Choosing Rectifier Modules for Edge Computing Nodes with Miniaturization and High Power Density

When you select a rectifier module for edge computing nodes, you must prioritize size, power density, and efficiency. The move to 48VDC power distribution now dominates the industry because it brings higher power density and better scalability. Companies like HIRO use 48VDC in their micro data centers to cut losses and boost efficiency. This shift supports miniaturization and lets you handle much greater power loads than older 12V systems. Focus on modules that balance electrical performance with thermal management and reliability for the best results.

Key Takeaways

Choose rectifier modules that offer high power density to deliver more energy in smaller spaces, supporting compact and efficient edge computing nodes.

Prioritize modules with advanced thermal management like heat sinks and high-conductivity materials to prevent overheating and ensure reliable operation.

Select modules using wide-bandgap semiconductors such as GaN or SiC for better efficiency, smaller size, and improved performance in demanding environments.

Match the rectifier module’s size, efficiency, and protection features to your edge node’s specific power needs and environmental conditions to avoid failures.

Use a step-by-step evaluation and a feature checklist to pick modules that balance miniaturization, efficiency, reliability, and integration for scalable edge solutions.

Power Needs

Edge Node Demands

You must understand the specific power requirements of your edge computing node before choosing a rectifier module. Edge nodes in manufacturing, energy, transportation, and agriculture often operate in diverse environments. Each sector demands different power levels and protection standards. For example, stationary automation equipment in factories needs stable, high-wattage power supplies, while mobile applications in mining or agriculture require robust, efficient modules that can handle variable loads. The installation location, operating temperature, and surge protection all influence your choice. High-quality power supply units (PSUs) prevent data loss and ensure stable performance.

Tip: Always match the PSU’s specifications to your node’s operational environment to avoid hardware failures.

Aspect | Details |

|---|---|

Power Consumption Relation | Larger equipment and more functions require higher wattage PSUs. |

Sector Deployment Focus | Manufacturing, energy, transportation, mining, agriculture—all have unique power needs. |

PSU Requirements | Power density, efficiency, reliability, and protection standards are critical. |

Environmental & Operational Factors | Location, input specs, temperature, IP rating, surge needs, and connectors affect PSU choice. |

Challenges | Instability can cause hardware and safety issues; efficiency and stability matter at all loads. |

Design Focus | Size reduction, efficiency, and thermal optimization improve performance. |

Miniaturization Impact

Miniaturization shapes every aspect of rectifier module selection. You must look for modules with compact layouts and surface-mount components. These designs integrate multiple functions into single chips, reducing size and improving reliability. Smaller modules also lower manufacturing costs. However, limited space increases vulnerability to tampering, so tamper-evident packaging and distributed security measures become essential. Efficient rectifier designs, such as those using Schottky diodes or synchronous rectification, help minimize power loss and ripple.

Miniaturization pushes for higher power density and lower standby power consumption.

Integrated solutions, like combining rectification with voltage regulation, save space and boost efficiency.

Wide-bandgap semiconductors (GaN, SiC) and adaptive efficiency techniques support robust power management in small footprints.

Power Density

You should prioritize power density when selecting rectifier modules for edge computing nodes. The shift to 48VDC power distribution increases power density and reduces conversion steps, which improves efficiency and lowers operational costs. HIRO’s Edge Micro Data Centers demonstrate that 48VDC systems save at least 40% on energy compared to older 12V systems. This architecture supports modular scalability and higher processing capability with only a small increase in power consumption.

Feature | Specification |

|---|---|

Operating Temperature | |

Power Output at 65°C | >2400W |

Efficiency | ~96.9% |

Power Density | 35W/in³ |

Application | High-density telecom and edge computing |

You can achieve reliable, efficient, and compact power delivery by focusing on modules that meet these benchmarks. This approach ensures your edge node operates safely and efficiently, even in demanding environments.

Rectifier Module Selection

Size and Form Factor

You should always start by considering the size and form factor of the rectifier module. Miniaturization has become possible with advanced materials like GaN and SiC. These materials allow you to use ultra-slim modules that fit into modern edge devices and IoT products. Smaller form factors make your devices more portable and reduce installation costs. This is especially important for edge nodes in both cities and remote areas.

Compact bridge rectifiers work well in tight spaces and remove the need for bulky transformers.

High-frequency switching power supplies, using wide-bandgap semiconductors, help you reduce heat and energy loss.

Modular designs let you scale power capacity up or down, so you can match the needs of different edge devices.

Smart features, such as remote monitoring, improve reliability and reduce downtime.

You can now find rectifier modules that offer high efficiency and reliability, even in very limited spaces.

Power Density

Power density is a key factor when you select a rectifier module for edge computing. High power density means you can deliver more power in a smaller space. This is critical for edge nodes that must handle demanding workloads without taking up much room.

Feature | Details |

|---|---|

Power Density | Achieves 73 W/in³, enabling compact and high-density power delivery for edge nodes |

Efficiency | Up to 99%, critical for energy savings and supporting 5G/6G network demands |

Semiconductor Technology | Integration of wide-bandgap semiconductors (SiC and GaN) enhances power density and thermal management |

Modularity and Scalability | Modular design allows easy scaling and maintenance, supporting dynamic edge computing needs |

Application Focus | Designed for powering small cells, base stations, and edge computing nodes in telecom infrastructure |

Thermal Management | Advanced thermal solutions enable reliable operation in compact, space-constrained environments |

Integration Capabilities | Compatible with Battery Energy Storage Systems (BESS) and DC microgrids for flexible deployment |

You should look for rectifier modules that use wide-bandgap semiconductors and modular designs. These features help you achieve high power density and easy scalability.

Efficiency

Efficiency directly affects the performance and energy cost of your edge node. You want a rectifier module that converts as much input power as possible into usable output, with minimal losses.

Power Capacity Category | Efficiency Range | Key Design Features and Applications |

|---|---|---|

Low-Capacity (<10kW) | Up to ~95% | Compact design, minimal wear components; suited for telecom and small industrial setups |

Medium-Capacity (10-50kW) | Above 95% | Modular structure, advanced diagnostics; used in larger industrial and renewable energy systems |

High-Capacity (>50kW) | Above 95%, up to 99% in some telecom systems | Enhanced cooling, fault-tolerant systems; designed for large-scale power grids and critical infrastructure |

You should choose a rectifier module with high efficiency, especially if your application involves 5G, 6G, or other high-demand networks. Using SiC and GaN semiconductors can help you reach efficiency levels up to 99%. This reduces heat, lowers operational costs, and supports reliable operation.

Thermal Management

Thermal management is essential for keeping your rectifier module safe and reliable. High power density and miniaturization increase the risk of overheating. You need to use effective cooling techniques to prevent failures.

Use substrates with high thermal conductivity, such as aluminum nitride or beryllium oxide, to move heat away from hot spots.

Arrange components to spread heat evenly and avoid local overheating.

Add thermal vias and copper planes inside the module to help distribute heat.

Attach heat sinks to increase the surface area for cooling.

For high-demand situations, use miniature fans or thermoelectric coolers.

Use thermal simulation tools to predict and fix hot spots before building your device.

Advanced packaging, like chip-scale or flip-chip bonding, can lower thermal resistance.

Monitor temperature with sensors and use automatic shutdown circuits to protect your system.

You should always match your thermal management strategy to the operating environment of your edge node.

Reliability

Reliability ensures your edge computing node runs smoothly, even in harsh conditions. You should select a rectifier module that meets strict reliability standards and certifications.

NEMA certification protects against heat, humidity, and dust.

UL 60950-1 certification confirms safety and effectiveness for telecom systems.

Environmental certifications, such as California Proposition 65 and China RoHS, show compliance with chemical and material safety standards.

You should also look for modules with features like remote monitoring and predictive maintenance. These features help you avoid downtime and extend the life of your equipment.

Integration

Integration techniques have advanced rapidly. You can now use 3D stacking and heterogeneous integration to combine different functional blocks in a single rectifier module. These methods let you pack more features into a smaller space and improve thermal management.

Recent trends include wafer-to-wafer and chip-to-wafer bonding, which increase interconnect density and boost performance. Hybrid bonding allows direct metal-to-silicon connections, reducing resistance and improving heat flow. Companies use 2.5D and 3D integration to stack chips and connect them closely, increasing functionality per volume.

You should also consider energy harvesting and wide power dynamic range when choosing a rectifier module. If your edge node uses energy from sources like RF, solar, or vibration, you need a module that works efficiently with low and variable input power. Look for designs that minimize leakage, match impedance, and support adaptive tuning. These features help you maintain efficiency and reliability, even when power conditions change.

Tip: Always balance electrical performance with thermal management. High-density computing and 5G networks require power systems that handle large loads and stay cool. Smart power distribution units with real-time monitoring and liquid cooling can help you manage these challenges.

Technology Comparison

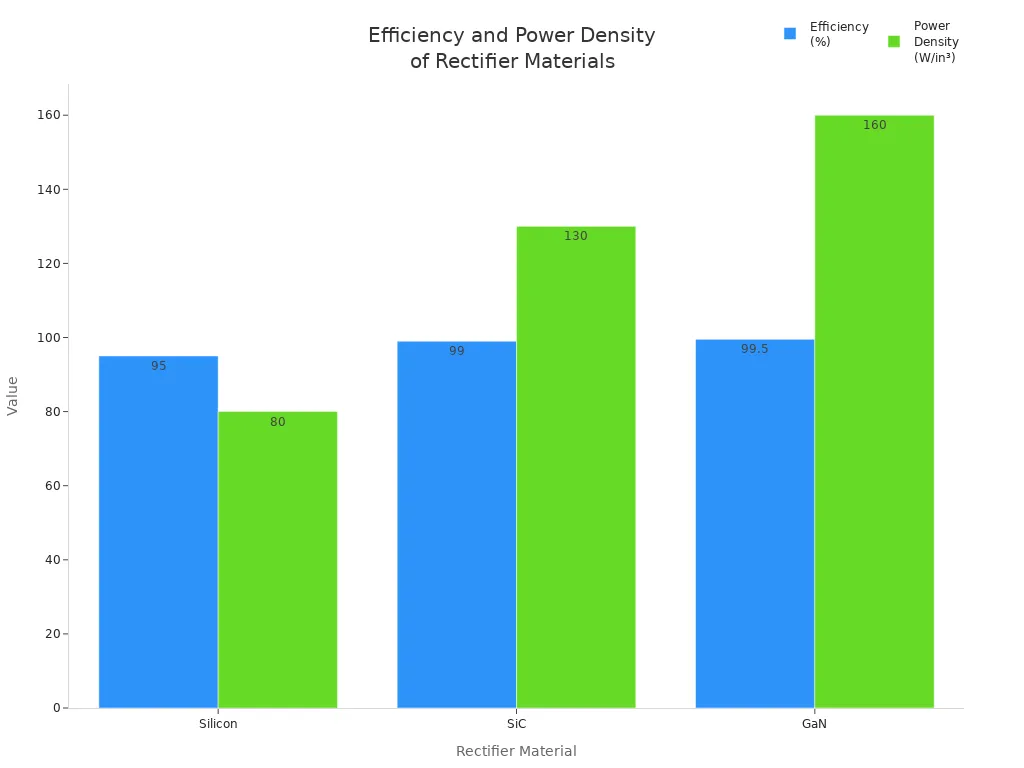

Silicon vs. SiC vs. GaN

When you choose a rectifier module for edge computing, you need to understand the differences between silicon, silicon carbide (SiC), and gallium nitride (GaN) technologies. Each material offers unique benefits for efficiency, power density, and application suitability.

Material | Voltage Range | Efficiency | Power Density | Application Suitability |

|---|---|---|---|---|

Silicon | N/A | Lower | Lower | Traditional rectifiers, less efficient for edge computing |

SiC | >500 V | >99% (high) | High | High-voltage systems, grid, high power density needs |

GaN | Up to 450 V | ~99% (very high) | ~160 W/in³ | Medium-voltage, telecom, high-frequency, compact designs |

You can see that SiC and GaN outperform silicon in both efficiency and power density. GaN stands out for its fast switching speed, which allows you to achieve about 20% higher power density than SiC. This makes GaN ideal for compact, lightweight modules in edge computing, 5G, and IoT workloads. SiC works best for high-voltage and high-power applications, such as grid systems and electric vehicle inverters. Both SiC and GaN enable you to build smaller, more reliable, and more efficient power solutions.

GaN achieves over 95% system efficiency in AC/DC converters.

GaN provides up to three times higher power density and lower weight than silicon.

Fast switching at 140 kHz enables about 20% higher power density compared to SiC.

GaN reduces solution size by up to 50%, making it perfect for edge computing.

Integrated current sensing in GaN devices improves efficiency and reduces PCB size.

Ultra-high-speed silicon technologies, such as SiC MOSFET-based modules, also help you reach higher efficiency and power density. These modules combine fast switching, integrated protection, and advanced thermal management. You can use them to reduce system size and improve reliability in edge applications.

Package Types

You should also pay close attention to the package type when selecting a rectifier module. The right package can help you save space, improve thermal performance, and ensure easy integration.

CFP3 and CFP5 packages reduce PCB space by 38% and up to 56% compared to older SMA and SMB packages.

The solid copper clip in CFP packages lowers thermal resistance, which boosts heat transfer and keeps your module cool.

CFP packages are industry standard for power diodes and are pin-compatible with Schottky and Fast Recovery diodes, so you can use them as drop-in replacements.

SiGe rectifiers in CFP packages support higher voltage ratings and maintain thermal stability up to 175°C, limited only by the package.

The Clip-bonded FlatPower (CFP) package design gives you superior thermal dissipation. This means your rectifier module can operate safely at higher temperatures, which is important for high-density edge computing. You also get flexibility because CFP packages work with many existing designs. By choosing the right package, you balance size reduction, thermal performance, and compatibility for your edge node.

Selection Process

Evaluation Steps

You can follow a clear process to evaluate and select the best rectifier module for your edge computing node. Start by defining your power requirements. Check the voltage and current levels your node needs. Next, review the environmental conditions. Consider temperature, humidity, and exposure to dust or vibration. After that, compare available modules based on size and form factor. Look for compact designs that fit your device.

You should also test efficiency. Measure how much input power the module converts to usable output. Assess thermal management features. Examine cooling methods such as heat sinks or advanced substrates. Reliability is another key factor. Review certifications and protection features. Finally, check integration options. Make sure the module supports advanced stacking or energy harvesting if your application requires it.

Tip: Document each step and result. This helps you make informed decisions and avoid costly mistakes.

Define power and environmental requirements.

Compare size and form factor.

Test efficiency and thermal management.

Review reliability and certifications.

Check integration and compatibility.

Document findings and select the best module.

Feature Checklist

You can use a checklist to make sure your chosen rectifier module meets all the needs of your edge computing application.

Feature | Why It Matters |

|---|---|

High Power Density | Supports compact, high-performance nodes |

Efficiency >95% | Reduces energy loss and heat |

Advanced Thermal Design | Prevents overheating and extends lifespan |

Wide Input Range | Handles variable power sources |

Certifications | Ensures safety and reliability |

Modular Design | Allows easy scaling and maintenance |

Integration Support | Enables 3D stacking and energy harvesting |

Remote Monitoring | Improves uptime and predictive maintenance |

You should check each feature before making your final choice. This approach helps you build a reliable and efficient edge computing system.

Pitfalls & Examples

Common Mistakes

When you select a rectifier module for edge computing nodes, you can easily make mistakes that impact performance and reliability. Here are some common pitfalls to avoid:

Ignoring Environmental Conditions: You might overlook the effects of temperature, humidity, or dust. This can lead to overheating or early failure.

Overlooking Power Density Limits: If you choose a module with low power density, your system may become bulky or inefficient.

Neglecting Thermal Management: Without proper cooling, even the best module can overheat and cause downtime.

Skipping Certification Checks: Using uncertified modules can result in safety hazards or regulatory issues.

Focusing Only on Cost: Cheaper modules may lack the reliability or efficiency needed for edge applications.

Poor Integration Planning: If you do not consider how the module fits with other components, you may face compatibility or maintenance problems.

Tip: Always review your application’s requirements and test modules under real-world conditions before finalizing your choice.

Case Studies

You can learn a lot from real-world examples. Outdoor edge nodes and AI data centers show how advanced strategies improve performance and reliability.

Outdoor Edge Nodes

Outdoor deployments face harsh weather and unstable power. You need modules with robust enclosures, wide temperature ranges, and strong surge protection. For example, telecom base stations in remote areas use compact, high-density modules with advanced cooling. This setup prevents failures during heat waves or storms.

AI Data Centers

AI data centers benefit from advanced rectifier module selection strategies:

Model predictive control (MPC) predicts load changes and adjusts power delivery, keeping systems safe during rapid AI workload spikes.

Supervisory controllers balance multiple modules and energy storage, reducing stress and improving resilience.

Pre-charging energy storage smooths large load steps, protecting sensitive equipment.

Advanced DC rectifier systems convert power efficiently, lower costs, and prevent outages.

Modular designs allow you to scale up or down without downtime.

Improved thermal management extends equipment life and boosts uptime.

These systems also integrate with renewable energy, supporting sustainability goals.

By studying these examples, you can see how the right choices lead to stable, efficient, and scalable edge computing solutions.

You can make the best choice for your edge node by matching rectifier module features to your miniaturization and power density goals. Use the checklist and follow a step-by-step evaluation. The table below highlights what to focus on:

Feature | Why It Matters for Edge Nodes |

|---|---|

Impedance Matching | Maximizes power transfer in compact designs |

Schottky Diodes | Supports high power density in small spaces |

SMD Components | Reduces circuit size and boosts performance |

System Integration | Enables efficient, compact power modules |

Modular designs allow quick upgrades and easy maintenance.

Integration supports real-time monitoring and predictive maintenance.

Prioritize reliability, efficiency, and integration when you design your next edge node.

FAQ

What is the most important factor when choosing a rectifier module for edge computing?

You should focus on power density. High power density lets you deliver more energy in a smaller space. This supports miniaturization and keeps your edge node efficient.

How do you improve thermal management in compact edge nodes?

You can use heat sinks, thermal vias, and high-conductivity substrates. These methods help spread heat and prevent overheating. Always monitor temperature with sensors for extra safety.

Why is 48VDC power distribution preferred for edge computing nodes?

You get higher efficiency and lower energy loss with 48VDC systems. This voltage supports compact designs and allows you to scale power for advanced edge applications.

Can you use rectifier modules with energy harvesting systems?

Yes, you can select modules that support wide input ranges and adaptive tuning. These features help you use solar, RF, or vibration energy sources in your edge node.

See Also

Telecom Cabinet Power Using Grid-Linked Solar Inverter Systems

Strategies To Maintain Consistent Power In Telecom Cabinets

ESTEL’s Intelligent Microgrid Energy Storage For Telecom Cabinets

Selecting Optimal Cooling Solutions For ESTEL Telecom Cabinets

Solar Energy Storage Systems Designed For Telecom Cabinet Power

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA