Why Telecom Cabinets Without Sensors Put Your Network at Risk

Sensors in Telecom Cabinet act as the frontline defense against hidden dangers. Without these sensors, undetected overheating, moisture, or unauthorized access can lead to equipment failure and severe network downtime. Reports show that the absence of temperature, humidity, and security sensors increases the risk of costly outages, emergency repairs, and even service disruptions. Network reliability suffers, and operational costs rise when issues remain hidden until damage occurs.

Key Takeaways

Telecom cabinets without sensors risk overheating, moisture damage, and unauthorized access, which can cause costly equipment failures and network downtime.

Sensors provide real-time alerts that help operators detect problems early, reducing repair costs and preventing long service interruptions.

Using multiple sensor types protects against environmental hazards and security threats, improving network reliability and equipment lifespan.

Remote monitoring with sensors speeds up response times and supports proactive maintenance, saving time and resources.

Upgrading telecom cabinets with sensors strengthens network performance, lowers maintenance costs, and keeps customers satisfied.

Equipment Failure

Overheating Risks

Telecom cabinets without sensors face a high risk of overheating. Operators cannot detect rising temperatures in real time, so equipment often runs hot for extended periods. Overheating occurs more frequently in cabinets lacking temperature sensors because there are no early warnings. This leads to several negative outcomes:

Equipment damage becomes more likely as heat builds up.

Unexpected downtime interrupts network services.

Repairs become more expensive and frequent.

The lifespan of critical components shortens.

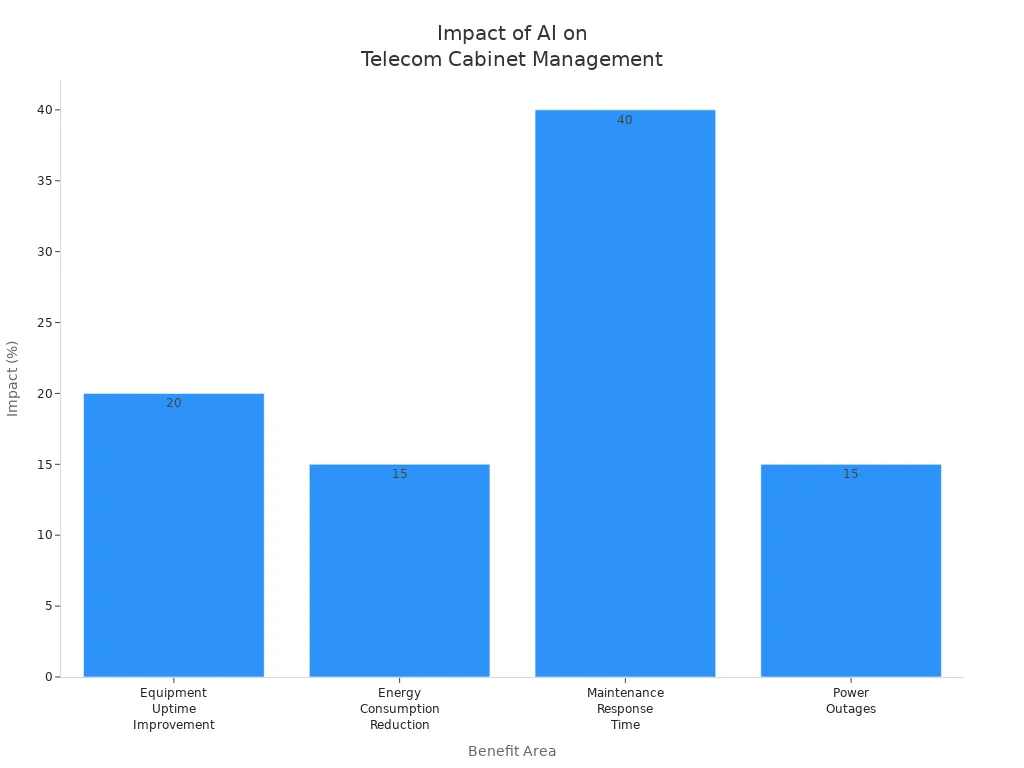

A field study showed that real-time alerts from temperature and humidity sensors allowed operators to respond within minutes to 378 alarms. This quick action reduced downtime by up to 25% and improved maintenance response times by 40%. Intelligent monitoring systems also improved equipment uptime by 20% and lowered energy consumption by 15%. Without sensors, overheating incidents become more common and severe, which increases maintenance costs and reduces network reliability.

Operators who rely on manual checks often miss early signs of overheating. Sensors provide the constant vigilance needed to protect sensitive equipment.

Environmental Damage

Environmental threats inside telecom cabinets go beyond heat. Cabinets without sensors cannot detect moisture, dust, or physical damage until problems become severe. The most common causes of equipment failure in these environments include:

Temperature and humidity extremes that cause overheating and moisture damage.

Dust and dirt that block airflow and contaminate components.

Water ingress from poor seals or weatherproofing, leading to corrosion and short circuits.

Corrosion from exposure to moisture and pollutants, which weakens cabinet structure.

Physical damage from wear, vandalism, or shock hazards.

The absence of sensor technology means these threats remain hidden. Operators only discover issues after equipment fails, which leads to costly repairs and longer downtime. Sensors help detect environmental threats early, allowing for proactive maintenance and extending the service life of network equipment.

Downtime and Delays

Slow Issue Detection

Telecom cabinets without sensors create a major blind spot for network operators. When a problem occurs, such as a temperature spike or a power disruption, operators often rely on manual inspections or wait for equipment to fail. This slow detection process leads to longer periods of undiagnosed issues. Equipment may operate under harmful conditions for hours or even days before anyone notices. As a result, minor problems can escalate into serious failures.

Operators who lack real-time monitoring cannot respond quickly. They miss early warning signs, so they only act after damage has already happened. This reactive approach increases the risk of extended downtime. Network reliability drops because issues remain hidden until they cause visible harm. In contrast, cabinets equipped with sensors send instant alerts when something goes wrong. Operators receive notifications about temperature changes, humidity spikes, or unauthorized access. This immediate feedback allows for fast intervention and prevents small issues from becoming major outages.

Quick detection is the key to minimizing network downtime. Sensors provide the eyes and ears that operators need to keep systems running smoothly.

Service Interruptions

Service interruptions have a direct impact on both customer satisfaction and business operations. When telecom cabinets lack sensors, the risk of unplanned outages rises sharply. Customers expect reliable service, so even short disruptions can damage trust and lead to complaints.

Operators who use real-time notifications and proactive maintenance tools see several benefits:

Instant alerts about power disruptions, security breaches, and system anomalies enable quick response.

Early detection and resolution of issues prevent costly breakdowns.

Reduced downtime ensures continuous network operation and improves service reliability.

Enhanced operational efficiency lowers costs and minimizes risk.

Scalable solutions support long-term network performance.

Unmonitored cabinets make it difficult to maintain high service standards. Delays in detecting and fixing problems lead to longer outages and higher costs. Over time, these interruptions can harm a company’s reputation and reduce customer loyalty. Reliable sensors help operators avoid these risks by enabling fast, effective responses to any threat.

Maintenance Costs

Reactive Repairs

Telecom cabinets without sensors force operators into a reactive maintenance cycle. They only discover problems after equipment fails or service interruptions occur. This approach leads to frequent emergency repairs and higher costs. Operators must often shut down entire cabinets for major repairs, which disrupts network operations and increases labor expenses.

PDUs with real-time sensor monitoring can reduce maintenance costs by up to 30%. Early detection of inefficiencies and power issues allows for timely intervention.

Advanced monitoring supports proactive maintenance, which lowers downtime and repair needs.

Basic PDUs without advanced monitoring require more frequent manual checks. Limited visibility into power distribution problems leads to higher maintenance demands.

Operators who use sensor-based monitoring systems benefit from targeted repairs. They can address issues panel by panel, rather than shutting down the whole cabinet. The following table highlights key differences:

Feature | Modular Cabinets (with sensor-based monitoring) | Fixed Cabinets (without sensor-based monitoring) |

|---|---|---|

Maintenance Approach | Panel-by-panel repairs | Full shutdown for major repairs |

Maintenance Time Reduction | 40% less maintenance time | N/A |

Inspection Frequency | Quarterly inspections of gaskets and connectors | Annual inspections |

Proactive maintenance enabled by sensors helps operators avoid costly emergency repairs and reduces overall maintenance time.

Resource Drain

A lack of sensors in telecom cabinets increases the strain on resources. Operators must allocate more staff and time to manual inspections and emergency responses. When issues go undetected, teams respond to crises rather than preventing them.

Missing Sensor Feature | |

|---|---|

Intrusion Detection Sensors | Security breaches go undetected, leading to emergency responses and increased resources needed. |

Remote Monitoring Systems | Issues are detected late, causing longer downtime and more urgent maintenance efforts. |

Smart Sensors | Manual inspections replace automated checks, increasing time and labor costs. |

Real-Time Alerts | Failures are not prevented early, resulting in emergency repairs and higher resource use. |

Operators who rely on manual processes face higher labor costs and longer repair times. Sensor-equipped cabinets allow for efficient resource allocation and faster problem resolution. This efficiency keeps maintenance budgets under control and supports reliable network performance.

Security and Environmental Threats

Unauthorized Access

Telecom cabinets often sit in remote or outdoor locations. Without access sensors, operators cannot detect when someone opens a cabinet or tampers with equipment. This lack of visibility creates serious risks. Unauthorized access can lead to theft, vandalism, or intentional damage. Attackers may disrupt services by cutting cables or removing critical components. These actions can cause network outages and expensive repairs.

Operators rely on physical security features like strong locks and tamper-proof designs. However, these measures alone do not provide real-time alerts. Sensors add a crucial layer of protection. They notify operators immediately if someone opens a door or tries to force entry. Early detection allows for quick response, reducing the chance of prolonged damage or service disruption.

Security sensors act as silent guards, alerting teams before small breaches become major incidents.

Key risks from missing access sensors include:

Increased chance of theft or vandalism

Delayed response to tampering

Higher risk of network downtime

Water, Smoke, and Fire

Environmental hazards threaten telecom cabinets every day. Cabinets use weatherproof seals and corrosion-resistant materials to block rain, dust, and extreme temperatures. Still, these defenses can fail over time. Without environmental sensors, operators cannot detect water leaks, smoke, or fire until equipment stops working.

Water ingress can corrode electronics and cause short circuits. Smoke and fire pose even greater dangers, risking total equipment loss. Sensors for water, smoke, and temperature changes provide early warnings. Operators can act before small leaks or overheating turn into disasters.

Water sensors detect leaks from failed seals or flooding.

Smoke sensors identify early signs of fire.

Temperature sensors warn of overheating before damage occurs.

A lack of environmental sensors means threats go unnoticed. This increases the risk of equipment failure, costly repairs, and long network outages. Reliable sensors help operators protect their infrastructure and maintain service quality.

Sensors in Telecom Cabinet

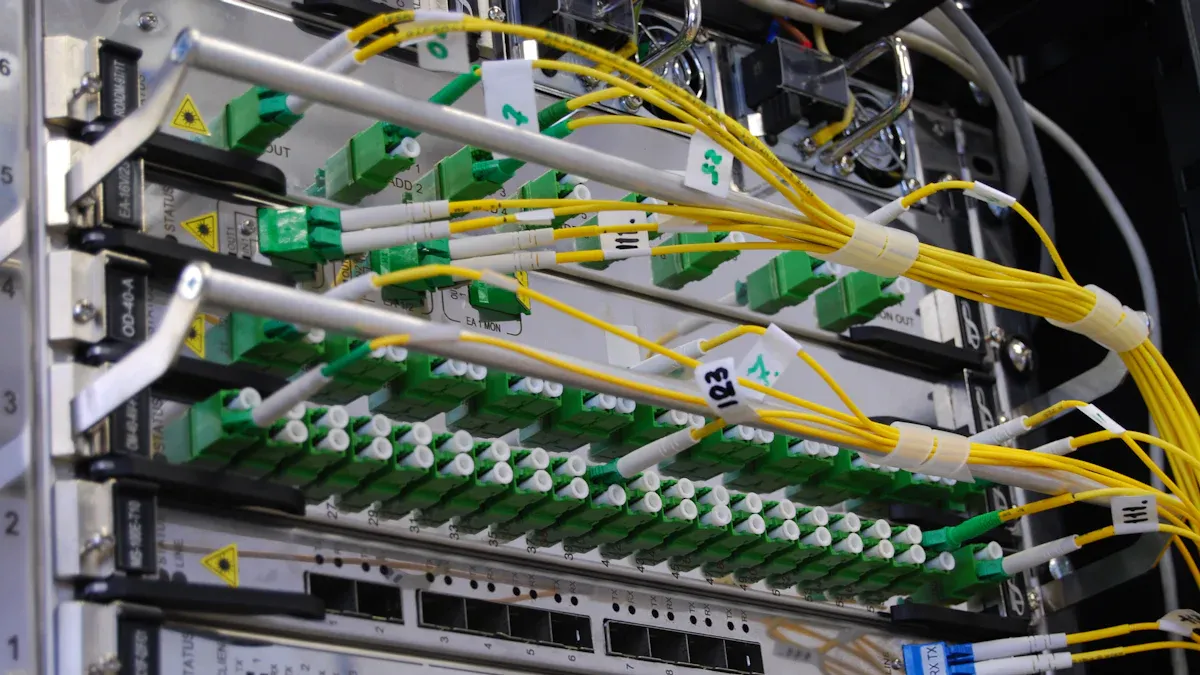

Types of Sensors

Sensors in Telecom Cabinet play a vital role in protecting network infrastructure from a wide range of threats. Each type of sensor addresses specific risks that can compromise equipment performance and network reliability.

Temperature Sensors: These sensors monitor internal cabinet temperatures. They help prevent overheating, which can damage sensitive electronics and shorten equipment lifespan.

Humidity Sensors: High humidity can cause corrosion and electrical shorts. Humidity sensors detect moisture levels, allowing operators to act before damage occurs.

Contact Closure Sensors: These sensors monitor the physical state of cabinet doors. They alert operators to unauthorized access or tampering, reducing the risk of theft or vandalism.

Smoke and Fire Sensors: Early detection of smoke or fire is crucial. These sensors provide instant alerts, enabling quick response to prevent catastrophic equipment loss.

Water Leak Sensors: Water ingress can destroy electronics. Water sensors detect leaks from failed seals or flooding, allowing for immediate intervention.

Vibration and Shock Sensors: Mechanical vibrations or shocks can loosen connections and damage hardware. These sensors help identify physical disturbances before they cause failures.

Battery Management System (BMS) Sensors: BMS sensors track voltage, current, temperature, and state of charge. They prevent electrical and thermal risks such as thermal runaway, overcharging, and overdischarging, ensuring battery safety and longevity.

Air Velocity Sensors: These sensors monitor airflow to ensure proper cooling and prevent hotspots.

Operators who install a comprehensive set of sensors in telecom cabinet environments gain early warnings for nearly every major threat, from environmental hazards to physical security breaches.

The latest advancements in sensor technology have made these devices more robust and adaptable. Integrated surge and power protection systems, modular cabinet designs, and compliance with industry standards ensure that sensors can withstand harsh conditions and support future technologies like edge computing and IoT devices.

Remote Monitoring

Remote monitoring transforms how operators manage telecom cabinets. Sensors in Telecom Cabinet environments send real-time data to centralized platforms, enabling instant detection of abnormal conditions such as temperature spikes, humidity changes, unauthorized access, and power anomalies.

Feature / Metric | Impact on Response Time and Incident Management |

|---|---|

Automated Incident Categorization | Reduces manual triage by 58%, speeding up initial response |

AI-driven Anomaly Detection | Enhances early detection in 65% of deployments, enabling faster action |

Mean Time to Repair (MTTR) | Decreases from 4.8 hours to 3.1 hours |

Real-time Drone Feeds | Improves resource deployment by 18%, cuts response time by 30 minutes |

Threshold alerts notify operators instantly when environmental parameters exceed safe limits. Motion and intrusion sensors detect unauthorized access quickly, while tilt and shock sensors monitor for physical disturbances. Automated incident reporting and ticketing reduce manual delays, and remote troubleshooting tools allow for faster problem resolution without on-site visits.

Remote monitoring services improve maintenance response times by approximately 40%. Proactive monitoring has prevented up to 80% of recent outages, and AI-driven predictive analytics can anticipate failures weeks in advance. This approach reduces unexpected downtime and improves network reliability.

Integration with broader environmental monitoring and security systems brings additional benefits:

Real-time detection and prevention of risks such as overheating, moisture, corrosion, and fire.

Instant security alerts on unauthorized access or tampering.

Centralized monitoring and automated actions reduce the need for on-site visits.

Proactive maintenance supported by data logging and early warnings.

Enhanced network reliability and asset management.

Compliance with industry standards and operational efficiency.

Centralized monitoring powered by sensors in telecom cabinet environments allows operators to act before small issues become major outages.

Selecting the right sensor solutions requires careful consideration of cabinet size, material, ventilation, power needs, cable management, and compliance with standards. Operators must also address environmental challenges, sensor calibration, scalability, and regulatory requirements. Modern cabinets support flexible and modular sensor integration, making it easier to adapt to changing network demands.

Sensors in Telecom Cabinet environments have become essential for proactive management, rapid response, and long-term network reliability. Their integration with remote monitoring and security systems ensures that operators can protect critical infrastructure and maintain high service standards.

Sensors in Telecom Cabinet protect networks from hidden dangers that threaten reliability and performance. Operating without these sensors exposes telecom networks to several risks:

Thermal buildup causes overheating, condensation, and corrosion.

Environmental damage from rain, dust, UV rays, and salt air increases.

Downtime rises, repair costs grow, and equipment lifespan shortens.

Lack of monitoring prevents proactive maintenance, leading to more emergency repairs.

Harsh climates make these risks even greater.

Network performance and long-term investment suffer.

Industry insights show that adding sensor solutions and remote monitoring allows operators to detect problems early. This approach reduces downtime, lowers maintenance costs, and improves network reliability. Decision-makers should assess their current infrastructure and upgrade with the right sensor technology to ensure strong, resilient networks.

FAQ

Why do telecom cabinets need multiple types of sensors?

Different sensors detect unique threats. Temperature sensors catch overheating, while humidity sensors spot moisture. Door sensors alert operators to unauthorized access. Using several types ensures full protection against equipment failure, environmental hazards, and security breaches.

Why does remote monitoring matter for telecom cabinets?

Remote monitoring allows operators to see problems as soon as they happen. This quick detection helps prevent downtime and reduces repair costs. Operators can act before small issues become big failures.

Why do undetected environmental changes cause network outages?

Environmental changes like heat, moisture, or dust can damage equipment. Without sensors, these threats go unnoticed. Damaged equipment often leads to unexpected outages and longer repair times.

Why should operators upgrade old cabinets with sensors?

Upgrading adds real-time alerts and better protection. Sensors help operators find problems early. This upgrade reduces emergency repairs and extends equipment life.

Why do sensors improve network reliability?

Sensors provide constant monitoring. They help operators fix issues before they cause outages. Reliable networks keep customers satisfied and reduce business losses.

See Also

Proven Strategies To Protect Communication Cabinets In Risky Zones

The Importance Of Outdoor Cabinets In Today’s Telecom Systems

Effective Ways To Safeguard Equipment Using Outdoor Telecom Cabinets

Best Practices For Monitoring Outdoor Telecom Cabinets Efficiently

A Clear Guide To Outdoor Communication Cabinets In Telecom Networks

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA