Passive Heat Dissipation Optimization of Smart PDUs in Telecom Cabinets: Noise Reduction Practice in Low-Noise Data Centers

You can make your data center quieter and more reliable by optimizing passive heat dissipation in your Smart Power Distribution Unit. Effective heat management reduces the need for noisy fans, helping you meet strict noise regulations. Many regions follow standards like ISO 9613-2 for outdoor noise, while the UK, EU, Australia, and Canada set comprehensive rules. Here is a quick look at current noise regulations:

Region/Organization | Noise Regulation Details |

|---|---|

US | Local ordinances vary; some tie limits to pre-operation ambient noise. Minimal federal guidance. |

UK, EU, Australia, Canada | Comprehensive frameworks exist for noise regulation. |

ISO 9613-2 | Primary standard in North America for outdoor noise prediction, updated in 2024. |

WHO, World Bank | Provide guidelines that can inform local noise ordinances. |

When you improve passive cooling, you lower energy consumption, prevent overheating, and extend equipment life. This approach reduces downtime and maintenance costs, making your data center more efficient and compliant with modern standards.

Key Takeaways

Optimize passive heat dissipation to reduce noise and improve reliability in data centers.

Implement effective cabinet layouts to enhance airflow and cooling efficiency, minimizing the need for noisy fans.

Select high-conductivity materials like copper and aluminum for heat sinks to ensure effective thermal management.

Regularly monitor temperature and humidity levels to prevent overheating and extend equipment lifespan.

Adopt advanced cooling solutions, such as fanless systems, to create a quieter and more comfortable working environment.

Heat Dissipation Importance

Reliability and Performance

You depend on your telecom equipment to run smoothly every day. Proper heat dissipation plays a key role in keeping your systems reliable. When you manage heat well, you protect sensitive electronics from damage and extend their lifespan. Over 55% of failures in electrical devices come from temperature issues. If you keep your equipment cool, you reduce the risk of sudden shutdowns and costly repairs.

Here is a quick look at how effective heat management benefits your telecom cabinets:

Benefit | Description |

|---|---|

Stable operation in extreme temperatures | Ensures equipment functions reliably under varying conditions. |

Lower energy losses | Reduces waste and operational costs. |

Longer equipment lifespan | Extends the life of sensitive electronics. |

Fewer unexpected shutdowns | Minimizes downtime and maintenance needs. |

If you use a Smart Power Distribution Unit with good passive cooling, you help maintain safe operation and maximize uptime. Poor heat dissipation can cause thermal failures, such as swollen capacitors or cracked solder joints. Humidity can also corrode terminals, leading to faults and reduced performance. In some cases, poor cooling can cut equipment life in half.

Noise Impact in Data Centers

Noise matters in modern data centers. High noise levels can distract staff and make the environment uncomfortable. When you rely on passive heat dissipation, you reduce the need for loud fans and mechanical cooling systems. This approach helps you meet strict noise regulations and creates a quieter workspace.

Tip: Lower noise levels not only improve comfort but also support better communication and focus for your team.

By optimizing passive cooling, you protect your equipment and create a better working environment. You also support the long-term reliability of your Smart Power Distribution Unit and other critical systems.

Challenges in Low-Noise Telecom Cabinets

Heat Sources and Ambient Factors

You face several heat sources inside telecom cabinets. These include fluctuating temperature and humidity, excessive heat from equipment, unstable power, and environmental risks like contamination. Each of these factors can affect the performance and reliability of your systems. The optimal operating temperature for most telecom equipment ranges from 15°C to 30°C (59°F–86°F). If temperatures rise above this range, you risk capacitor swelling, circuit warping, and condensation that can lead to corrosion.

Excessive heat from electronic components

Unstable power supply

Environmental risks such as humidity or contamination

Ambient temperature and humidity play a critical role in cooling efficiency. High ambient temperatures increase the thermal load, making it harder for passive systems to keep equipment cool. High humidity can cause condensation, which threatens sensitive electronics. You need to select cooling methods that account for these environmental conditions to ensure effective heat dissipation. Studies show that evaluating both temperature and humidity is essential when choosing cooling strategies for telecom cabinets.

Noise Sensitivity Issues

Noise sensitivity presents unique challenges in low-noise data centers. You must consider not only the comfort of your staff but also the impact on nearby communities. Noise levels in data centers can reach up to 96 dBA, which may cause hearing damage with prolonged exposure. Staff working in noisy environments often experience decreased productivity and higher stress. Communities near data centers sometimes report health issues like headaches, stress, and sleep disturbances due to noise pollution.

Note: Many data centers now use advanced architectural designs and quieter equipment to reduce noise. These strategies help protect the health and comfort of both personnel and local residents.

You can address these challenges by optimizing passive cooling in your Smart Power Distribution Unit. This approach reduces reliance on noisy fans and mechanical systems, supporting a quieter and healthier environment.

Passive Cooling Strategies for Smart Power Distribution Unit

Cabinet Layout and Airflow

You can improve passive heat dissipation by focusing on the layout of your telecom cabinets. The way you arrange your equipment directly affects airflow and cooling efficiency. Here are some practical steps you can follow:

Place racks away from heat sources. Racks near windows often have twice as many hot spots.

Maintain a clearance of 2–3 feet around cooling units and rack air intakes or exhausts. This space allows air to flow freely.

Plan the layout of cabinets across your facility. Consistent airflow prevents temperature imbalances.

Design cabinets to support front-to-back airflow. High perforation rates in cabinet doors help cool air move efficiently.

Manage cables carefully. Poor cable management blocks airflow and reduces cooling performance.

Align cabinet rows to create hot aisle and cold aisle configurations. This setup keeps hot and cold air from mixing, which maximizes cooling.

Tip: Good airflow design reduces the need for mechanical fans, which helps lower noise levels in your data center.

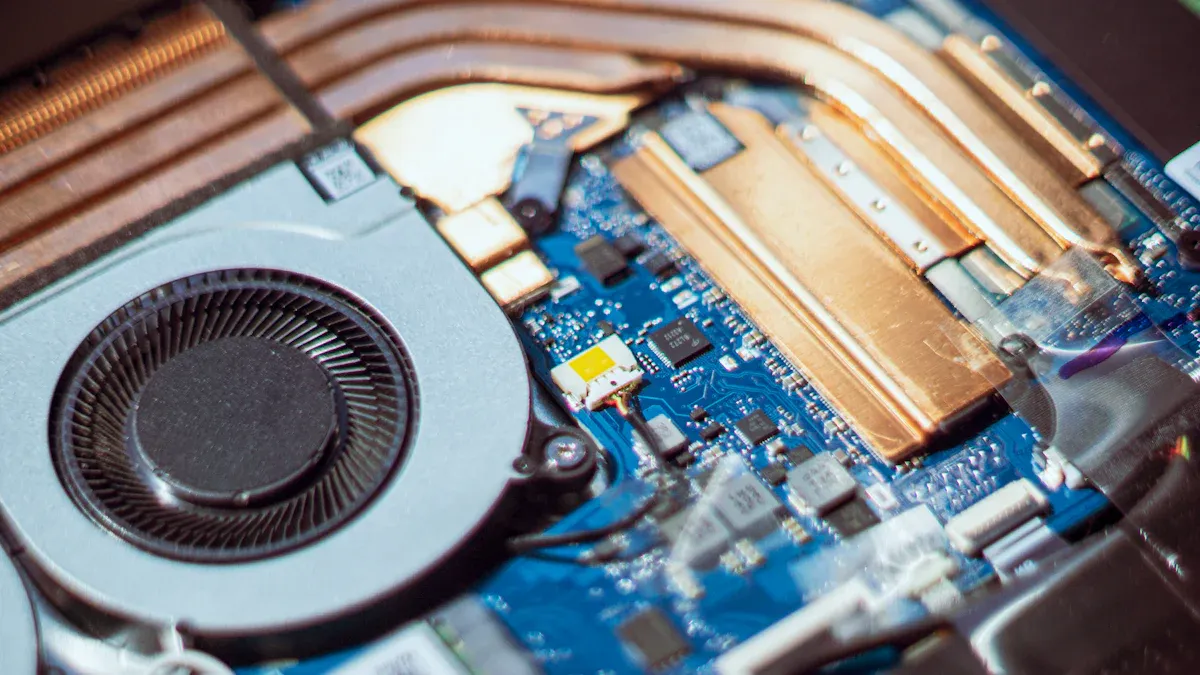

Advanced Heat Sink Design

You can boost passive cooling by using advanced heat sink designs in your Smart Power Distribution Unit. Modern heat sinks use modular structures that allow you to scale and adapt heat dissipation as needed. These designs increase the surface area, which helps spread heat more effectively.

Modular heat sinks offer flexibility and can be adjusted for different equipment loads.

Enhanced surface area improves heat transfer and keeps temperatures stable.

Integration with advanced thermal management features increases efficiency and reliability.

Optimized models, such as patented maxiFLOW™ designs, maintain safe operating temperatures and support long-term equipment performance.

When you use these advanced heat sinks, you help your equipment run cooler and quieter. This approach extends the life of your Smart Power Distribution Unit and reduces the risk of overheating.

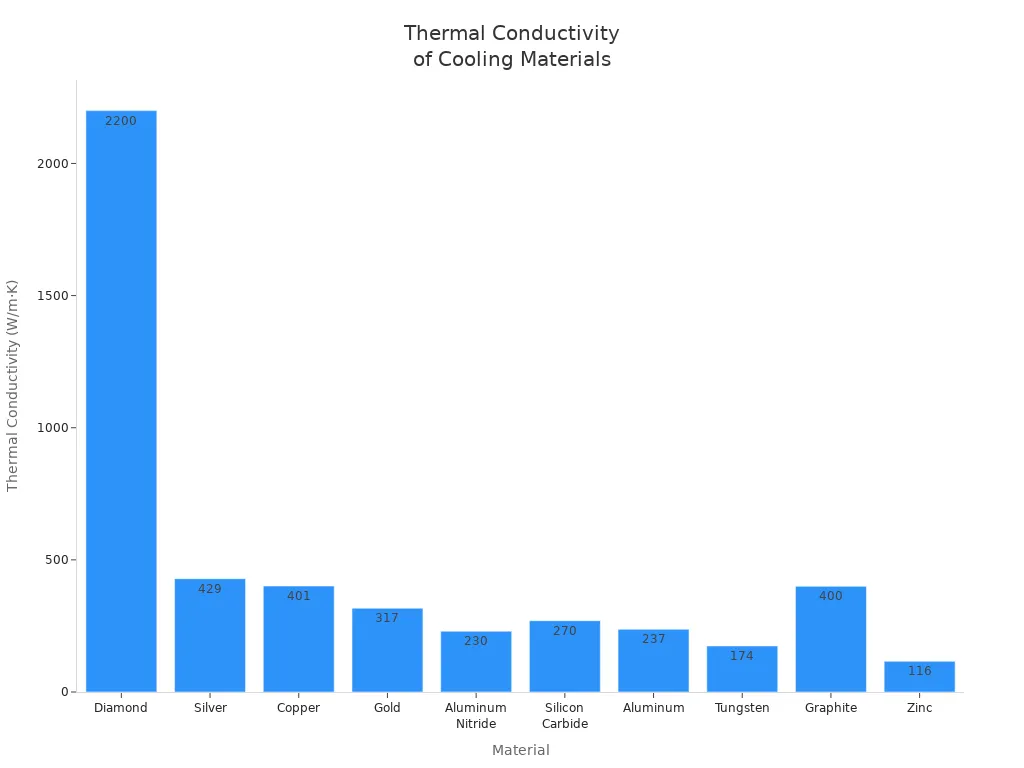

Material Selection

Choosing the right materials for your telecom cabinets and heat sinks is essential for effective passive cooling. Materials with high thermal conductivity transfer heat away from sensitive components quickly. The table below shows the thermal conductivity of common materials used in passive cooling:

Material | Thermal Conductivity (W/m·K) | Applications |

|---|---|---|

Diamond | 2000-2200 | Efficient heat spreader in high-power electronics, AI chips, quantum computing |

Silver | 429 | Electronic components, AI servers, green technologies |

Copper | 401 | Consumer electronics, data center thermal management |

Gold | 317 | High-end electronics, quantum computing, aerospace |

Aluminum Nitride | 170-230 | Power semiconductors, EV electronics |

Silicon Carbide | 120-270 | Power electronics, high-temperature applications |

Aluminum | 237 | Lightweight applications, alloys for specific needs |

Tungsten | 174 | Stability at high temperatures |

Graphite | 100-400 | Flexible and high-temperature battery cooling |

Zinc | 116 | Alloy form, applications in battery cooling |

Copper and aluminum are popular choices for heat sinks in telecom cabinets. They combine high thermal conductivity with durability and cost-effectiveness. When you select the right materials, you ensure that your Smart Power Distribution Unit stays cool and operates efficiently.

ESTEL’s Passive Cooling Solutions

ESTEL offers passive cooling solutions that help you meet strict noise and reliability standards in your data center. The design of ESTEL’s Smart Power Distribution Unit includes features that support efficient heat dissipation and quiet operation.

Solution Feature | Impact on Noise Levels | Benefit for Cooling Systems |

|---|---|---|

Absorbent material in cabinet ceiling | Improves cooling efficiency | |

Filling cavities between panels | Decreases by 0.2–0.5 dB | Maintains cooling performance |

Passive noise attenuation design | Achieves required noise levels | Ensures efficient passive cooling |

ESTEL’s cabinets use high-quality materials and advanced airflow designs. These features reduce the need for active cooling, which lowers noise and energy use. You benefit from a quieter environment and longer equipment life.

Effective cabinet cooling prevents overheating and keeps your equipment efficient.

Operating within safe temperature limits reduces strain on electronic components and extends their lifespan.

Passive cooling methods, such as phase change materials, help regulate internal temperatures and protect sensitive electronics.

Note: By choosing ESTEL’s Smart Power Distribution Unit, you invest in a solution that supports both noise reduction and equipment longevity. You also ensure compliance with international standards for telecom infrastructure.

Real-World Applications and ESTEL Case Study

Low-Noise Data Center Success

You can see the benefits of passive heat dissipation in real-world data centers. Many facilities now use fanless cooling towers to reduce both energy use and noise. These towers do not rely on mechanical fans, so they create a quieter environment. The table below shows how these solutions have improved data center operations:

Example | Description | Outcome Metrics |

|---|---|---|

Fanless Cooling Towers | Used in data centers to reduce energy consumption and noise pollution. | 15-20% reduction in energy costs and significant decrease in noise levels. |

You can achieve similar results by focusing on passive cooling strategies. Lower noise levels help your staff work comfortably and safely. Energy savings also reduce your operating costs.

ESTEL Smart Power Distribution Unit in Practice

You can improve your data center’s performance by using ESTEL’s Smart Power Distribution Unit. Many low-noise data centers have already adopted this solution. They report measurable improvements in both energy efficiency and equipment reliability. The table below highlights the outcomes you can expect:

Outcome Description | Percentage Improvement |

|---|---|

Reduction in energy consumption | |

Improvement in equipment uptime | 20% |

You can see that these improvements make a real difference. Lower energy use means you spend less on electricity. Better uptime means your equipment stays online longer, which reduces maintenance and downtime. ESTEL’s design supports passive cooling, so you do not need to rely on noisy fans. This approach helps you meet strict noise standards and keeps your data center running smoothly.

Tip: When you choose solutions that focus on passive heat dissipation, you invest in a quieter, more reliable future for your telecom infrastructure.

Best Practices Checklist

Action Steps for Data Centers

You can optimize passive heat dissipation in your telecom cabinets by following a clear set of actions. These steps help you maintain a quiet, efficient, and reliable data center environment:

Use Free Cooling: Take advantage of cooler outdoor air to regulate cabinet temperatures. This method works best in regions with lower ambient temperatures.

Install Heat Exchangers: Devices like the PKS 3000 Series transfer heat efficiently and protect your equipment from dust and contaminants.

Choose Insulated Cabinet Designs: Select cabinets with double-wall construction and insulation. These features minimize heat transfer and keep internal temperatures stable.

Plan Cabinet Layouts Carefully: Arrange cabinets to support optimal airflow. Avoid placing racks near heat sources or blocking air intakes.

Monitor Humidity Levels: Keep humidity within recommended ranges to prevent condensation and corrosion.

Select High-Conductivity Materials: Use copper or aluminum for heat sinks and cabinet components to improve thermal performance.

Maintain Cable Management: Organize cables to prevent airflow blockages and support passive cooling.

Tip: Regularly review your cooling strategies. Small adjustments can lead to significant improvements in noise reduction and energy efficiency.

Maintenance and Monitoring

You need to maintain and monitor your passive cooling systems to ensure long-term reliability. Routine checks and data tracking help you catch issues early and keep your Smart Power Distribution Units running smoothly.

Evidence Type | Details |

|---|---|

Component Lifespan Reduction | Improper cooling can lead to a 20% reduction in component lifespan. |

Energy Loss Contribution | Overheating contributes to over 30% of energy losses in power distribution systems. |

Importance of Thermal Management | Effective thermal management is crucial for long-term reliability and safety in electrical systems. |

Schedule regular inspections for cabinet insulation, heat exchangers, and airflow paths. Track temperature and humidity data using smart monitoring tools. Address any signs of overheating or condensation immediately. By following these practices, you protect your equipment, reduce energy losses, and extend the lifespan of your telecom infrastructure.

You can optimize passive heat dissipation in your Smart Power Distribution Units to reduce noise and boost reliability. The table below shows how passive cooling strategies help you meet compliance standards in low-noise data centers:

Passive Cooling Strategy | Benefits | Compliance Impact |

|---|---|---|

Silent Cooling Systems | Operate quietly, improve energy efficiency | Support noise regulations |

Natural Sound Barriers | Absorb and scatter noise, help community comfort | Shield nearby residential areas from noise |

Consider ESTEL’s solutions for your telecom infrastructure needs:

ESTEL’s battery systems deliver reliable, efficient performance for modern networks.

Safety features like heat control and live monitoring protect your equipment.

ESTEL’s commitment to quality has reduced battery failure rates significantly.

Apply these strategies and tools to create a quieter, more compliant data center.

FAQ

How does passive heat dissipation reduce noise in data centers?

Passive heat dissipation removes heat without using fans or mechanical systems. You avoid extra noise because you do not need moving parts. This method helps you create a quieter environment for your staff and equipment.

What materials work best for passive cooling in telecom cabinets?

You get the best results with copper or aluminum. These materials transfer heat quickly and last a long time. You can also use advanced materials like aluminum nitride for special applications.

Can ESTEL’s Smart Power Distribution Unit operate in harsh environments?

Yes! You can rely on ESTEL’s Smart Power Distribution Unit in extreme conditions. The robust design and high-quality materials protect your equipment from dust, humidity, and temperature swings.

How do I maintain optimal cooling performance in my cabinets?

Tip:

You should check airflow paths, clean vents, and monitor temperature and humidity regularly. Good cable management also helps you keep air moving freely inside your cabinets.

See Also

Exploring Various Cooling Techniques for Telecom Cabinet Efficiency

Effective Strategies for Reducing Noise in Server Enclosures

Maintaining Ideal Temperature in Outdoor Telecom Cabinets

Selecting the Most Effective Cooling Solution for ESTEL Cabinets

Enhancing Outdoor Cabinets Through Power, Cooling, and Monitoring

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA