What Are the Most Common Sensors Found in Communication Cabinets

Communication cabinets typically contain a range of sensors that support environmental control, equipment protection, and security.

Temperature sensors measure internal heat levels to prevent overheating.

Humidity sensors maintain proper moisture to reduce corrosion risk.

Air quality sensors detect harmful particles that threaten sensitive electronics.

Current sensors monitor electrical flow for early fault detection.

Proximity sensors identify movement near the cabinet to enhance access control.

Security sensors, such as contact or vibration types, help prevent unauthorized entry.

Multisensors combine several detection methods to provide comprehensive monitoring.

Reliable sensor integration ensures continuous protection and operational stability for critical infrastructure.

Key Takeaways

Temperature and humidity sensors keep communication cabinets safe by preventing overheating and moisture damage.

Air quality and water leak sensors detect harmful particles and moisture early to protect sensitive electronics.

Security and proximity sensors help stop unauthorized access and alert staff to tampering or movement near cabinets.

Current sensors monitor electrical flow to prevent faults and support energy management.

Wireless and multisensors simplify installation and provide real-time, combined monitoring for better control and faster response.

Temperature Sensors

Function

Temperature sensors monitor the internal environment of communication cabinets by measuring heat levels. These devices provide real-time data, allowing operators to track temperature fluctuations and respond quickly to any abnormal changes. Common types include Resistance Temperature Detectors (RTDs), thermocouples, and thermistors. RTDs use changes in electrical resistance to determine temperature, often employing platinum for stability. Thermocouples generate a voltage from two different metals, while thermistors offer high accuracy within a limited range. Most temperature sensors in communication cabinets deliver accuracy within a few tenths of a degree Celsius, ensuring precise monitoring.

Importance

Maintaining the correct temperature inside communication cabinets is essential for protecting sensitive electronic equipment. Even a small increase in ambient temperature can raise the temperature of critical components like CPUs and servers, which are highly sensitive to heat. If temperatures rise above recommended levels—typically between 64°F and 80°F (18°C to 27°C)—equipment may overheat, risking shutdowns or permanent damage. High-precision sensors, such as those with an accuracy of ±0.54°F (±0.3°C), enable real-time monitoring and immediate alerts. This proactive approach minimizes downtime and prevents costly failures.

Quick response to temperature alerts can prevent silent equipment shutdowns and critical network failures.

Use Cases

Operators install temperature sensors in several locations within a cabinet to monitor both intake and exhaust air. For example, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) recommends at least six sensors per rack for comprehensive coverage. Real-time network-connected monitoring systems allow staff to receive instant notifications when temperatures exceed safe thresholds. Typical scenarios include telecom cabinets housing servers, switches, and power supplies, where overheating could disrupt service. Wireless sensor networks, such as those using ZigBee technology, further enhance monitoring by providing remote visibility and reducing the need for on-site inspections.

Humidity Sensors

Function

Humidity sensors play a vital role in communication cabinets by continuously measuring the relative humidity inside the enclosure. These devices provide real-time data, allowing operators to maintain optimal environmental conditions. Most humidity sensors offer high precision and factory calibration, ensuring accurate readings. They often feature wireless data transmission, which enables remote monitoring and instant alerts when humidity levels fall outside the recommended range of 40% to 60% relative humidity (RH). Many models support integration with HVAC systems, optimizing energy efficiency and reducing operational costs. Operators can configure alerts to receive notifications through multiple channels, such as email or text, for immediate response.

Prevention of condensation and static electricity

Threshold alerting with tiered warnings

Integration with HVAC for energy savings

Support for remote monitoring and notifications

Tip: Strategic placement of humidity sensors near air intake vents ensures precise monitoring and early detection of environmental changes.

Importance

Maintaining proper humidity levels inside communication cabinets is essential for equipment reliability and longevity. High humidity can cause condensation, which damages sensitive electronic components. Moisture ingress, especially in outdoor installations, increases the risk of corrosion and electrical faults. Frequent door openings allow humid air to enter, placing extra load on desiccant systems and making it difficult to stabilize internal humidity. If not managed, these conditions can lead to reduced equipment lifespan and increased maintenance costs. Effective humidity control, supported by accurate sensors, helps prevent static electricity buildup and moisture-related failures. Reliable humidity management also supports compliance with health and safety regulations.

Use Cases

Industry case studies show that humidity sensors are commonly used to monitor and maintain optimal humidity levels in telecom and data center environments. Operators typically deploy one sensor per five racks, placing them at the front of the rack for best results. These sensors work alongside temperature sensors to provide comprehensive environmental monitoring. Administrators set thresholds to detect critical humidity values and take preventive action before failures occur. Remote monitoring and alerting capabilities allow for proactive maintenance, reducing downtime and protecting mission-critical equipment. By optimizing HVAC performance, humidity sensors also contribute to energy-efficient operation and infrastructure protection.

Air Quality and Water Leak Sensors

Air Quality Sensors

Air quality sensors in communication cabinets detect harmful gases and particles that can damage sensitive electronics. These devices monitor the internal environment and provide early warnings when air quality drops below safe levels. Operators often choose compact models that fit easily inside enclosures and offer real-time data.

Sensor Model | Contaminants Detected | Features |

|---|---|---|

AQS 1 Urban Air Quality Monitor | Particulate matter (TSP, PM10, PM4, PM2.5, PM1), NO2, O3, CO, H2S, SO2, VOCs | Multi-gas and particulate measurement, 1-minute data, weatherproof, urban/industrial use |

AXIS D6210 Air Quality Sensor | PM, VOCs, NOx, CO2 | Indoor use, integrates with IP devices, measures humidity and temperature |

These sensors use advanced technologies such as MEMS-based electrochemical sensors and laser particle counters. They detect a wide range of contaminants, including particulate matter, carbon monoxide, carbon dioxide, hydrogen sulfide, volatile organic compounds, nitrogen oxides, sulfur dioxide, and ozone. The table below summarizes common sensor types and their targets:

Sensor Type | Contaminants Detected | Notes |

|---|---|---|

Particulate Matter (PM2.5, PM10) | Fine/coarse airborne particles | Critical for air quality monitoring |

Carbon Monoxide (CO) | Carbon monoxide gas | Toxic gas, workplace safety |

Carbon Dioxide (CO2) | Carbon dioxide | Monitors ventilation efficiency |

Hydrogen Sulfide (H2S) | Hydrogen sulfide gas | Toxic, flammable, industrial safety |

VOCs | Organic chemical pollutants | Detects harmful organic gases |

Nitrogen Oxides (NOx) | Nitrogen oxides | Urban/industrial pollutant |

Sulfur Dioxide (SO2) | Sulfur dioxide | Industrial pollutant |

Ozone (O3) | Ozone | Monitors environmental ozone levels |

Operators rely on air quality sensors to maintain compliance with health and safety standards and to protect equipment from corrosion or malfunction caused by airborne contaminants.

Water Leak Sensors

Water leak sensors provide early detection of moisture or liquid intrusion inside communication cabinets. These devices use conductive strips or probes to sense the presence of water. When they detect moisture, they trigger immediate alerts, allowing operators to respond before damage occurs.

Detects leaks from HVAC failures, roof leaks, or condensation

Sends instant notifications to maintenance teams

Prevents corrosion, electrical shorts, and equipment downtime

Operators often place water leak sensors at the base of cabinets or near cable entry points. These sensors play a critical role in environments where water exposure poses a significant risk to electronic systems. By providing real-time alerts, they help prevent costly repairs and service interruptions.

Security and Proximity Sensors

Security and proximity sensors play a vital role in protecting communication cabinets from unauthorized access and physical threats. These devices help operators monitor cabinet status, detect tampering, and respond quickly to security incidents. The following table summarizes common sensor types, their typical installation locations, and their main functions:

Sensor Type | Typical Installation Location(s) | Purpose/Function |

|---|---|---|

Contact Closure | Rack door entrances; critical electrical and control panels | Alert when contact across adjoining surfaces is broken; monitor unauthorized access to cabinets. |

Proximity | Alongside contact closure sensors near cabinet entrances | Detect presence of someone passing nearby the cabinet. |

Vibration (Shock) | Inside cabinets or directly on IT equipment | Detect shock and vibrations in three perpendicular directions; monitor physical shocks and environmental impacts. |

Door Contact Sensors

Door contact sensors use magnetic or mechanical switches to detect when a cabinet door opens or closes. Operators install these sensors at rack door entrances and on critical control panels. When someone opens a door without authorization, the sensor triggers an alert. This immediate notification helps security teams respond before any equipment is compromised. Door contact sensors also support audit trails by recording every access event.

Tip: Regularly test door contact sensors to ensure reliable operation and accurate event logging.

Proximity Sensors

Proximity sensors detect movement or the presence of individuals near the cabinet. Technicians often place these sensors alongside door contact sensors at cabinet entrances. When someone approaches the cabinet, the proximity sensor activates and can trigger lights, alarms, or video surveillance. This early warning system discourages unauthorized access and helps staff monitor activity around sensitive equipment.

Vibration Sensors

Vibration sensors, sometimes called shock sensors, monitor for physical impacts or tampering attempts. Operators install these sensors inside cabinets or directly on IT equipment. The sensors detect vibrations in three perpendicular directions, allowing them to sense forced entry, drilling, or environmental disturbances. When the sensor registers unusual movement, it sends an alert to security personnel. This rapid response capability helps prevent theft, vandalism, or accidental damage.

Security and proximity sensors form the first line of defense for communication cabinets, ensuring only authorized personnel gain access and that any tampering is detected immediately.

Current and Wireless Sensors

Current Sensors

Current sensors play a crucial role in communication cabinets by converting the electrical current flowing through conductors into proportional voltage signals. This process enables real-time monitoring and control of electrical loads. Operators use these sensors to detect abnormal current levels, which helps prevent equipment damage and ensures safe operation. Current sensors also support energy management by tracking power usage and identifying inefficiencies.

Main Function | Electrical Parameter Monitored | Description |

|---|---|---|

Monitoring and Control | Electric current (AC/DC) | Converts current into measurable signals for monitoring and control. |

Protection (Overcurrent Detection) | Overcurrent events | Detects overcurrent and initiates protective actions. |

Energy Management | Current, voltage drop | Measures and manages energy usage. |

Power Supply Monitoring | Output current | Ensures reliable functioning of power supplies. |

Types of Sensors Used | - | Includes shunt resistors, current transformers, Rogowski coils, Hall-effect, and fluxgate. |

Operators select the sensor type based on the specific application and current type. For example, Hall-effect sensors work well for both AC and DC currents, while current transformers are ideal for AC monitoring. These sensors provide essential data for system protection and performance optimization.

Tip: Regular calibration of current sensors ensures accurate readings and reliable protection for sensitive equipment.

Wireless Sensors

Wireless sensors offer several advantages in communication cabinets compared to traditional wired alternatives. Installation requires no drilling or wall modifications, making the process quick and cost-effective. Operators can move these sensors easily, which supports flexible cabinet layouts and future upgrades. Battery operation allows wireless sensors to function during power outages, providing continuous monitoring even when the main power supply fails.

Feature/Aspect | Wireless Sensors Advantages | Wired Sensors Advantages |

|---|---|---|

Installation | No drilling; DIY-friendly | Requires professional installation |

Portability | Portable; easy to move | Not portable |

Power Resilience | Battery-operated; immune to outages | Susceptible to outages |

Signal Reliability | May face interference | No interference; more reliable |

Maintenance | Needs battery replacement | Little upkeep; no batteries needed |

Wireless sensors help operators overcome installation challenges in crowded or remote cabinet locations. They also reduce downtime during maintenance or reconfiguration. While signal interference can occur, most modern wireless systems use secure protocols to minimize disruptions.

Note: Operators should monitor battery levels regularly to maintain uninterrupted sensor performance.

Multisensors and Integrated Solutions

Multisensors

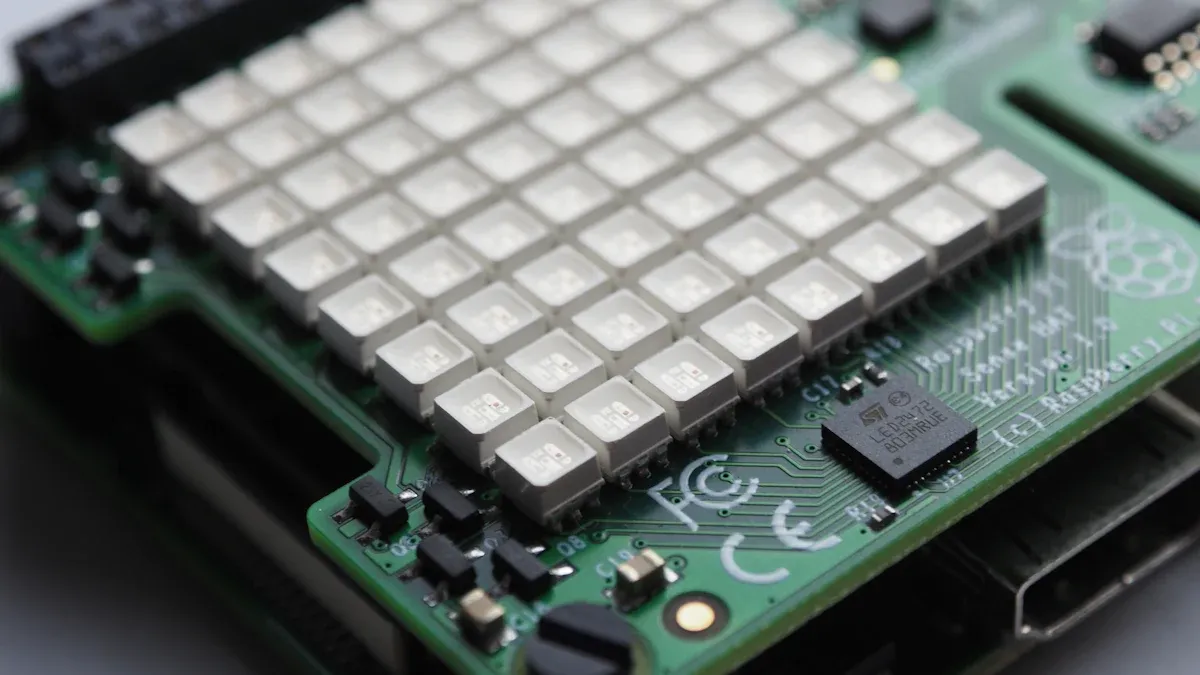

Multisensors combine several sensing technologies into a single compact device, providing a streamlined approach to monitoring communication cabinets. These devices often integrate movement detection, temperature, humidity, and air quality measurement, along with security features such as door contact monitoring. For example, the MultiSensor-MINI Smart Sensor attaches directly to cabinet doors and uses wireless ZigBee communication to transmit data to a centralized AlarmManager. Battery power allows for up to four years of operation, reducing maintenance needs. The KMS TI Smart Sensor offers thermal sensing, hotspot detection, and security threat monitoring, supporting both wireless and LAN communication. Operators can manage these devices through an IoT hub, which aggregates data from sensors, IP cameras, and access systems for real-time oversight.

Feature/Aspect | Description |

|---|---|

Device Example | MultiSensor-MINI Smart Sensor |

Sensor Integration | Movement, temperature, humidity, air quality, door contact |

Communication | Wireless (ZigBee), LAN |

Power Supply | Battery (up to 4 years) |

Application Context | Security and environmental monitoring in cabinets and IT racks |

Integration with Systems | Connects to centralized management platforms for alerting and data analysis |

Multisensors simplify installation and reduce wiring complexity, making them ideal for both new and retrofit cabinet deployments.

Integrated Monitoring

Integrated monitoring solutions bring together multiple sensor types under a unified management system. These solutions typically include wireless temperature and humidity sensors, open-closed sensors for doors, motion and occupancy detection, water leak sensors, and current meters. Operators connect these devices to a single hub, such as SoniLink, which can support up to 500 sensors and uses protocols like LoRaWAN, cellular, Ethernet, and Wi-Fi. This setup enables comprehensive monitoring of environmental and security conditions across multiple cabinets and sites.

Common integrated monitoring features:

Real-time alerts for temperature, humidity, and access events

Predictive maintenance based on continuous sensor data

Centralized dashboards for data aggregation and analysis

Support for regulatory compliance and energy efficiency

Operators benefit from a 20% increase in equipment uptime and 40% faster maintenance response times. Real-world deployments show that integrated monitoring reduces site visits and operational costs, while AI-driven analytics help anticipate failures and optimize energy use. These solutions ensure that communication cabinets remain secure, efficient, and reliable.

Effective communication cabinet monitoring relies on a combination of temperature, humidity, air quality, water leak, security, and current detection. Integrated systems deliver real-time alerts, streamline response workflows, and reduce false alarms through video verification and cloud-based monitoring.

Industry standards such as ASHRAE TC 9.9 and NFPA 75 recommend strategic sensor placement and regular maintenance to ensure optimal performance and compliance.

Recommendation | Benefit |

|---|---|

Regular security audits | Early vulnerability detection |

Wireless sensor integration | Simplified installation and remote access |

Advanced locking mechanisms | Enhanced access control |

Facility managers should evaluate their cabinet monitoring strategies to align with best practices and future-proof their infrastructure.

FAQ

What types of sensors help prevent equipment failure in communication cabinets?

Temperature, humidity, air quality, and current sensors monitor environmental and electrical conditions. These sensors provide early warnings, allowing operators to take action before equipment fails.

What is the main advantage of using wireless sensors in communication cabinets?

Wireless sensors offer flexible installation and easy relocation. Operators can deploy them quickly without complex wiring, which reduces downtime and supports rapid upgrades.

What should operators do if a water leak sensor triggers an alert?

Operators should inspect the cabinet immediately for moisture or leaks. Quick response prevents corrosion, electrical shorts, and potential equipment damage.

What information do multisensors provide in a communication cabinet?

Multisensors deliver combined data on temperature, humidity, movement, and door status. This integration simplifies monitoring and improves response times for environmental or security events.

What is the recommended placement for security sensors in communication cabinets?

Operators typically install security sensors at cabinet doors, access panels, and near sensitive equipment. Strategic placement ensures effective detection of unauthorized access or tampering.

See Also

Step-By-Step Guide To Installing Smoke Detectors In Cabinets

Exploring Outdoor Communication Cabinets And Their Essential Features

An Overview Of Outdoor Communication Cabinets And Their Uses

The Role Of Outdoor Communication Cabinets In Telecom Networks

Professional Advice On Protecting Cabinets In High-Risk Locations

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA