96% vs. 92% Efficiency: How Much Electricity Can a Telecom Cabinet Save Annually? Real Data Calculation

A telecom cabinet running on a 10 kW load with a 92% efficient rectifier module consumes about 95,652 kWh annually. Upgrading to a 96% efficient module reduces this to 91,667 kWh, saving nearly 4,000 kWh per year.

Real data shows this upgrade can cut electricity costs by over $600 annually for a single cabinet. Energy efficiency drives significant savings and supports sustainable network growth.

Key Takeaways

Upgrading telecom cabinet rectifier modules from 92% to 96% efficiency saves nearly 4,000 kWh and over $600 annually per cabinet.

Higher efficiency reduces energy waste and heat output, lowering electricity bills and cooling costs while improving equipment lifespan.

Modern rectifiers with modular designs and smart monitoring cut maintenance needs, boost network uptime, and support easy scaling.

Energy savings multiply across large networks, leading to millions in cost reductions and significant carbon emission cuts.

Operators should consider payback periods, available incentives, and proper planning to maximize benefits from efficiency upgrades.

Efficiency Matters

Electricity Costs

Telecom operators face substantial electricity expenses. Energy consumption accounts for a significant portion of operational costs, as shown in the table below:

Source | Percentage of Total Operational Costs Attributed to Electricity Consumption |

|---|---|

GSMA | 20-40% of network OPEX |

Ericsson | 10-25% of OPEX on energy (with 80% consumed by RAN) |

Oliver Wyman | Average ~5% of overall OPEX, up to 15% for mobile-focused operators |

These figures highlight that electricity costs can reach up to 40% of total network operating expenses. Efficient rectifier modules play a crucial role in reducing these costs. Modern rectifiers, such as those from ESTEL, convert AC to DC power with minimal losses, often exceeding 95% efficiency. High efficiency reduces energy waste and heat generation, directly lowering annual electricity consumption. Operators who upgrade to more efficient modules see immediate reductions in their energy bills and overall operational expenditure.

Rectifier module efficiency also impacts energy consumption through load management. When modules operate at higher loads, efficiency improves, and energy loss decreases. Power-saving algorithms and dynamic load management further optimize usage, resulting in network-wide savings. For example, Turkcell achieved an average energy saving of 2.5% across sites by removing underutilized modules and activating power-saving features, saving millions of kilowatt-hours annually.

Operational Impact

Improving rectifier module efficiency delivers measurable operational benefits. The table below summarizes key impacts:

Operational Impact | Evidence / Statistic | Explanation / Operational Benefit |

|---|---|---|

Rectifier Module Efficiency | Reduces energy losses and operational costs by minimizing power waste. | |

Battery Failure Rate | 98% reduction (2018 to 2024) | Enhances network reliability by lowering battery failures, improving uptime. |

Network Uptime | 20% improvement | Increases service availability and reliability, reducing downtime. |

Operational Costs | 25-35% reduction | Achieved through energy savings and hybrid power integration, lowering total cost of ownership. |

Scalability | Modular, plug-and-play designs | Enables rapid scaling and maintenance without service disruption, supporting network growth. |

AI and IoT Integration | Up to 50% downtime reduction via predictive maintenance | Optimizes performance and reduces maintenance costs, further improving operational efficiency. |

Sustainability | >90% efficiency, 20-30% energy savings, CO2 emissions cut by up to 40% | Supports environmental goals and regulatory compliance, enhancing corporate responsibility. |

Operators who invest in high-efficiency rectifiers experience lower operational costs, improved reliability, and greater sustainability. Enhanced efficiency reduces battery failures and boosts network uptime, supporting uninterrupted service. Modular designs and predictive maintenance features enable rapid scaling and minimize downtime, ensuring telecom networks remain robust and future-ready.

Rectifier Module Efficiency

Typical Ratings

Telecom operators rely on rectifier modules to convert AC power to DC power efficiently. Over the past decade, efficiency ratings have improved significantly. Modern rectifier modules, such as the Eltek Valere Flatpack2 HE, typically achieve 96% efficiency. Previous generations operated around 92%. The table below summarizes key performance parameters:

Parameter | Details |

|---|---|

Typical Efficiency | 96% (Eltek Valere Flatpack2 HE Rectifier Module) |

Previous Typical Efficiency | Around 92% |

Efficiency Peak Load | About 50% load (where max efficiency occurs) |

Input Voltage Range | 180 Vac to 300 Vac |

Efficiency Variation | Drops ~1% at low input voltage (180 Vac) |

Operating Temperature Range | -40°C to 85°C |

Efficiency Impact by Temp | Slight degradation at high temperature |

Output Voltage | Nominal 48 Vdc; typically adjusted up to 54 Vdc for battery charging |

Power Output | Up to 2000 W per unit; multiple units can combine up to 100 kW |

Control Features | Digital control, CAN bus interface for system integration and monitoring |

Most telecom cabinets worldwide use either silicon-controlled rectifiers (SCR), switch mode power supplies (SMPS), or silicon carbide (SiC) rectifier modules. SCR modules, common in legacy systems, offer 85–90% efficiency. SMPS modules, now standard in modern cabinets, reach 92–96%. SiC rectifier modules, used in high-performance sites, deliver 96–98% efficiency and higher power density.

Latest Technologies

Recent advancements have pushed rectifier module efficiency even higher. Manufacturers now use advanced semiconductor materials like gallium nitride (GaN) and silicon carbide (SiC). These materials enable efficiencies up to 98% and reduce power loss by up to 75% compared to older designs. Synchronous rectification, improved magnetic components, and optimized winding techniques further minimize energy waste.

Modern rectifier modules also feature modular designs, hot swap capability, and real-time monitoring. These features allow operators to maintain systems without downtime and quickly detect performance issues. Power factor correction and advanced topologies, such as resonant switching converters, help optimize energy use. SiC rectifier modules stand out for their low switching losses, wide temperature range, and reduced cooling needs. Although they cost more initially, they provide significant operational savings and support sustainability goals.

Higher efficiency in a rectifier module means less energy lost as heat. Operators benefit from lower electricity bills and reduced cooling requirements. Over time, these savings offset the initial investment and contribute to a more reliable, environmentally friendly telecom network.

Power Consumption

Cabinet Load

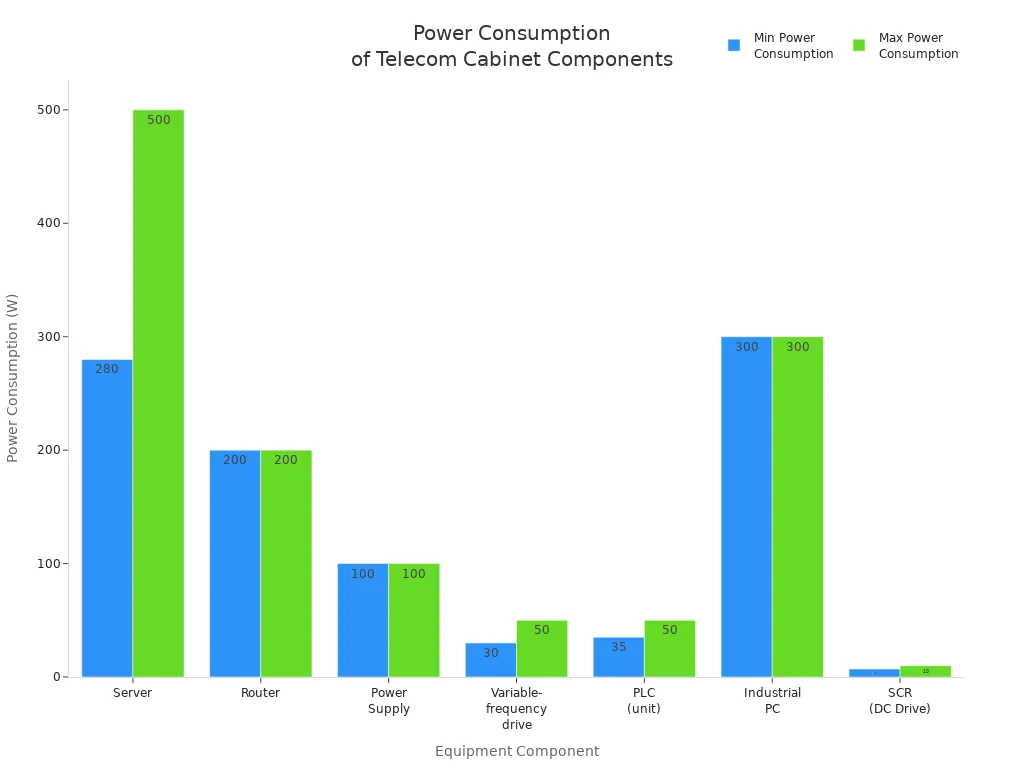

Telecom cabinets house several critical components, each with distinct power requirements. Operators must understand these demands to optimize energy use and select appropriate rectifier modules. The table below summarizes the typical power consumption ranges for common equipment found in telecom cabinets:

Equipment Component | Power Consumption Range (W) |

|---|---|

Server | 280 - 500 |

Router | 200 |

Power Supply | 100 |

Variable-frequency drive (1KW) | 30 - 50 |

PLC (group as a unit) | 35 - 50 |

Industrial personal computer | 300 |

UPS (20% of its power) | Varies |

SCR (1KW DC Drive) | 7 - 10 |

A typical cabinet may operate with a server drawing 500 W, a router using 200 W, and a power supply consuming 100 W. These devices run continuously, resulting in a daily energy demand of 19.2 kWh. When factoring in external heat loads, the total daily requirement can reach 22.14 kWh before applying a safety margin. Operators often use this data to size rectifier modules and cooling systems accurately.

Usage Patterns

Power consumption in telecom cabinets fluctuates based on operational patterns and environmental conditions. Seasonal changes play a significant role in shaping these patterns:

Summer temperatures increase the need for cooling fans, raising energy demand.

Winter conditions require heaters to maintain optimal operating temperatures.

Battery performance varies with temperature extremes, affecting energy output and reliability.

Proper enclosure design, including thermal protection and weatherproofing, helps maintain efficiency year-round.

Operators also adjust solar panel sizing to account for seasonal variations in sunlight. In regions with shorter daylight hours or lower solar intensity, larger photovoltaic panels ensure consistent power supply. These adjustments help maintain reliable network performance and prevent service interruptions. By understanding usage patterns, operators can implement targeted strategies to reduce energy waste and improve overall cabinet efficiency.

Annual Savings Calculation

Input Power Comparison

Telecom operators often evaluate the efficiency of rectifier modules to determine annual energy consumption. Consider a telecom cabinet with a constant load of 10 kW. The efficiency of the rectifier module directly affects the amount of input power required from the grid.

Operators calculate input power using the formula:

Input Power (kW) = Output Power (kW) / Efficiency

For three efficiency scenarios, the input power required is:

Efficiency | Output Power (kW) | Input Power (kW) |

|---|---|---|

92% | 10 | 10.87 |

96% | 10 | 10.42 |

98% | 10 | 10.20 |

Multiply the input power by the number of hours in a year (8,760 hours) to get annual energy consumption:

92% Efficiency:

10.87 kW × 8,760 hours = 95,365 kWh96% Efficiency:

10.42 kW × 8,760 hours = 91,639 kWh98% Efficiency:

10.20 kW × 8,760 hours = 89,352 kWh

Operators see that upgrading from a 92% to a 96% efficient rectifier module saves 3,726 kWh per year. Moving to a 98% efficient module increases savings to 6,013 kWh annually.

📊 Tip: Even a small increase in efficiency can result in thousands of kilowatt-hours saved each year for a single cabinet.

Energy and Cost Savings

Operators translate energy savings into cost savings by applying average electricity rates. In the United States, commercial office buildings—including telecom operations—typically pay an average of $0.10 to $0.15 per kWh. For calculation purposes, use $0.15 per kWh.

Step-by-step cost savings calculation:

Calculate annual energy savings:

Upgrade from 92% to 96% efficiency:

95,365 kWh − 91,639 kWh = 3,726 kWh saved per yearUpgrade from 92% to 98% efficiency:

95,365 kWh − 89,352 kWh = 6,013 kWh saved per year

Convert energy savings to cost savings:

3,726 kWh × $0.15 = $559 per year (92% → 96%)

6,013 kWh × $0.15 = $902 per year (92% → 98%)

Operators can use energy billing audits to identify additional savings. These audits analyze invoices and contracts to find overcharges and optimize tariff usage. The savings from upgrading rectifier modules add to these hidden savings, reducing total operational costs.

💡 Note: The cost savings multiply across large networks. Hundreds or thousands of cabinets can generate six-figure annual savings for telecom operators.

A high-efficiency rectifier module not only reduces electricity bills but also supports sustainability goals. Operators who invest in advanced modules see immediate financial benefits and long-term operational improvements.

Network-Wide Impact

Multiple Cabinets

Telecom operators rarely manage just a single cabinet. Most networks deploy hundreds or even thousands of cabinets across cities and regions. When operators upgrade multiple cabinets to advanced rectifier modules, the cumulative effect becomes substantial.

Upgrading to 98% efficiency rectifiers has delivered cumulative electricity savings of approximately £9 million over five years compared to 96% efficiency technology.

Modern rectifiers can cut energy consumption by up to 20% each year, especially when deployed across multiple sites.

Efficiency improvements above 95% reduce energy waste and optimize power use, even during periods of low demand.

These upgrades lower the carbon footprint, with some networks reporting up to a 40% reduction in CO2 emissions.

Operators also benefit from reduced maintenance needs and longer equipment life, which further increases total cost savings.

📈 Note: The more cabinets upgraded, the greater the operational and environmental benefits. These savings compound year after year, supporting both financial and sustainability goals.

Large Networks

Large telecom networks see even more dramatic results from efficiency upgrades. Modern rectifier modules reach conversion efficiencies as high as 97.8%, which significantly reduces energy loss during AC to DC conversion. Smart energy management features dynamically adjust power usage, preventing waste and further lowering costs.

Modular and scalable rectifier designs allow operators to upgrade gradually, aligning with network expansion and minimizing upfront costs.

Integration with renewable energy sources, such as solar panels, reduces reliance on grid power and supports green initiatives.

Advanced protection mechanisms and redundancy features ensure continuous operation, even if individual modules fail, which prevents costly downtime.

Stable, clean power supply extends equipment life and reduces replacement frequency.

Rectifier Upgrade | Efficiency Improvement | Cost Savings | CO2 Emission Reduction |

|---|---|---|---|

Older Models (Pre-2008) | ~92% efficiency | N/A | N/A |

Flatpack2 HE (2008) | $835 million saved | 5 million tons reduced | |

Flatpack2 SHE (Newer) | 98% efficiency | N/A | N/A |

Operators who invest in network-wide rectifier upgrades achieve significant improvements in annual energy consumption, operational reliability, and environmental performance. These benefits position telecom networks for future growth and sustainability.

Additional Benefits

Heat Reduction

High-efficiency rectifier modules deliver more than just energy savings. They also play a crucial role in reducing heat output within telecom cabinets. Operators see several advantages when they upgrade to advanced rectifier designs:

Modules in the mid to high 90% efficiency range waste less energy as heat.

Low RDS(ON) MOSFETs cut conduction losses and voltage drops.

Synchronous rectification replaces traditional diodes, minimizing power loss.

Less energy lost means less heat generated by the rectifier modules.

Reduced heat output lowers the need for large cooling systems, which decreases operational costs and improves thermal management.

By generating less heat, these rectifiers help maintain stable internal temperatures. This stability protects sensitive electronic components and extends their lifespan. Operators also benefit from quieter cabinets, as cooling fans run less often or at lower speeds.

🔥 Tip: Lower heat output not only saves energy but also reduces the risk of thermal-related failures, supporting long-term network reliability.

Maintenance Savings

Telecom operators experience significant maintenance savings when they deploy high-efficiency rectifier modules. The Benning Slimline NG series, for example, achieves over 97% efficiency and reduces power loss by up to 30% compared to older models. This improvement leads to smaller, lighter modules that are easier to handle and install. The modular design allows for hot-swappable modules, so technicians can perform maintenance without interrupting the power supply. Integrated monitoring and control units enhance reliability and enable early fault detection, making maintenance scheduling more efficient.

Operators also benefit from:

Lower energy wastage and reduced operating costs.

Modular and scalable systems that simplify expansion and maintenance.

Remote monitoring and control for proactive management.

Hot-swappable modules that minimize service interruptions.

Advanced protection features that safeguard equipment and extend system lifespan.

Centralized control and monitoring units oversee load distribution and module performance. If a module fails or needs servicing, others take over, ensuring uninterrupted operation. This modularity and real-time monitoring reduce both the frequency and complexity of maintenance tasks. As a result, operators see lower maintenance costs, improved system uptime, and greater overall reliability.

Upgrade Considerations

Payback and ROI

Telecom operators often evaluate upgrades based on return on investment. High-efficiency rectifier modules, such as the Eaton NPR24, achieve about 97.8% efficiency. These modules typically deliver a payback period of around two years in grid-connected telecom cabinet applications. This short payback period results from significant energy savings and reduced operational costs. Operators who invest in these upgrades recover their initial costs quickly, making the decision financially sound. Over time, the savings continue to accumulate, improving the overall profitability of network operations.

Government and utility programs can further improve the financial outlook for upgrades. Many regions offer incentives, tax credits, or grants for energy-efficient infrastructure. The table below highlights several programs that support telecom operators in reducing upgrade costs and accelerating payback:

Program Name | Description | Incentives/Benefits |

|---|---|---|

Save on Energy Retrofit Program | Financial incentives for equipment upgrades and energy reduction in businesses | Up to $1,200/kW or $0.13/kWh for custom projects |

BizEnergy Saver Program | Supports upgrades to energy-efficient options like LED and VFDs | Incentives from 25% to 50%, up to 100% for specific upgrades |

Ottawa Retrofit Accelerator | $10 million program for deep retrofits and emission reduction | Covers up to 75% of study costs (max $50,000); free support services |

Enhanced Capital Cost Allowance (CCA) | Accelerated write-off for clean energy equipment | 75% write-off in the first year |

Clean Technology Investment Tax Credit | 30% refundable tax credit for wind, solar, and energy storage technologies | Available from 2023 to 2034 |

💡 Tip: Operators should explore local and national incentive programs to maximize savings and shorten the payback period.

Implementation Tips

Successful upgrades require careful planning and attention to detail. Operators should consider the following factors:

Schedule regular inspections and cleaning to prevent dust buildup.

Keep detailed maintenance records and involve trained experts for best practices.

Monitor for overheating and voltage fluctuations, addressing issues promptly.

Integrate smart power management systems, including renewable energy sources and energy storage.

Ensure compatibility with backup and emergency power systems for uninterrupted service.

Maintain a steady 48V DC supply and install protective devices.

Provide adequate ventilation to prevent overheating and extend equipment life.

Leverage modular designs, AI, and IoT features for real-time monitoring and predictive maintenance.

Operators who follow these guidelines can maximize the benefits of high-efficiency rectifier modules. They improve reliability, reduce downtime, and extend the lifespan of critical telecom infrastructure.

Telecom operators who upgrade to high-efficiency rectifier modules see substantial annual savings.

Modern designs reduce electricity bills and cooling expenses by minimizing energy loss and heat generation.

Intelligent energy management and remote monitoring lower maintenance costs and improve reliability.

These upgrades support sustainability by reducing carbon emissions and resource consumption.

Industry trends show rapid advances in semiconductor technology, thermal management, and AI-powered monitoring. Operators who invest in energy-efficient solutions position their networks for long-term growth and environmental responsibility.

FAQ

What is a rectifier module in a telecom cabinet?

A rectifier module converts alternating current (AC) from the grid into direct current (DC) for telecom equipment. Operators rely on these modules to ensure stable power delivery and protect sensitive devices.

How does higher efficiency impact electricity bills?

Higher efficiency reduces energy loss during conversion. Operators see lower electricity bills because less power is wasted as heat. Upgrading modules can save thousands of kilowatt-hours each year.

Are there any environmental benefits to upgrading rectifier modules?

Operators who upgrade to high-efficiency modules cut carbon emissions and reduce resource consumption. Networks become more sustainable and meet regulatory requirements for energy use.

What factors should operators consider before upgrading?

Operators should evaluate compatibility, payback period, available incentives, and maintenance requirements. They must also assess network load and future expansion plans.

📌 Tip: Consult with equipment vendors for tailored upgrade recommendations.

See Also

Methods For Calculating Power Systems And Batteries In Telecom

Analyzing Telecom Cabinet Design And Associated Cost Factors

Solar Energy Storage Solutions For Telecom Cabinet Power Systems

Integrating Grid-Tied Solar Inverters And Batteries In Telecom Cabinets

Formula For Selecting Air Conditioning In ESTEL Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA