Understanding Rectifier Cabinets and Their Industrial Applications

A rectifier cabinet changes alternating current (AC) into direct current (DC). This provides a steady energy flow for industrial machines. These cabinets power important equipment like factory lines and telecom systems. They work very efficiently. New models can reach 97.83% efficiency at 277 VAC. Businesses using rectifiers save up to 20% yearly on power. Adding renewable energy lowers both costs and pollution. Smart designs also reduce downtime, making these cabinets essential for industries that use a lot of energy.

Key Takeaways

Rectifier cabinets change AC power into DC power. This gives steady energy to machines and lowers downtime.

Using rectifier cabinets can cut energy costs by up to 20%. This makes them a good choice for saving money.

Taking care of rectifier cabinets, like checking cooling and control parts, stops problems and makes them last longer.

Many industries, like factories, green energy, and transport, need rectifier cabinets for steady power.

Picking the right rectifier cabinet for your needs improves how well it works and helps it grow with your business.

What Are Rectifier Cabinets?

Definition and Purpose

A rectifier cabinet is a box for changing electricity. It turns alternating current (AC) into direct current (DC). This change is important for devices needing steady DC power. Rectifier cabinets are used in factories, telecom systems, and green energy setups.

The main job of a rectifier cabinet is to give machines the right power. Many devices cannot work well with AC power. By switching AC to DC, rectifiers keep machines running smoothly. They also protect equipment from power changes that might cause harm or slow it down.

Role in Power Conversion and Industrial Use

Rectifier cabinets are key in industrial power systems. They help machines work without stopping. For example, in factories, they power robots, conveyor belts, and other tools. In telecom, they keep data centers and cell towers running.

Different rectifiers are used for different jobs. Bridge rectifiers are for big systems. Half-wave and full-wave rectifiers are for smaller tasks. Each type has special uses, so you can pick what fits best.

More industries are using rectifier cabinets now. The table below shows how they are used in energy and transport:

Application/Region | Revenue Forecast (2018-2029) | Sales Forecast (2018-2029) |

|---|---|---|

Railway Transportation System | N/A | N/A |

Wind Farm | N/A | N/A |

Solar Farm | N/A | N/A |

North America | N/A | N/A |

Europe | N/A | N/A |

Asia | N/A | N/A |

This shows rectifier cabinets are popular in green energy and transport. Using them saves energy and lowers costs.

Components of a Rectifier Cabinet

Rectifiers

Rectifiers are the main part of a rectifier cabinet. They change alternating current (AC) into direct current (DC) to give steady power. Different rectifiers are used for different jobs. Bridge rectifiers work for high-power systems. Half-wave and full-wave rectifiers are better for smaller tasks. Picking the right rectifier depends on what your machines need.

Rectifiers are very efficient, often working at 90% or more. This helps save energy and makes machines run better. They can handle a wide range of voltages. This reduces downtime and keeps things running smoothly. Numbers like Mean Time Between Failures (MTBF) show how reliable they are. These numbers tell you how long a rectifier works without problems.

Transformers

Transformers are important for adjusting voltage in rectifier cabinets. They increase or decrease AC voltage to match what the rectifier needs. This helps the rectifier work at its best. Transformers also protect equipment from power surges by isolating electricity.

Good transformers are key for smooth operations. They handle different voltage levels and keep working well. With proper care, transformers can last many years. This makes them a smart and cost-saving choice for rectifier cabinets.

Cooling Systems

Cooling systems keep rectifier cabinets from overheating. Heat from power conversion can harm parts if not controlled. Air-cooled cabinets use fans to remove heat. Oil-cooled cabinets use liquid cooling for tougher jobs.

Good cooling improves performance and makes rectifier cabinets last longer. It also stops overheating, which can cause failures. Choose air or liquid cooling based on your needs and environment.

Tip: Check and maintain your cooling system often to avoid problems and save money on repairs.

Control Panels and Monitoring Systems

Control panels and monitoring systems help run rectifier cabinets well. The control panel lets you manage and adjust the cabinet. It has buttons, switches, and screens for easy use. You can turn the cabinet on or off and change voltage. It also shows the system's status for quick checks.

Monitoring systems give live updates about how the rectifier is working. They show details like voltage, current, and temperature. This helps spot problems early before they get worse. For example, if it gets too hot, the system warns you. Fixing issues early keeps the cabinet running smoothly.

Modern panels often have digital screens and smart features. Some even let you check the cabinet from your phone or computer. This makes managing the rectifier easier, especially in big factories.

Tip: Check the control panel and monitoring system often. Fix any warnings quickly to avoid expensive repairs.

Load Distribution Modules

Load distribution modules share power evenly with connected devices. They split the direct current into smaller parts. This stops overloading and gives each device the right power.

Think of these modules as traffic managers for electricity. They send power where it’s needed most. This is very useful for systems with many devices, like air-cooled or oil-cooled cabinets. Sharing power properly makes things work better and avoids damage.

Good load distribution modules also make systems safer. They have circuit breakers and fuses to stop power surges. These protect your machines and lower the chance of downtime.

Note: Check load distribution modules often to ensure they work well. Replace old parts to keep everything running smoothly.

How Does a Rectifier Cabinet Work?

AC to DC Conversion Process

Rectifier cabinets change AC power into DC power. AC switches direction, but DC flows one way. Inside the cabinet, parts like diodes or thyristors do this job. These parts stop electricity from going backward. This makes sure the DC power stays steady.

Different rectifiers work for different tasks. Half-wave rectifiers are for simple jobs. Full-wave rectifiers handle more power. Bridge rectifiers are best for big systems needing strong power. Picking the right one keeps machines running without problems.

Tip: Check rectifiers often to keep them working well and avoid issues.

Power Regulation and Distribution

Power regulation gives devices the right voltage and current. Transformers in the cabinet adjust voltage to match machine needs. Control panels watch and manage the power flow. This stops sudden changes that could harm equipment.

Distribution modules share DC power with connected devices. They stop overloading and give each device the right amount. In factories, they send power to tools like conveyor belts and robotic arms.

Here’s a table comparing different rectifier cabinet features:

Performance Metric | Description |

|---|---|

Conversion Efficiency | Good for steady power needs, saves energy. |

Cost of Deployment | Low cost, great for basic power setups. |

Control Delay | Quick response, easy to use. |

Scalability | Works best for small or medium systems. |

Computational Complexity | Simple design, easy to maintain. |

Knowing these features helps you pick the right cabinet for your needs.

Efficiency and Performance Optimization

Efficiency lowers energy costs and improves machine work. Modern cabinets are very efficient, often over 90%. This saves energy and keeps machines running smoothly. Cooling systems stop overheating, which helps efficiency.

To improve performance, check and maintain the cabinet often. Smart control panels show live data like voltage and temperature. Use this info to fix problems early. For example, fixing cooling issues quickly avoids expensive repairs.

Note: Keep your cabinet working well by inspecting it regularly and replacing old parts.

Benefits of Using Rectifier Cabinets

Reliable and Stable Power Supply

Rectifier cabinets give steady and reliable power to machines. They change alternating current (AC) into direct current (DC) for smooth operation. This stable power stops damage from sudden power changes. In factories, they keep conveyor belts and robots working without stopping.

These cabinets handle heavy loads well. Parts like transformers and load modules share power evenly. This stops overloading and gives each machine the right energy. Machines work better and last longer with this setup.

Tip: Check your rectifier cabinet often to avoid sudden breakdowns.

Energy Efficiency and Cost Savings

Rectifier cabinets help save energy and lower costs. New designs, like oil-cooled ones, waste less energy. This saves electricity and cuts down your bills.

Studies show how much energy these cabinets save. For example:

Evidence Description | Energy Savings | Cost Reduction |

|---|---|---|

Use of VFDs | Up to 30% | Big drop in running costs |

Adaptive frequency control | Cuts idle power by 30% | Not listed |

Factory case study | 35% less energy used | 25% lower running costs |

These numbers show rectifier cabinets are good for saving energy. They also help the environment by using less power. Investing in them means saving money and being eco-friendly.

Scalability and Customization for Industrial Needs

Rectifier cabinets can grow and change to fit your needs. Whether your business is small or big, there’s a cabinet for you. Modular designs let you add more power as your business grows.

You can pick features like rectifier type, cooling system, and controls. For example, oil-cooled cabinets work well in tough conditions. Custom options make sure the cabinet fits your setup perfectly. This improves how well it works and lasts.

Note: Ask an expert to design a cabinet that suits your needs.

Longer Equipment Life and Less Downtime

Rectifier cabinets help machines last longer. They give steady power, protecting equipment from voltage changes and power spikes. When machines get consistent energy, they work better and avoid damage.

How Rectifier Cabinets Prevent Downtime

Downtime stops work and costs money. Rectifier cabinets lower this risk by keeping power steady. Their smart systems find problems early so you can fix them fast. Cooling systems stop overheating, which often breaks machines.

Tip: Check cooling systems and monitors often to catch issues early.

Features That Help Machines Last

Rectifier cabinets have parts that protect equipment:

Voltage Regulation: Keeps power steady to avoid machine stress.

Load Distribution Modules: Share power evenly to stop overloading.

Cooling Systems: Keep machines cool to avoid heat damage.

These parts work together to keep machines safe and reliable.

Real-Life Advantages

Think of a factory where machines run smoothly all day. Rectifier cabinets make this happen by stopping power problems. Over time, this lowers repair costs and helps machines last longer.

Note: Buying good rectifier cabinets saves money by cutting repairs and downtime.

With good care, rectifier cabinets keep machines running for years. This boosts work output and saves money.

Industrial Applications of Rectifier Cabinets

Manufacturing and Automation Systems

Rectifier cabinets are important in factories and automated systems. They give steady DC power to machines like robots and conveyor belts. This keeps everything running smoothly and avoids delays. Reliable power helps factories meet deadlines and stay productive.

Saving energy is very important in factories. Rectifiers in these cabinets work at over 90% efficiency. This means less energy is wasted, which lowers costs. Many factories now use smart rectifier cabinets with digital monitors. These let workers check performance and fix problems early.

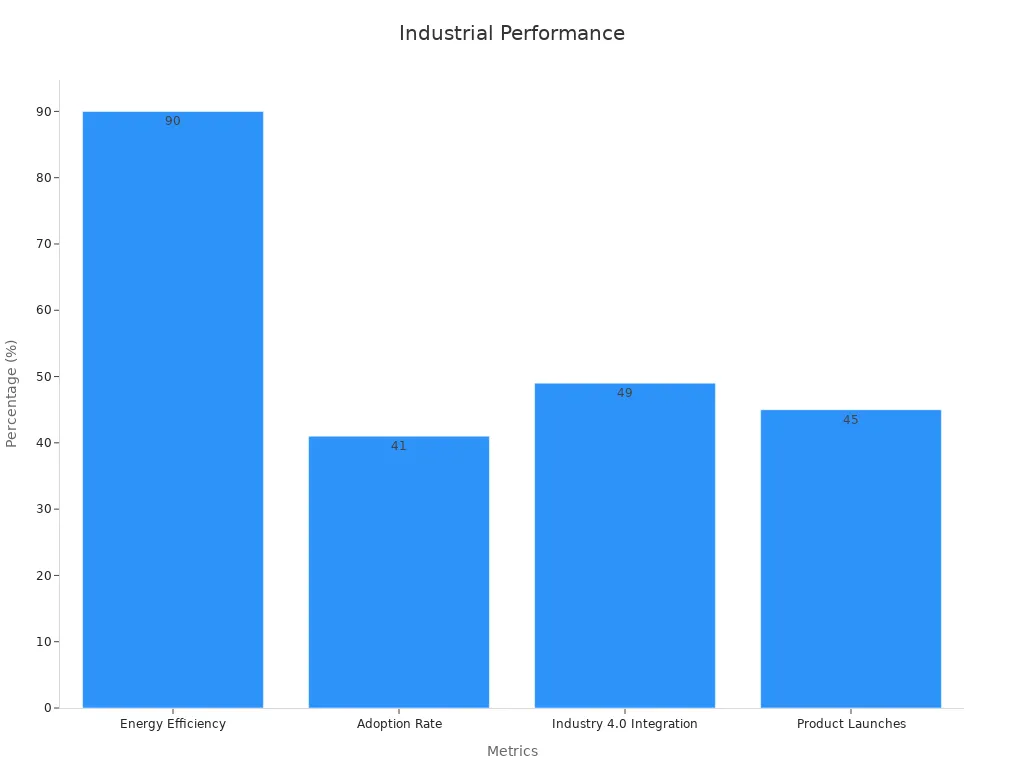

Here’s how rectifier cabinets help in manufacturing:

Statistic/Insight | Description |

|---|---|

Energy Efficiency | Rectifiers rated over 90% improve energy efficiency. |

Adoption Rate | Over 41% of manufacturing systems now depend on DC power. |

Industry 4.0 Integration | Approximately 49% of companies use rectifiers with digital monitoring capabilities. |

Product Launches | 45% of new products in 2023-2024 feature compact and fanless designs. |

Using rectifier cabinets saves energy, reduces downtime, and helps factories stay competitive.

Renewable Energy Systems (e.g., Solar and Wind Power)

Renewable energy systems need rectifier cabinets to manage power. Solar panels and wind turbines make electricity as AC power. Rectifier cabinets change this into DC power for batteries or devices.

In solar farms, rectifier cabinets keep energy flowing steadily, even with less sunlight. In wind farms, they balance power during changes in wind speed. This protects equipment and uses energy better.

Modern rectifier cabinets also work with both renewable and regular power grids. This mix helps save energy and use fewer non-renewable sources. Adding rectifier cabinets to renewable setups saves money and helps the environment.

Transportation and Railways

Trains, subways, and trams need rectifier cabinets for power. These vehicles use DC motors, which need steady DC power. Rectifier cabinets change AC power from the grid into DC power. This keeps trains running smoothly and safely.

In railways, rectifier cabinets power lights, signals, and communication systems. They also help with regenerative braking, which turns braking energy into electricity. This extra energy goes back into the system, saving power.

Rectifier cabinets are also used in electric car charging stations. They control power to make charging safe and efficient. Using rectifier cabinets in transportation improves reliability, saves energy, and supports eco-friendly travel.

Telecommunications Infrastructure

Telecom systems need steady power to work properly. Rectifier cabinets help by changing AC power into DC power. This DC power is crucial for running servers, routers, and signal devices. Without rectifiers, systems might fail, causing dropped calls or slow internet.

Cell towers and base stations depend on rectifier cabinets for stable power. These towers need consistent DC power to keep signals strong. Rectifiers ensure smooth operation even during power changes. Many modern rectifiers have monitors that warn about problems. This helps fix issues quickly and reduces downtime.

Data centers also use rectifier cabinets for steady power. These centers hold important IT equipment that needs reliable energy. Rectifiers improve energy use and lower costs. Some data centers now pair rectifiers with solar panels for eco-friendly power.

Tip: Check your rectifier cabinets often to avoid failures and keep them working well.

Heavy-Duty Equipment (e.g., Cranes, Electromagnets, Plasma Arc Systems)

Big machines need strong DC power to work well. Rectifier cabinets power cranes, electromagnets, and plasma arc tools. They give the right voltage and current for these machines to perform their best.

Cranes in construction and shipping use rectifiers for motors and controls. Stable DC power helps cranes lift and move heavy items safely. Electromagnets in scrap yards rely on rectifiers to create magnetic fields. These fields lift and sort metal objects easily.

Plasma arc systems, used for cutting and welding, need steady DC power too. Rectifiers help make high-temperature plasma for clean cuts. This also reduces wear on the tools.

Modern rectifier cabinets for heavy-duty jobs have cooling systems. These systems stop overheating and make equipment last longer.

Note: Choose a rectifier cabinet that fits your power needs and is durable for heavy use.

Safety Tips and Maintenance Advice

How to Stay Safe When Using Rectifier Cabinets

Using rectifier cabinets safely is very important. Follow these tips:

Wear safety gear like gloves and goggles when working with electricity.

Make sure the cabinet is grounded to avoid electric shocks.

Keep the area around the cabinet clean to prevent fires.

Never touch wires or parts while the cabinet is on.

Use special tools made for electrical work to stay safe.

Tip: Teach your team safety rules often so everyone knows how to use rectifier cabinets correctly.

Checking and Maintaining Your Cabinet

Regular checks keep your rectifier cabinet working well. Look at it every month to find and fix problems early.

Look for loose wires or broken parts and fix them.

Clean dust from cooling fans to stop overheating.

Test the control panel to make sure it works right.

Check that power is shared evenly by the load modules.

Taking care of your cabinet makes it last longer. It also helps avoid sudden breakdowns.

Note: Hire a professional once a year to fix big problems.

Fixing Common Problems

Even with care, problems can happen. Knowing how to fix them helps a lot.

If it gets too hot, check the fans and clean them.

If power is uneven, look at the rectifiers and transformers.

If the control panel shows errors, restart it and watch for issues.

After a power surge, check the load modules and replace blown fuses.

Tip: Write down all repairs and checks. This helps you see patterns and improve your system.

By following these steps, you can keep your rectifier cabinet safe and working well. This ensures steady power for your machines.

Knowing how a rectifier cabinet works shows its importance in power. These cabinets change AC power into DC, giving steady energy to machines. Parts like rectifiers, transformers, and cooling systems work together. They help machines run better, save energy, and avoid breakdowns.

Many industries depend on rectifier cabinets for reliable power. They are used in factories and renewable energy systems to keep things running. Buying these systems boosts efficiency and protects machines. With good care, they stay vital for managing industrial power.

FAQ

How long does a rectifier cabinet last?

If cared for well, it can work for 10–15 years. Regular checks and replacing worn parts help it last longer.

Can rectifier cabinets be used outside?

Yes, some are made for outdoor use. These have special designs to resist rain, dust, and temperature changes.

How do you pick the right rectifier cabinet?

Think about your power needs and where it will be used. Talk to an expert to find one that fits your equipment and setup.

Are rectifier cabinets good at saving energy?

Yes, newer models are over 90% efficient. They waste less energy and help lower electricity bills.

Do rectifier cabinets need a lot of maintenance?

Not much, but check them monthly and get a yearly inspection. Clean cooling parts and watch performance to avoid problems.

Tip: Follow the maker’s guide to keep it working its best.

See Also

Benefits of ESTEL Cooling Solutions in Industrial Settings

Ensuring Consistent Power Supply for Telecom Cabinet Operations

Exploring Various Applications of Telecom Cabinets

Integrating Solar Inverters and Batteries in Telecom Cabinets

Assessing Power Requirements for Communication Cabinet Supplies

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA