Sensors in EATEL Telecom Cabinet: The Silent Watchdogs

You rely on Sensors in Telecom Cabinet systems to silently monitor every environmental detail, from temperature to humidity. Sensors in Telecom Cabinet setups act as your silent guardians, detecting even the smallest changes in the environment. With continuous environmental monitoring provided by Sensors in Telecom Cabinet systems, you can prevent equipment failures before they happen. These environmental monitoring systems use real-time data from Sensors in Telecom Cabinet units to reduce the risk of undetected threats. You avoid costly downtime because Sensors in Telecom Cabinet systems monitor conditions remotely and minimize manual inspection errors. By integrating Sensors in Telecom Cabinet environments, you extend equipment lifespan and lower operational costs, especially in challenging settings where cabinets face environmental and physical risks.

Key Takeaways

Sensors in telecom cabinets monitor temperature, humidity, airflow, power, and security to protect equipment and prevent failures.

Real-time alerts from sensors help you act quickly, reducing downtime and costly repairs.

Combining multiple sensors creates strong protection against environmental threats like overheating, moisture, and unauthorized access.

Integrating sensors with power and cooling systems improves energy efficiency and keeps equipment running safely.

Regular maintenance and proper sensor placement ensure reliable monitoring and fewer false alarms.

Sensors in Telecom Cabinet

Monitoring Essentials

You depend on sensors in telecom cabinet systems to act as silent watchdogs, always on guard for changes in the environment. These sensors work around the clock, collecting data from inside your cabinets and sending it to your monitoring devices. You gain real-time insight into critical factors such as temperature, humidity, airflow, and power quality. This constant environmental monitoring helps you spot problems before they become serious.

Sensors in telecom cabinet setups include a variety of monitoring devices, each designed for a specific purpose. You use temperature sensors to monitor heat levels and prevent overheating. Humidity sensors help you avoid moisture buildup that can cause corrosion or condensation. Airflow sensors ensure that cool air circulates properly, preventing hotspots and keeping equipment safe. Power sensors track energy usage and alert you to outages or electrical issues. Magnetic door contact sensors and intrusion alarms protect your cabinets from unauthorized access.

Tip: By combining multiple sensors in telecom cabinet environments, you create a layered defense that covers every major threat.

You can connect many sensors to a single monitoring system. Modern solutions support both wired and wireless sensors, making it easy to expand your setup as your needs grow. You also benefit from remote monitoring capabilities. Using protocols like Modbus over RS-485 and IP connectivity, you can access sensor data from anywhere. GSM connectivity lets you receive alerts even when you are offsite, ensuring you never miss a critical event.

Environmental Threats

Your telecom cabinets face several environmental threats that can disrupt operations or damage equipment. You need to monitor these risks closely to maintain reliable service.

Temperature: High temperatures can cause equipment to overheat and fail. Temperature sensors in telecom cabinet systems detect heat spikes and send alerts when readings exceed safe limits.

Humidity: Excess humidity leads to condensation and corrosion. Humidity sensors monitor moisture levels, helping you keep the environment within safe ranges.

Water Ingress: Leaks or flooding pose a serious risk. Water detection sensors alert you to the presence of water before it can cause damage.

Airflow: Poor airflow creates hotspots and reduces cooling efficiency. Airflow sensors monitor air movement, ensuring your cooling systems work effectively.

Power Issues: Power outages or fluctuations can shut down equipment. Power sensors monitor both consumption and quality, alerting you to problems immediately.

Unauthorized Access: Intrusion detection sensors and magnetic door contacts help you monitor for break-ins or tampering, protecting your network from physical threats.

Here is a summary of the main environmental parameters and their purposes:

Environmental Parameter | Purpose/Description |

|---|---|

Temperature | Prevents overheating and ensures optimal performance |

Humidity | Avoids condensation and corrosion, targets safe levels |

Airflow | Maintains efficient cooling and prevents hotspots |

Water Leakage | Detects leaks early to prevent equipment damage |

Power Consumption/Quality | Prevents outages and ensures stable power delivery |

Physical Security | Monitors access and protects equipment from intrusion |

Sensors in telecom cabinet environments do more than just monitor—they enable early detection and rapid response. When a sensor detects an abnormal condition, it sends a real-time alert to your monitoring devices. You can act quickly, reducing downtime and preventing costly repairs. Many systems now use AI-driven anomaly detection to spot unusual patterns, making your monitoring even more effective.

You also benefit from modular sensor designs and hot-swappable parts. This means you can replace or upgrade sensors without shutting down your cabinets, keeping your network running smoothly.

Note: Environmental monitoring with sensors in telecom cabinet systems is not just about collecting data. It is about giving you the power to act before small issues become big problems.

With the right combination of sensors, monitoring devices, and remote communication protocols, you create a robust defense against environmental threats. You protect your equipment, ensure reliable service, and gain peace of mind knowing your cabinets are always under watch.

Environment Monitoring

Data Center Environmental Sensors

You need to monitor the environment inside your data center to protect your equipment and ensure reliable operations. Data center environmental sensors give you real-time insights into critical conditions. These sensors track temperature, humidity, airflow, air quality, and even security status. By using a combination of wired and wireless sensors, you create a comprehensive monitoring system that covers every corner of your telecom cabinet.

You can find several types of data center environmental sensors in modern monitoring systems:

Temperature sensors help you maintain optimal equipment performance. They keep the temperature within safe ranges, usually between 18°C and 27°C. Data center temperature monitoring prevents overheating and supports cooling efficiency.

Humidity sensors and data center humidity sensors monitor moisture levels. High humidity can cause condensation and corrosion, while low humidity increases the risk of static discharge. Humidity control is essential for protecting sensitive electronics.

Air quality sensors detect airborne contaminants that may harm your equipment.

Airflow sensors monitor cooling effectiveness and prevent hotspots.

Multisensors combine temperature, humidity, pressure differential, and water leak detection in a single device. This simplifies installation and gives you a complete view of the environment.

Security sensors, such as contact closure and proximity sensors, alert you to unauthorized access or tampering.

Tip: Multisensors and IoT-enabled devices allow you to monitor multiple environmental parameters at once, making data center management more efficient.

A typical monitoring architecture uses an IIoT edge gateway inside or near the telecom cabinet. This gateway collects data from both wired and wireless sensors. It supports interfaces like analog/digital I/Os, industrial Ethernet, Bluetooth Low Energy, and WiFi. The gateway can also use a 5G modem to send data to central servers or cloud platforms. Local processing and storage let you filter and forward only important data, which saves bandwidth and improves scalability.

You can connect groups of sensors—such as temperature, humidity, and current sensors—to local monitoring devices. These devices often include microcontrollers and GSM modems. They collect sensor data and transmit it wirelessly to a central server for analysis. This setup supports remote monitoring and control, even in locations where wiring is difficult or expensive.

With these monitoring systems, you gain early warning of environmental changes. You receive alerts for temperature and humidity spikes, water leaks, or unauthorized access. This proactive approach helps you prevent downtime and equipment failure.

Power and UPS Integration

Power stability is critical for telecom cabinets. You must monitor power quality and ensure backup systems like UPS (Uninterruptible Power Supply) are always ready. Environment monitoring systems integrate with UPS and power monitoring equipment using multiple communication interfaces.

You often see RS485, RS232, and Ethernet ports in these systems. These interfaces support protocols like Modbus and SNMP, which allow seamless communication with UPS devices and power meters. You can monitor UPS alarms, schedule battery discharge tests, and configure settings remotely through web browsers or terminal interfaces.

Here is a table showing common integration features:

Interface Type | Description |

|---|---|

RS485 Ports | Connect up to 96 MODBUS RTU/ASCII devices, including UPS systems |

RS232 & Ethernet | Support legacy and modern devices using RJ45 (TCP/IP) or conversion modules |

Protocols Supported | Modbus, IEC 61850, SNMP for broad compatibility |

Inputs | 16 analog (4–20mA or 0–5V) and 16 digital alarm inputs for precise monitoring |

Outputs | 16 relay outputs for automated control and alarms |

Monitoring & Control | Real-time monitoring, alarm logging, remote management, and linkage control |

Dry-contact interfaces play a key role in early warning and remote alerts. These flexible inputs support dry contact closures without external voltage, making installation simple and reliable. You can use dry contacts to monitor door status, smoke detection, battery alarms, and more. When a sensor detects a problem, the system sends alerts through SNMP traps, email, or secure messaging. This reduces the need for site visits and helps you respond quickly to issues.

Dry-contact interfaces support multiple communication protocols, including HTTP, SNMP, RS232, and Ethernet.

They capture and transmit critical alarm data, such as mains failure, generator status, and battery faults.

Modular expansion lets you add more monitoring points as your needs grow.

Note: Early warning systems and remote monitoring capabilities give you peace of mind. You can monitor your data center environment from anywhere and act before small problems become major failures.

By integrating data center environmental sensors, power monitoring, and dry-contact interfaces, you build a robust environment monitoring solution. This approach supports effective data center management, improves environmental control, and ensures reliable operation of your telecom cabinets.

Data Center Cooling

Temperature Sensors

You rely on temperature sensors to keep your telecom cabinets safe and efficient. These sensors monitor the internal temperature in real time, giving you instant feedback on the environment inside your cabinets. When the temperature rises above safe levels, sensors trigger alerts so you can act quickly. This early warning helps you prevent overheating, which can damage sensitive equipment and cause costly downtime.

Temperature sensors work closely with thermostats and air conditioning units. They help maintain stable temperature and humidity, which protects your equipment from corrosion, condensation, and electrostatic discharge. By using temperature sensors, you ensure that your data center cooling system responds to actual conditions, not just preset schedules. This approach supports energy efficiency and extends the life of your telecom equipment.

Tip: Place sensors at different points inside the cabinet for the most accurate temperature readings.

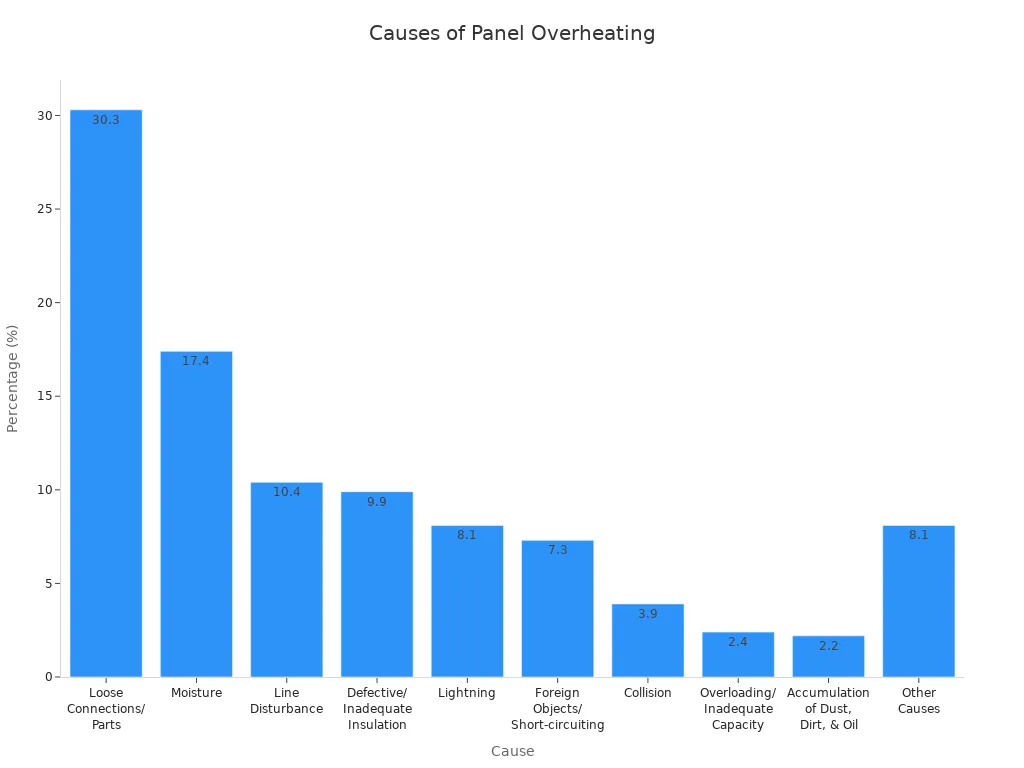

Overheating remains a significant risk in telecom cabinets. The table below shows common causes of electrical panel overheating and their percentages:

Cause | Percentage |

|---|---|

Loose Connections/Parts | 30.3% |

Moisture | 17.4% |

Line Disturbance | 10.4% |

Defective/Inadequate Insulation | 9.9% |

Lightning | 8.1% |

Foreign Objects/Short-circuit | 7.3% |

Collision | 3.9% |

Overloading/Inadequate Capacity | 2.4% |

Accumulation of Dust, Dirt, & Oil | 2.2% |

Other Causes | 8.1% |

Air Conditioning Control

You need reliable air conditioning control to keep your data center cooling effective. Telecom cabinets use several cooling methods, including fans, heat sinks, and air conditioning units. Outdoor cabinets often require special cooling systems that handle extreme weather and prevent dust from entering. Intelligent cooling systems adjust their output based on real-time temperature data from sensors. This dynamic response saves energy and keeps your equipment in a stable environment.

You can choose from different types of air conditioning systems:

Type of Air Conditioning System | Description | Suitability |

|---|---|---|

Closed-Loop Systems | Circulate air within the cabinet, isolating from outside contaminants | Harsh or dirty environments |

Open-Loop Systems | Bring in external air for cooling | Clean, cool outdoor air available |

Split Systems | Separate evaporator and condenser units | Large cabinets or tight spaces |

Most telecom cabinets use air-cooled systems because they are reliable and easy to maintain. Digital thermostats let you set precise temperature ranges, usually between 20°C and 45°C. Smart features allow remote monitoring and adjustment through RS485 interfaces or Ethernet networks. You receive alerts if temperatures rise too high, so you can respond before problems occur.

Intelligent control systems optimize cooling and reduce wasted energy.

IoT integration enables remote adjustments and predictive maintenance.

Energy-efficient designs can cut power use by up to 50%, lowering costs and environmental impact.

By combining sensors, smart controls, and efficient cooling, you protect your telecom cabinets and ensure reliable operation.

Impact & Best Practices

Real-World Scenarios

You can see the value of sensors in telecom cabinets through real-world examples. Many companies have improved their operations by using advanced monitoring and intelligent power management. The table below highlights some key results:

Case Study Description | Demonstrated Benefit |

|---|---|

Telecommunications company implementing intelligent PDUs | Achieved a 20% increase in equipment uptime and significantly reduced maintenance costs |

Use of remote monitoring and troubleshooting tools | Improved maintenance response times by 40% |

Intelligent PDUs with load-balancing features | Reduced unintentional power outages by 15% |

These examples show that when you monitor your cabinets with the right sensors, you prevent downtime and avoid costly repairs. You also respond faster to problems and keep your network running smoothly.

Deployment Tips

To get the most from your sensors, you need to follow best practices for deployment and maintenance. Here are some tips to help you maximize reliability and minimize false alarms:

Select sensors designed for telecom cabinets, such as photoelectric smoke detectors.

Test and calibrate your sensors every month to ensure they work correctly.

Clean sensors once a year with a vacuum and brush to prevent dust buildup.

Install sensors away from airflow sources and humid or dusty areas.

Replace batteries every 6 to 12 months and test them monthly.

Adjust alarm sensitivity based on your site’s baseline data.

Perform routine maintenance, including cleaning and inspection.

Troubleshoot false alarms by checking the environment, cleaning, and adjusting sensitivity.

Regularly check wiring and network connections for secure integration.

Tip: Schedule regular inspections and keep your monitoring equipment firmware up to date. This proactive approach helps you catch issues early and keeps your monitoring system reliable.

You may face challenges like security risks, data management, or harsh environments. You can overcome these by using secure protocols, scalable architectures, and sensors rated for extreme conditions. Always monitor your system’s performance and update your maintenance plan as your network grows.

You play a vital role in protecting your telecom infrastructure by using environmental sensors and advanced monitoring systems. Proactive monitoring gives you real-time visibility, reduces unnecessary alarms, and helps you prevent costly downtime.

Wireless sensor networks simplify deployment and support centralized monitoring, making your operations more efficient.

Real-time data and predictive analytics enable you to resolve issues before they escalate, ensuring long-term reliability.

Adopt best practices and upgrade your monitoring systems to keep pace with innovations in environmental management and network automation.

FAQ

What are the main benefits of using sensors in telecom cabinet environments?

You gain real-time insights into temperature, humidity, and airflow. These sensors help you prevent equipment failures and downtime. Monitoring systems send alerts when conditions change, so you can act quickly. You improve environmental control and extend the life of your cabinets.

How do data center environmental sensors support environment monitoring?

You use data center environmental sensors to monitor temperature, humidity, and air quality. These sensors provide accurate data for environment monitoring. You can track changes in the environment inside your data center and receive alerts for any abnormal conditions.

Why is data center cooling important for telecom cabinets?

You need data center cooling to keep equipment safe. Temperature sensors and cooling systems work together to prevent overheating. Proper cooling protects your cabinets from damage and supports reliable data center management.

How do humidity sensors and airflow sensors improve environmental monitoring?

You rely on humidity sensors for humidity control and to avoid condensation. Airflow sensors help you monitor cooling efficiency. Both sensors give you real-time insights, so you can maintain a stable environment and prevent equipment issues.

Can you monitor power and security with these monitoring devices?

You can monitor power quality and detect unauthorized access using monitoring devices. These systems send alerts for power issues or security breaches. You keep your cabinets safe and ensure stable operation.

See Also

Best Practices For Monitoring Outdoor Telecom Cabinets Effectively

Exploring The Function Of Outdoor Cabinets In Telecom Networks

Safety Features Of Custom ESTEL Outdoor Telecom Cabinet Designs

Effective Ways To Safeguard Equipment Using Outdoor Telecom Cabinets

Power Solutions With Energy Storage Batteries For ESTEL Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA