How High-Efficiency Telecom Cabinet Rectifiers Cut O&M Costs by 30%: Optimizing Inspection Frequency & Fault Response

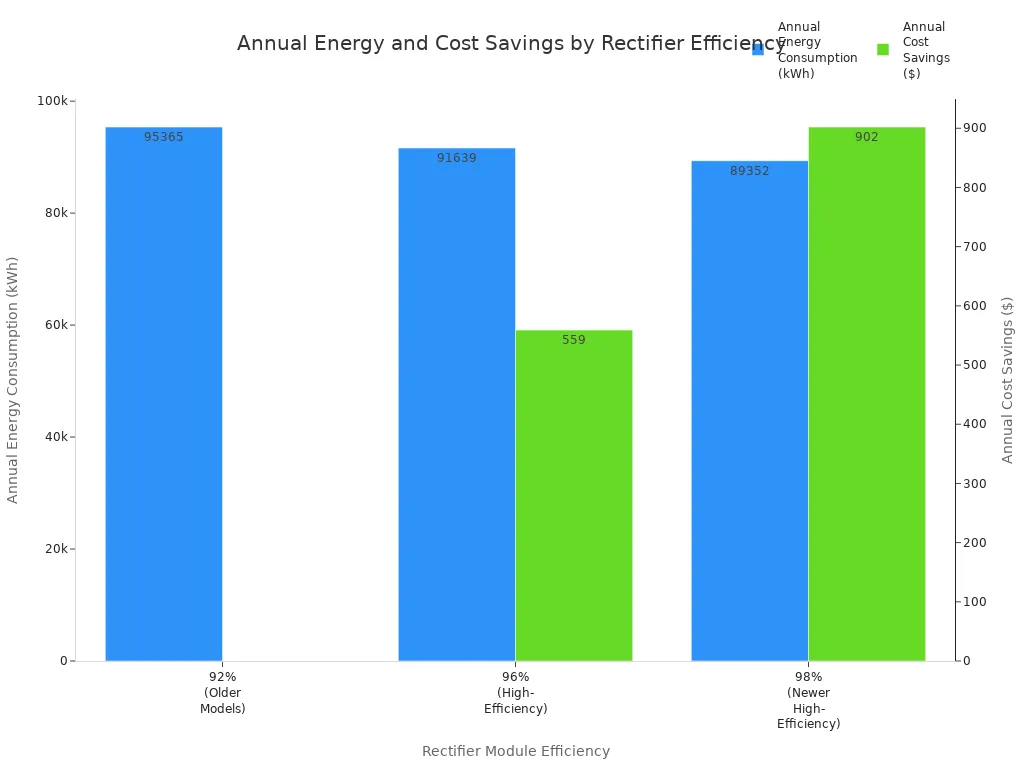

Upgrading to high-efficiency rectifier modules in telecom cabinets enables operators to cut operations and maintenance costs by up to 30%. Optimized inspection frequency and rapid fault response drive these savings, supported by advanced monitoring and predictive maintenance features. The following table shows how efficiency improvements deliver tangible financial results:

Metric | Evidence / Statistic | Explanation |

|---|---|---|

Average O&M Cost Reduction | Achieved through energy savings and hybrid power integration. | |

Annual Energy Savings per Cabinet | Over $600 saved | Upgrading from 92% to 96% efficiency reduces electricity use by nearly 4,000 kWh. |

Maintenance Savings | Significant reduction | Modular, hot-swappable rectifier modules and remote monitoring simplify upkeep. |

Network-wide Savings | Millions of dollars | Savings scale across large telecom networks. |

Operators achieve measurable reductions in energy use and maintenance complexity, making high-efficiency rectifier modules a strategic investment for telecom networks.

Key Takeaways

Upgrading to high-efficiency rectifier modules can cut telecom operations and maintenance costs by up to 30%, mainly through energy savings and easier maintenance.

Improved rectifier efficiency reduces electricity use and cooling costs, saving over $600 per cabinet annually and lowering heat inside cabinets.

Smart rectifier modules with predictive maintenance and remote monitoring help detect faults early, reduce downtime, and allow faster, remote troubleshooting.

Automated alerts and hot-swappable modules speed up fault response, cutting repair times and minimizing service interruptions.

Following best installation and maintenance practices, including modular designs and proper cooling, further lowers costs and improves network reliability.

Rectifier Module Efficiency

Energy Savings

Telecom operators can achieve substantial energy savings by upgrading to high-efficiency rectifier modules. When a network transitions from 92% to 96% efficiency, each cabinet consumes nearly 4,000 kWh less electricity per year. This improvement translates to over $600 in annual savings per cabinet, which can scale to millions across a large network.

Operators should follow these steps to maximize energy savings:

Assess Current Efficiency: Review the efficiency ratings of existing rectifier modules in all telecom cabinets.

Calculate Potential Savings: Multiply the number of cabinets by the expected kWh and dollar savings per unit.

Plan Upgrades Strategically: Prioritize sites with the highest energy consumption for immediate upgrades.

Tip: High-efficiency rectifier modules not only lower direct electricity costs but also reduce the load on backup power systems, extending battery life and minimizing generator runtime.

Cooling Cost Reduction

Improved rectifier efficiency offers another critical benefit: lower cooling costs. Less energy lost during power conversion means less heat generated inside the cabinet. As a result, air conditioning and ventilation systems work less, consuming less energy.

A recent industry analysis highlights that rectifier systems with over 97% conversion efficiency achieve this by minimizing power loss through advanced design features. Lower forward voltage drop and reduced leakage current help decrease wasted energy, which directly reduces heat output. Scientific studies further demonstrate that optimizing rectifier efficiency can cut cooling energy consumption by up to 28% under certain conditions. These findings show that enhanced rectifier module performance leads to measurable reductions in both electrical and cooling energy use.

Operators can optimize cooling cost reduction by:

Selecting High-Efficiency Models: Choose rectifier modules with proven low heat generation.

Monitoring Cabinet Temperatures: Use remote sensors to track temperature trends and adjust cooling settings accordingly.

Scheduling Regular Maintenance: Ensure cooling systems remain clean and efficient to maximize the benefits of reduced heat loads.

By focusing on both energy and cooling savings, telecom operators can significantly lower their overall O&M costs while improving network reliability.

Smart Rectifier Module Features

Modern telecom networks demand reliability, efficiency, and minimal downtime. Smart rectifier module features address these needs by combining advanced hardware design with intelligent software capabilities. Operators can leverage these innovations to streamline maintenance, optimize inspections, and ensure continuous service.

Predictive Maintenance

Predictive maintenance transforms traditional upkeep by shifting from reactive repairs to proactive interventions. Smart rectifier modules use real-time monitoring of voltage, current, and temperature to detect early signs of wear or abnormal operation. Integrated controllers and remote monitoring tools track system health, issuing alerts when parameters deviate from optimal ranges.

Operators benefit from:

Early Fault Detection: Alarm codes and fault indicators highlight issues before they escalate, allowing technicians to prioritize and resolve problems quickly.

Intelligent Battery Management: Advanced units monitor battery charge and discharge cycles, optimizing performance and extending battery life.

Environmental Monitoring: Sensors track internal cabinet conditions, such as temperature and humidity, to prevent overheating and equipment degradation.

Self-Diagnostics: Built-in diagnostics and standardized components simplify repairs, reducing downtime and maintenance costs.

Redundancy: N+1 configurations ensure continuous operation, even if one module fails.

By implementing predictive maintenance, telecom operators reduce unplanned downtime and extend the lifespan of critical infrastructure. Smart power systems, supported by IoT and AI technologies, analyze historical data to forecast failures and recommend timely interventions. This approach minimizes service interruptions and supports high network availability.

Tip: Schedule regular reviews of predictive maintenance data to identify trends and optimize inspection intervals. This proactive strategy helps prevent costly outages and improves overall reliability.

Remote Monitoring

Remote monitoring empowers operators to manage rectifier modules from any location, reducing the need for on-site inspections. Modern systems provide real-time performance tracking, enabling early detection of faults and rapid response to emerging issues.

Key features include:

Real-Time Status Checks: Operators can view rectifier status, power distribution, battery health, and environmental conditions through web browsers, mobile apps, or local displays.

Automated Alerts: Intelligent alarms notify staff of deviations, failures, or unauthorized access via SMS, phone, email, or visual indicators.

Integration with Third-Party Platforms: Protocols such as SNMP, ModbusTCP, MQTT, and HTTP allow seamless data sharing and centralized management.

Flexible Access: Remote desktop management and mobile inspection tools enable quick responses, even outside regular working hours.

Scalability: Modular design combined with remote monitoring supports easy expansion and high operational reliability.

AI and IoT integration further enhance remote monitoring. Smart sensors collect continuous data, while machine learning algorithms analyze trends to predict failures and optimize maintenance schedules. Operators receive automatic alerts for anomalies, enabling timely interventions and reducing manual inspection frequency.

Note: Implementing remote monitoring not only reduces operational expenses but also improves network uptime by facilitating faster troubleshooting and repair.

Operators who adopt these smart rectifier module features achieve greater efficiency, lower maintenance costs, and improved service continuity. By combining predictive maintenance with robust remote monitoring, telecom networks can optimize inspection frequency and respond rapidly to faults, ensuring long-term operational excellence.

Fault Response Optimization

Automated Alerts

Automated alert systems play a crucial role in optimizing fault response for telecom power systems. These systems detect anomalies in real time and notify operators immediately, reducing the need for manual checks. Operators can leverage automated alerts to streamline their maintenance workflow and minimize downtime.

Metric Description | Reduction/Improvement |

|---|---|

Mean Time to Repair (MTTR) | Reduced from 4.8 hours to 3.1 hours (1.7-hour reduction, ~35%) |

Manual triage time via automated incident categorization | Reduced by 58% |

Response time reduction from real-time drone feeds during crises | Reduced by 30 minutes |

Maintenance response time improvement via remote monitoring services | Improved by 40% |

To optimize fault response using automated alerts, operators should:

Set up real-time monitoring tools that track voltage, current, and temperature.

Configure alert thresholds for critical parameters.

Integrate alert notifications with mobile devices and centralized dashboards.

Train staff to interpret and act on alerts promptly.

Tip: Automated alerts not only speed up fault detection but also help prioritize maintenance tasks, ensuring that critical issues receive immediate attention.

Rapid Troubleshooting

Rapid troubleshooting depends on advanced diagnostic tools and streamlined maintenance procedures. Modern systems provide features that enable technicians to identify and resolve faults quickly, minimizing service interruptions.

Diagnostic tools display error codes and warnings, allowing technicians to pinpoint root causes.

Real-time monitoring and control features provide instant access to system health data.

Digital control systems enable precise adjustments for reliability and efficiency.

Alarm and error codes alert users to issues early, supporting prompt intervention.

Hot-swap capability allows quick replacement of faulty modules without shutting down the system.

Firmware update mechanisms address bugs and improve stability, aiding troubleshooting.

Smart power management systems, such as those with hot-pluggable modules and remote controllers, allow operators to replace faulty components without interrupting service. This design reduces the need for site visits and supports continuous network operation. Operators should also maintain a record of alarm codes and ensure that maintenance personnel receive comprehensive training. These steps help teams resolve faults efficiently and maintain high network uptime.

Note: Routine maintenance, environmental controls, and the use of high-quality replacement parts further enhance rapid troubleshooting and reduce the risk of recurring faults.

Cost Reduction Strategies

Maintenance Savings

Telecom operators can achieve significant cost reductions by targeting energy, maintenance, downtime, and installation expenses. High-efficiency rectifier modules play a central role in this process. Operators often see energy consumption drop by up to 50% due to improved conversion efficiency, which directly lowers electricity bills. Reliable system design and advanced monitoring features reduce the need for frequent site visits. Smart rectifier modules enable remote monitoring and predictive maintenance, allowing early detection of potential failures. This approach cuts maintenance visits by up to 40% compared to reactive maintenance, saving both time and labor costs.

Operators can implement the following strategies to maximize maintenance savings:

Simplify system design with one cabinet per site and modular, hot-swappable components.

Integrate AC input, rectifier modules, batteries, and monitoring units into a single cabinet to reduce cable complexity and failure points.

Use AI-enabled monitoring for autonomous network management and optimal resource allocation.

Replace lead-acid batteries with lithium batteries to extend battery life and reduce replacement frequency.

Tip: Modular and scalable designs make upgrades and repairs faster, minimizing downtime and technician travel.

Installation Best Practices

Proper installation ensures long-term reliability and further reduces operational costs. Operators should select redundancy levels that match their reliability needs. The table below summarizes common redundancy configurations:

Redundancy Level | Suitable For | Key Benefit | Main Trade-Off |

|---|---|---|---|

N+1 | Most commercial systems | Balanced reliability | Moderate cost and complexity |

N+2 | High-availability systems | Enhanced resiliency | Higher cost and space |

2N | Mission-critical operations | Maximum uptime | Highest cost and complexity |

Operators should follow these best practices:

Ensure proper cooling by maintaining airflow and cleaning heat sinks.

Monitor performance with real-time tools to detect anomalies early.

Choose high-efficiency rectifier modules with modular, hot-swappable designs.

Consider environmental conditions and follow manufacturer guidelines for installation and replacement.

Balance initial investment with total cost of ownership, factoring in energy savings and reduced maintenance.

Field studies show that these practices can reduce maintenance costs by 35% and increase system uptime by 25%. Operators who follow structured decision-making and risk assessment avoid hidden costs and reliability gaps, ensuring continuous service and predictable maintenance schedules.

Telecom operators who upgrade to high-efficiency rectifier modules see up to 30% reductions in O&M costs. The table below highlights long-term financial benefits, including lower energy expenses, reduced maintenance, and improved scalability.

Financial Benefit Aspect | Description and Impact on Long-Term Costs |

|---|---|

Energy Efficiency | Reduces electricity and cooling costs. |

Maintenance & Support | Cuts maintenance costs and site visits. |

Scalability | Enables cost-effective network growth. |

Renewable Energy Integration | Supports sustainability goals. |

Reliability & Uptime | Minimizes downtime and protects revenue. |

Operators should select certified modules, such as NEBS Level 3 and CSA/UL, to ensure reliability and safety. Overcoming barriers like high initial costs and compatibility issues requires modular designs and AI-driven maintenance. These strategies maximize ROI and support long-term network growth.

FAQ

How can operators determine if their cabinets need rectifier upgrades?

Operators should review energy bills and inspect module efficiency ratings. They can compare current consumption with high-efficiency benchmarks. If costs exceed industry averages, upgrades may deliver significant savings.

What steps improve fault response times in telecom cabinets?

Operators should enable automated alerts and remote monitoring. They must train staff to interpret notifications and act quickly. Using hot-swappable modules allows technicians to replace faulty units without service interruption.

Which features support predictive maintenance in rectifier modules?

Smart modules use sensors to monitor voltage, current, and temperature. Integrated controllers analyze data and issue early warnings. Operators can schedule maintenance based on these alerts, preventing unexpected failures.

What installation practices maximize rectifier module reliability?

Operators should select certified modules and follow manufacturer guidelines. They must maintain proper airflow and clean heat sinks regularly. Using modular designs simplifies upgrades and repairs, reducing downtime.

How do remote monitoring systems reduce O&M costs?

Remote monitoring provides real-time data on cabinet performance. Operators can detect issues early and avoid unnecessary site visits. Automated alerts and centralized dashboards streamline maintenance, lowering operational expenses.

See Also

Steps To Guarantee Consistent Power For Telecom Cabinets

Understanding Telecom Cabinet Design And Associated Expenses

Best Practices For Effective Outdoor Telecom Cabinet Monitoring

Exploring Various Cooling Techniques Used In Telecom Cabinets

Reasons Lithium Batteries Excel Over Others In Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA