Low Efficiency of Telecom Cabinet Rectifiers = Hidden Losses? A ¥200k Annual Electricity Waste Case Study

Low efficiency in telecom cabinet rectifiers often results in significant hidden electricity losses, sometimes reaching ¥200k each year. Many operators overlook the importance of rectifier module efficiency, even though these devices consume power continuously. Telecom sites that ignore such inefficiency face unnecessary costs. Operators should closely examine their equipment and consider the true impact of these hidden losses.

Key Takeaways

Hidden electricity losses in telecom sites come from inefficient power conversion, standby power, heat, and partial load operation, causing high annual costs.

Low-efficiency rectifier modules waste energy as heat, increasing electricity bills and cooling needs, while modern high-efficiency modules save money and reduce emissions.

A case study showed a telecom site wasted about ¥200,000 yearly due to old equipment, poor HVAC, and inefficient lighting, highlighting the cost of ignoring energy efficiency.

Upgrading to modern rectifiers with advanced materials and modular designs improves efficiency, lowers energy waste, and supports sustainable operations.

Regular monitoring, maintenance, and timely upgrades help operators detect inefficiencies early, reduce hidden losses, and improve both financial and environmental performance.

Hidden Electricity Losses

What Are Hidden Losses?

Hidden electricity losses refer to the energy consumed by telecom equipment that does not contribute to actual network operations. These losses often occur inside power conversion devices. When a telecom site runs continuously, small inefficiencies add up over time. Operators may not see these losses on a daily basis, but they appear in the annual electricity bill.

Many telecom cabinets contain components that convert AC to DC power. During this process, some energy escapes as heat or gets wasted due to outdated technology. Hidden losses can result from poor design, aging hardware, or improper load management.

A typical telecom site may experience hidden losses from several sources:

Standby power consumption

Heat dissipation

Partial load operation

Operators who ignore these factors risk paying for electricity that does not support their network.

Why Losses Go Unnoticed

Telecom operators often focus on visible issues, such as network downtime or hardware failures. Hidden losses rarely trigger alarms or alerts. Electricity meters measure total consumption, but they do not separate useful energy from wasted energy.

Routine maintenance checks may overlook inefficiency in power conversion.

Many sites operate at partial load, which increases the proportion of wasted energy.

Outdated equipment may continue running for years without efficiency upgrades.

Operators may not realize the impact until they review annual costs. The lack of real-time monitoring tools makes it difficult to pinpoint the source of losses.

Regular audits and efficiency assessments help uncover hidden electricity losses. By identifying and addressing these issues, operators can reduce unnecessary expenses and improve overall site performance.

Rectifier Module Efficiency

How Rectifier Modules Work

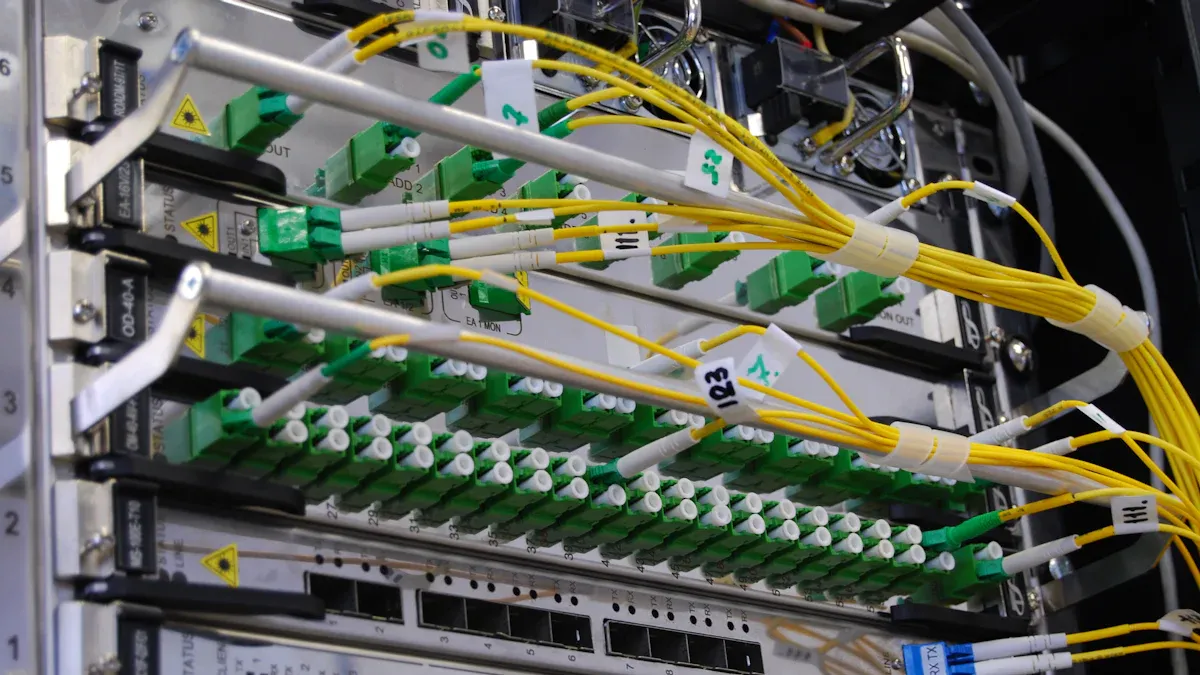

Telecom cabinet rectifier modules play a critical role in converting alternating current (AC) from the grid into stable direct current (DC) for network equipment. These modules use advanced rectifier designs, such as bridge rectifiers, to process both halves of the AC waveform. Diodes inside the module allow current to flow in one direction, blocking unwanted portions of the AC signal. Modern designs often include three-phase rectifiers for higher power demands, which improves efficiency and reduces electrical ripple.

Engineers use semiconductor materials like silicon carbide and gallium nitride to boost performance. These materials enable the rectifier module to operate at higher voltages and temperatures. The modular design supports scalability and redundancy, making maintenance easier and ensuring reliable operation. Most modules run in Continuous Conduction Mode, which helps maintain consistent power delivery. Industry standards require modules to meet strict safety and efficiency certifications, such as CE and RoHS, to guarantee optimal performance.

Impact of Low Efficiency

Low efficiency in a rectifier module leads to increased energy waste and higher operational costs for telecom operators. Older rectifiers often lose up to 70% of input energy as heat, which drives up electricity consumption and cooling requirements. Modern modules, such as the Eltek Valere Flatpack2 HE, reach up to 96% efficiency, cutting energy losses by about 50% compared to standard models.

Aspect/Feature | Description/Value |

|---|---|

Rectifier Efficiency | |

Power Loss Reduction | Up to 75% less power loss compared to older models |

Cooling Energy Savings | Reduced heat generation lowers cooling needs |

Energy Use Reduction Example | 30% reduction in energy use (GreenConnect project) |

CO2 Emissions Reduction | 40% drop in CO2 emissions (GreenConnect project) |

Operators who use low-efficiency rectifier modules face higher electricity bills and increased environmental impact. Inefficient modules also limit market reach in regions with tight budgets. Real-time monitoring and built-in safeguards help maintain optimal efficiency, but outdated systems often lack these features. Upgrading to high-efficiency modules reduces energy waste, lowers costs, and supports sustainability goals.

Tip: Regularly assess rectifier module efficiency and consider upgrades to meet industry standards. Improved efficiency not only saves money but also reduces carbon emissions.

Case Study: Electricity Waste

Site Overview

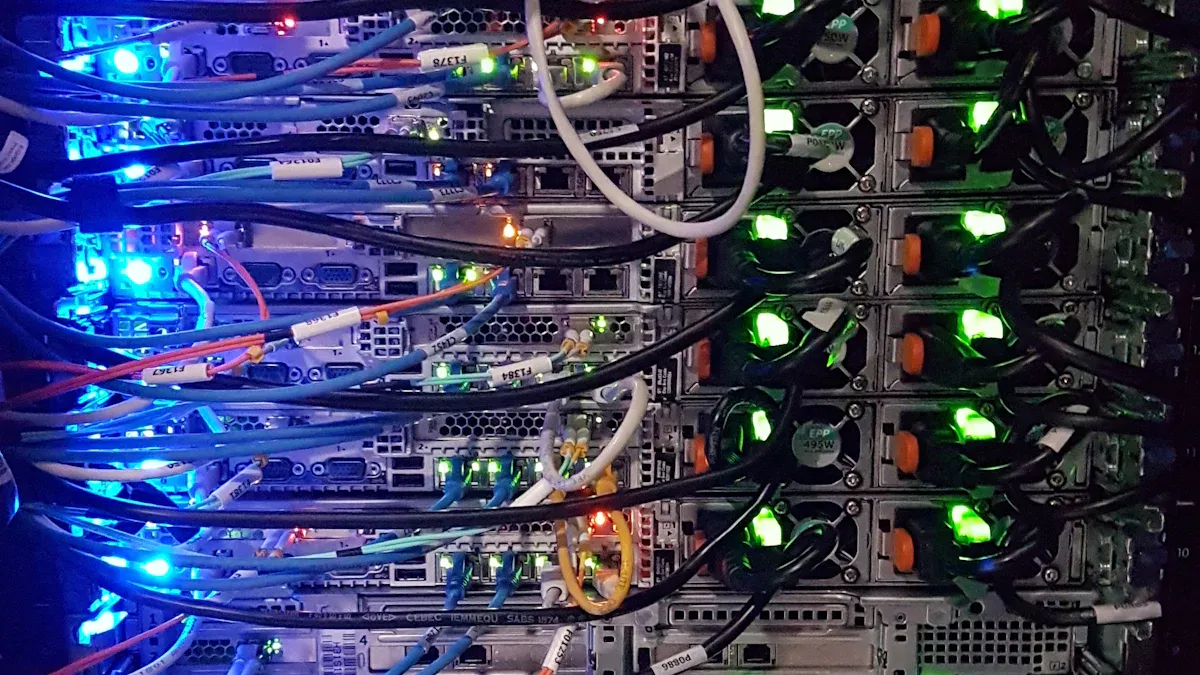

A large telecom operator in eastern China manages a network site that supports both urban and rural communications. The site houses multiple telecom cabinets, each equipped with several rectifier modules. These cabinets supply continuous DC power to base station equipment, routers, and backup systems. The facility operates 24 hours a day, 365 days a year. Staff members perform routine maintenance, but the site relies on equipment installed over a decade ago. The operator has not upgraded the power infrastructure or implemented modern energy management systems.

The site also includes a small office area for technicians. Lighting, heating, and cooling systems run throughout the year. The operator has not adopted energy-saving practices or modernized the lighting and HVAC systems. As a result, the site consumes more electricity than similar facilities with newer technology.

Loss Calculation

The operator reviewed annual electricity bills and discovered that the site used approximately 400,000 kWh in one year. Industry benchmarks suggested that a similar site with high-efficiency rectifier modules and optimized energy management would consume only 250,000 kWh. The difference—150,000 kWh—represented wasted energy. At an average electricity rate of ¥1.3 per kWh, the annual hidden loss reached nearly ¥200,000.

The calculation process included the following steps:

Measured total site electricity consumption over 12 months.

Compared actual usage to expected consumption for a site with modern, efficient equipment.

Identified the gap as wasted energy, primarily due to inefficient rectifier modules, poor HVAC practices, and outdated lighting.

Multiplied the wasted kWh by the local electricity rate to estimate the annual financial loss.

The operator realized that most of the waste came from power conversion losses, excessive heat generation, and unnecessary operation of support systems. By upgrading to high-efficiency rectifier modules and improving energy management, the site could save a significant portion of this cost.

Key Factors

Several factors contributed to the high electricity waste at the site:

Use of old, inefficient equipment that increases energy consumption and requires costly upgrades.

Poor HVAC practices, including leaving doors or windows open and running heating and cooling simultaneously, which significantly raise energy use.

Inefficient lighting, such as reliance on incandescent bulbs instead of energy-saving LEDs or CFLs.

Running electronics unnecessarily in empty offices, wasting energy when devices could be powered down or unplugged.

Lack of an energy management system, which prevents effective monitoring and control of energy usage.

Modern rectifier modules using advanced semiconductor materials, such as gallium nitride (GaN) and silicon carbide (SiC), achieve efficiencies above 97% even at partial loads. These modules reduce energy losses and heat generation, which protects sensitive electronics and lowers operational costs. Modular designs allow telecom power systems to scale power delivery efficiently according to demand. This approach ensures that partial load operation does not degrade overall energy efficiency. In fact, adaptive load management can lead to further energy savings.

The SLIMLINE series rectifiers, for example, maintain efficiency greater than 98% over a wide load range from 20% to 90%. Active power management dynamically connects or disconnects modules based on load demand, optimizing energy use and minimizing losses. Sites that upgrade to these technologies see immediate reductions in electricity waste and operational expenses.

Operators who address these key factors can transform hidden losses into measurable savings, improving both financial performance and sustainability.

Technical Causes

Conversion Losses

Conversion losses occur during the process of changing AC power to DC power inside a rectifier module. Several technical factors contribute to these losses:

Conduction losses result from the forward voltage drop across rectifier devices.

Switching losses arise during high-frequency operation, especially when the rectifier switches on and off rapidly.

Thermal losses develop if the system cannot dissipate heat efficiently.

Device material and design, such as the use of silicon versus silicon carbide, also influence the level of energy lost.

Advanced rectifiers with silicon carbide technology minimize conduction and switching losses. Schottky diodes, especially those based on silicon carbide, offer fast switching and low voltage drops, which further reduce wasted energy. When operators use outdated rectifier modules, they often see up to 20% of input power lost during conversion, compared to less than 4% in modern systems.

Heat Generation

Heat generation inside telecom cabinets represents a major source of hidden electricity loss. Traditional ORing diodes in rectifier modules create excessive heat due to voltage drops. This heat forces cooling systems to work harder, increasing overall power consumption. High temperatures can shorten the lifespan of electronic components, leading to more frequent replacements and higher maintenance costs. Hot-standby modules, which remain powered but unused, experience greater heat stress and reduced reliability. Modern designs use MOSFET-based controllers to cut down on heat, but heat management remains a critical challenge.

Note: Improved thermal management not only saves energy but also extends equipment life and reduces operational expenses.

Low Utilization Effects

Low utilization occurs when telecom sites operate rectifier modules at partial loads. Older designs struggle to maintain efficiency under these conditions. As a result, energy losses increase, and cooling demands rise. Modern modular rectifiers allow operators to match the number of active modules to the actual load, concentrating power delivery and improving efficiency. Hot-swappable and scalable designs make it easier to adapt to changing power needs, reducing downtime and maintenance costs. Upgrading to efficient rectifiers can lower energy costs by up to 30% and support sustainable operations.

Efficiency Comparison

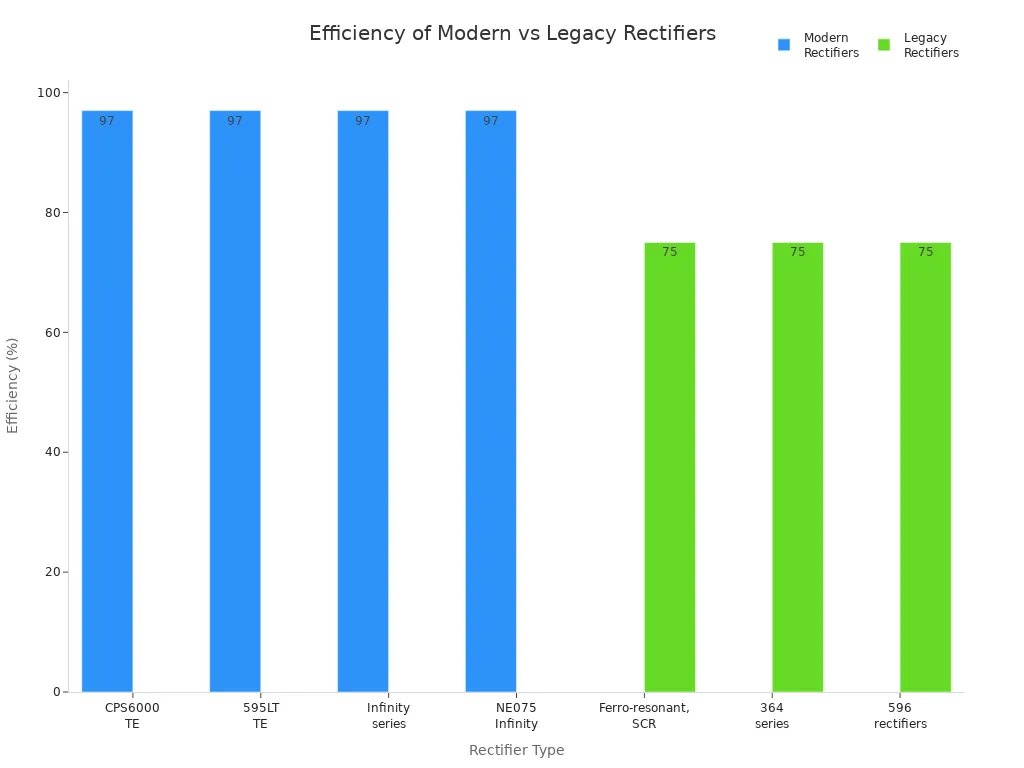

Efficient vs. Inefficient Modules

Modern telecom sites rely on high-efficiency rectifiers to minimize energy loss. Legacy models, such as ferro-resonant or SCR-based units, often waste a significant portion of input power. Modern switched mode rectifiers, including the CPS6000 TE and Infinity series, achieve efficiencies near 97%. These upgrades deliver more power to network equipment and reduce the amount lost as heat.

Rectifier Type | Era/Category | Efficiency (Modern) | Energy Savings Compared to Legacy | Notes on Upgrade Benefits |

|---|---|---|---|---|

Ferro-resonant, SCR | Legacy | N/A | Baseline (lower efficiency) | Discontinued, replaced by modern rectifiers |

364 series | Legacy | N/A | Baseline (lower efficiency) | Legacy telecom rectifiers |

596 rectifiers | Legacy | N/A | Baseline (lower efficiency) | Discontinued, replaced by Infinity rectifiers |

CPS6000 TE | Modern switched mode | ~97% | >50% reduction in energy loss | Plug-and-play retrofit, preserves cabling and distribution |

595LT TE | Modern switched mode | ~97% | Significant efficiency gain | Retrofits legacy ferro/SCR rectifiers, advanced management |

Infinity series | Modern switched mode | ~97% | Significant efficiency gain | Upgrades legacy 364 series rectifiers |

NE075 Infinity rectifiers | Modern switched mode | ~97% | Significant efficiency gain | Replaces 596 rectifiers, retains infrastructure |

Upgrading to modern rectifiers brings additional benefits. Operators gain higher power density, advanced management features, and minimal disruption during installation. These improvements support both operational reliability and long-term cost savings.

Cost Impact

The difference in efficiency between modern and legacy rectifiers translates directly into financial outcomes. Efficient rectifiers, with up to 96.5% efficiency and a power factor of 0.99, help operators save over $7,000 per year for every 1000A of load at $0.3 per kWh. Upgraded systems can reduce annual energy usage by 15-20%, and some case studies report up to 30% lower energy consumption.

Aspect | Efficient Rectifiers | Inefficient Rectifiers / Older Models |

|---|---|---|

Efficiency | Up to 95% - 96.5% | Lower efficiency, wastes more electricity |

Power Factor | 0.99 | Lower power factor, more energy loss |

Annual Cost Savings | Over $7,000 saved per 1000A at $0.3/kWh | Higher energy costs due to waste |

Energy Cost Reduction | About 5% savings yearly | No such savings |

Energy Savings in Upgraded Systems | Up to 20% more energy saved yearly | No improvement |

Case Study (GreenConnect) | 30% reduction in energy use, millions saved | Higher energy consumption and costs |

Cost Reduction in Remote Areas | Up to 50% lower costs | Higher operational costs |

Operators who invest in efficient rectifiers see immediate reductions in electricity bills. Lower energy waste also means less strain on cooling systems and reduced maintenance needs. Over time, these savings can reach millions, especially for large-scale networks or remote sites where operational costs run high.

Note: Choosing efficient rectifiers is not just a technical upgrade. It is a strategic decision that impacts both the bottom line and environmental sustainability.

Reducing Hidden Losses

Identifying Inefficiency

Telecom operators can reduce hidden losses by identifying inefficiency in their power systems. They should follow a systematic approach to spot issues early:

Conduct regular visual inspections for physical damage, corrosion, or overheating in rectifier modules.

Monitor output voltage, current, and efficiency to ensure effective power conversion.

Use predictive maintenance tools and sensors to detect abnormal temperature changes or voltage fluctuations.

Inspect cooling systems and airflow to prevent overheating.

Check and secure electrical connections and cabling.

Clean dust and replace air filters to maintain optimal conditions.

Update firmware to improve performance and security.

Review system alarms and logs to address issues before they cause downtime.

Operators who follow these steps can quickly identify and address inefficiency, preventing unnecessary energy waste.

Monitoring and Maintenance

Regular monitoring and maintenance play a crucial role in maintaining efficient telecom power systems. Operators benefit from:

Real-time monitoring and intelligent alarms for quick fault detection.

Continuous data collection and historical records to support proactive maintenance.

Remote inspection options, including local displays, web interfaces, and mobile apps.

Optimized system architecture for rapid and cost-effective maintenance.

High reliability features, such as dual power supplies and watchdogs, to ensure stable operation.

Efficient data management and integration for consistent performance.

Tip: Proactive monitoring and maintenance help minimize faults, reduce downtime, and keep rectifier modules operating at peak efficiency.

Upgrading Rectifier Modules

Upgrading to modern rectifier modules delivers significant energy and cost savings. For example, the DPR6000B achieves 96% power conversion efficiency, reducing waste heat and lowering operating expenses. These upgrades also improve system stability and reduce maintenance needs. Many telecom operators face barriers such as high initial costs for advanced materials, scalability challenges, and the need to justify operational expenses. Modular designs and AI-driven predictive maintenance can help overcome these obstacles by allowing incremental upgrades and extending equipment lifespan.

Operators who invest in high-efficiency rectifier modules see lower energy consumption, reduced maintenance costs, and improved sustainability. These benefits support both financial goals and long-term operational reliability.

Hidden electricity losses from outdated rectifiers can lead to substantial costs for telecom operators. Addressing these inefficiencies supports both financial savings and sustainability goals. Operators benefit by:

Reducing energy waste and carbon footprint through high-efficiency designs and eco-friendly materials.

Extending equipment lifespan with modular upgrades and predictive maintenance.

Meeting global energy standards and supporting circular economy practices.

Operators should take practical steps such as routine performance checks, real-time monitoring, and leveraging remote management tools to optimize efficiency and reliability.

FAQ

What is a telecom cabinet rectifier?

A telecom cabinet rectifier converts AC power from the grid into DC power for telecom equipment. It ensures stable voltage and protects sensitive devices. Operators rely on rectifiers for continuous, reliable network operation.

How does low rectifier efficiency increase costs?

Low-efficiency rectifiers waste more electricity as heat. Operators pay for this wasted energy. Over time, these hidden losses can add up to significant annual expenses.

Can upgrading rectifier modules reduce electricity bills?

Yes. Upgrading to high-efficiency rectifier modules lowers energy waste. Operators see immediate reductions in electricity bills and maintenance costs.

What signs indicate inefficient rectifier modules?

Operators may notice higher electricity bills, frequent overheating, or increased cooling needs. Outdated modules often lack real-time monitoring and advanced management features.

How often should operators check rectifier efficiency?

Experts recommend checking rectifier efficiency during every scheduled maintenance cycle. Regular monitoring helps operators catch issues early and maintain optimal performance.

See Also

Methods To Calculate Power Systems And Batteries For Telecom Cabinets

Using Solar Energy Storage Systems To Power Telecom Cabinets

Steps To Guarantee Consistent Power Supply For Telecom Cabinets

Understanding The Design And Expenses Of Telecom Cabinets

Grid-Tied Solar Inverter And Battery Solutions For Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA