5G Telecom Cabinet Rectifier Efficiency Requirements: How High Power Density Supports Stable Power for Dense Base Stations

You see over 90% of telecom rectifier modules now achieve more than 97% efficiency, with some aiming for 98% or higher. This high efficiency cuts energy losses and reduces heat, helping you lower operational costs and maintain stable power for dense 5G base station cabinets. High power density lets you fit more capacity into compact cabinets, making upgrades and expansions easier without increasing cabinet size. By choosing advanced semiconductor technologies, you support reliable, scalable, and cost-effective 5G network operation.

Key Takeaways

Choose rectifier modules with over 97% efficiency to reduce energy loss, lower cooling costs, and keep 5G base stations running reliably.

High power density lets you fit more power into smaller cabinets, saving space and making upgrades easier in crowded urban areas.

Advanced semiconductor materials like silicon carbide and gallium nitride improve efficiency and power density, supporting compact and efficient designs.

Effective thermal management is essential to control heat in dense 5G cabinets and protect equipment from damage and outages.

Modular and scalable rectifier designs help you grow your 5G network smoothly while keeping costs and space under control.

5G Power Demands

Load Challenges

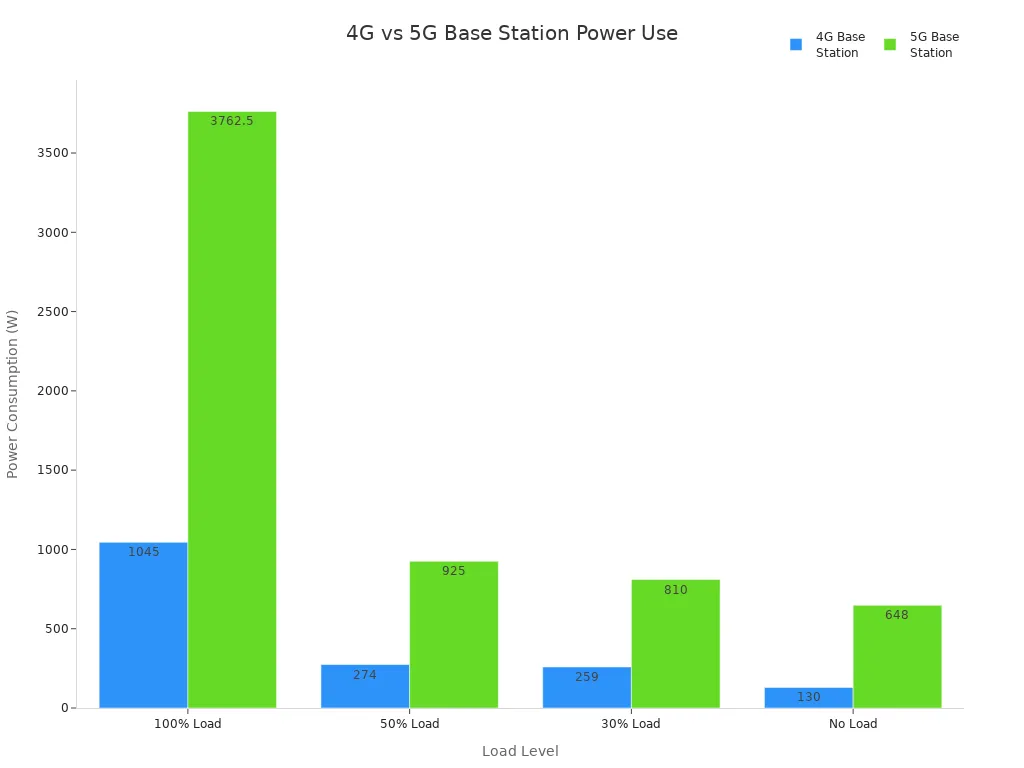

You face much higher power demands with 5G base stations than with previous generations. The jump in power use is clear when you compare typical consumption levels:

Load Level | 4G Base Station Power Consumption (W) | 5G Base Station Power Consumption (W) | Power Consumption Ratio (5G to 4G) |

|---|---|---|---|

100% | ~1045 | 3675 - 3850 | ~3.5 times |

50% | ~274 - 273 | ~893 - 957 | N/A |

30% | ~259 | ~763 - 857 | N/A |

No Load | ~23 - 237 | ~633 - 663 | N/A |

At full load, a 5G base station can use about 3700 watts—over three times more than a 4G site. You also need to deploy more 5G stations in dense urban areas, which multiplies total network power use. This rise comes from higher data traffic, more users, and advanced technologies like massive MIMO antennas. Air conditioning for cooling can account for over half of the total power draw. Fluctuating network loads, seasonal temperature changes, and rapid switching between low and high power modes add complexity. You must select rectifier modules that maintain high efficiency across these changing loads to avoid wasted energy and overheating.

Tip: Efficient rectifiers (96%–98%) help you reduce energy losses and keep heat under control, even as loads shift throughout the day.

Cabinet Constraints

Urban 5G deployments push you to fit more equipment into smaller, less visible spaces. You often install cabinets on poles, rooftops, or sidewalks, where space is tight and visual impact must stay low. These cabinets need to handle dense cable layouts, advanced cooling, and backup batteries—all within a compact footprint. You also need to meet strict safety, weatherproofing, and regulatory standards.

Compact, integrated DC/DC modules save up to 90% of board space compared to traditional designs.

Modular layouts let you customize for each site, improving airflow and thermal management.

Cabinets use rugged, tamper-proof materials to protect sensitive electronics from weather and vandalism.

Flexible mounting options (pole, pad, wall) help you adapt to different urban locations.

You must choose rectifier modules that deliver high power density and efficiency, so you can support growing 5G demands without expanding cabinet size. This approach keeps your deployments scalable, reliable, and ready for future upgrades.

Rectifier Module Efficiency

Efficiency Standards

You need to meet strict efficiency standards when selecting a rectifier module for 5G base stations. Most modern rectifier modules now achieve over 97% efficiency, with some reaching as high as 98%. This level of performance marks a significant improvement over older 4G and legacy systems, which often relied on less efficient power supplies. The jump in efficiency comes from the need to support massive MIMO antennas and increased server loads in 5G networks. Older rectifier modules cannot keep up with these demands, so upgrading becomes essential.

You also see new technologies like wide bandgap semiconductors—specifically silicon carbide (SiC) and gallium nitride (GaN)—pushing efficiency even higher. These materials allow rectifier modules to reach up to 99% efficiency in some cases. GaN, for example, offers fast switching speeds and about 20% higher power density than SiC, making it ideal for compact telecom applications. SiC works well in high-voltage, high-power scenarios. Both materials help reduce heat and energy loss, which improves reliability and supports the miniaturization of power systems.

Semiconductor Material | Efficiency | Power Density | Application Suitability |

|---|---|---|---|

Silicon | Lower | Lower | Traditional rectifiers, less efficient for edge computing |

Silicon Carbide (SiC) | >99% | High | High-voltage, high-power applications, grid systems |

Gallium Nitride (GaN) | ~99% | ~20% higher than SiC | Medium-voltage, telecom, high-frequency, compact designs |

Note: Wide bandgap semiconductors like SiC and GaN help you achieve higher efficiency and power density, which are critical for 5G cabinet designs.

Energy Savings

When you upgrade to a high-efficiency rectifier module, you unlock major energy savings. Modules with more than 97% efficiency can cut operating costs by up to 30% compared to older designs. This happens because less energy is lost as heat, so you spend less on cooling and electricity. For example, a rectifier module like the Flatpack2 48V/3000W HE achieves up to 96.5% efficiency, reducing energy losses by about 50% compared to standard industry models. As a result, you lower your energy bills and reduce the strain on your cooling systems.

High-efficiency rectifier modules reduce energy losses and heat, which lowers cooling costs.

Active power factor correction improves how you use electricity, cutting utility expenses.

Less heat and better power quality mean your equipment lasts longer, so you spend less on maintenance and replacements.

Digital power control lets you monitor and optimize performance in real time, reducing downtime and improving reliability.

You also support low-latency, high-capacity 5G needs by keeping power stable and reliable. Intelligent control algorithms and advanced rectifier diodes help maintain high efficiency across different load levels. This ensures your network can handle peak demand without wasting energy or risking outages.

Tip: Upgrading to a rectifier module with >97% efficiency is one of the fastest ways to cut operational costs and future-proof your 5G power infrastructure.

High Power Density

Space Savings

High power density sets a new standard for 5G telecom cabinets. You often see a benchmark of 400 kW/m², which means you can deliver more power in less space than ever before. This shift changes how you design and deploy your network infrastructure.

The Benning Slimline NG rectifier system reduces the physical footprint by over 33% compared to older models. You can fit more power into the same cabinet or even shrink the cabinet size.

Modular rectifier modules, each providing 2 kW output, let you scale from 2 kW up to 400 kW in a single rack. This flexibility supports both small and large deployments.

The compact 19" 1H carrier design minimizes space requirements, making it easier to install equipment in crowded urban environments.

Lightweight systems like the IPack65, which weighs only 27.2 kg with four 4 kW modules, allow you to install or upgrade cabinets by hand, without heavy machinery.

Hot-pluggable modules enable you to expand or replace capacity without shutting down the system, saving time and reducing disruption.

Tip: High power density lets you maximize every inch of your cabinet, so you can add more radios, batteries, or cooling systems without running out of space.

Thermal Management

Packing more power into a smaller space creates new challenges for heat management. You must control temperature precisely to keep your equipment running reliably.

High power density increases heat generation. A single 5G base station can use as much power as 73 households, so cabinets get hot quickly.

Traditional cooling methods, like passive airflow or simple fans, often cannot handle the intense heat in high-density setups.

Advanced cooling solutions, such as heat exchangers and thermoelectric (TEC) air conditioning, provide precise temperature control. These systems keep sensitive electronics safe, even during peak loads or hot weather.

Closed-loop heat exchangers isolate internal air, reducing dust and moisture contamination. This design improves reliability and extends equipment life.

TEC air conditioning maintains stable internal temperatures, protecting your investment and reducing the risk of outages.

Efficient cooling not only protects your equipment but also lowers your energy bills. Choosing the right thermal management system is essential for sustainable 5G network growth.

Scalability

High power density gives you the flexibility to grow your network as demand increases. You can upgrade existing sites or roll out new ones without expanding your cabinet footprint.

You can increase power capacity to meet the needs of 5G radios, which require about 60% more power than 4G radios, without making cabinets larger.

Retrofit rectifiers let you upgrade power systems in place, preserving your current infrastructure and saving on installation costs.

Modular and scalable designs support "pay-as-you-grow" strategies. You add more modules as your network expands, avoiding upfront overinvestment.

In ultra-dense small cell deployments, high power density enables you to place more base stations closer together. This approach increases network capacity and improves user experience.

Shorter distances between base stations reduce interference and boost throughput, supporting more users with better performance.

Advanced techniques, like multi-connectivity, help you manage the challenges of dense deployments, such as interference and handovers.

By choosing high power density rectifier modules, you future-proof your network. You meet today’s demands and stay ready for tomorrow’s growth—all without needing more space.

Implementation

Rectifier Module Selection

You need to choose a rectifier module that matches the demands of your 5G telecom cabinet. Focus on efficiency first. High efficiency reduces energy loss and heat, which lowers your operational costs and extends equipment life. Reliability matters just as much. Look for modules with high mean time between failures, surge current capability, and robust protection circuits. You should also check for wide operating temperature ranges and strong construction. Effective thermal management is critical. Advanced heat sinks, low thermal resistance packages, and temperature sensors help prevent overheating. Package type affects integration and cooling. Options like TO-220, TO-247, or compact module-based designs offer different benefits. Make sure your choice meets industry standards and certifications such as UL, CE, and TUV. Modular designs allow you to expand capacity and upgrade technology as your network grows. Compatibility with battery systems and DC microgrids increases reliability and efficiency.

Tip: Silicon carbide and gallium nitride technologies offer superior efficiency and power density, making them ideal for 5G telecom applications.

Integration Tips

You can optimize your rectifier module installation by following a few key steps. Start by verifying system specifications, including voltage, current, and compliance with standards. Prepare tools like DC distribution panels and monitoring devices. Always isolate power and use protective equipment for safety. Position the module in a clean, ventilated area with good temperature control. Connect input power using insulated wiring and keep the power off during installation. Wire output connections with rated cables and label them for easy maintenance. Integrate battery backup systems and test voltage before use. Synchronize the module with your communication equipment, confirming voltage compatibility. Configure system settings and enable monitoring features. Test the system under load conditions to ensure stability. Maintain proper ventilation and grounding to extend equipment lifespan.

Support communication protocols such as SNMP, Ethernet, and Modbus for remote monitoring.

Use environmental monitoring with temperature sensors to optimize longevity.

Ensure waterproof and insulated cabinets to protect against moisture and humidity.

Note: Proper sizing, redundancy, and advanced protection mechanisms enhance reliability and reduce downtime.

Real-World Cases

You can see the benefits of high-efficiency and high power density in real deployments. For example, a 1% efficiency improvement can save over $1,200 each year, so modules with more than 97% efficiency yield even greater savings. The Vertiv Liebert APM Plus UPS achieves 97% double conversion efficiency and saves up to 50% space, which is vital for space-constrained 5G cabinets. This UPS operates reliably in harsh environments up to 50°C. Modularity and rapid deployment support quick site rollouts and scalability. Telecom operators have improved reliability and cost-effectiveness by upgrading to advanced rectifier modules. These modules meet increased power requirements, enhance conversion efficiency, and support near 100% uptime. Integration of renewable energy sources and intelligent power management further boosts reliability and sustainability. Advanced cooling and thermal management prevent overheating, which is crucial for dense 5G deployments.

By choosing the right rectifier module and following best practices, you can minimize operational costs, reduce cooling needs, and enable flexible power capacity adjustments for your 5G network.

You gain reliable and energy-efficient 5G base station power by choosing rectifier modules with over 97% efficiency and high power density. This approach helps you save costs, optimize cabinet space, and prepare for future network growth. To upgrade your system, assess your current infrastructure, select the right cabinet type for your environment, and use advanced monitoring for real-time performance. Regular maintenance and modular designs keep your network scalable and resilient.

FAQ

What does rectifier efficiency mean for 5G base stations?

Rectifier efficiency shows how much input power you convert into usable DC power. Higher efficiency means less energy wasted as heat. You save on electricity and cooling costs, which helps your 5G network run reliably.

Why is high power density important in telecom cabinets?

High power density lets you fit more power into a smaller space. You can add more equipment or upgrade your site without making the cabinet bigger. This helps you deploy 5G in crowded urban areas.

How do wide bandgap semiconductors improve rectifier performance?

Wide bandgap semiconductors, like SiC and GaN, switch faster and handle higher voltages. You get better efficiency and smaller, lighter modules. These materials help you meet strict 5G power and space requirements.

Can I upgrade existing 4G cabinets for 5G with new rectifiers?

Yes, you can often retrofit high-efficiency, high-density rectifiers into existing cabinets. You boost power capacity and efficiency without replacing the whole cabinet. This saves you time and money during your 5G upgrade.

See Also

Steps To Guarantee Consistent Power For Telecom Cabinets

Solar Energy Storage Solutions Designed For Telecom Cabinets

The Importance Of Upgrading Telecom Cabinets By 2025

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA