Balancing Efficiency & Lifespan of Telecom Cabinet Rectifiers: 10 Years of O&M Data from a Supplier

Telecom operators achieve a balance between efficiency and lifespan by leveraging 10 years of O&M data to select advanced rectifier module designs and implement predictive maintenance.

Redundant and modular power supply designs increase network reliability.

Hot-swappable modules reduce downtime and maintenance costs by up to 35%.

AI-driven predictive maintenance cuts operational expenses and improves uptime by 20%.

Aspect | Statistic | Operational Impact |

|---|---|---|

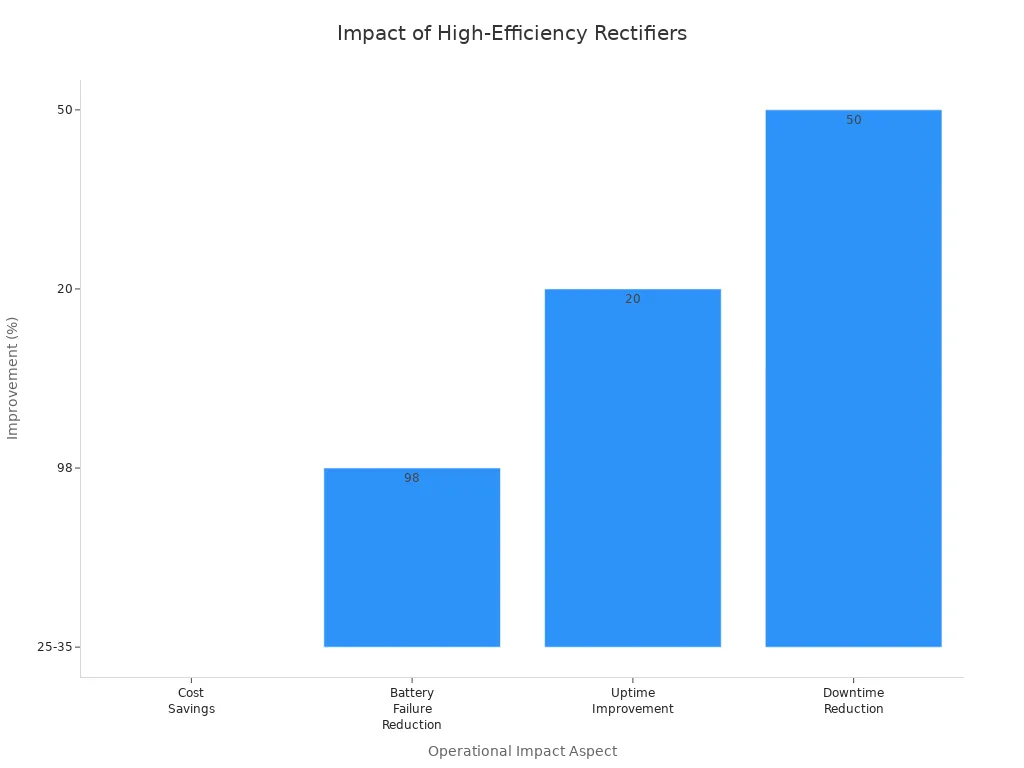

Efficiency | 96-98% | 25-35% cost savings, less energy loss |

Battery Failure Rate | 98% reduction | Higher reliability |

Maintenance | Modular, hot-swappable | Fewer disruptions |

Key Takeaways

Modular rectifier systems improve reliability, reduce downtime, and allow easy upgrades and maintenance.

Predictive maintenance using AI cuts costs, prevents failures, and boosts equipment uptime by detecting issues early.

Upgrading to rectifiers with 96–98% efficiency saves energy, lowers operating costs, and supports sustainability goals.

Proper temperature control, regular inspections, and environmental protection extend rectifier lifespan and performance.

Real-time monitoring and data analytics help operators optimize power use, plan upgrades, and maintain network stability.

O&M Data Insights

Efficiency Trends

Over the past decade, telecom operators have seen significant improvements in rectifier module efficiency. The conversion efficiency increased from 94% to 98%, which reduced conversion power loss by 66%. This change led to lower energy consumption and less heat dissipation. Operators also benefited from higher power density, allowing more power in a smaller footprint and saving up to 50% of user space compared to traditional modules.

Efficiency Improvement Aspect | Description and Impact |

|---|---|

Conversion Efficiency | Increased from 94% to 98%, reducing conversion power loss by 66%, leading to lower energy consumption and heat dissipation. |

Power Density | Improved, allowing more power in a smaller footprint, saving 50% user space compared to traditional modules. |

Reliability | Reduced power failure rates and noise levels, enhancing system stability. |

Modular Design | Supports smooth capacity expansion and intelligent redundancy, enabling shutdown of modules during low traffic to save power. |

Energy Management OSS (NetEco) | Provides real-time monitoring, refined energy management, and actionable intelligence for energy conservation. |

Thermal Management Innovations | Cabinet compartmentalization and use of high-temperature batteries reduce air conditioning runtime and parasitic loads. |

System-wide and Network-wide Optimization | Shift from single-module efficiency to holistic energy optimization across sites and networks. |

Operators now rely on energy management platforms for real-time monitoring and refined control. These platforms help optimize energy use and support sustainability goals. The shift from single-module efficiency to system-wide optimization has become a best practice in the industry.

Lifespan Patterns

Long-term O&M analysis reveals several factors that affect the lifespan of telecom cabinet rectifiers. Operators observed that ignoring load variations, especially during peak periods, often leads to rectifier overload and system downtime. Environmental conditions such as temperature extremes and dust exposure also play a critical role in reducing lifespan. Using non-certified rectifiers can result in regulatory and safety issues, while incompatible packages complicate installation and maintenance.

Ignoring load variations, especially peak loads, causes rectifier overload and system downtime.

Overlooking environmental conditions such as temperature extremes and dust exposure reduces rectifier lifespan.

Neglecting compliance by using non-certified rectifiers leads to regulatory and safety issues.

Choosing incompatible packages complicates installation and maintenance.

Skipping regular testing and maintenance allows minor issues to escalate, reducing reliability and lifespan.

High ambient temperatures, especially those above 55°C, cause overheating and accelerate equipment wear. Humidity and moisture exposure degrade performance, making waterproof, sealed, and insulated cabinets essential. Proper cooling and ventilation, including fans and heat exchangers, prevent overheating. Environmental monitoring systems with temperature sensors help maintain optimal conditions. Regular inspections and cleaning prevent dust buildup, which can impair performance.

Trade-Offs

Operators face several trade-offs when balancing efficiency and lifespan. Increasing conversion efficiency often requires advanced thermal management and higher-quality components, which can raise initial investment costs. However, these investments reduce operational expenses over time by lowering energy consumption and minimizing downtime.

Benchmarking and analytics play a vital role in guiding operational decisions. Industry benchmarks recommend aiming for at least 99% energy efficiency in telecom rectifiers to minimize energy losses and reduce operational costs. Regular testing and design validation ensure consistent performance and reliability under varying load conditions. Adherence to industry standards guarantees safety and compliance.

AI-driven predictive maintenance enables operators to monitor real-time performance and predict failures before they occur. This proactive approach reduces downtime by up to 50% and cuts maintenance costs by as much as 30%. Analytics also guide design improvements, set efficiency targets, and support sustainability goals by tracking energy consumption and environmental impact. Proper thermal management, informed by analytics, protects equipment investment and reduces premature failures.

Operators must weigh the cost of upgrading rectifier modules against the long-term benefits of improved efficiency and reliability. Strategic deployment, informed by market analytics, helps identify underserved regions and optimize asset utilization.

Efficiency & Lifespan Factors

Operating Conditions

Telecom cabinet rectifier module performance depends heavily on operating conditions. Temperature management stands out as a critical factor. Excessive heat degrades components and reduces efficiency. Operators maintain safe temperature limits, often up to 55°C, to prevent overheating and extend equipment life. Advanced heat sinks, low thermal resistance packaging, and temperature sensors help manage heat effectively. Environmental exposure, including humidity, dust, lightning storms, and heavy rainfall, can cause frequent failures and costly repairs. Durable, weather-resistant construction and high protection ratings such as NEMA and IP safeguard rectifier modules against harsh environments. Real-time monitoring and automatic voltage regulation stabilize power output and enable early issue detection.

Operating temperature range: -25°C to +55°C

High durability and protection ratings

Conversion efficiency above 95%

Advanced surge and fault protection

Modularity and scalability for capacity expansion

Maintenance Practices

Effective maintenance practices extend the lifespan of telecom cabinet rectifiers. Operators perform regular inspections to identify physical damage, corrosion, or loose connections. Cleaning and tightening electrical connections prevent overheating and voltage instability. Monitoring operating temperatures between 68°F and 77°F ensures efficiency. Prompt replacement of worn components with original parts maintains system stability. Keeping the environment dust-free by cleaning vents, fans, and filters avoids overheating. For air-cooled rectifiers, maintaining airflow is essential. For water-cooled systems, checking water lines and pumps for leaks and controlling humidity prevents condensation. Operators maintain detailed records of inspections and repairs to track performance and recurring issues.

Tip: Use tools such as multimeters, thermal cameras, and software monitoring to detect early signs of failure and follow manufacturer instructions during all maintenance activities.

Corrective maintenance complements preventive strategies. Timely repairs and addressing inefficiencies reduce downtime and maintain consistent power delivery. AI-driven monitoring tools and self-checking rectifiers enable early fault detection and correction, optimizing long-term reliability.

Rectifier Module Design

Design features play a pivotal role in achieving high efficiency and extended lifespan. Manufacturers use aluminum bases for efficient heat dissipation, maintaining safe operating temperatures under heavy loads. Compact designs allow adaptability without compromising performance. Selection of diodes with low forward voltage drop and high breakdown voltage reduces energy losses and improves reliability. Effective thermal management, robust protection against over-voltage and over-current, and vibration isolation prevent premature failure.

Design Feature | Contribution to Efficiency and Lifespan |

|---|---|

Aluminum Base | Efficient heat dissipation, durability under heavy loads |

Adaptability, optimal module selection | |

Diode Selection | Reduced energy losses, improved reliability |

Heat Dissipation Methods | Prevents overheating, extends component lifespan |

Robust Protection | Safeguards against faults, enhances durability |

Industry standards such as NEBS Level 3 and GR-3108 ensure rectifier modules meet rigorous telecom requirements. High energy efficiency, robust construction, advanced monitoring, modularity, and hot-swap capabilities support reliability and maintainability. Redundancy modules provide backup power, ensuring uninterrupted operation during failures.

Balancing Strategies

Optimal Parameters

Telecom operators optimize rectifier module performance by maintaining strict control over environmental and electrical parameters. Clean and controlled environments, including regulated temperature and humidity, prevent damage and improve efficiency. Operators use cooling systems and dehumidifiers to manage heat and moisture, ensuring proper airflow and reducing stress on rectifier modules. Regular monitoring of voltage and current levels with sensors and diagnostic tools helps detect early signs of wear or failure.

Operators employ advanced modulation strategies, such as phase-shifting and space vector modulation, to enhance energy efficiency and minimize recovery time. Recovery times typically range from 80 to 147 milliseconds, depending on the chosen strategy. Routine cleaning every three to six months prevents dust buildup, which can cause overheating and degrade performance. Frequent inspection and tightening of connections, along with prompt replacement of damaged parts, maintain stable operation.

Updating firmware and software quarterly enhances reliability, security, and compatibility with new technologies. Operators schedule maintenance tasks—monthly, quarterly, and annually—tailored to environmental conditions and usage patterns. Selecting rectifiers with appropriate voltage and current ratings prevents overloading and premature failure. Advanced semiconductor materials, such as Silicon Carbide (SiC) and Gallium Nitride (GaN), improve thermal conductivity and electrical efficiency, supporting operation at higher voltages and temperatures.

Tip: Operators should always follow manufacturer guidelines and preventive maintenance schedules to maximize rectifier module lifespan and efficiency.

Predictive Maintenance

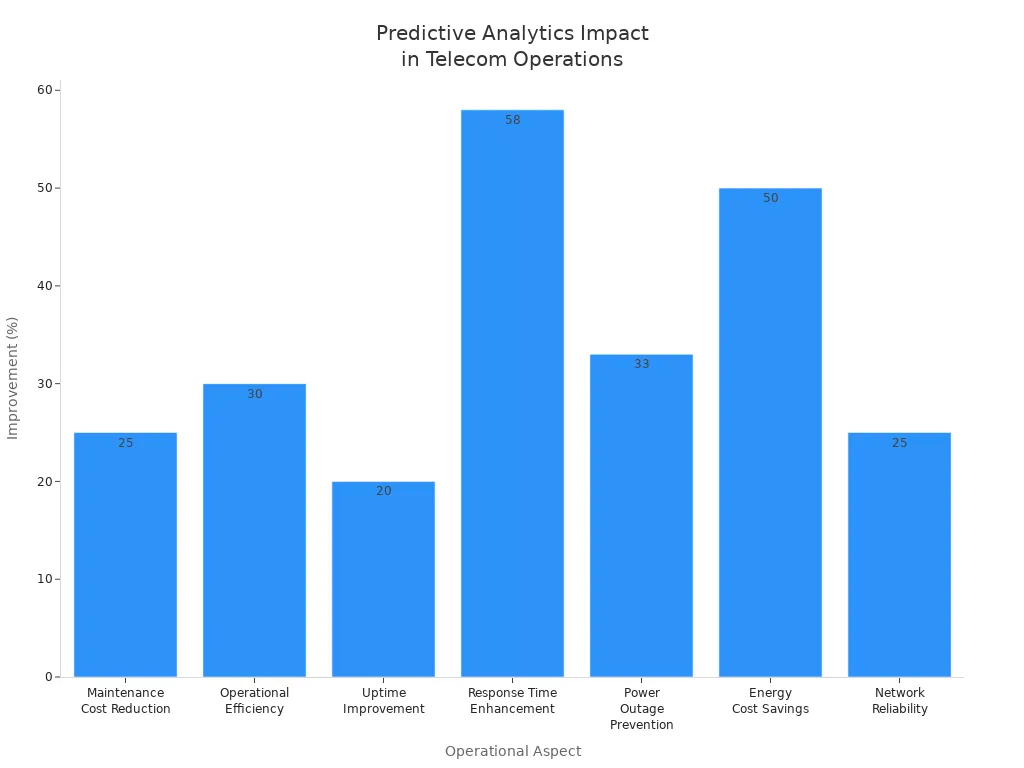

Predictive maintenance has transformed telecom cabinet operations. AI-driven analytics anticipate failures weeks in advance, enabling proactive interventions and reducing unexpected disruptions. Real-time monitoring with intelligent power distribution units (PDUs) and environmental sensors improves operational efficiency by approximately 30%. Automated incident categorization and anomaly detection reduce manual triage by 58%, cutting mean time to repair from 4.8 to 3.1 hours.

Continuous tracking of temperature, humidity, and airflow prevents overheating and environmental damage, extending equipment life. Real-time power consumption monitoring helps prevent overloads and power-related outages, which account for 33% of downtime. Facilities equipped with backup power and predictive analytics experience a 25% increase in operational reliability. Case studies show a 20% improvement in equipment uptime due to predictive maintenance and real-time monitoring.

Operators reduce emergency repairs and unnecessary site visits by up to 25%, lowering maintenance expenses. Advanced cooling and ventilation monitoring can decrease air conditioner power consumption by over 50%, contributing to cost management. Proactive monitoring and predictive analytics prevent 80% of recent telecom outages, demonstrating the value of data-driven maintenance strategies.

Upgrade Timing

Strategic upgrade timing balances cost, performance, and risk for telecom operators. Decision-makers focus on total cost of ownership, prioritizing energy efficiency to reduce operational and maintenance expenses. Matching rectifier module size to system power needs avoids overload and wasted energy. Advanced semiconductor technologies, such as GaN and SiC, achieve high efficiency levels between 97% and 98.5%. Modular designs support scalability and simplify future upgrades.

Operators mitigate risk by avoiding undersized modules, which can cause overloads and system failures. Compatibility with surge protective devices protects against voltage spikes. Certified converters meeting standards like NEBS Level 3, CSA/UL, VDE, GR-3108, and CE Mark ensure safety and reliability. Advanced monitoring tools enable early issue detection, while modularity simplifies maintenance and upgrades.

Cost Factors: Operators evaluate total cost of ownership, emphasizing energy efficiency and reduced maintenance expenses.

Performance Factors: Matching module size to power needs and using advanced technologies ensures optimal efficiency.

Risk Factors: Operators select certified converters and ensure compatibility with protective devices to safeguard sensitive electronics.

Additional Considerations: Environmental resilience and electromagnetic interference protection support long-term stable operation.

Note: Operators should schedule upgrades based on performance analytics, regulatory requirements, and evolving network demands to maintain reliability and cost-effectiveness.

Case Studies

Success Stories

Telecom operators have achieved remarkable results by adopting high-efficiency rectifier modules and data-driven maintenance strategies. A leading telecom provider improved energy efficiency to 97.8%, detected issues early, and expanded its network without experiencing downtime. GreenConnect reduced energy use by 30%, cut downtime by 25%, and lowered CO₂ emissions by 40%. These outcomes demonstrate the impact of advanced rectifier technology and predictive maintenance.

Case Study | Measurable Outcomes Related to Cost Savings and Reliability |

|---|---|

Leading Telecom | - Energy efficiency improved up to 97.8% |

Provider | - Early issue detection prevented service disruptions |

- Enabled seamless network expansion without downtime | |

GreenConnect | - 30% reduction in energy use |

- 25% reduction in downtime | |

- 40% decrease in CO₂ emissions |

Operators also reported maintenance costs dropping to 7% of those for traditional systems. Remote cloud-based monitoring reduced site visits. Battery life extended to 10 years, compared to the typical 2-year lifespan of lead-acid batteries. Pilot sites maintained reliable operation under extreme temperatures ranging from 20°F to 110°F. Many operators realized immediate and long-term savings, with payback periods between 6 months and 3 years.

Tip: Uninterrupted power supply and minimal routine maintenance have become standard for modern telecom cabinets.

Lessons Learned

Past O&M experiences have shaped current best practices for telecom cabinet rectifiers. Operators now integrate AI-driven predictive maintenance to forecast failures and minimize downtime. Wide bandgap semiconductors, such as silicon carbide and gallium nitride, enhance efficiency and thermal performance.

Regular performance monitoring with advanced tools prevents sudden failures.

Comprehensive training programs improve maintenance effectiveness.

Routine cleaning every 3–6 months, especially in harsh environments, avoids overheating.

Firmware updates every quarter boost reliability.

Early detection and repair of minor issues reduce costly downtime.

Environmental controls, including dust management and cooling, extend lifespan.

Keep detailed maintenance records and involve trained experts.

Monitor for overheating and voltage fluctuations.

Integrate smart power management systems and ensure compatibility with backup power.

Provide adequate ventilation and leverage modular designs for scalability.

Use AI and IoT for real-time monitoring and predictive maintenance.

Explore incentive programs to maximize savings.

Note: Matching voltage and current ratings, confirming surge protection, and complying with safety standards remain critical for long-term reliability.

Recommendations

Practical Steps

Telecom operators can achieve significant gains in efficiency and lifespan by following a structured approach to rectifier management. The following steps provide a clear roadmap for implementation:

Adopt modular and scalable rectifier systems. These systems allow easy upgrades, maintenance, and network expansion as demand grows.

Integrate remote monitoring and digital control systems. Real-time diagnostics and predictive maintenance reduce downtime and minimize on-site visits.

Leverage AI and automation technologies. These tools optimize energy use and detect faults early, supporting efficient network operation.

Use advanced materials such as silicon carbide and gallium nitride. These materials improve rectifier efficiency, reduce size, and enhance performance.

Incorporate hybrid power systems. Combining renewable energy sources like solar and wind with rectifiers increases sustainability and reliability.

Employ intelligent control and monitoring systems. Real-time data analytics and predictive alerts integrate seamlessly with network management platforms.

Implement intelligent battery backup systems. These systems ensure resilience during power outages and extend battery lifespan.

Evaluate current rectifier infrastructure. Consulting with experts helps select high-efficiency, redundant modules, such as N+1 configurations, to minimize downtime and energy loss.

Utilize emerging architectures like rectiverters. These enable flexible DC power flow, energy storage integration, and seamless backup transitions.

Stay informed about new technologies and regulations. Continuous learning ensures rectifier management aligns with evolving sustainability goals.

Operators should also consider the following recommended features and technologies for monitoring and optimizing rectifier performance:

Feature | Description |

|---|---|

Remote Monitoring | Enables operators to manage and monitor power systems remotely, providing real-time oversight. |

High Efficiency | Minimizes energy wastage and reduces operating costs. |

Modularity & Scalability | Supports easy expansion and flexible system upgrades. |

Redundancy & Backup | Ensures continuous power during outages with built-in redundancy and battery backup. |

Hot Swappable Modules | Allows maintenance without interrupting power supply, improving uptime. |

Advanced Protection | Safeguards equipment against overvoltage, overcurrent, and overheating. |

Operators who implement these steps and technologies position their networks for long-term reliability and cost savings.

Continuous Improvement

Ongoing success in rectifier management depends on continuous monitoring and adaptation. Operators should track key metrics and use advanced tools to maintain high performance:

Real-time monitoring of electrical parameters, such as voltage and current, ensures stable power delivery.

Tracking temperature and thermal management metrics, including temperature uniformity and thermal resistance, reduces stress and extends equipment lifespan.

Monitoring energy efficiency ratings helps minimize energy loss. Modern rectifiers often achieve efficiencies above 95%.

Utilizing AI-powered predictive maintenance, enabled by IoT technologies, allows operators to analyze performance data, predict failures, and reduce downtime.

Ensuring compliance with global energy standards and reducing standby power losses through advanced power management features, such as low-power sleep modes and zero-power standby circuits.

Operators should regularly review performance data, update firmware, and train staff on new technologies. These actions support a culture of continuous improvement and help maintain optimal efficiency and reliability.

By focusing on these practical steps and ongoing improvements, telecom operators can maximize the value of their rectifier investments and support the long-term stability of their networks.

Telecom operators achieve optimal results by combining high-efficiency rectifiers, modular designs, and AI-powered predictive maintenance. Key takeaways from a decade of O&M data include:

Modular systems lower upfront costs and support easy expansion.

Predictive maintenance reduces downtime and extends equipment lifespan.

Upgrading to 96–98% efficiency delivers significant energy and cost savings.

Integrated monitoring and regular inspections maximize reliability.

Operators who leverage benchmarking and analytics position their networks for long-term stability and growth.

FAQ

What is the ideal efficiency rating for telecom cabinet rectifiers?

Telecom experts recommend an efficiency rating between 96% and 98%. This range reduces energy loss and operating costs. High-efficiency modules also support sustainability goals and improve network reliability.

How often should operators perform preventive maintenance?

Operators should schedule preventive maintenance every three to six months. Regular inspections, cleaning, and firmware updates help prevent failures and extend equipment lifespan.

Which environmental factors most affect rectifier lifespan?

Temperature extremes, humidity, and dust exposure impact rectifier lifespan. Operators use sealed cabinets, cooling systems, and environmental sensors to maintain optimal conditions and protect equipment.

What are the benefits of modular rectifier designs?

Modular designs allow easy upgrades, quick repairs, and flexible capacity expansion. Operators can replace faulty modules without disrupting service, which improves uptime and reduces maintenance costs.

How does predictive maintenance improve network reliability?

Predictive maintenance uses AI and real-time monitoring to detect issues before failures occur. Operators reduce downtime, lower repair costs, and maintain stable power delivery across the network.

See Also

Steps To Guarantee Consistent Power For Telecom Cabinets

Solar Energy Storage Solutions Designed For Telecom Cabinets

Methods To Calculate Power Systems And Batteries For Telecom

Reasons Lithium Batteries Are Superior For Telecom Cabinets

Essential Material Specifications For Outdoor Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA