Balancing cost and reliability in rectifier module selection with N+1 and N+2 configurations

A single rectifier module failure can disrupt critical systems and lead to costly downtime. Operators face real challenges in weighing system uptime against budget constraints. For instance, ESTEL rectifier modules use AI and IoT for real-time monitoring, which allows early detection of issues and supports predictive maintenance. As shown in recent reliability data, even components like press-pack IGBT modules and metallised film capacitors have measurable failure rates that directly affect system stability. Every application demands a careful balance between cost and the level of redundancy needed to protect vital operations.

Key Takeaways

Choosing the right redundancy level balances system reliability with cost, helping avoid costly downtime while managing budget limits.

N+1 redundancy adds one extra module to handle a single failure, offering good reliability at moderate cost, ideal for many commercial uses.

N+2 redundancy adds two extra modules to handle two failures, providing higher uptime and safety for critical systems like data centers and telecom.

Modular rectifier systems allow easy upgrades and maintenance without shutting down power, supporting scalability and reducing downtime.

A structured decision process, including risk assessment and cost-benefit analysis, helps select the best redundancy setup for each application.

Cost vs. Reliability

The Trade-Off

Organizations often face a complex decision when selecting rectifier module redundancy levels. They must weigh the benefits of increased reliability against the financial impact of higher redundancy. The following points highlight the most common cost-related concerns:

Companies must balance the need for enough rectifier modules to ensure redundancy and battery charging with the desire to reduce energy costs.

Adding more modules improves reliability but increases both capital expenditure (CAPEX) and operational costs (OPEX).

Operating with fewer modules can boost efficiency and lower energy consumption, reducing OPEX.

Removing excess modules leads to energy savings, but this approach can compromise fault tolerance and AC phase redundancy.

Advanced control algorithms allow excess modules to enter standby mode, optimizing load sharing and reducing energy costs without sacrificing redundancy.

Organizations can re-use removed modules at new sites, which helps lower CAPEX by avoiding new purchases.

Energy costs represent a significant portion of OPEX—often exceeding 20%—making energy efficiency and redundancy optimization critical financial considerations.

Upgrading to more efficient rectifier modules can cut OPEX, but the high initial investment often limits such upgrades.

Tip: Decision-makers should consider both immediate and long-term costs. While reducing the number of modules may save money upfront, it can expose the system to greater risk and potential downtime.

When to Prioritize Each

The decision to prioritize cost or reliability depends on the specific needs and risk profile of the application. In mission-critical environments, such as telecom infrastructure or data centers, reliability often takes precedence. Prioritizing reliability typically means investing in durable components and advanced designs, which increases the initial purchase price. However, this upfront investment can result in substantial long-term savings through improved efficiency, reduced maintenance, and fewer repairs.

Field studies show that selecting high-quality, reliable rectifiers and following best installation practices can reduce maintenance costs by approximately 35% and increase system uptime by 25%. These savings stem from fewer technician visits, reduced failures, and more predictable maintenance schedules. Modular designs also simplify maintenance, minimizing downtime and operational disruptions.

Priority | When to Choose | Key Benefits | Potential Drawbacks |

|---|---|---|---|

Cost | Non-critical applications, budget constraints | Lower initial investment, reduced energy costs | Increased risk of downtime, reduced fault tolerance |

Reliability | Critical systems, high uptime requirements | Higher system availability, lower long-term costs | Higher CAPEX, increased operational complexity |

Decision-makers should assess the criticality of their operations, the acceptable level of risk, and the total cost of ownership. Investing slightly more in reliable and efficient rectifiers can lead to significant cost savings over the equipment's lifetime, especially in environments where uptime is essential. Conversely, in less critical applications, organizations may opt for lower redundancy to conserve resources.

N+1 and N+2 Explained

N+1 Redundancy

N+1 redundancy stands as a foundational approach in rectifier module systems. Engineers design these systems so that if the load requires N modules to supply power, the configuration includes one additional module. This extra module ensures uninterrupted operation even if a single rectifier module fails. For example, a system needing 15A can use four 5A modules in parallel. If one module stops working, the remaining three still deliver the required current. This setup maintains continuous power supply and prevents downtime. N+1 redundancy provides a cost-effective balance between reliability and investment, making it suitable for many commercial and industrial applications.

N+2 Redundancy

N+2 redundancy offers an even higher level of protection. In this configuration, the system includes two extra rectifier modules beyond the number required to meet the load. This design allows the system to withstand the failure of two modules without any impact on performance. N+2 redundancy suits environments where uptime is critical and the risk of multiple failures cannot be ignored. Data centers, telecom facilities, and industrial automation systems often rely on N+2 redundancy to guarantee continuous operation. Although this approach increases initial investment, it significantly reduces the risk of service interruptions.

Why Redundancy Matters

Redundancy in rectifier module systems directly contributes to system reliability and uptime. Modular designs enable continuous operation by allowing scalability and easy upgrades. They minimize service interruptions, even if one or two modules fail. The following table highlights how different components support reliability and uptime:

Component | Contribution to System Reliability and Uptime |

|---|---|

Modular Rectifier Systems | Enable continuous operation through redundancy; allow scalability and upgrades; minimize service interruptions. |

Maintenance-Free Batteries | Extend asset life and reduce replacements, supporting continuous operation. |

Load Low Voltage Disconnects | Preserve battery capacity during disturbances, further extending uptime. |

Redundant rectifier module configurations ensure stable DC power, prevent downtime, and allow maintenance without shutting down the entire system. These benefits make redundancy a vital consideration for organizations that depend on uninterrupted power.

Rectifier Module Redundancy

System Availability

System availability measures how consistently a power system delivers uninterrupted service. N+1 and N+2 redundancy schemes play a vital role in maintaining high availability for rectifier module systems. In an N+1 configuration, engineers add one extra module beyond the minimum required to support the load. This backup module instantly takes over if a failure occurs, ensuring seamless power delivery. N+2 redundancy increases protection by including two additional modules, allowing the system to withstand two simultaneous failures or maintenance events.

High availability is essential in environments such as data centers and healthcare facilities, where even brief interruptions can cause significant disruptions.

The following table compares system availability between N+1 and N+2 configurations:

Redundancy Type | Description | Fault Tolerance | Impact on System Availability |

|---|---|---|---|

N+1 | Adds one extra component beyond minimum capacity (N) | Can handle one component failure or maintenance without downtime | Provides basic redundancy, allowing continuous operation during a single failure or maintenance event |

N+2 | Adds two extra components beyond minimum capacity (N) | Can handle two simultaneous component failures or maintenance without downtime | Offers higher availability and resiliency, minimizing risk during multiple failures or concurrent maintenance |

Fault Tolerance

Fault tolerance refers to a system’s ability to continue operating when one or more components fail. N+1 redundancy in rectifier module systems means the system can maintain full rated power and functionality even if one module fails. For example, a system designed for a 2 KW load might use three 1 KW modules. If one module fails, the remaining two still supply the required power. N+2 redundancy extends this protection, allowing the system to tolerate two simultaneous failures without losing capacity.

N+1 redundancy provides protection against a single module failure.

N+2 redundancy increases fault tolerance, supporting continuous operation during two concurrent failures.

Modular redundancy enables maintenance or replacement of modules without interrupting power, supporting scalability and reliability.

These redundancy mechanisms ensure that rectifier module systems deliver continuous power, minimize downtime, and support system growth. Organizations benefit from improved fault tolerance and higher availability, especially in critical applications.

Cost Factors

Initial Investment

Organizations face significant upfront costs when deploying rectifier module redundancy. N+1 and N+2 configurations require purchasing extra modules beyond the minimum needed for the load. This increases capital expenditure, especially in large-scale systems. Modular designs offer flexibility, allowing companies to start with a base configuration and expand as demand grows. By avoiding overprovisioning, businesses can align spending with actual requirements. Investing in high-quality modules often leads to lower failure rates and longer service life, which supports reliability and reduces future replacement costs.

Note: Choosing scalable architectures helps organizations avoid unnecessary expenses and supports future upgrades.

Maintenance Costs

Maintenance represents an ongoing expense for redundant power systems. Regular inspections, predictive monitoring, and timely replacement of aging modules help maintain system reliability. Advanced monitoring technologies, such as IoT-enabled diagnostics, allow early detection of faults and reduce emergency repair costs. Organizations benefit from modular systems because technicians can replace faulty modules without shutting down the entire system. This approach minimizes downtime and lowers labor costs. Keeping spare modules on-site further streamlines maintenance and supports continuous operation.

Routine checks extend module lifespan.

Predictive maintenance reduces unexpected failures.

On-site spares enable quick replacements.

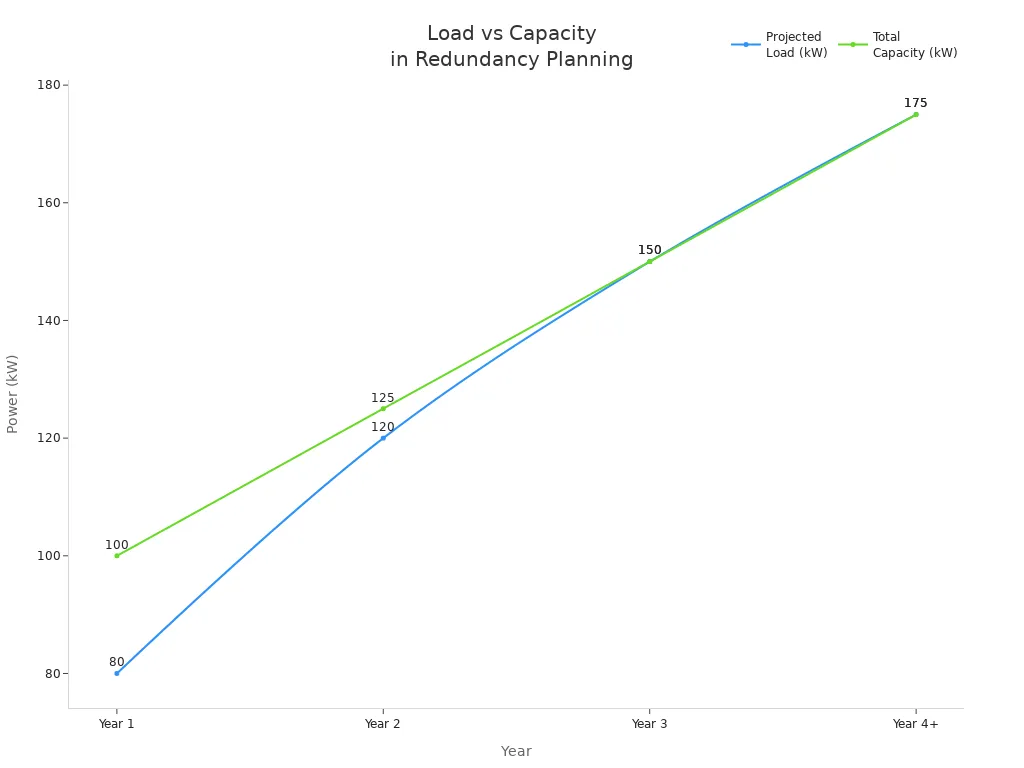

Budget Planning

Effective budget planning ensures organizations maintain financial flexibility while supporting system reliability. Many companies adopt a pay-as-you-grow strategy, adding modules incrementally as load requirements increase. This staged investment approach aligns capital expenditure with actual growth and spreads costs over several years. The following table illustrates how organizations can plan module additions based on projected load:

Year | Projected Load (kW) | Modules Installed | Total Capacity (kW) |

|---|---|---|---|

1 | 80 | 4 x 25 kW | 100 |

2 | 120 | 5 x 25 kW | 125 |

3 | 150 | 6 x 25 kW | 150 |

4+ | 175 | 7 x 25 kW | 175 |

Modular redundancy supports scalability and future-proofs investments. Flexible design architectures allow organizations to integrate new technologies and adapt to evolving power needs. By spreading investments over multiple budget cycles, companies maintain high efficiency and minimize maintenance costs during early stages.

Reliability Factors

Uptime

High system uptime remains a top priority for organizations that depend on continuous operations. Uptime measures the percentage of time a system remains fully functional and available. Redundant power configurations, such as N+1 and N+2, directly support this goal. When a single module fails, the system continues to deliver power without interruption. This approach reduces the risk of unplanned outages and supports scheduled maintenance. Operators can replace faulty modules while the system remains online, which minimizes service disruptions. Consistent uptime protects sensitive equipment and maintains productivity.

Reliable power systems help organizations avoid costly downtime and maintain customer trust.

Multiple Failures

Systems must withstand more than one failure to ensure true reliability. N+2 redundancy provides a safety net against two simultaneous failures. This configuration proves essential in environments where equipment faces harsh conditions or where maintenance windows are limited. Operators can perform repairs or upgrades without risking a complete shutdown. The ability to handle multiple failures increases confidence in the system’s resilience. Organizations benefit from fewer emergency repairs and lower risk of cascading failures.

A comparison of redundancy levels:

Redundancy Level | Handles Single Failure | Handles Double Failure | Maintenance Flexibility |

|---|---|---|---|

N+1 | ✅ | ❌ | Moderate |

N+2 | ✅ | ✅ | High |

Critical Applications

Certain industries require the highest levels of reliability. N+2 redundancy supports critical operations where power loss can threaten safety or disrupt essential services. Applications that benefit most include:

Underground communication systems that maintain seamless coordination.

Conveyor belt systems that prevent production delays.

Ventilation and cooling systems that ensure safe air quality and temperature.

Emergency backup systems, such as alarms and lighting, that must operate during outages.

Drilling and excavation equipment that demands precise, reliable power.

These applications rely on uninterrupted power to protect personnel, maintain safety standards, and ensure operational continuity. N+2 redundancy delivers peace of mind in these demanding environments.

Decision Framework

Checklist

Selecting the right redundancy configuration for rectifier modules requires a structured approach. Decision-makers should evaluate several factors to ensure the system meets both reliability and budget goals. The following checklist provides a practical guide:

Assess Application Criticality

Determine if the system supports critical operations, such as data centers, healthcare, or industrial automation. High-impact environments often require higher redundancy.Analyze Risk Tolerance

Identify the acceptable level of downtime. Systems with low tolerance for interruptions benefit from N+2 redundancy.Estimate Load Growth

Project future power requirements. Modular designs allow for easy expansion as demand increases.Conduct Cost-Benefit Analysis

Use frameworks like Life-Cycle Cost Analysis (LCCA), Return on Investment (ROI), and Payback Period calculations. These methods help balance initial investment, ongoing operational costs, and reliability improvements.Evaluate Component Selection

Choose components with proven reliability. Consider derating strategies, which involve operating modules below their maximum ratings to extend lifespan.Consider Design Optimization

Opt for modular and scalable architectures. Value engineering can reduce costs without sacrificing reliability.Review Manufacturability

Favor designs that simplify assembly and reduce manufacturing defects. Design for Manufacturability (DFM) improves both reliability and cost efficiency.Explore Hybrid Redundancy Schemes

Some systems combine different redundancy types to achieve optimal reliability at a reasonable cost.

Tip: A structured decision-making process ensures that organizations do not overlook hidden costs or reliability gaps. Regularly revisit these criteria as system requirements evolve.

Step | Key Question | Why It Matters |

|---|---|---|

Application Criticality | Is downtime acceptable? | Guides redundancy level |

Risk Tolerance | What is the impact of failure? | Determines need for extra modules |

Load Growth | Will demand increase? | Supports scalability |

Cost-Benefit Analysis | Do benefits outweigh costs? | Justifies investment |

Are modules reliable and robust? | Reduces failure rates | |

Can design lower costs without risk? | Balances efficiency and reliability | |

Manufacturability | Is assembly simple and defect-free? | Lowers production costs, boosts uptime |

Hybrid Redundancy | Can mixed schemes improve value? | Enhances flexibility and performance |

Pitfalls

Even well-planned redundancy strategies can encounter challenges. Awareness of common pitfalls helps organizations avoid costly mistakes:

Inefficient Power Sharing

Traditional ORing diodes in N+1 setups often cause excessive power loss and heat due to voltage drops. This increases thermal management demands and can shorten component life.Standby Module Issues

Cold-standby spares may introduce startup delays, risking brief outages during module switchover. Hot-standby spares, while ready instantly, can experience higher heat stress, which may reduce reliability over time.Complexity with Advanced Controllers

Replacing ORing diodes with MOSFET-based ideal diode controllers improves efficiency but adds circuit complexity. These controllers require careful management of reverse current and voltage spikes, especially during abrupt supply failures.Thermal and Electrical Stress

Abrupt input failures can cause reverse current through MOSFETs until the gate discharges. Fast-response controllers and protective measures, such as diode clamping and transient voltage suppression, become essential.Overlooking System Complexity

Increasing redundancy can complicate maintenance and troubleshooting. More modules mean more potential points of failure and higher system complexity.Ignoring Total Cost of Ownership

Focusing only on initial investment may lead to higher long-term costs. Maintenance, energy consumption, and replacement expenses must factor into the decision.

⚠️ Note: The trade-off between reliability, efficiency, thermal management, and system complexity remains a central challenge. Decision-makers should ask:

Will the chosen redundancy scheme introduce new risks?

Are maintenance teams trained for the added complexity?

Does the design support quick fault isolation and repair?

By following a structured checklist and remaining alert to these pitfalls, organizations can achieve a balanced, reliable, and cost-effective rectifier module system.

Real-World Examples

Data Centers

Data centers demand high system availability. Operators often select N+2 redundancy for rectifier modules to guarantee uninterrupted power. This approach allows the system to withstand two simultaneous failures. Technicians can perform maintenance without shutting down critical servers. Many facilities use modular rectifier systems. These systems support easy expansion as computing needs grow. Operators value the ability to swap modules quickly. This reduces downtime and protects sensitive data. In large data centers, even a brief power loss can lead to significant financial losses. N+2 redundancy provides peace of mind and supports strict service-level agreements.

Industrial Automation

Manufacturing plants and automated production lines rely on continuous power. N+1 redundancy often meets their needs. This configuration balances cost and reliability. If one rectifier module fails, the backup module takes over instantly. Production continues without interruption. Operators can replace faulty modules during scheduled maintenance. This minimizes the risk of unplanned downtime. Many industrial systems use modular rectifiers. These designs allow for quick upgrades as production demands increase. By choosing N+1 redundancy, companies control costs while maintaining high system uptime.

Telecom

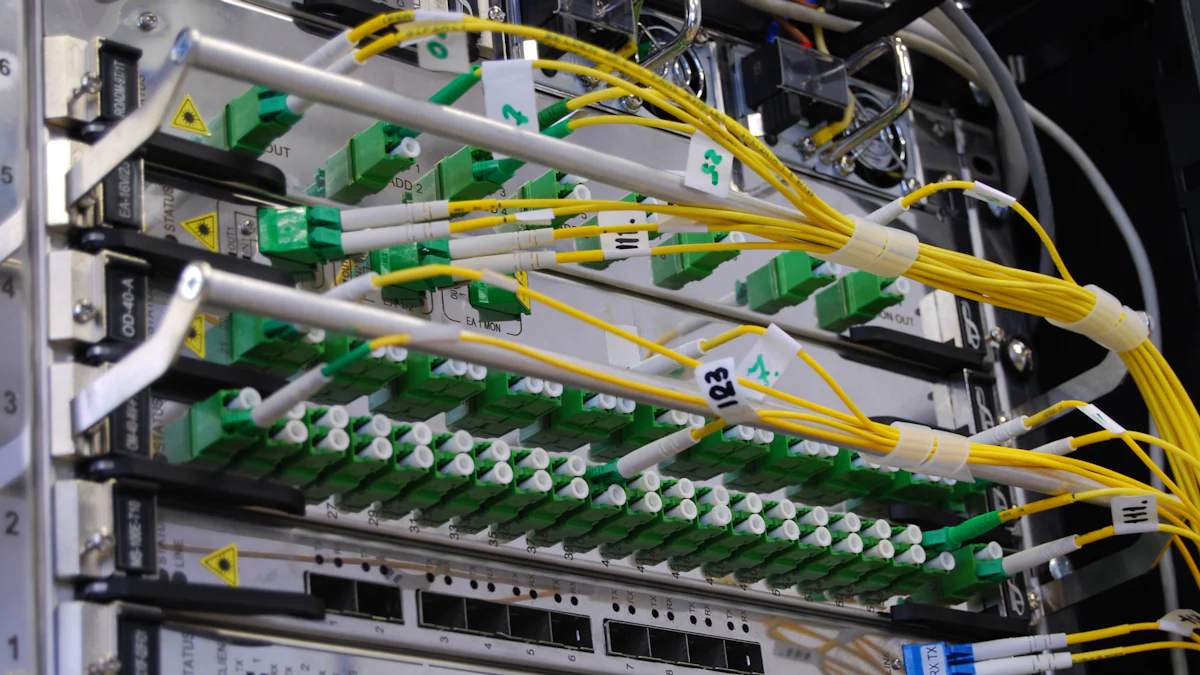

Telecom networks require robust power solutions. Operators use several strategies to balance cost and reliability for rectifier modules:

Redundant and modular power supply designs improve network resilience.

Hot-swappable power supplies enable maintenance or replacement without downtime.

Redundant systems provide failover protection for mission-critical applications.

Modular designs support scalability and easy maintenance.

Backup systems such as batteries and UPS ensure high availability.

Intelligent power management increases energy efficiency.

These strategies help telecom providers maintain continuous service. They reduce capital expenditure by allowing gradual system expansion. Technicians can perform repairs without disrupting network operations. Modular and redundant designs also simplify upgrades as network demands grow. This approach ensures reliable communication, even during equipment failures or maintenance activities.

Recommendations

Selecting the right redundancy configuration for rectifier modules requires careful evaluation of system needs and operational priorities. Industry experts emphasize several best practices that help organizations achieve optimal reliability without overspending.

Assess Business Continuity Requirements

Organizations should identify the criticality of their workloads. Systems supporting essential operations, such as healthcare or financial services, often demand higher redundancy levels. N+1 redundancy provides backup for a single module failure, while N+2 or even 2N configurations offer greater resiliency for environments where downtime is unacceptable.Balance Cost and Resiliency

N+1 and N+2 configurations deliver a practical compromise between reliability and cost. Higher redundancy increases capital and operational expenses, requires additional chassis space, and adds complexity. Decision-makers should conduct a thorough cost-benefit analysis before committing to advanced redundancy schemes.Consider Load-Sharing and Hot-Swappability

Load-sharing modes distribute electrical demand evenly across modules. This approach reduces thermal stress and extends the lifespan of each unit. Hot-swappable designs allow technicians to replace failed modules without interrupting service, supporting non-disruptive maintenance and minimizing downtime.Evaluate Environmental and Regulatory Factors

Geographic risks, such as extreme weather or unstable power grids, may justify higher redundancy. Regulatory compliance can also influence redundancy requirements, especially in industries with strict uptime mandates.Plan for Scalability and Efficiency

Modular architectures support future growth. Organizations should select systems that allow incremental expansion and easy integration of new technologies. Energy efficiency remains a key consideration, as additional modules increase thermal load and power consumption.

Tip: Regularly review redundancy strategies as business needs evolve. System requirements may change due to growth, new regulations, or emerging risks. Proactive planning ensures continued reliability and cost control.

Redundancy Level | Suitable For | Key Benefit | Main Trade-Off |

|---|---|---|---|

N+1 | Most commercial systems | Balanced reliability | Moderate cost/complexity |

N+2 | High-availability systems | Enhanced resiliency | Higher cost/space |

2N | Mission-critical operations | Maximum uptime | Highest cost/complexity |

Organizations that follow these recommendations position themselves for reliable, scalable, and cost-effective power solutions.

Balancing cost and reliability in rectifier module selection involves several key considerations:

Understanding how efficiency, reliability, and cost interact

Using modular designs for scalability and easier maintenance

Applying value engineering and design for manufacturability to optimize expenses

To ensure the right redundancy level, organizations should:

Conduct thorough risk assessments and regular system testing

Implement protection circuits and maintain compliance with safety standards

Consult with expert teams, such as those at ESTEL, for tailored guidance

Ongoing review of system requirements helps maintain optimal performance as operational needs evolve.

FAQ

What does N+1 redundancy mean for rectifier modules?

N+1 redundancy means the system includes one extra rectifier module beyond the minimum required. This extra module ensures continuous power delivery if one module fails. Many commercial systems use N+1 for balanced reliability and cost.

How does N+2 redundancy improve system reliability?

N+2 redundancy adds two spare modules to the system. This configuration allows the system to operate normally even if two modules fail. Data centers and telecom providers often choose N+2 to minimize downtime and protect critical operations.

Are modular rectifier systems easy to upgrade?

Modular rectifier systems support easy upgrades. Technicians can add or replace modules without shutting down the system. This flexibility helps organizations scale power capacity as demand grows and reduces maintenance time.

What factors affect the total cost of ownership for rectifier modules?

Key factors include initial investment, energy consumption, maintenance frequency, and replacement costs. Efficient modules and predictive maintenance lower long-term expenses. Organizations should consider all these elements when planning budgets.

Can redundancy configurations reduce maintenance downtime?

Redundancy configurations, such as N+1 and N+2, allow technicians to replace faulty modules while the system remains online. This approach minimizes service interruptions and supports scheduled maintenance without risking power loss.

See Also

Steps To Guarantee Consistent Power For Telecom Cabinets

Solar Inverter And Battery Solutions Linked To Telecom Grids

ESTEL’s Detailed Approach To Assessing Telecom Battery Risks

Methods For Calculating Power Systems And Batteries In Telecom

Reasons Lithium Batteries Excel Over Others In Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA