Why ESTEL Scalable DC Power Systems Matter for Industries in 2025

Modern industries rely on scalable DC rectifier systems to maintain efficiency and adapt to changing demands. These systems improve reliability and simplify operations, making them indispensable for businesses. ESTEL’s innovative solutions stand out by offering modular designs that grow with your needs. You can expand or upgrade without replacing entire systems, ensuring adaptability and cost savings. Whether powering data centers or supporting renewable energy, ESTEL’s scalable DC rectifier systems deliver unmatched flexibility. Their ability to meet evolving industrial requirements showcases why they matter now more than ever.

Key Takeaways

Scalable DC power systems improve efficiency and flexibility. Industries can expand without changing all their equipment.

ESTEL systems have modular designs. These make upgrades and repairs simple, cutting downtime and keeping power steady.

ESTEL systems include safety features. These protect workers and machines from electrical problems.

Using scalable systems prepares businesses for new tech like green energy and electric cars.

Picking ESTEL systems saves money and boosts efficiency. They use energy better and create less waste.

Understanding Scalable DC Power Systems

Definition and Features of DC Rectifier Systems

A DC rectifier system is a critical component in modern industrial operations. It converts alternating current (AC) into direct current (DC), ensuring a stable and reliable power supply for sensitive equipment. These systems are widely used in applications such as electroplating, anodizing, and industrial power distribution. Their high efficiency and precise voltage control make them indispensable for industries requiring configurable power supplies.

Key features of DC rectifier systems include their ability to adjust AC supply voltage based on specific requirements. This adaptability ensures optimal performance across various industrial processes. Additionally, these systems combine a transformer with a rectifier unit, enhancing their efficiency and reliability. The table below highlights some essential aspects of DC rectifier systems:

Feature | Description |

|---|---|

Key Drivers | Information related to key drivers, restraints, and opportunities in the rectifiers controllers market. |

Market Growth Scenario | Current market is quantitatively analyzed to highlight growth scenario. |

Competitive Analysis | Porter’s five forces analysis illustrates the potency of buyers & suppliers in the market. |

Market Analysis | Detailed analysis based on competitive intensity and future competition shape. |

Scalability and Flexibility in Industrial Applications

Scalability and flexibility are essential for industries aiming to adapt to evolving demands. DC rectifier systems excel in these areas, offering modular designs that allow you to expand or reconfigure power supplies as needed. This capability reduces downtime and ensures seamless integration with emerging technologies.

Recent studies emphasize the scalability benefits of DC power systems. These systems enhance operational efficiency, handle high power loads, and support renewable energy integration. For example, advancements in power electronics have made DC systems more modular, simplifying their scaling for applications like green buildings and EV infrastructure. By investing in scalable solutions, you future-proof your operations and maintain a competitive edge.

The Importance of Safety in Power Distribution

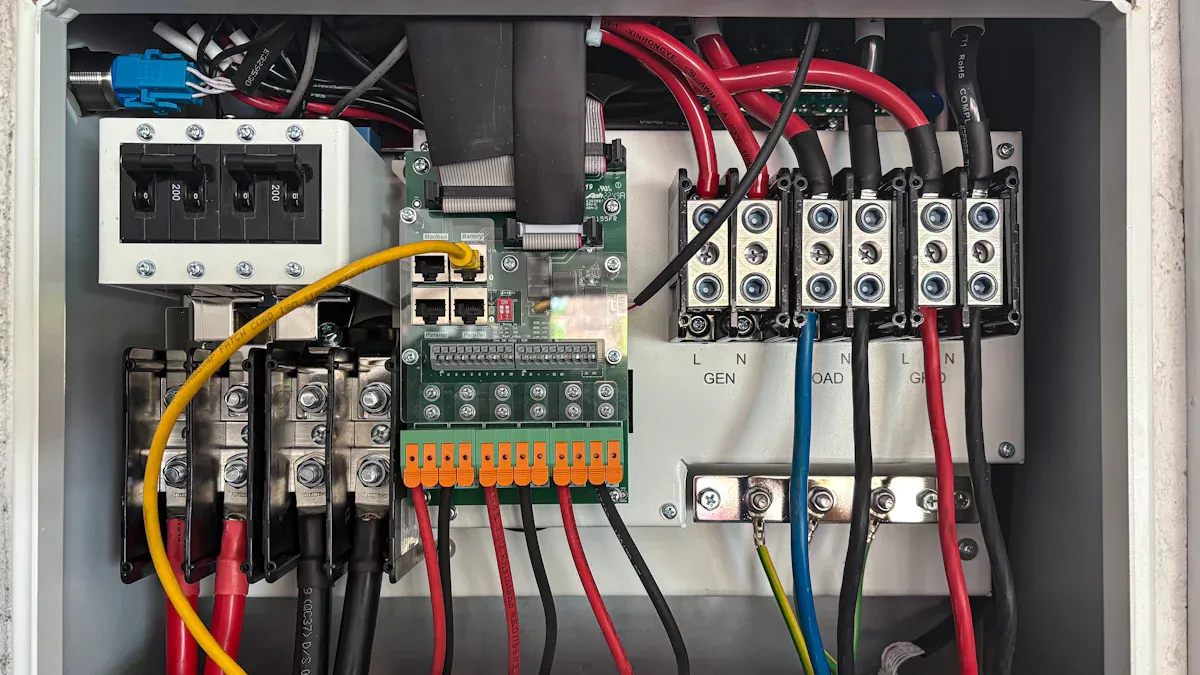

Safety is a cornerstone of any industrial power system. DC rectifier systems incorporate advanced safety features to protect both equipment and personnel. Circuit breakers, ground fault interrupters, and surge protectors mitigate risks associated with electrical faults. Real-time monitoring tools further enhance safety by identifying potential issues before they escalate.

Busways, a common component in modern power distribution, offer additional safety benefits. They provide arc flash protection, reducing the risk of dangerous explosions. Their modular design minimizes human error by enabling connections without direct exposure to live electrical components. By prioritizing safety and compliance, you ensure the longevity and reliability of your power systems.

Challenges Without Scalable DC Power Systems

Inefficiencies in Industrial Power Distribution Systems

Without scalable DC power systems, industrial power distribution systems often face significant inefficiencies. Traditional systems struggle to handle the growing demands of modern industries. As your operations expand, these systems fail to distribute power effectively, leading to energy losses and higher operational costs. This inefficiency directly impacts your bottom line and reduces overall productivity.

Conventional industrial power distribution systems also lack the ability to adapt to varying power loads. For instance, when multiple grid nodes operate at diverse voltage levels, traditional systems experience bottlenecks. Simulations show that scalable platforms efficiently manage datasets from multiple grid nodes, ensuring smooth processing. In contrast, outdated systems increase processing time and resource usage as grid complexity grows. These inefficiencies highlight the need for scalable solutions to maintain operational efficiency and reduce energy waste.

Limited Scalability and Operational Constraints

Traditional industrial power distribution systems impose severe limitations on scalability. As your business grows, these systems cannot expand or adapt to meet new requirements. This lack of flexibility forces you to invest in entirely new infrastructure, which increases costs and disrupts operations. Scalable DC power systems, on the other hand, allow you to add or reconfigure modules as needed, ensuring seamless growth.

Operational constraints also arise from the inability of conventional systems to handle complex industrial processes. For example, as the number of grid nodes increases, traditional systems struggle to distribute computational loads effectively. This results in delays and inefficiencies that hinder your ability to meet production targets. Research shows that scalable platforms distribute loads efficiently, even as grid size and complexity increase. By adopting scalable solutions, you can overcome these constraints and future-proof your operations.

Increased Risks to Safety and Reliability

Safety and reliability are critical in industrial power distribution systems. Without scalable DC power systems, you face increased risks of equipment failures and outages. Severe weather events, for example, account for over half of electric disturbances, affecting millions of customers annually. Traditional systems lack the advanced safety features needed to mitigate these risks, leaving your operations vulnerable to disruptions.

Equipment failures and human error also contribute to reliability issues. Studies reveal that 70% of electrical outages stem from equipment problems, while human error accounts for up to 17%. These incidents not only disrupt operations but also increase costs due to property damage and business interruptions. Upgrading to scalable DC power systems enhances safety by incorporating advanced monitoring tools and fault protection mechanisms. These features reduce the likelihood of accidents and ensure consistent power distribution across your facilities.

Refineries and chemical plants have already begun investing in automation and upgrading legacy safety systems to address these challenges. By adopting scalable DC power systems, you can enhance safety, improve reliability, and minimize the risks associated with outdated infrastructure.

Benefits of ESTEL Scalable DC Power Systems

Modularity for Tailored Industrial Solutions

Modularity is a game-changer for industries seeking tailored power supply solutions. ESTEL's scalable DC power systems offer modular designs that adapt to your specific needs. You can add or replace individual modules without overhauling the entire system. This flexibility ensures that your operations remain uninterrupted, even as your power demands evolve.

The modular nature of these systems also enhances reliability. Faults are isolated to specific modules, reducing downtime and simplifying maintenance. For example, if one module experiences an issue, the rest of the system continues to function seamlessly. This design minimizes disruptions and ensures consistent power delivery.

The table below highlights the key benefits of modularity in ESTEL's scalable DC power systems:

Benefit | Description |

|---|---|

Scalability | Modular designs allow operators to easily scale systems by adding or replacing individual modules. |

Reliability | Faults are isolated to specific modules, reducing downtime and maintenance efforts. |

Future-proofing | Flexibility in modular designs supports seamless expansion as network demands grow without overhauling the entire system. |

By investing in modular solutions, you gain the ability to customize your power systems while ensuring enhanced reliability and scalability.

Cost-Effectiveness and Operational Efficiency

Cost-effectiveness and operational efficiency are critical for maintaining a competitive edge. ESTEL's scalable DC power systems deliver both by optimizing energy usage and reducing operational costs. These systems feature advanced cooling methods, such as electric thermostats, which activate only when necessary. This approach conserves energy and minimizes waste.

Comparing ESTEL's solutions to traditional systems reveals significant advantages. Traditional air-to-air cooling methods may have lower initial costs but often result in higher energy consumption over time. In contrast, ESTEL's liquid-to-air cooling systems offer superior performance and lower long-term costs. The table below illustrates these differences:

Cooling Method | Efficiency Description | Cost Implication |

|---|---|---|

Traditional Air-to-Air | Relies on passive heat pipe or folded fin cores for heat dispersion. | Generally lower initial costs but may have higher operational costs due to energy consumption. |

Liquid-to-Air | Utilizes a closed-loop system for higher cooling performance. | Higher initial investment but potentially lower operational costs due to efficiency. |

ESTEL's Solutions | Features an electric thermostat for energy conservation, activating only when necessary. | Potentially lower overall costs due to reduced energy usage. |

By choosing ESTEL's power supply solutions, you achieve improved efficiency and long-term savings. These systems not only reduce energy consumption but also enhance operational efficiency, making them a smart investment for your industrial needs.

Future-Proofing for Emerging Technologies

Future-proofing your operations is essential in a rapidly evolving industrial landscape. ESTEL's scalable DC power systems are designed to support emerging technologies, ensuring that your infrastructure remains relevant and adaptable. These systems integrate seamlessly with energy management systems, enabling you to adopt energy-efficient practices and meet sustainability goals.

Market forecasts validate the importance of future-proofing. Organizations increasingly seek modular and scalable solutions to adapt to changing operational needs. For instance, ESTEL's systems play a crucial role in supporting electric vehicle (EV) charging infrastructure. Their adaptability and efficiency make them ideal for fast-charging stations, which are vital for sustainable transportation.

The table below highlights key points that emphasize the future-proofing capabilities of ESTEL's solutions:

Evidence Description | Key Points |

|---|---|

Importance of DC PDUs | Emphasizes adaptability, efficiency, and integration capabilities crucial for future-proofing power management strategies. |

Modular and Scalable Solutions | Organizations seek flexible systems that can adapt to changing operational needs, validating ESTEL's scalable systems. |

Role in EV Charging Infrastructure | DC PDUs are essential for fast-charging stations, supporting sustainable transportation and urban energy systems. |

Market Growth Projection | The global market for DC PDUs is expected to grow significantly, reflecting the increasing emphasis on energy-efficient technologies. |

By adopting ESTEL's scalable DC power systems, you position your business for long-term success. These solutions not only enhance reliability but also align with sustainability and environmental responsibility, ensuring that your operations remain competitive in the future.

Real-World Applications of ESTEL Systems in 2025

Manufacturing: Enhancing Automation and Robotics

In manufacturing, ESTEL scalable DC power systems play a pivotal role in enhancing automation and robotics. These systems provide reliable power control, ensuring that automated processes run smoothly without interruptions. High energy efficiency, exceeding 96%, minimizes waste and reduces operational costs. This efficiency supports sustainability goals while maintaining high performance.

Modern manufacturing facilities rely on advanced configurations to optimize production. For instance:

The morbidelli ux200 drilling cell machines two pieces simultaneously, cutting processing times in half.

The stefani cell H enables flexible production without stopping for parameter changes, improving daily efficiency.

The morbidelli cx210 drilling machine achieves a production rate of 350 pieces per shift, showcasing exceptional productivity.

These examples highlight how ESTEL systems support critical applications in manufacturing by delivering consistent power and enabling seamless automation.

Data Centers: Reliable and Scalable Power Solutions

Data centers demand reliable power control to ensure uninterrupted operations. ESTEL systems excel in this domain by offering advanced monitoring and consistent voltage regulation. These features protect sensitive equipment and enhance operational efficiency. Clients report significant reductions in downtime, which improves reliability and reduces costs.

The scalability of ESTEL solutions allows data centers to expand services without infrastructure failures. Modular designs make it easy to add capacity as needed, ensuring that your systems grow with your business. The table below summarizes key benefits for data centers:

Benefit | Description |

|---|---|

Consistent Voltage Regulation | Protects equipment and ensures stable output. |

Advanced Monitoring | Provides real-time insights for proactive issue resolution. |

Reduced Downtime | Minimizes disruptions, enhancing reliability. |

Cost Savings | Optimizes energy usage and extends component lifespan. |

Enhanced Reliability | Supports seamless expansion without compromising performance. |

By adopting ESTEL solutions, you ensure that your data center remains efficient, scalable, and reliable.

Renewable Energy: Supporting Solar and Wind Integration

Integrating renewable energy sources like solar and wind into the grid requires advanced power systems. ESTEL solutions provide the scalability and reliability needed for this task. These systems enhance the efficiency of renewable energy projects by supporting energy storage devices and power management schemes.

For example, ESTEL systems facilitate the integration of large-scale solar energy into the grid. They work seamlessly with energy storage solutions to ensure a stable and reliable power supply. This capability is critical for supporting renewable energy projects and achieving sustainability goals.

By leveraging ESTEL scalable DC power systems, you can overcome the challenges of integrating renewable energy sources. These solutions ensure that your operations remain efficient and environmentally responsible.

Scalable DC power systems are essential for keeping your industrial operations competitive and efficient in 2025. ESTEL's solutions stand out by offering unmatched scalability, safety, and adaptability. These features make them indispensable for modern industries navigating rapid technological advancements.

The benefits of adopting ESTEL's solutions are evident across various sectors. For example:

Industry | Future-Proof Benefits |

|---|---|

Data Centers | Supports high-density power loads and adapts to increasing server demands. |

Renewable Energy | Integrates seamlessly with advanced energy storage systems and smart grids. |

Transportation | Ensures compatibility with evolving infrastructure technologies like EV charging. |

Industry trends further validate the need for scalable power solutions:

The modular power supplies market is growing rapidly due to rising demand in data centers and telecommunications.

The adoption of IoT and big data is driving investments in scalable systems to meet changing demands.

The rise of electric vehicles and 5G infrastructure highlights the shift toward advanced automation.

By choosing ESTEL's solutions, you ensure sustainable growth and operational excellence. These systems empower your business to adapt to emerging challenges while maintaining efficiency and reliability.

FAQ

What makes ESTEL scalable DC power systems unique?

ESTEL systems stand out due to their modular design, advanced safety features, and energy efficiency. You can scale them easily to meet growing demands, ensuring long-term adaptability. Their innovative cooling methods and seamless integration with emerging technologies make them a future-proof choice for industries.

How do these systems improve operational efficiency?

ESTEL systems optimize energy usage through advanced cooling and monitoring technologies. They reduce energy waste and minimize downtime by isolating faults to specific modules. This ensures consistent power delivery, helping you achieve higher productivity and lower operational costs.

Are ESTEL systems suitable for renewable energy projects?

Yes! ESTEL systems support solar and wind energy integration by enhancing energy storage and power management. Their scalability ensures compatibility with large-scale renewable projects, helping you meet sustainability goals while maintaining reliable power distribution.

Can ESTEL systems handle the demands of data centers?

Absolutely. ESTEL systems provide consistent voltage regulation and advanced monitoring, ensuring uninterrupted operations. Their modular design allows you to expand capacity as needed, making them ideal for data centers with growing server demands.

How do these systems enhance safety?

ESTEL systems include features like circuit breakers, surge protectors, and real-time monitoring tools. These components reduce risks associated with electrical faults. Their modular design also minimizes human error, ensuring safer power distribution across your facilities.

See Also

Exploring ESTEL's Industrial Cabinet Cooling Solutions And Benefits

Innovative Energy Storage Systems For ESTEL Telecom Cabinets

Future-Ready Sustainable Outdoor Communication Cabinets For 2025

Understanding ESTEL PDUs And Their Importance In Data Centers

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA