintenance but frequent cleaning needed due to dust accumulation |

Longevity | Provides longer equipment life by preventing overheating and moisture damage | May wear out faster in harsh, dusty, or humid conditions |

Environmental Suitability | Performs well in harsh, dusty, humid, or extreme weather conditions | Best suited for stable, mild climates |

You see that air conditioners excel in environments where dust, humidity, or extreme temperatures threaten your equipment.

Air Conditioner Disadvantages

You should also consider some disadvantages when choosing air conditioners for your enclosures:

You may face higher energy consumption, especially in extreme climates.

Increased ventilation rates can triple energy use in cold conditions.

Some cities experience up to a 92% increase in peak electricity demand with high outdoor air use.

Annual energy costs can rise by 45% or more in certain locations.

In colder climates, electric resistance heating can account for most of the HVAC energy use.

You may need to perform regular maintenance, such as filter changes and component checks.

⚠️ Note: While air conditioners provide excellent protection, you should weigh these factors against your operational needs and budget.

Best Uses

You get the most value from outdoor cabinet air conditioners in demanding environments. For example, cruise ships use corrosion-protected air conditioning units on outdoor control cabinets. These units have operated reliably for nearly five years, even with salt spray and tropical heat. The table below shows more best-use scenarios:

Application Area | Use Case Description | Equipment Protected | Cooling Capacity / Power Data |

|---|---|---|---|

Industrial Control Cabinets | Prevent overheating in factory control panels | Control panels, PLCs | Cooling capacity up to 10 kW or more |

Telecom Enclosures | Maintain optimal temperature for network gear | Routers, switches | Steady cooling even in sunny outdoor conditions |

Battery Storage Boxes | Extend battery life by preventing heat damage | Lithium and lead-acid batteries | Example: Peltier air coolers with 15-19 W cooling at 12V DC |

Outdoor Electrical Panels | Protect electrical circuits from sun and weather | Electrical circuits | Units with corrosion protection for marine environments |

Laboratory Equipment Cabinets | Maintain stable temperature for experiments | Instruments, chemicals | Energy-efficient models with ENERGY STAR certification |

You should choose air conditioners when you need reliable, sealed, and precise cooling in harsh or unpredictable outdoor settings.

Outdoor Enclosure Cooling Systems Comparison

Cooling Performance

When you compare cooling performance, you see clear differences between cabinet fans and outdoor cabinet air conditioners. Cabinet fans work by moving ambient air through your enclosure. This method only cools your equipment down to the outside temperature. Fans cannot lower the temperature below what you feel outdoors. They work best for low to moderate heat loads and in environments where the outside air is clean and not too hot.

Outdoor cabinet air conditioners use a closed-loop system. They actively cool the air inside your enclosure, often lowering it well below the outside temperature. These systems use refrigerants to absorb heat and move it outside. You can rely on air conditioners for high heat loads and harsh outdoor environments. Their cooling capacity ranges from 300 to 6,000 watts (1,000 to 20,000 BTU/hr), which gives you much more control over the internal temperature.

Cooling System Type | Description | Typical Use Cases |

|---|---|---|

Fan Filter Units (FFU) | Circulate ambient air via filters; open loop system | Indoor environments, light heat loads |

Enclosure Air Conditioners | Actively cool air below ambient using refrigerants | High heat loads, outdoor or hot sites |

🧊 Tip: If you need to keep your equipment cooler than the outside air, choose an air conditioner. For mild climates, fans may be enough.

Cost

Cost is a major factor when you select between these two outdoor enclosure cooling systems. Cabinet fans have a lower upfront cost. You can install them for much less than an air conditioner. Fans also use less energy, especially in moderate climates, which helps you save on your electricity bill.

Outdoor cabinet air conditioners cost more to buy and install. Prices often range from $3,000 to $15,000 or more, depending on size and features. They also use more energy, which increases your operational costs. However, in extreme heat or dusty environments, the higher cost may be justified because air conditioners protect your equipment and prevent expensive failures.

Cost Aspect | Forced Fan Systems | Air Conditioners |

|---|---|---|

Lower upfront cost | Higher upfront cost ($3,000 to $15,000+) | |

Energy Consumption | Lower energy use, can save up to 80% energy in moderate (~25ºC) climates | Higher energy consumption, increasing operational costs |

Operational Cost | Generally lower due to energy efficiency | Higher due to energy use and maintenance |

Maintenance | Simpler design, lower maintenance costs | Requires regular upkeep (filter cleaning, refrigerant checks) |

Suitability | Cost-effective in moderate, clean climates | Justified in extreme heat or dusty environments |

Long-term Savings | Limited, but low running costs | Possible with high-efficiency models |

Performance in Extreme Heat | Less effective, may fail to maintain safe temps | Essential to maintain safe internal temperatures |

Energy Efficiency

You want to keep your energy bills low. Cabinet fans use less energy because they only move air. In moderate climates, you can save up to 80% on energy compared to air conditioners. Fans work best when the outside temperature is close to your target temperature inside the enclosure.

Air conditioners use more energy because they run compressors and refrigerant cycles. In hot or humid climates, energy use can rise quickly. Some high-efficiency models help reduce this cost, but you still pay more for the extra cooling power. If you need to maintain a much lower temperature inside your enclosure, air conditioners are the better choice, but you should expect higher energy bills.

Maintenance

Maintenance needs differ between these two outdoor enclosure cooling systems. Cabinet fans have a simple design. You only need to clean or replace the fans and filters. This makes maintenance easy and low-cost. You can often handle these tasks yourself or with basic training.

Air conditioners require more attention. You need to check and clean filters, inspect coils, and monitor refrigerant levels. Experts recommend at least annual cleaning of condenser and evaporator coils. Regular maintenance helps prevent breakdowns and extends the life of your system. You should also budget for unexpected repairs, as complex systems can develop issues over time. Consistent maintenance reduces the risk of costly failures and keeps your equipment safe.

🔧 Note: Regular maintenance for both systems helps you avoid sudden failures and keeps your cooling system running efficiently.

Environmental Suitability

You must match your cooling system to your local environment. Cabinet fans work well in mild, clean climates. They struggle in areas with high heat, humidity, or dust because they bring outside air into your enclosure. If you operate in a place with stable weather and little pollution, fans offer a cost-effective solution.

Outdoor cabinet air conditioners perform better in harsh environments. They keep your enclosure sealed from dust, moisture, and extreme temperatures. You can rely on them in hot, humid, or dusty locations. Studies show that advanced cooling systems adapt to different climates, such as hot regions in India or humid summers in Taiwan. Simulation tools help predict cooling loads in cold climates, ensuring your system works year-round.

🌦️ Tip: Always consider your local climate before choosing a cooling system. The right choice protects your equipment and saves you money over time.

Choosing the Right System

Assessing Needs

You should start by evaluating your specific application. Begin with the heat load inside your enclosure. Electronic equipment generates heat, and too much can cause failures or shorten component lifespan. Use a method like the Manual J load calculation to estimate how much heat your enclosure produces. This method considers the size of your enclosure, insulation, local climate, and the type of equipment inside. Specialized software tools can help you calculate the exact cooling load in BTUs per hour. Accurate calculations prevent you from choosing a system that is too large or too small, which can lead to wasted energy or equipment risk.

Next, look at your environment. Outdoor enclosures face challenges like dust, moisture, and extreme temperatures. If your site experiences high heat, humidity, or airborne contaminants, you need a cooling system that can handle these conditions. Closed-loop systems, such as air conditioners with high IP ratings, protect your equipment from dust and water. In milder climates with clean air, a fan system may be enough.

📝 Tip: Always consider the worst-case scenario for temperature and weather when sizing your cooling system.

Key Factors

When you compare outdoor enclosure cooling systems, several key factors help you make the right choice:

Heat Load: High heat loads require more powerful cooling, often best handled by air conditioners.

Enclosure Size: Larger enclosures need higher cooling capacity.

Environmental Conditions: Dust, moisture, and extreme weather call for sealed, closed-loop systems with high IP or NEMA ratings.

Energy Efficiency: Fans use less energy in moderate climates, but air conditioners with energy-saving features can lower costs in harsh environments.

Maintenance: Fans are easier to maintain, but air conditioners need regular filter and component checks.

Long-Term Reliability: Stable temperature management extends equipment life. A 10°C rise in temperature can cut component lifespan in half.

Budget: Fans cost less upfront and to operate, but air conditioners may save money by preventing equipment failures in tough environments.

Here is a quick comparison table:

Factor | Cabinet Fan | Outdoor Cabinet Air Conditioner |

|---|---|---|

Cooling Precision | Moderate | High |

Environmental Protection | Low to Moderate | High (IP54, IP65, NEMA 4X, etc.) |

Energy Use | Low | Moderate to High |

Maintenance | Simple | Regular, more involved |

Upfront Cost | Low | Higher |

Best For | Mild, clean environments | Harsh, dusty, or humid environments |

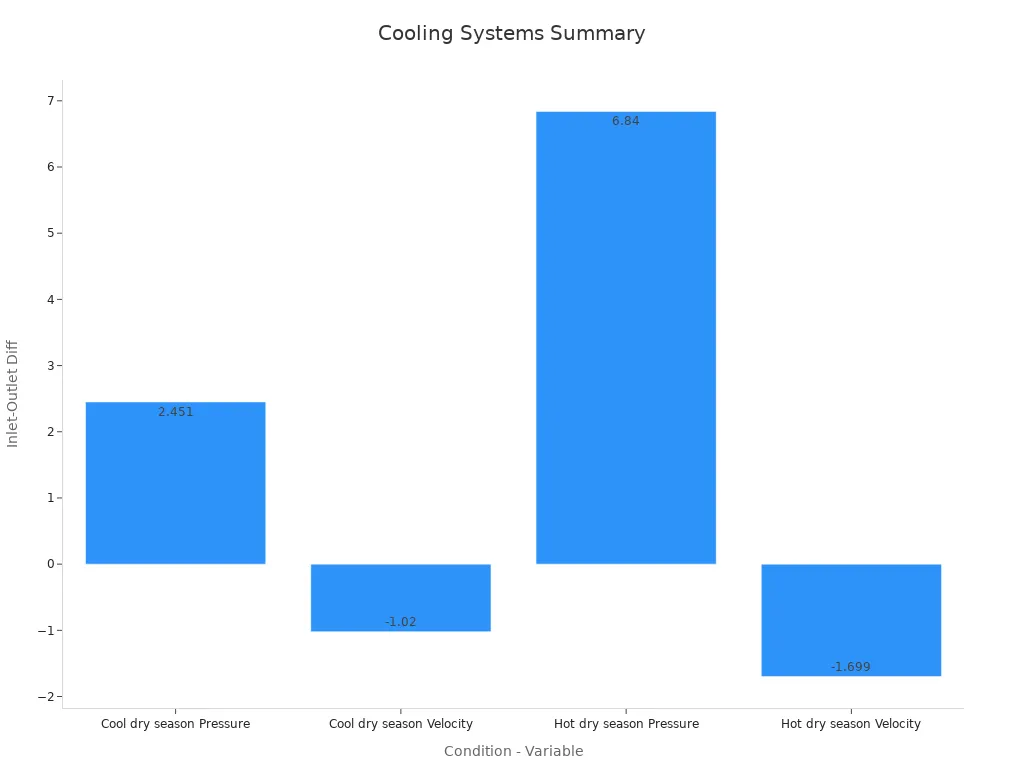

You now see that cabinet fans offer simple, cost-effective cooling for mild climates, while air conditioners deliver precise control in harsh environments. The table below highlights performance differences in pressure and velocity across seasons, showing how each system responds to changing conditions.

Condition | Variable | Inlet Value | Outlet Value |

|---|---|---|---|

Cool dry season | Pressure (Pa) | 2.543 | 0.092 |

Velocity (m/s) | 1.599 | 2.619 | |

Hot dry season | Pressure (Pa) | 7.125 | 0.285 |

Velocity (m/s) | 2.676 | 4.375 |

Choose outdoor enclosure cooling systems based on your climate, equipment needs, and long-term reliability. Always weigh total cost of ownership and environmental factors before making your final decision.

FAQ

What is the main difference between a cabinet fan and an outdoor cabinet air conditioner?

A cabinet fan moves outside air through your enclosure. An outdoor cabinet air conditioner uses a sealed system to cool and dehumidify the air inside. You get better protection from dust and humidity with an air conditioner.

Which system is more energy efficient?

Cabinet fans use less energy because they only circulate air. Outdoor cabinet air conditioners consume more power due to compressors and refrigerants. You save more energy with fans in mild climates, but air conditioners work better in extreme conditions.

When should you choose a cabinet fan over an air conditioner?

Choose a cabinet fan if you have a mild climate, low heat load, and clean air. Fans cost less and require less maintenance. Air conditioners suit harsh, dusty, or humid environments where you need precise temperature control.

How does maintenance compare between the two systems?

You spend less time maintaining cabinet fans. Cleaning or replacing filters is simple. Outdoor cabinet air conditioners need regular checks for filters, coils, and refrigerant. You may need professional service for air conditioners.

See Also

The Importance Of Cooling In Outdoor Communication Cabinets

Selecting The Ideal Cooling Solution For ESTEL Telecom Cabinets

Understanding Outdoor Enclosure Cabinets And Their Advantages

Enhancing Outdoor Cabinets Through Power Cooling And Monitoring

ESTEL Cooling Solutions Designed For Industrial Cabinet Needs

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA