What Types of Sensors Are Used in ESTEL Telecom Cabinets

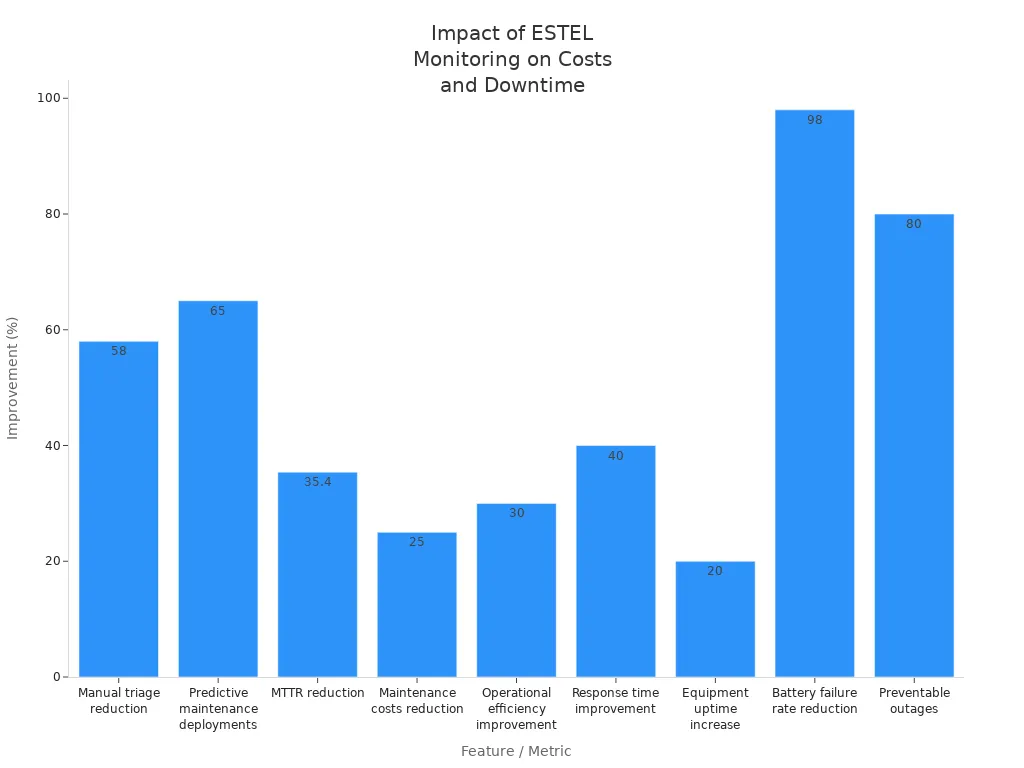

ESTEL telecom cabinets feature a range of sensors, including temperature, humidity, air quality, current, proximity, security, multisensors, and motion or light sensors. These telecom cabinet sensors help guard critical equipment, provide real-time monitoring, and support remote monitoring systems. Sensors in telecom cabinet environments detect changes quickly, which helps reduce network downtime by 25%. A table below highlights the impact of telecom cabinet sensors:

Impact Area | Statistical Evidence | Description of Sensor Role and Benefits |

|---|---|---|

Equipment Protection | Sensors enable early detection of risks and send real-time alerts. | |

Operational Efficiency | Up to 35% downtime reduction | Sensors support predictive maintenance and optimize cooling. |

Security | Immediate alerts | Security sensors detect intrusion attempts. |

Real-time monitoring and environmental monitoring ensure rapid response to threats. Remote monitoring systems also allow teams to act before issues escalate, saving energy and improving uptime.

Key Takeaways

ESTEL telecom cabinets use various sensors like temperature, humidity, security, and power sensors to protect equipment and reduce network downtime by up to 25%.

Temperature and humidity sensors monitor internal conditions to prevent overheating and moisture damage, extending equipment life and lowering maintenance costs.

Security sensors such as proximity and door sensors detect unauthorized access and trigger real-time alerts to keep equipment safe.

Power and current sensors track energy use and battery health, helping operators save energy and maintain service during outages.

Multisensor devices combine multiple functions in one unit, simplifying installation and improving monitoring efficiency for faster problem detection.

Sensors in Telecom Cabinet

Temperature Sensors

Temperature sensors play a vital role in telecom cabinet sensors. These devices constantly track the internal temperature, ensuring that sensitive electronics operate within safe limits. The ESTEL WeatherProof Galvanised Steel Integrated Outdoor Telecom Cabinet, for example, uses an Environment Monitoring Unit equipped with industrial-grade temperature sensors. These sensors feature an IP55 rating, which means they resist dust and rain, making them ideal for outdoor environments.

Metric | Value / Description |

|---|---|

Temperature Accuracy | ±0.3°C at critical points; ±0.63°C in telecom cabinet applications |

Laboratory Precision | Up to 0.001°C |

Temperature Measurement Range | -40°C to +75°C |

Temperature Resolution | 0.1°C increments |

Response Time | Fast response to quickly detect temperature spikes, enabling prompt cooling system reaction |

Accurate temperature monitoring helps prevent overheating, which can damage equipment and cause network outages. Fast response times allow cooling systems to activate before temperatures reach dangerous levels. Telecom cabinet sensors with these features support real-time monitoring and remote alerts, reducing downtime and maintenance costs.

Tip: Regular temperature monitoring with industrial-grade sensors helps maintain optimal performance and extends equipment life.

Humidity Sensors

Humidity sensors are another essential component of sensors in telecom cabinet environments. These sensors detect moisture levels inside the cabinet, providing early warnings before condensation forms on electronic components. High humidity can lead to corrosion, short circuits, and equipment failure.

Humidity sensors alert maintenance teams to rising moisture, allowing quick action to prevent damage.

They help avoid costly repairs and replacement of corroded parts.

By protecting sensitive electronics, these sensors reduce downtime and extend the lifespan of telecom equipment.

Humidity monitoring also prevents small leaks or humidity spikes from causing major disruptions.

Humidity monitoring enables timely interventions, such as drying, sealing leaks, or adjusting environmental controls. This proactive approach keeps the internal environment stable and safe for critical electronics.

Data Center Temperature Sensors

Data center temperature sensors in ESTEL cabinets provide real-time monitoring to maintain optimal conditions for servers and networking equipment. These sensors help ensure compliance with industry standards, such as those recommended by ASHRAE. They track temperature and humidity, preventing overheating and excessive moisture that could harm sensitive devices.

Real-time data supports proactive risk mitigation and predictive maintenance.

Detailed reporting features help with audit documentation and regulatory compliance.

Advanced analytics allow teams to identify trends and address potential issues before they escalate.

Temperature and humidity sensors in data centers help maintain reliability and safety, supporting continuous operation and reducing the risk of costly downtime.

Data Center Humidity Sensors

Data center humidity sensors monitor moisture levels to protect valuable equipment from condensation and corrosion. These sensors continuously check for humidity spikes, which can lead to equipment failure if left unchecked. By providing early alerts, they enable maintenance teams to act quickly, preventing damage and ensuring a stable environment.

Continuous humidity monitoring helps maintain safe conditions for servers and networking hardware.

Early detection of moisture buildup allows for timely maintenance, such as drying or adjusting environmental controls.

These sensors play a key role in extending equipment life and minimizing service interruptions.

Telecom cabinet sensors, including data center humidity sensors, form the backbone of environmental monitoring in modern telecom infrastructure. They help operators maintain high standards of reliability, security, and efficiency.

Security and Access Sensors

Proximity Sensors

Proximity sensors serve as the first line of defense in ESTEL telecom cabinets. These sensors detect when someone approaches or interacts with the cabinet doors. The most effective proximity sensor for this application is a 28VDC 10W door sensor. This device is designed for outdoor telecom cabinets and can sense door opening events within an action distance of 35mm. When someone tries to force the door open, the sensor triggers an alarm signal. The sensor operates at up to 28VDC, with a contact power of 10W and a current of 0.5A. Technicians embed the sensor into the cabinet door. When unauthorized access occurs, the sensor immediately sends an alarm to the monitoring center. This quick response helps prevent theft, vandalism, and unauthorized entry.

Note: Proximity sensors in ESTEL cabinets provide reliable, real-time alerts that help security teams respond quickly to threats.

Door Sensors

Door sensors play a crucial role in physical security and access control. They monitor the opening and closing of cabinet doors and log every access event. These sensors work with smart lock systems and digital tools, replacing traditional keys. This setup allows remote control of access permissions and ensures only authorized personnel can enter.

Smart lock management enables digital access and remote permission control.

Real-time monitoring through sensors and cameras provides continuous surveillance.

Motion detectors trigger alarms or notifications when they detect suspicious activity.

Door sensors log every access event and trigger alerts for unauthorized entry.

Intrusion detection systems linked to these sensors can activate alarms or lock down cabinets.

This combination of features helps maintain strict control over sensitive equipment and protects against unauthorized access.

Intrusion Detection

Intrusion detection systems in ESTEL telecom cabinets use a network of sensors to identify and respond to security threats. These systems link proximity and door sensors to a central monitoring platform. When the system detects forced entry or unauthorized access, it can trigger alarms, send instant notifications, or even lock down the cabinet automatically. This proactive approach ensures that security teams can act before any damage occurs. Intrusion detection not only protects valuable equipment but also helps maintain network reliability and service continuity.

Air Quality and Environmental Sensors

Air Quality Sensors

Air quality sensors in ESTEL telecom cabinets monitor several critical parameters that influence equipment longevity. These sensors track smoke, water ingress, temperature, humidity, door status, and vibration. Each parameter plays a unique role in protecting sensitive electronics. For example, smoke sensors provide early fire detection, while water sensors alert operators to leaks that could cause corrosion. Temperature and humidity sensors help maintain optimal internal conditions, reducing the risk of overheating or moisture damage. Vibration sensors detect mechanical shocks that might harm delicate components. The table below summarizes these monitored parameters and their impact:

Sensor Type | Monitored Parameter | Operational Range | Impact on Equipment Longevity |

|---|---|---|---|

Smoke sensor | Smoke presence | N/A | Early detection of fire risk, preventing damage |

Water sensor | Water ingress | N/A | Early warning of moisture intrusion, avoiding corrosion |

Temperature sensor | Internal temperature | -40℃ to +55℃ | Prevents overheating, thermal stress on electronics |

Humidity sensor | Internal humidity | 5% to 95% (no condensation) | Avoids moisture-related damage and corrosion |

Door sensor | Door status | N/A | Monitors physical security, preventing unauthorized access |

Vibration sensor | Mechanical disturbances | N/A | Detects shocks that could damage sensitive components |

Maintaining these parameters within safe ranges extends the life of telecom equipment and supports reliable operation.

Smoke and Gas Detection

ESTEL telecom cabinets use advanced smoke and gas detection systems. These systems combine optical smoke sensors, heat sensors, and gas sensors for comprehensive coverage. Wired smoke detectors connect directly to centralized monitoring, ensuring continuous power and rapid alerts. Multi-sensor integration reduces false alarms and increases detection accuracy. The use of Low Smoke Zero Halogen (LSZH) cables meets strict fire safety standards such as IEC 60332, UL 1666, and NFPA. These cables resist flames, moisture, and chemicals, making them ideal for outdoor environments. Compliance with standards like FM Global and the International Fire Code ensures safe lithium battery storage. Early fire detection and reliable alerts protect both equipment and personnel.

Data Center Environmental Sensors

Data center environmental sensors in ESTEL cabinets provide real-time monitoring of temperature, humidity, and airflow. Operators use these sensors to detect anomalies, such as overheating or water leaks, before they cause failures. Multiple sensors, including data center airflow sensors and data center pressure differential sensors, are placed near air intake vents for precise readings. Data center water leak sensors and data center contact closure sensors add another layer of protection by identifying leaks and unauthorized access. Data center vibration sensors detect shocks or disturbances. These sensors work together to form an early warning system, sending threshold alerts and enabling predictive maintenance. IoT-enabled platforms connect all sensors for remote monitoring and rapid response. This comprehensive environmental monitoring approach reduces downtime and improves equipment reliability.

Power and Current Sensors

Current Sensors

Current sensors in ESTEL telecom cabinets measure the flow of electrical current to ensure safe and efficient operation. These sensors help detect overloads, short circuits, and abnormal power consumption. ESTEL uses several types of current sensors, each with unique strengths. Current transformers provide high accuracy for AC current measurement. DC-CT® Platise Flux sensors offer precision for both AC and DC currents, reaching accuracy levels as fine as 0.01%. Fluxgate sensors deliver low hysteresis and high precision, making them ideal for sensitive equipment. Hall effect sensors, especially closed-loop designs, add versatility and stability for both AC and DC monitoring.

Sensor Type | Common Usage in Telecom Cabinets | Measurement Accuracy Range |

|---|---|---|

Current Transformers | AC current measurement; reliable and accurate | High accuracy and linearity |

DC-CT® Platise Flux | AC and DC; high-end precision measurements | 0.1% down to 0.01% |

Fluxgate Sensors | Precision current measurements | High accuracy, low hysteresis |

Hall Effect Sensors | AC and DC; closed-loop for better accuracy | Moderate to high accuracy |

These sensors allow operators to monitor power usage in real time, prevent equipment damage, and maintain network reliability.

Power Monitoring

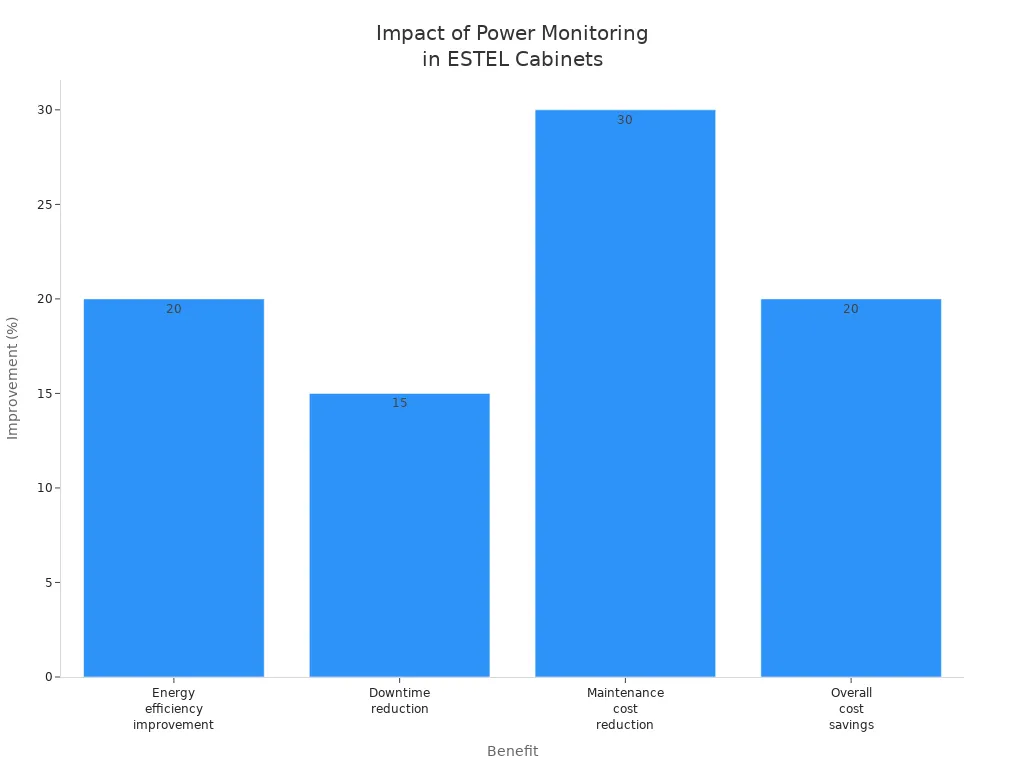

Power monitoring systems in ESTEL telecom cabinets track energy consumption and help optimize power usage. Intelligent PDUs (Power Distribution Units) and real-time monitoring tools identify inefficiencies and support predictive maintenance. Operators can reduce energy waste and lower operational costs by analyzing power data and adjusting usage patterns.

Benefit | Measurement |

|---|---|

Energy efficiency improvement | |

Downtime reduction | 15% decrease in downtime |

Maintenance cost reduction | 30% lower maintenance expenses |

Overall cost savings | Up to 20% savings in operational costs |

Operators benefit from remote monitoring, which reduces travel costs and enables quick troubleshooting. ESTEL’s modular design also supports long-term adaptability and compliance with energy standards.

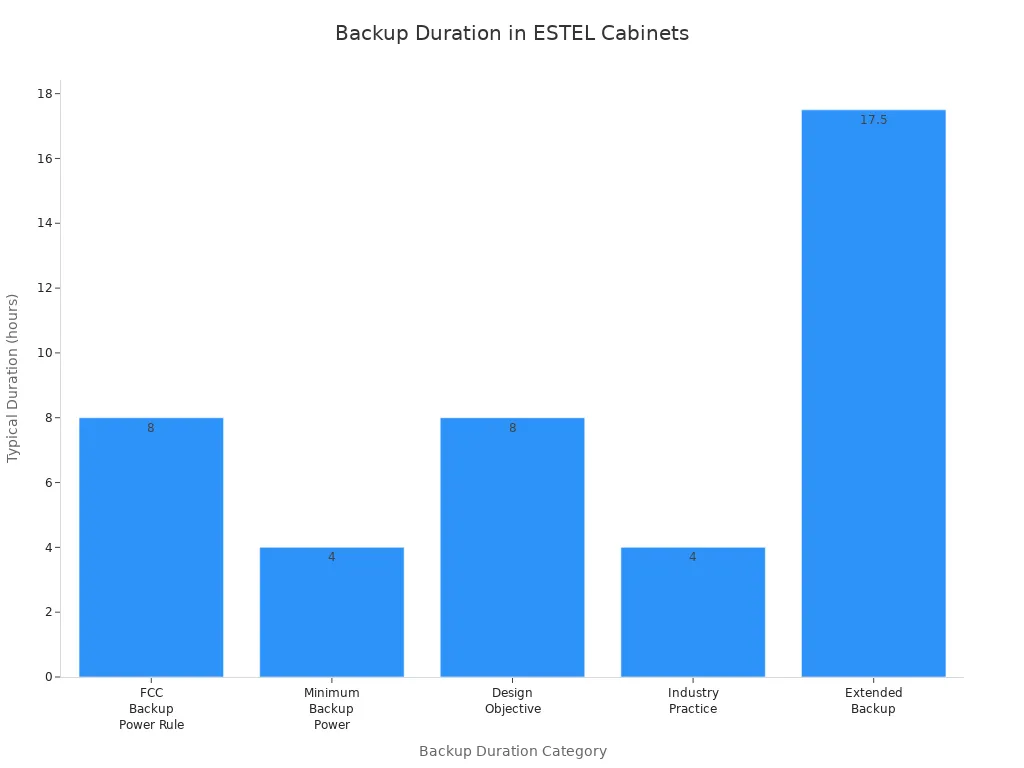

Battery and Backup Sensors

Battery and backup sensors in ESTEL telecom cabinets ensure continuous operation during power outages. These sensors monitor battery health, charge levels, and backup duration. Most cabinets provide a minimum of 4 hours of backup power, with 8 hours as a common design goal. Some systems extend backup to 15–20 hours, reducing the risk of service loss to just 2%.

Backup Duration Category | Typical Duration | Notes |

|---|---|---|

FCC Backup Power Rule | 8 hours | Applies to cell sites and remote terminals; 24 hours for central offices |

Minimum Backup Power | 4 hours | Standard minimum backup duration for remote terminals |

Design Objective | 8 hours | Recommended for most outages to ensure service continuity |

Industry Practice | 4+ hours | 80% of wireless remote terminals have at least this backup |

Extended Backup | 15-20 hours | Further reduces risk of service loss to about 2% |

These sensors help operators maintain service during emergencies, protect critical equipment, and meet industry standards for reliability.

Multisensors and Advanced Features

Multisensor Devices

Multisensor devices combine several sensing technologies into a single unit. These devices often monitor temperature, humidity, smoke, and even vibration at the same time. Operators use multisensors in ESTEL telecom cabinets to simplify installation and reduce wiring complexity. A single multisensor can replace multiple individual sensors, saving space and lowering maintenance costs. Multisensors also provide unified data streams, which help monitoring systems detect patterns and respond to environmental changes more quickly.

Multisensor devices improve reliability by reducing the number of failure points in the cabinet. They also support remote diagnostics, making it easier for technicians to identify issues without visiting the site.

Motion and Light Sensors

Motion and light sensors add another layer of intelligence to ESTEL telecom cabinets. Motion sensors detect movement near or inside the cabinet. They trigger alarms or activate cameras when unauthorized access occurs. Light sensors measure ambient light levels and can control internal cabinet lighting automatically. This feature saves energy and ensures technicians have proper visibility during maintenance.

Motion sensors help security teams respond to threats in real time.

Light sensors reduce energy consumption by turning lights on only when needed.

These sensors work together to enhance both security and operational efficiency.

Sensor Enclosures

Sensor enclosures protect sensitive electronics from harsh environments. ESTEL uses enclosures with different IP and NEMA ratings to match specific installation needs. The table below summarizes common ratings and their protection levels:

Rating Type | Protection Description |

|---|---|

IP54 / NEMA 3 | Protection against dust and rain, suitable for outdoor use |

IP55 / NEMA 12 | Protection against dust and low-pressure water sprays, suitable for indoor use |

IP66 / NEMA 4, 4X | Complete protection against dust and high-pressure water jets; 4X adds rust protection for harsh or corrosive environments |

Additional features include marine-grade aluminum alloys, which resist salt spray and maintain stability for over 15 years. Corrosion-resistant coatings, such as zinc-aluminum alloys, enhance durability and meet environmental standards. Moisture-wicking polyester filters reduce dust ingress by about 72%, protecting internal components. UV-resistant materials and weatherproof seals prevent water and sunlight damage, ensuring long-term reliability.

Selecting the right enclosure protects sensors from dust, moisture, and corrosion. This choice extends the life of both sensors and the telecom equipment they monitor.

ESTEL telecom cabinet sensors deliver strong protection for critical equipment, boost uptime, and drive energy efficiency. Operators benefit from real-time monitoring and proactive alerts, which help prevent failures and reduce maintenance costs. Key features include:

Advanced monitoring of power, temperature, humidity, and security risks

Predictive maintenance and remote monitoring systems for faster response

Energy savings through intelligent power management and automated controls

With advanced sensor integration, ESTEL cabinets support long-term reliability and secure telecom operations.

FAQ

What is the main purpose of sensors in ESTEL telecom cabinets?

Sensors protect equipment by monitoring temperature, humidity, power, and security. They help operators detect risks early. Real-time alerts allow quick action, which reduces downtime and prevents costly damage.

How do temperature and humidity sensors improve cabinet reliability?

Temperature and humidity sensors track environmental changes. They alert teams before conditions become dangerous. This early warning helps prevent overheating, condensation, and corrosion, which keeps equipment running longer.

Can operators monitor ESTEL cabinet sensors remotely?

Yes. Operators use remote monitoring systems to check sensor data in real time. These systems send alerts for any abnormal readings. Remote access saves time and improves response speed.

What types of security sensors do ESTEL cabinets use?

ESTEL cabinets use proximity sensors, door sensors, and intrusion detection devices. These sensors detect unauthorized access. They trigger alarms and send notifications to security teams.

Why are multisensor devices popular in telecom cabinets?

Multisensor devices combine several functions, such as temperature, humidity, and smoke detection. They save space and reduce wiring. Operators find them easier to install and maintain.

See Also

Ensuring Safety In Custom ESTEL Outdoor Telecom Cabinets

A Comprehensive Look At ESTEL Outdoor Telecom Cabinet Design

Power Solutions Using Energy Storage Batteries In ESTEL Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA