Why Telecom Cabinets Without Sensors Put Networks at Risk

Sensors in Telecom Cabinet play a vital role in protecting network infrastructure. Without these sensors, networks face silent threats from heat, moisture, and unauthorized entry. Equipment can fail without warning, causing sudden outages. Companies may experience expensive repairs and damaged hardware. Customers lose trust quickly when services go down.

Failing to monitor conditions inside telecom cabinets creates an environment where small problems become major disasters.

Key Takeaways

Sensors in telecom cabinets detect heat, moisture, and unauthorized access to prevent equipment damage and network outages.

Real-time monitoring with sensors helps operators respond quickly to problems, reducing downtime and costly repairs.

Predictive maintenance uses sensor data to spot issues early, saving money and extending equipment life.

Sensor-equipped cabinets lower maintenance costs by reducing manual inspections and preventing frequent failures.

Installing sensors improves safety for workers, ensures legal compliance, and builds customer trust through reliable service.

Real-Time Monitoring Risks

Temperature and Humidity

Telecom equipment depends on stable temperature and humidity levels. Without sensors, cabinets cannot detect dangerous changes. High temperatures can cause batteries to lose up to 35% of their capacity at 104°F (40°C). Excessive humidity speeds up battery self-discharge and reduces runtime. The table below shows recommended conditions and the effects of poor control:

Aspect | Recommendation / Effect |

|---|---|

Recommended Storage Temp | Around 59°F (15°C) |

Optimal Relative Humidity | Approximately 50% |

Temperature Range | 50°F to 68°F (10°C to 20°C) |

Humidity Range | 40% to 60% |

Effects of High Temp | Up to 35% capacity loss at 104°F (40°C) |

Effects of High Humidity | Faster battery self-discharge, reduced runtime |

Failing to monitor these factors leads to undetected overheating, corrosion, and battery failure. Real-time alerts help operators act before damage occurs.

Airflow and Cooling

Proper airflow keeps telecom equipment cool and prevents hotspots. Cabinets without airflow sensors cannot detect blocked vents or failed fans. Heat builds up, causing condensation and corrosion inside the cabinet. Over time, this environment damages sensitive components and shortens equipment life. Scientific studies show that poor airflow distribution leads to heat accumulation and inefficient cooling. Without real-time data, operators miss early signs of trouble, increasing the risk of sudden shutdowns and costly repairs.

Door and Intrusion

Unauthorized access poses a major risk to network security. Door sensors detect when someone opens a cabinet. Without these sensors, intrusions go unnoticed. Thieves or vandals can tamper with equipment, steal valuable parts, or disrupt service. Real-time alerts from door switches notify operators instantly, allowing quick response. The most common real-time alerts in telecom cabinets include:

Temperature spikes

Humidity changes

Door openings

Smoke detection

Vibration from tampering

These alerts protect equipment and data by enabling rapid intervention. Without them, networks remain vulnerable to both environmental threats and security breaches.

Outage Escalation

Small Issues Grow

Small problems inside telecom cabinets can quickly become major threats when left undetected. Sensors such as smoke detectors and power usage monitors play a crucial role in catching early warning signs. Without these devices, operators miss the first signs of trouble.

Smoke detectors alert staff to overheating or smoldering, preventing fires that could destroy equipment.

Power usage monitors track energy consumption, revealing inefficiencies before they cause failures.

Environmental sensors watch for temperature and humidity changes, stopping overheating and moisture damage.

Alarm systems provide instant notifications about power irregularities, allowing for fast action.

When these sensors are missing, minor hazards like a small temperature spike or a loose wire can go unnoticed. Over time, these small issues grow, leading to equipment breakdowns and network outages. Operators lose the chance to intervene early, which increases the risk of widespread service disruptions.

Delayed Response

Delayed response often results from a lack of real-time monitoring. Manual checks cannot match the speed and accuracy of automated alerts. When operators rely on periodic inspections, they may miss sudden changes in temperature, humidity, or power. This slow reaction allows problems to escalate.

For example, remote monitoring software in Alaska reduced site visits and improved reliability by tracking over 85 alarm points. Real-time alerts enabled quick action, cutting troubleshooting time by 30% and lowering battery failure rates by 98%. These improvements show why immediate detection is essential for network reliability.

Equipment Damage

Unchecked environmental changes and delayed responses lead to equipment damage. Sensitive telecom hardware cannot withstand prolonged exposure to heat, moisture, or power fluctuations.

The following table highlights real-world cases where small issues escalated due to insufficient monitoring:

Case Study | Initial Issue | Escalation Path | Impact | Contributing Factors |

|---|---|---|---|---|

BT Outage (2023) | Misconfigured server setting | Server overload, cascading fail | 10.5-hour outage, 14,000 failed calls | Lack of monitoring, slow detection |

Optus Outage (2023) | Router safety limit triggered | Nationwide self-isolation | 14-hour outage, 10 million+ affected | Default settings, no early alerts |

These examples show why telecom cabinets need sensors. Early detection and fast response prevent minor faults from turning into costly disasters.

Sensors in Telecom Cabinet

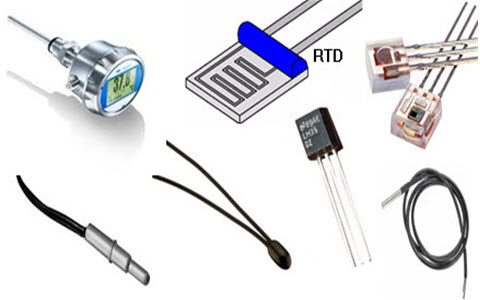

Types of Sensors

Telecom networks face many threats inside their cabinets. Sensors in Telecom Cabinet help operators detect and address these risks before they cause harm. Each sensor type targets a specific danger. The table below shows the main sensors and the problems they solve:

Sensor Type | Specific Risks Addressed |

|---|---|

Temperature Sensors | Monitor heat levels to prevent overheating and equipment damage due to high temperatures. |

Humidity Sensors | Detect moisture to avoid damage to sensitive electronics and prevent condensation-related faults. |

Power Usage Sensors | Track energy consumption to optimize efficiency and detect anomalies indicating power issues. |

Access Sensors | Alert on unauthorized cabinet openings to prevent theft, tampering, and vandalism. |

Smoke and Fire Sensors | Warn about fire hazards early to prevent fire damage and ensure safety. |

Operators use these sensors to monitor environmental, security, and operational threats. Sensors in Telecom Cabinet also include air velocity sensors for airflow, water intrusion sensors for leaks, and voltage sensors for electrical stability. Each sensor provides a layer of protection that reduces the chance of undetected failures.

Note: Without these sensors, telecom cabinets become blind spots in the network, increasing the risk of outages and costly repairs.

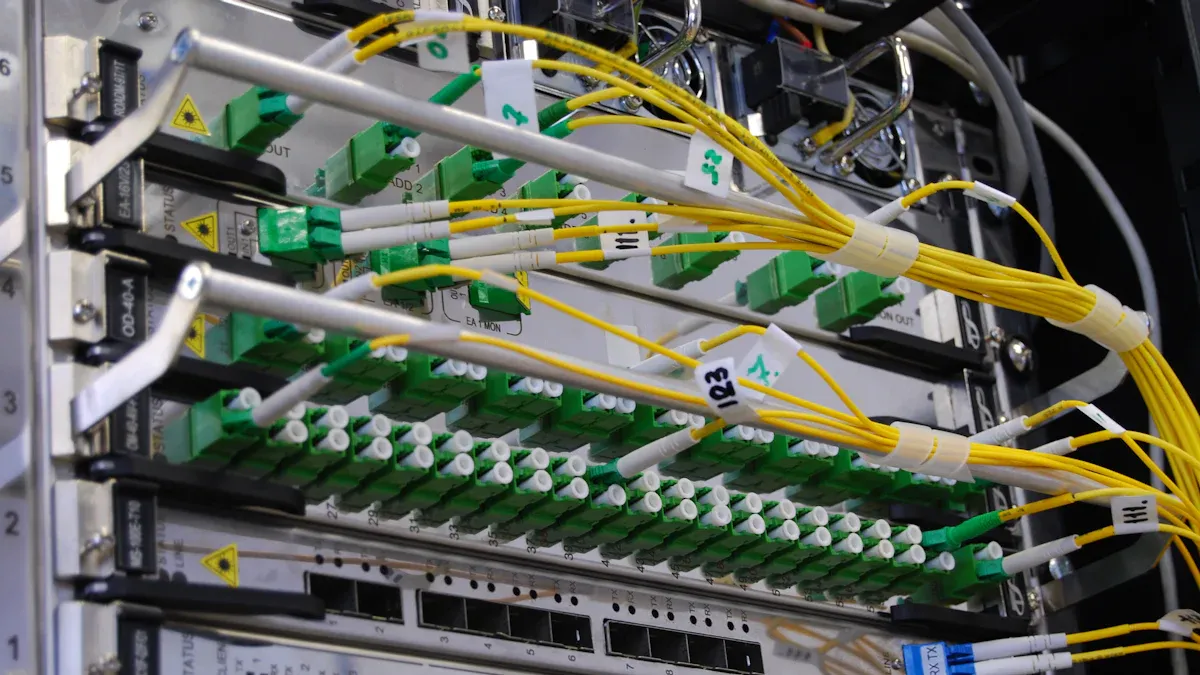

Remote Monitoring

Remote monitoring technology transforms how operators manage telecom cabinets. Sensors in Telecom Cabinet send real-time data to centralized systems, allowing teams to spot problems instantly. This approach improves incident detection and response times for several reasons:

Immediate detection of power failures and battery health issues, which is vital for remote sites.

Dedicated alarm collectors focus on power and battery concerns, reducing distractions from unrelated alerts.

Detailed alarms include response instructions, so technicians arrive prepared.

Notifications reach emails and smartphones, enabling fast and flexible responses.

Advanced battery monitoring sensors provide real-time data on voltage, temperature, and resistance, supporting predictive maintenance.

The system reduces unnecessary site visits and labor time, as technicians know what to expect and bring the right tools.

High-precision sensors and real-time analytics give operators immediate insights into system performance. Machine learning algorithms predict equipment failures, so teams can act before problems escalate. Automated notifications and detailed reports reach the right people quickly, minimizing damage and service disruptions.

Predictive Maintenance

Predictive maintenance uses data from Sensors in Telecom Cabinet to prevent failures before they happen. Smart sensors track conditions like temperature, vibration, and pressure. These sensors send early warning signals when equipment shows signs of wear or faults. When operators connect this data to a centralized maintenance system, they gain real-time asset intelligence. This allows for dynamic, condition-based scheduling instead of relying on fixed intervals or waiting for breakdowns.

AI-powered predictive maintenance analyzes sensor data from base stations, cables, and switching centers. The system detects subtle anomalies and predicts faults before they disrupt service. Major telecom operators have reported significant reductions in downtime by using AI to predict up to 80% of network failures. This proactive approach optimizes maintenance schedules, prevents outages, and improves customer experience.

Telecom companies benefit from fewer emergency repairs and more consistent network uptime. Predictive maintenance ensures that teams intervene only when necessary, reducing costs and extending equipment life. Customers enjoy reliable connectivity, and operators avoid the high expenses linked to unexpected failures.

Impact on Uptime and Costs

Downtime

Telecom cabinets without sensors create blind spots in network monitoring. Operators cannot detect early signs of trouble, so outages last longer and occur more often. Real-time monitoring with sensors allows teams to respond quickly, reducing downtime. The table below shows how sensor-equipped cabinets improve network uptime:

Benefit Area | Reported Downtime Reduction or Impact |

|---|---|

Downtime reduction | |

Downtime reduction (case example) | Up to 35% (major operator with predictive maintenance) |

Sensor-equipped cabinets help operators avoid costly service interruptions. They detect temperature spikes, humidity changes, and unauthorized access before these issues cause failures. This proactive approach keeps networks running and prevents widespread outages.

Maintenance Expenses

Sensorless cabinets require frequent manual inspections and repairs. Operators must send technicians to check for problems, which increases labor and operational costs. Automated monitoring systems reduce the need for these visits. The following table compares maintenance expenses between networks with and without sensors:

Feature/Aspect | With Sensor-Equipped Cabinets | Without Sensor-Equipped Cabinets |

|---|---|---|

Maintenance System | Automated, sensor-driven | Manual, tool-based |

Maintenance Frequency | Reduced | Higher |

Maintenance Costs | ~35% lower | Higher |

Component Failures | 40% fewer | More frequent |

Labor and Operational Expense | Lower | Higher |

Equipment Longevity | Improved | Shorter lifespan |

Operators report significant cost savings after deploying sensor-based monitoring. Fewer technician visits, less equipment failure, and extended hardware life all contribute to lower total ownership costs.

Customer Trust

Network downtime and service disruptions damage customer trust. When undetected cabinet issues cause outages, customers experience frustration and may switch providers. Regular hardware inspections and real-time alerts prevent these problems. Reliable service builds loyalty and helps operators retain customers. Without sensors, networks face longer outages and more frequent failures, leading to dissatisfaction and lost business.

Smart cabinets with sensors protect both network performance and customer relationships by ensuring consistent, high-quality service.

Compliance and Safety

Industry Standards

Telecom operators must follow strict industry standards to ensure network reliability and safety. Organizations such as the Environmental Protection Agency (EPA) and international standards like ISO 14001 require continuous monitoring of environmental conditions inside telecom cabinets. These standards exist because undetected threats, such as overheating or water leaks, can cause severe equipment failures and service interruptions. Operators who install sensors in their cabinets can meet these requirements and avoid penalties. Real-time monitoring systems also help operators prepare for audits and demonstrate their commitment to best practices. Meeting industry standards protects both the network and the company’s reputation.

Personnel Safety

Sensors in telecom cabinets play a critical role in protecting maintenance teams and emergency responders. Without these devices, technicians face hidden dangers during routine checks or urgent repairs. Key safety benefits include:

Water sensors detect leaks early, preventing electrical hazards like short circuits and fires.

Early alerts from water sensors allow technicians to act quickly, reducing the risk of electric shocks.

Real-time notifications help teams fix leaks before they cause downtime or injuries.

Wired smoke detectors provide continuous monitoring for smoke and heat, offering early fire detection.

Immediate alerts from smoke detectors enable fast intervention, stopping fires before they escalate.

Integration with centralized systems ensures coordinated emergency responses and instant notifications.

Advanced sensors reduce false alarms, so personnel trust and respond to real threats.

These features explain why sensor-equipped cabinets create safer working environments for all staff.

Legal Risks

Telecom operators who ignore sensor requirements face serious legal risks. Regulatory agencies demand strict compliance with environmental and operational monitoring. Failing to install sensors can result in:

Fines and legal actions for not meeting regulatory standards.

Increased risk of operational failures, leading to further legal and reputational damage.

Loss of trust from stakeholders and customers.

Difficulty preparing for audits without automated reporting systems.

Greater exposure to lawsuits if outages or accidents occur due to undetected hazards.

Real-time alerts and automated monitoring help operators stay compliant and avoid costly legal consequences. Proactive sensor deployment shows a strong commitment to safety and regulatory requirements, reducing the risk of penalties and protecting the company’s future.

Operating telecom cabinets without sensors exposes networks to hidden threats, leading to costly outages and equipment failures. Real-time monitoring remains essential for network reliability. As telecom infrastructure evolves, operators should adopt strategies such as deploying environmental and access sensors, integrating remote monitoring, and using high-quality enclosures.

Investing in Sensors in Telecom Cabinet protects critical assets, reduces downtime, and prepares networks for future demands. Proactive management ensures safer, more resilient, and customer-focused operations.

FAQ

Why do telecom cabinets need sensors for temperature and humidity?

Sensors help operators detect dangerous changes in temperature and humidity. These changes can damage equipment and cause outages. Early detection allows quick action, which protects network reliability and reduces repair costs.

Why does real-time monitoring matter for telecom cabinets?

Real-time monitoring gives operators instant alerts about problems. This fast response prevents small issues from becoming major failures. Networks stay more reliable, and customers experience fewer service interruptions.

Why do sensors improve network uptime?

Sensors catch early warning signs of trouble. Operators can fix problems before equipment fails. This proactive approach keeps networks running longer and reduces downtime.

Why should telecom operators invest in predictive maintenance?

Predictive maintenance uses sensor data to spot equipment issues early. Operators can schedule repairs before failures happen. This strategy saves money and extends equipment life.

Why does the lack of sensors increase legal and safety risks?

Without sensors, operators may miss hazards like overheating or water leaks. These risks can lead to accidents, legal penalties, and damage to company reputation. Sensors help maintain safety and meet industry standards.

See Also

The Importance Of Outdoor Cabinets In Modern Telecom Systems

Professional Advice On Protecting Cabinets In Dangerous Locations

A Guide To Outdoor Cabinets And Their Telecom Functions

Strategies To Achieve Effective Monitoring Of Outdoor Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA