Comparing ESTEL Sensors and Other Top Telecom Cabinet Solutions in 2025

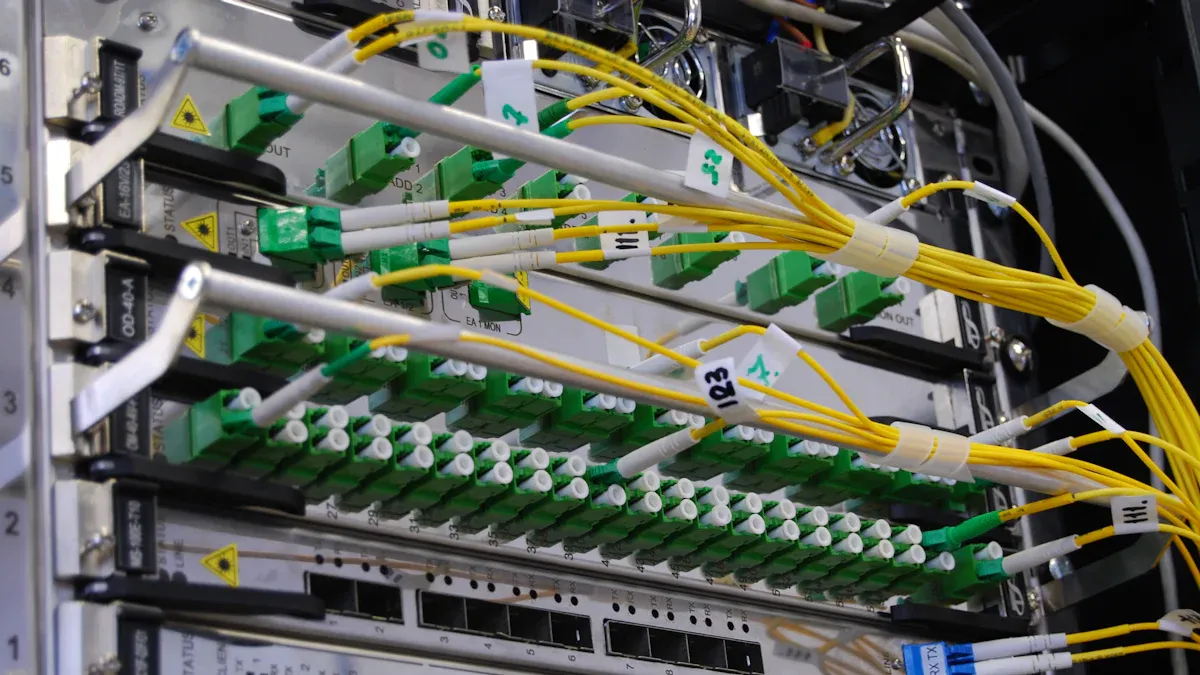

In 2025, ESTEL stands out as a leader for telecom cabinet sensor solutions, offering robust performance and advanced features. Sensors in telecom cabinet environments now provide real-time monitoring of temperature, humidity, airflow, smoke, water leaks, and security threats. Operators benefit from early hazard detection, threshold alerts, and remote monitoring, which support rapid intervention and predictive maintenance. IoT integration, modular sensor designs, and compliance with environmental standards like NEMA ratings play a critical role in protecting equipment and ensuring network reliability.

Key Takeaways

ESTEL leads the telecom cabinet sensor market in 2025 with advanced features like predictive maintenance and modular design that improve uptime and energy efficiency.

Modern sensors provide real-time monitoring of temperature, humidity, airflow, and security, helping operators detect hazards early and reduce downtime.

IoT integration and AI-driven automation enable remote monitoring, smarter data analysis, and faster response to issues, boosting network reliability.

Top competitors like Schneider Electric and Rittal offer strong alternatives focusing on security, cooling, and energy savings, giving operators choices based on site needs.

Choosing the right sensor solution requires considering cabinet type, environment, integration capabilities, and compliance with standards to ensure long-term performance.

Quick Verdict

ESTEL’s Position in 2025

ESTEL holds a commanding position in the telecom cabinet sensor market in 2025. The company delivers a comprehensive suite of sensor solutions that address the evolving needs of telecom operators. ESTEL’s High-Density Rack PDU stands out for its modular design, real-time monitoring, and outlet-level control. These features enable operators to scale their infrastructure efficiently and maintain high levels of energy efficiency. ESTEL’s focus on compatibility with modern server racks ensures seamless integration into both legacy and next-generation telecom environments. The company’s commitment to innovation and reliability has made its solutions a preferred choice for organizations seeking robust environmental monitoring and network protection.

ESTEL’s leadership stems from its ability to combine advanced technology with practical deployment flexibility. Operators benefit from predictive maintenance, rapid hazard detection, and compliance with stringent environmental standards. These strengths position ESTEL as a go-to provider for telecom cabinet sensor solutions in 2025.

Top Competitors

Several global brands compete closely with ESTEL in the telecom cabinet sensor market. Each brings unique strengths to the table:

Schneider Electric: Known for the APC Rack PDU, which offers remote monitoring, outlet-level control, and seamless integration with DCIM systems. Schneider Electric excels in performance and energy efficiency.

Eaton: Offers the ePDU G3 Metered Input, recognized for billing-grade metering accuracy, modular design, and remote monitoring. Eaton’s solutions suit high-density server racks.

Vertiv: Delivers the Geist Intelligent Rack PDU, featuring remote monitoring, outlet-level control, scalability, and compatibility with modern racks. Vertiv emphasizes energy efficiency and reliability.

Raritan: Provides the PX4 Smart PDU, which includes advanced power quality monitoring, billing-grade accuracy, and enhanced security features. Raritan’s solutions appeal to organizations requiring detailed power metrics.

These competitors challenge ESTEL by offering specialized features and strong integration capabilities. The market in 2025 remains dynamic, with each brand pushing the boundaries of what sensors in telecom cabinet environments can achieve.

Sensors in Telecom Cabinet: 2025 Trends

Environmental Monitoring

Telecom operators in 2025 demand advanced environmental monitoring to protect critical infrastructure. Sensors in telecom cabinet environments now deliver real-time data on temperature, humidity, and power conditions. Operators rely on these systems to detect early signs of overheating, moisture intrusion, or power fluctuations. Smart monitoring and remote management capabilities, often powered by IoT and AI, have become standard. These features enable predictive maintenance and automated environmental control, reducing downtime and maintenance costs.

Operators also prioritize climate-controlled cabinet designs. Weatherproofing, tamper resistance, and robust thermal management systems ensure reliable operation in harsh outdoor settings. Cabinets use weatherproof seals, corrosion-resistant materials, and secure locking systems to protect sensitive equipment. Thermal management solutions, such as fans and heat exchangers, maintain optimal temperatures. Remote monitoring supports service reliability during natural disasters and environmental challenges. Investments in R&D continue to improve durability, ease of installation, and integration with high-speed data environments.

Note: Outdoor telecom cabinets now provide secure, environmentally controlled housing for 5G and edge computing equipment, supporting resilience against extreme conditions.

IoT and Integration

IoT integration has transformed sensors in telecom cabinet solutions. Modern cabinets feature built-in environmental sensors that monitor temperature, humidity, and power status in real time. Smart Power Distribution Units (PDUs) offer granular power monitoring and remote power cycling. Integrated security controls, such as biometric access and IP cameras, enhance physical security.

Operators benefit from remote monitoring, which enables proactive maintenance and reduces the need for costly site visits. These integrated features streamline maintenance processes, improve network uptime, and optimize power distribution. AI and edge computing further enhance these systems by enabling real-time data processing, predictive maintenance, and automated operations. As a result, telecom networks achieve higher efficiency, reliability, and security.

Key integration trends in 2025:

Real-time monitoring and remote operation

Enhanced data security

Smarter data analysis with AI and machine learning

Support for sustainability and regulatory compliance

ESTEL Sensor Solutions

Features

ESTEL sensor solutions in 2025 deliver a comprehensive set of features that set them apart in the telecom industry. The following table highlights the unique offerings and their impact:

Feature Category | ESTEL's Unique Offering | Impact / Benefit |

|---|---|---|

Advanced Sensors & Analytics | Real-time data collection with predictive maintenance | |

Modular & Scalable Design | Adaptable for small offices and large data centers | Enables easy upgrades without downtime |

Energy Efficiency | Smart PDUs and power optimization | Achieves up to 20% energy savings |

Compliance | Meets UL, CE, IEC international standards | Ensures safety and reliability |

Integration | Seamless with DCIM tools | Provides unified monitoring and control |

Automation | AI-driven incident categorization and anomaly detection | Reduces manual triage by 58%, enables early issue detection |

Security | Encrypted protocols and multi-factor authentication | Protects data integrity and business security |

ESTEL also provides real-time remote visibility and control over network devices and power usage. Automation handles routine maintenance and incident management, reducing manual workload and human error. Strong security measures, including encrypted communication, safeguard sensitive data.

Pros and Cons

Pros:

Predictive maintenance prevents failures before they disrupt operations.

Modular design allows easy scaling and integration with other management tools.

Automation improves response times by up to 40% and boosts equipment uptime.

Compliance with international standards ensures reliability.

Cons:

Initial setup may require specialized training for staff.

Advanced features can increase upfront investment compared to basic sensor systems.

Tip: Organizations seeking long-term reliability and scalability often find the higher initial investment justified by reduced downtime and maintenance costs.

Best Applications

ESTEL sensor solutions excel in diverse telecom environments. Operators deploy them in outdoor cabinets, edge computing sites, and large data centers. The modular design adapts to both small-scale and enterprise-level installations. Sensors in Telecom Cabinet environments benefit from ESTEL’s predictive analytics and automation, making them ideal for mission-critical networks, 5G base stations, and remote sites where uptime is essential.

Schneider Electric Sensor Solutions

Features

Schneider Electric delivers a robust suite of sensor solutions for telecom cabinets in 2025. The NetBotz appliances and EcoStruxure IT platform form the core of their offering. NetBotz appliances provide environmental sensors, surveillance cameras, and key card access controls. These devices fit into a 1RU rack space or mount externally, preserving valuable rack space. Operators can choose between hardwired and wireless connectivity, which adds flexibility for different cabinet layouts.

The system supports built-in network management through web browsers, command-line interfaces, or SNMP. Integration with EcoStruxure IT enables cloud-based remote monitoring, real-time alerts, and management from desktop or mobile apps. Smart enclosure fans with integrated sensors and remote diagnostics improve thermal control and preventive maintenance. Security features help organizations comply with data and IT security standards.

Note: Schneider Electric’s platform supports 24/7 continuous monitoring and from-anywhere access, which enhances operational efficiency for both manned and unmanned sites.

Pros and Cons

Pros | Cons |

|---|---|

Comprehensive environmental and security monitoring | Initial investment may be higher |

Flexible installation options (rack or external mount) | Advanced features may require training |

Seamless integration with DCIM and third-party systems | Some features depend on cloud connectivity |

Real-time alerts and remote management | |

Smart thermal control and predictive maintenance |

Schneider Electric’s solutions offer strong integration and automation, which help reduce manual intervention and improve uptime. The flexibility in installation and connectivity options supports a wide range of telecom cabinet designs.

Best Applications

Schneider Electric sensors excel in environments where real-time environmental and physical security monitoring is critical. Operators deploy these solutions in data centers, colocation facilities, and distributed IT sites. The sensors detect temperature, humidity, smoke, and water leaks, which are essential for protecting telecom infrastructure. Integration with EcoStruxure IT DCIM software enables comprehensive monitoring, management, and predictive analytics. The vendor-neutral and IoT-enabled design allows seamless integration with legacy and third-party systems.

Sensors in Telecom Cabinet environments benefit from Schneider Electric’s advanced monitoring and security features. These solutions suit telecom cabinets that require DCIM integration to ensure optimal performance and sustainability.

Rittal Sensor Solutions

Features

Rittal sensor solutions in 2025 focus on energy efficiency, advanced cooling, and digital connectivity. The Blue e+ cooling units stand out by reducing power consumption by up to 72% compared to earlier models. Hybrid cooling technology combines speed-controlled compressors with heat pipe systems. This approach maintains stable enclosure temperatures and avoids sudden energy spikes. Digital interfaces allow operators to access real-time data and receive immediate fault alerts. These features help improve system reliability and support proactive maintenance.

Rittal integrates enclosure cooling directly into its cabinet designs. This integration reduces the bill of materials and simplifies both design and installation. Adjustable thermostats and high-performance fans enable precise temperature management. The enclosures provide strong protection against corrosion and contamination, which extends equipment lifespan. Maintenance becomes easier with fan-filter units that have fewer parts and allow tool-less filter replacement.

Pros and Cons

Pros:

Blue e+ cooling units deliver significant energy savings.

Hybrid cooling ensures stable temperatures and efficient operation.

Digital interfaces provide real-time monitoring and quick fault detection.

Integrated cooling reduces complexity and installation time.

Maintenance is simple due to accessible, tool-free filter replacement.

Enclosures offer robust protection, increasing equipment longevity.

Cons:

Industry reports in 2025 do not identify explicit drawbacks for Rittal sensor solutions.

Operators value Rittal for its reliable climate control and ease of maintenance, especially in demanding telecom environments.

Best Applications

Rittal sensor solutions fit a wide range of telecom cabinet scenarios. Operators often choose these systems for outdoor cabinets, edge computing sites, and locations with strict energy efficiency requirements. Sensors in Telecom Cabinet environments benefit from Rittal’s precise climate control and robust protection features. These solutions work well in settings where equipment longevity and minimal downtime are critical. Rittal’s simplified maintenance and digital connectivity also make it a strong choice for remote or unmanned sites.

Comparative Analysis

Performance and Reliability

ESTEL, Schneider Electric, and Rittal each deliver strong performance and reliability, but their approaches differ. ESTEL emphasizes predictive maintenance and modular sensor deployment, which helps operators prevent failures and maintain high uptime. Schneider Electric focuses on comprehensive environmental and security monitoring, using real-time alerts and remote diagnostics to ensure continuous operation. Rittal stands out with advanced cooling technology, such as Blue e+ units and hybrid cooling, which maintain stable temperatures and reduce energy spikes.

Advanced thermal management plays a critical role in the effectiveness of sensors in telecom cabinet environments. These features ensure optimal temperature control, prevent overheating, and enable adaptive cooling that matches changing thermal loads. Real-time monitoring and dynamic airflow management support precise environmental data collection, which improves sensor accuracy and reliability. Smart thermal solutions, including remote temperature monitoring and predictive maintenance, help extend equipment lifespan and boost network reliability.

Operators who prioritize stable operating conditions and long-term reliability often choose solutions with advanced thermal management and predictive analytics.

Integration and Compatibility

Integration and compatibility have become essential in 2025, as telecom networks demand seamless data flow and unified management. ESTEL offers strong integration with DCIM tools and supports both legacy and next-generation telecom environments. Its modular design allows operators to scale and adapt their infrastructure without major disruptions. Schneider Electric excels in vendor-neutral integration, allowing its sensors to work with third-party systems and cloud-based platforms like EcoStruxure IT. This flexibility supports hybrid and distributed IT environments.

Rittal integrates digital interfaces and real-time monitoring into its enclosures, making it easy for operators to access data and receive alerts. The company’s focus on modularity and digital connectivity ensures compatibility with IoT-enabled devices and advanced monitoring systems.

NEMA ratings influence sensor selection by defining the required level of protection against environmental challenges such as dust, water, and corrosion. Cabinets designed for outdoor use often require higher NEMA ratings and corrosion-resistant materials to ensure sensor durability and accuracy. Compliance with NEMA standards ensures that sensors in telecom cabinet environments remain reliable, even in harsh conditions. Leading brands design modular and scalable cabinets that accommodate advanced sensors, supporting operational efficiency and future-proofing telecom infrastructure.

Tip: When selecting a sensor solution, operators should consider both integration capabilities and environmental protection standards to ensure long-term compatibility and reliability.

Cost and Maintenance

Cost and maintenance considerations vary among the leading brands. ESTEL’s solutions may require a higher initial investment due to advanced features and automation, but they often deliver lower total cost of ownership through reduced downtime and maintenance needs. Predictive maintenance and modular upgrades minimize manual intervention and extend equipment life.

Schneider Electric’s systems also involve a significant upfront cost, especially for advanced monitoring and security features. However, the flexibility in installation and strong integration with DCIM platforms can reduce ongoing maintenance expenses. Operators benefit from real-time alerts and remote management, which help prevent costly failures.

Rittal focuses on energy efficiency and simplified maintenance. Its integrated cooling and tool-free filter replacement reduce both energy consumption and service time. The robust enclosure design protects equipment and sensors, lowering the risk of environmental damage and unplanned repairs.

Brand | Initial Cost | Maintenance Needs | Energy Efficiency | Upgrade Flexibility | Long-Term Value |

|---|---|---|---|---|---|

ESTEL | High | Low (predictive, modular) | High | Excellent | Strong ROI |

Schneider Electric | High | Moderate (cloud, remote) | Moderate-High | Good | High |

Rittal | Moderate | Low (easy maintenance) | Very High | Good | High |

Operators should weigh the initial investment against long-term savings from reduced downtime, energy efficiency, and simplified maintenance. Advanced thermal management and modularity further enhance cost-effectiveness by extending equipment lifespan and supporting easy upgrades.

Choosing the Right Solution

Key Considerations

Selecting the right sensor solution for telecom cabinets in 2025 requires a careful evaluation of several critical factors. Operators must assess cabinet type, deployment environment, and network requirements to ensure optimal performance and long-term reliability.

Factor | Explanation |

|---|---|

Size and Space | Measure available space. Consider vertical or wall-mounted options. Plan for future expansion. |

Type of Cabinet | Choose between wall-mounted (compact, small equipment) and freestanding (larger, more robust). |

Ventilation and Cooling | Ensure built-in ventilation or cooling units. Use passive or fan-assisted airflow to manage heat. |

Security Features | Lockable doors and tamper-resistant designs prevent unauthorized access. |

Cable Management | Look for cable entry points and tie-downs to keep cables organized and improve airflow. |

Load Capacity | Check cabinet’s weight capacity to avoid structural failure and equipment damage. |

Operators should also consider the integration of real-time monitoring features. Many modern server rack cabinets include sensors that track temperature and environmental changes. Built-in alert systems notify teams of door openings or temperature shifts, enabling rapid response and enhancing equipment protection.

When evaluating sensors in telecom cabinet environments, operators must match the solution to the specific deployment scenario. For outdoor installations, robust environmental protection is essential. Solutions should comply with standards such as NEMA 4X, IEC 60529, and NEBS GR-78 to ensure durability against dust, water, and corrosion. Modular and serviceable designs support remote monitoring and smart telemetry integration, which are vital for distributed and unmanned sites.

Tip: Always verify that the chosen solution supports future expansion and integrates with existing network management platforms.

Scenario Recommendations

Different telecom applications demand tailored sensor solutions. The following recommendations address common deployment scenarios in 2025:

1. Outdoor Cabinets in Harsh Environments

Operators managing outdoor cabinets in challenging climates should prioritize humidity sensors with fan speed modulation. Hydrophobic vent valves help equalize internal pressure while blocking moisture ingress. Desiccant or silica packs protect sensitive electronics from humidity. Combining filtered fans, thermostatically controlled air conditioners, and humidity relief valves maintains optimal internal conditions and prevents overheating or moisture buildup.

Recommended components include:

Fan and filter units with multi-stage filtration (e.g., CE ROHS Certified LK6626 Series)

Roof fans and cooling fans sized for heat dissipation needs

Air conditioners with automatic condensate evacuation and precise temperature control (±2 °C)

Compliance with IEC, UL, and NEMA 4X standards

This approach balances high IP sealing with active ventilation, ensuring reliability and longevity for sensors in telecom cabinet deployments exposed to extreme weather.

2. Telecom Base Stations

Base stations require advanced sensor ecosystems to support 5G expansion, edge computing, and high network uptime. AI-powered algorithms optimize network traffic and enable predictive maintenance, reducing human intervention. Edge computing platforms process data locally, minimizing latency and supporting real-time analytics.

Key sensor technologies for base stations include:

Sensor Type / Technology | Application in Telecom Base Stations | Benefits and Features |

|---|---|---|

Current Transformer (CT) Sensors | Energy monitoring and detection of unauthorized power usage | Real-time tracking, alerts on deviations, reduced energy waste |

Temperature & Voltage Sensors | Thermal hazard detection in 5G equipment and batteries | Continuous monitoring, AI analytics, prevention of overheating |

PIR Motion Sensors & Vibration Detectors | Security monitoring to detect theft and unauthorized access | Integrated with AI, triggers alarms, reduces security breaches |

Multi-Protocol Edge Computing Gateways | Integration of legacy systems and real-time data processing | Supports Modbus, SNMP, MQTT, enables sub-second alerts, ensures high uptime |

Industrial 5G Routers | Reliable connectivity for mission-critical and remote sites | Rugged design, extreme temperature operation, dual SIM failover |

AI-Driven Predictive Maintenance | Failure forecasting and downtime reduction | Proactive maintenance, significant downtime reduction, cost savings |

Solar-Powered Gateways with NB-IoT | Off-grid site energy optimization | Supports renewable energy, reduces site visits, maintains real-time data transmission |

This integrated sensor ecosystem addresses energy efficiency, thermal safety, security, and future-proofing for 5G and edge deployments.

3. Broadband and Distributed IT Sites

Broadband cabinets and distributed IT sites benefit from modular sensor solutions that support remote monitoring and easy upgrades. Operators should select cabinets with built-in temperature and humidity sensors, real-time alert systems, and compatibility with DCIM platforms. Modular designs allow for quick expansion as network demands grow.

Recommended features:

Real-time monitoring of temperature, humidity, and power status

Automated alert systems for rapid incident response

Integration with cloud-based management tools for centralized oversight

4. Solar-Powered and Off-Grid Sites

For solar-powered or off-grid telecom sites, energy-efficient sensor solutions are essential. Solar-powered gateways with NB-IoT connectivity enable real-time data transmission and reduce the need for physical site visits. These solutions support 100% renewable energy operation and maintain network reliability in remote locations.

Note: Operators should always match sensor solutions to the specific environmental and operational requirements of each site. Modular, serviceable designs and compliance with industry standards ensure long-term success.

ESTEL leads the market with advanced automation, predictive maintenance, and modular solutions. Schneider Electric and Rittal offer strong alternatives for specific needs. Operators should evaluate sensors in telecom cabinet environments by considering IoT integration, modularity, and environmental standards. Key priorities include real-time monitoring, scalable modular designs, and robust protection for outdoor deployments. Future-ready solutions will combine smart IoT features, flexible expansion, and eco-friendly materials to support evolving network demands.

FAQ

What makes ESTEL sensors stand out in telecom cabinet applications?

ESTEL sensors offer predictive maintenance, modular design, and seamless integration with DCIM tools. Operators benefit from real-time monitoring, energy efficiency, and compliance with international standards. These features help reduce downtime and improve network reliability.

How do Schneider Electric and Rittal compare to ESTEL for outdoor deployments?

Schneider Electric provides strong security and DCIM integration. Rittal focuses on advanced cooling and energy efficiency. ESTEL excels in automation and modularity. Operators should match solutions to site needs, such as climate control or remote management.

Are ESTEL sensor solutions compatible with legacy telecom cabinets?

Yes. ESTEL designs its sensors for compatibility with both legacy and next-generation cabinets. Operators can upgrade existing infrastructure without major changes, ensuring a smooth transition and protecting previous investments.

What environmental standards should operators consider for telecom cabinet sensors?

Standard | Purpose |

|---|---|

NEMA 4X | Outdoor protection, corrosion |

IEC 60529 | Dust and water resistance |

UL, CE | Safety and compliance |

Operators should select sensors that meet these standards for reliable performance in harsh environments.

See Also

Best Components Used In ESTEL Outdoor Telecom Cabinets 2025

A Closer Look At ESTEL Outdoor Telecom Cabinet Designs

The Importance Of Enhanced Telecom Cabinets In 2025

How Custom ESTEL Cabinets Ensure Outdoor Telecom Safety

Latest Innovations Shaping Outdoor Telecom Cabinet Technology

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA