How to Set Up Remote Monitoring for Telecom Cabinets with ESTEL

You can set up remote monitoring for telecom cabinets with ESTEL by first identifying your monitoring needs, then selecting suitable sensors, integrating hardware and software, and configuring alerts. Real-time monitoring lets you detect issues early, improve security, and reduce downtime. When you choose the right equipment and connectivity, you gain real-time alerts for telecom cabinet conditions.

Key performance indicators include device status, bandwidth usage, and network component availability. Alerts for hardware failure and security threats help you minimize downtime and enhance operational efficiency.

Benefit Description | Numerical Evidence | Impact Description |

|---|---|---|

Activation of power saving algorithm on rectifiers | > 2% decrease in overall site energy consumption | Over 30 million kWh energy saved annually |

Removal of excess converter modules | > 500,000 kWh energy saved annually | Reduced residual electricity consumption |

Deployment of free air cooling remote management | Site temperature increased from 24°C to 30°C | > 10 million kWh annual savings in air conditioning energy |

Follow each step to build a reliable and scalable remote monitoring system for your telecom cabinets.

Key Takeaways

Remote monitoring helps detect telecom cabinet issues early, reducing downtime and improving security.

Using sensors for temperature, power, and access control increases equipment uptime and cuts maintenance time.

Setting up involves planning sensor types, installing hardware carefully, and configuring software alerts.

Real-time alerts and reports allow quick responses to problems, preventing costly failures.

Design your system for scalability and strong data security to support network growth and protect sensitive information.

Why Remote Monitoring for Telecom Cabinet

Common Issues in Telecom Cabinets

You face many challenges when managing telecom cabinets. Without remote monitoring for telecom cabinet systems, you often rely on manual inspections, which are costly and inefficient. Problems can go unnoticed, leading to unexpected failures and service interruptions. Here are some of the most common issues:

Common Issue Category | Specific Issues / Parameters Monitored | Impact / Reason for Remote Monitoring Adoption |

|---|---|---|

Battery Health Monitoring | Voltage, temperature, internal resistance of individual units | Early detection of battery failures, extends power supply life |

Power Monitoring | Rectifier current, voltage, power, multiple power sources | Prevents power failures, optimizes energy consumption |

Intrusion Detection & Security | Door open alarms, smoke detectors, access control systems | Enhances site security, prevents unauthorized access and vandalism |

Environmental Monitoring | Temperature, humidity, smoke, flooding risks | Protects sensitive equipment from environmental damage |

Generator Management | Start/stop control, fuel level monitoring | Ensures reliable backup power, optimizes fuel usage |

Communication Protocols | Handling multiple protocols, alarm inputs/outputs | Enables integration and scalability of monitoring systems |

Notification & Control Systems | Real-time alerts via text, email, voice; remote control commands | Reduces on-site interventions, speeds response, minimizes downtime |

Frequent physical inspections increase costs and do not always catch problems early. Real-time monitoring helps you detect equipment issues before they cause downtime. Security risks, such as theft or vandalism, also require constant attention.

Benefits of Remote Monitoring

Remote monitoring for telecom cabinet solutions give you powerful tools to protect your equipment and maintain network uptime. Real-time monitoring tracks temperature, humidity, and power usage, allowing you to respond quickly to any changes. You can prevent failures and extend the life of your telecom equipment.

Feature/Metric | Impact/Description |

|---|---|

Predictive Maintenance | Continuous monitoring prevented a major malfunction that could have caused a three-day production halt, reducing unplanned downtime. |

Automated Incident Categorization | Reduced manual triage by 58%, speeding up initial response to telecom events. |

AI-driven Anomaly Detection | Improved early issue detection in 65% of deployments, enabling proactive maintenance. |

Mean Time to Repair (MTTR) | Reduced from 4.8 hours to 3.1 hours, ensuring faster incident resolution. |

Instant notifications for critical events like unauthorized access or power failures minimize downtime. | |

Mean Time Between Failures (MTBF) | Rated at over 100,000 hours, indicating very high reliability and low failure rates. |

Thermal Management | Temperature sensors and automatic shutdown prevent overheating and failures. |

Fault Tolerance | Design features prevent downtime by effectively handling faults, ensuring continuous operation. |

You benefit from up to 21% annual electricity cost savings and a 5.8% reduction in cooling system energy use. These improvements support network uptime and reduce operational costs. Remote monitoring also supports scalability, so you can expand your telecom network without major changes. With centralized management, you improve operational efficiency and reduce training needs. Equipment protection becomes proactive, not reactive, and you gain peace of mind knowing your telecom cabinets are secure and reliable.

System Components

Telecom Cabinet Sensors

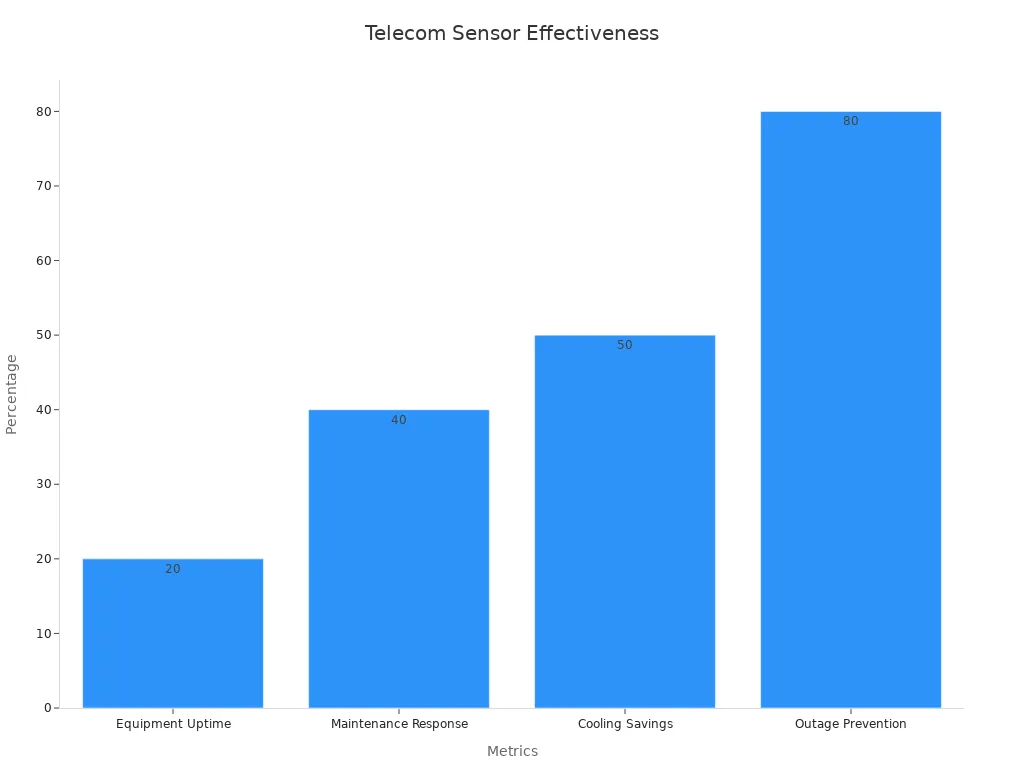

You rely on telecom cabinet sensors to keep your telecom infrastructure safe and efficient. These sensors track temperature, humidity, airflow, battery health, motion, door status, tilt, shock, smoke, and water presence. By using telecom cabinet sensors, you gain real-time monitoring and proactive maintenance. This approach reduces on-site visits and increases equipment uptime by 20%. You also see maintenance response times improve by 40%. Sensors with backup power keep working during outages, so you never lose critical data. Cabinet analysis sensors create thermal maps and detect hot spots, which helps prevent failures and fire risks. Security sensors like motion and door sensors add extra layers of equipment protection. Intelligent monitoring and automated energy management can cut cooling power use by over 50%. AI-driven analytics in telecom cabinet sensors predict failures weeks in advance, so you can schedule just-in-time repairs and avoid downtime.

Aspect | Evidence and Findings |

|---|---|

Sensor Types | Temperature, humidity, airflow, battery health, motion, door, tilt, shock, smoke, water sensors |

Monitoring Capabilities | Real-time remote monitoring enables proactive maintenance and reduces on-site visits |

Performance Improvements | 20% increase in equipment uptime; 40% faster maintenance response times; energy savings via intelligent power management |

Power Independence | Backup power ensures continuous sensor operation during outages, enhancing reliability |

Thermal Management | Cabinet analysis sensors measure multiple temperature points and differential pressure to create thermal maps and detect hot spots, preventing equipment failures and fire risks |

Security Enhancements | Motion, door, tilt, and shock sensors add layers of physical security to telecom cabinets |

Energy Efficiency | Intelligent monitoring and automated energy management reduce power consumption, with documented reductions over 50% in cooling power usage in related systems |

Predictive Maintenance | AI-driven analytics anticipate failures weeks in advance, enabling just-in-time maintenance and reducing downtime |

Network Uptime | Real-time alerts and remote monitoring help prevent outages, with research showing 80% of recent outages were preventable through such measures |

Power Monitoring

Power monitoring forms the backbone of reliable telecom cabinet operations. You use high-efficiency rectifier power supplies that often exceed 97% efficiency, which saves energy and reduces costs. Modular rectifier systems let you scale up or add redundancy without service interruptions. Real-time monitoring of voltage, battery status, and system health allows you to spot issues early and take action before they cause downtime. Advanced battery management features extend uptime during power disturbances. Protection mechanisms like over-voltage and short-circuit protection keep your telecom equipment safe from power fluctuations. Smart thermal management and surge protection further enhance equipment protection and network uptime. These features reduce field service visits and lower operational expenses.

Access Control

Access control systems play a vital role in telecom cabinet security. You secure your telecom cabinets with lockable doors, tamper-proof designs, and restricted access systems. Advanced access control sends alerts if someone tries to open a cabinet without permission or if environmental conditions change suddenly. These features are especially important for outdoor telecom installations, where theft and vandalism risks are higher. By using access control, you protect valuable network equipment and ensure the reliability of your telecom infrastructure.

Setup Steps

Planning and Assessment

You start your remote monitoring project by planning and assessing your telecom cabinet needs. Begin by identifying the key performance indicators you want to track, such as temperature, humidity, power usage, and access events. List all telecom cabinets that require monitoring and note their locations. Evaluate the environment for each site. Some cabinets may be in harsh outdoor conditions, while others sit in controlled indoor spaces. This assessment helps you choose the right sensors and hardware.

Next, select the types of sensors and devices you need. You can use digital, analog, or MODBUS sensors from different brands, but always confirm compatibility and test them before full deployment. Decide if you need wired or wireless sensors based on your site’s infrastructure. For remote sites, cellular or satellite connectivity may work best. For urban or indoor locations, Ethernet or WiFi may be more reliable.

Plan for system scalability. Choose a base unit that supports your current number of sensors and allows for future expansion. Consider backup power options to keep your monitoring system running during outages. This step ensures continuous monitoring and reliable threshold alerts, even when the main power fails.

Tip: Involve your field engineers early. Their experience with telecom cabinets and monitoring systems can help you avoid common pitfalls.

Hardware Installation

After planning, move to hardware installation. Start by mounting the sensors inside each telecom cabinet. Place temperature and humidity sensors away from heat sources for accurate readings. Install door and motion sensors at entry points to detect unauthorized access. Use water and smoke sensors in areas prone to leaks or fire risks.

You can connect your monitoring units to a wide range of sensors, but always test for compatibility.

Some installations are simple, but complex environments like pump houses may need an electrician or contractor.

Choose the right communication method: internet, WiFi, cellular, or landline. Match the method to your site’s needs and available infrastructure.

Select a system that can handle your current and future sensor requirements.

Use backup batteries to keep threshold alerts and monitoring active during power outages.

Install power distribution units (PDUs) to monitor and manage power usage. Intelligent PDUs provide real-time monitoring and send alerts if power thresholds are breached. This helps you prevent equipment damage and downtime. Secure all cables and label each sensor for easy identification during maintenance.

Note: Careful installation and calibration of sensors ensure accurate data and reliable threshold alerts.

Software Configuration

Once you finish hardware installation, configure the software platform. Use a step-by-step approach to set up your remote monitoring system:

Add each telecom cabinet and its sensors to the management dashboard.

Assign clear names and locations to each device for easy tracking.

Set up data visualization tools to display real-time monitoring information.

Configure threshold alerts for each parameter. For example, set temperature alerts to trigger if the cabinet exceeds safe limits.

Integrate access control systems so you receive alerts for unauthorized entry.

Enable data logging to keep a record of all events and sensor readings.

Test the system by simulating different scenarios, such as opening a cabinet door or raising the temperature.

Document Type | Purpose | Relevance to Remote Monitoring Setup |

|---|---|---|

Method of Procedure (MoP) to commission OLT | Step-by-step setup of primary access network device | Ensures correct initial configuration of devices critical for remote monitoring |

MoP to commission ONT | Procedures to bring ONT online and prepare for management | Supports device provisioning and monitoring readiness |

MoP for deploying new software baseline | Instructions for receiving, assessing, and deploying software updates | Ensures software versions are correctly applied for monitoring stability and features |

Design of network monitoring solutions | Specifications for telemetry and monitoring tools integration | Directly supports remote monitoring setup and operation |

Backup and restore strategies | Procedures to secure and recover configuration and provisioning data | Critical for maintaining configuration integrity in remote monitoring environments |

You should train your team on how to use the software, interpret data, and respond to alerts. Regular training ensures everyone can act quickly when threshold alerts occur.

Alerts and Reporting

Alerts and reporting form the core of your telecom remote monitoring system. Set up threshold alerts for every critical parameter, such as temperature, humidity, power load, and unauthorized access. Use tiered alerts to notify the right people based on the severity of the issue. For example, a minor temperature rise might send an email, while a power failure triggers a phone call and text message.

Backup power systems increase reliability by 25%, keeping threshold alerts active during outages.

Remote monitoring services improve maintenance response times by 40%, so you resolve issues faster.

PDUs send alerts when power thresholds are exceeded, helping you prevent equipment damage.

Environmental sensors provide alerts for temperature and humidity risks, allowing you to act before problems escalate.

Intelligent PDUs with real-time monitoring and remote management reduce downtime risks by sending instant alerts.

Different PDU types offer real-time monitoring, alarming, and remote control, all supporting telecom cabinet uptime.

You can use the reporting tools to analyze trends and identify recurring issues. Reports help you spot patterns, such as frequent threshold alerts for high temperature in a specific cabinet. This insight lets you take preventive action, like improving ventilation or upgrading equipment.

Remember: Continuous monitoring and timely threshold alerts protect your telecom infrastructure and keep your network running smoothly.

Best Practices for Remote Monitoring

Scalability

You should design your telecom remote monitoring system with scalability in mind. As your telecom network grows, your monitoring solution must adapt without causing disruption. ESTEL’s smart PDUs and environmental monitoring systems integrate with DCIM tools, allowing you to manage both IT and physical infrastructure from a single platform. This unified approach supports expansion and reduces complexity. For example, a major data center in Asia used ESTEL’s smart PDUs and achieved a 15% reduction in energy consumption. Another telecom company improved equipment uptime by 20% and lowered maintenance costs after deploying intelligent PDUs across its network.

Case Study Description | Outcome |

|---|---|

Major data center in Asia implemented ESTEL’s smart PDUs | 15% reduction in energy consumption, supporting scalable growth |

Telecom company deployed intelligent PDUs for outlet-level monitoring | 20% increase in equipment uptime, reduced maintenance costs |

You can also use predictive maintenance to forecast equipment failures and schedule timely interventions. This approach prevents service disruptions and supports long-term scalability.

Maintenance

Regular maintenance is essential for reliable telecom cabinet operation. You need to schedule routine checks and system health assessments to catch issues early. Research shows that equipment downtime can cause annual losses exceeding €360,000, much of which you can prevent with early warning systems. Remote monitoring detects deviations in temperature or humidity, allowing you to perform preventative maintenance before failures occur. Real-time alerts via SMS or email help you respond quickly and optimize your maintenance schedule.

Schedule regular inspections and software updates.

Use trend analysis to identify patterns and address recurring issues.

Keep detailed records of all maintenance actions for compliance and future reference.

Wireless and internet-based remote monitoring reduce labor costs and provide 24/7 oversight.

By following these steps, you extend the lifespan of your telecom equipment and maintain network uptime.

Data Security

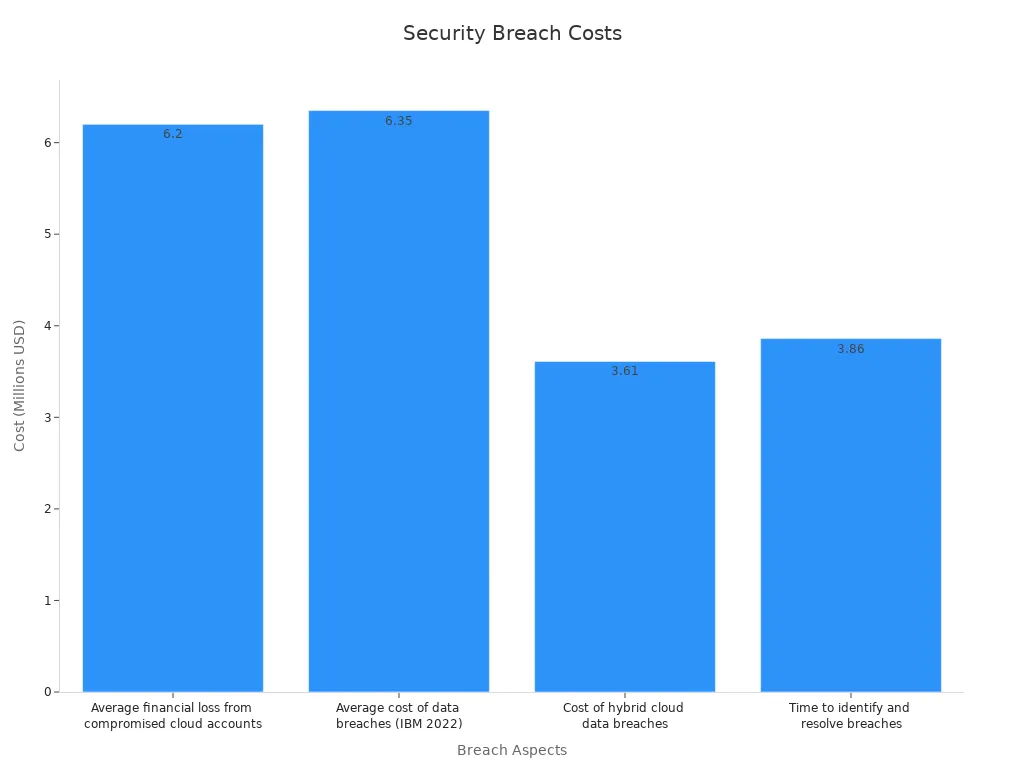

You must prioritize security in your telecom remote monitoring setup. Data breaches can have severe financial impacts. For example, breaches involving remote work cost $1 million more on average than those without remote work. Cloud data breaches are common, with 98% of companies experiencing at least one in recent years. The average cost of a data breach reached $6.35 million in 2022.

Evidence Aspect | Statistic / Finding | Impact / Cost (USD) |

|---|---|---|

Cost difference of breaches involving remote work | $4.99M vs $4.02M | $1M higher with remote work |

Prevalence of cloud data breaches | 98% of companies affected | N/A |

Average cost of data breaches (IBM 2022) | Up to $6.35M | $6.35M |

Time to identify and resolve breaches | 186 days to identify, 65 days to remediate | $3.86M total cost |

To protect your telecom cabinets, use encrypted communication, strong authentication, and regular security audits. Always update firmware and software to patch vulnerabilities. Limit access to authorized personnel and monitor for unusual activity. These steps help you safeguard sensitive data and maintain the integrity of your telecom network.

You can achieve reliable network performance by following the steps for remote monitoring for telecom cabinet systems with ESTEL. Proactive monitoring improves security and keeps your equipment running. Case studies show that telecom operators reduced alarm frequency by 19% and increased first-time resolution rates by 92% after using real-time monitoring. You gain fewer alarms, faster repairs, and less downtime. Start your journey today or reach out to ESTEL for expert support and tailored solutions.

FAQ

What types of sensors can you use with ESTEL remote monitoring?

You can use temperature, humidity, door, motion, smoke, water, and power sensors. ESTEL supports both digital and analog sensors. Always check compatibility before installation.

How do you receive alerts from the system?

You receive alerts by SMS, email, or phone call. The system sends notifications based on the severity of the issue. You can customize alert settings for each cabinet.

Can you monitor multiple telecom cabinets from one dashboard?

Yes, you can view and manage all your telecom cabinets from a single dashboard. This feature helps you track equipment status and respond quickly to any issues.

Is it possible to expand the monitoring system as your network grows?

You can easily add more sensors or cabinets to your ESTEL system.

The platform supports scalability, so you can expand without replacing existing equipment.

How do you keep your monitoring data secure?

You protect your data with encrypted communication, strong passwords, and regular software updates. Only authorized users can access the system. Regular audits help you maintain security.

See Also

Best Practices For Effective Monitoring Of Outdoor Telecom Cabinets

Simplified Steps To Install ESTEL Outdoor Telecom Cabinets

Understanding The Power System Inside ESTEL Telecom Cabinets

Exploring The Safety Design Of Custom ESTEL Outdoor Cabinets

How Supervision Systems Are Integrated Into ESTEL Outdoor Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA