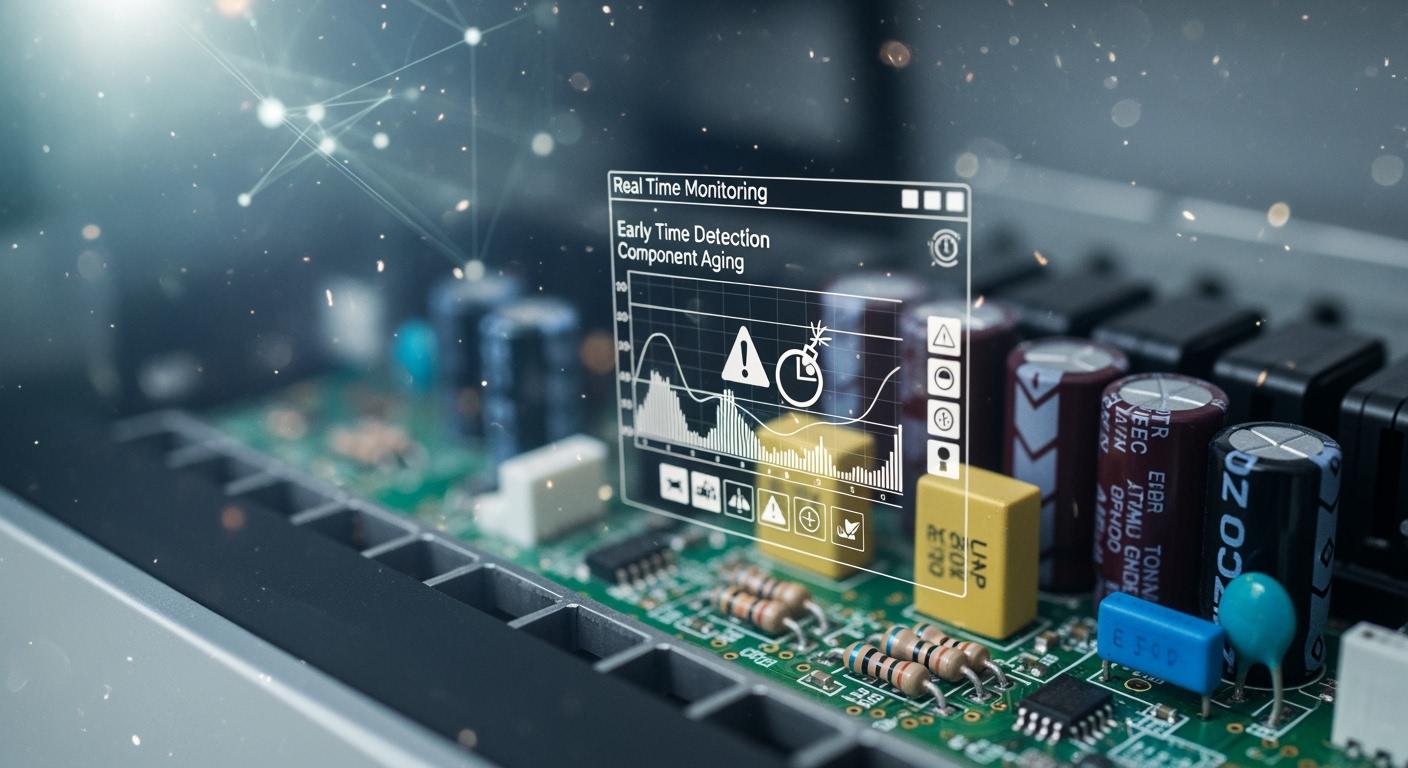

Equipment Aging Monitoring System of Smart PDUs: Early Warning for Capacitor/Resistor Parameter Drift

You rely on the Smart Power Distribution Unit to keep your telecom and data center equipment running smoothly. Equipment aging monitoring helps you detect changes in capacitor and resistor parameters early. This early warning lets you address potential issues before they cause failures. Regular monitoring reduces downtime and lowers maintenance costs. You benefit from a reliable system that protects your infrastructure and extends the life of your equipment.

Key Takeaways

Regular monitoring of capacitors and resistors in Smart Power Distribution Units helps detect aging early, preventing unexpected failures.

Real-time monitoring provides instant feedback on system health, allowing for proactive maintenance and reducing downtime.

Remote management features enable you to access system data from anywhere, saving time and improving efficiency in managing multiple sites.

Implementing early warning algorithms alerts you to parameter drift, allowing you to take action before issues escalate.

Following best practices for integration and maintenance of Smart PDUs ensures reliable performance and extends the lifespan of your equipment.

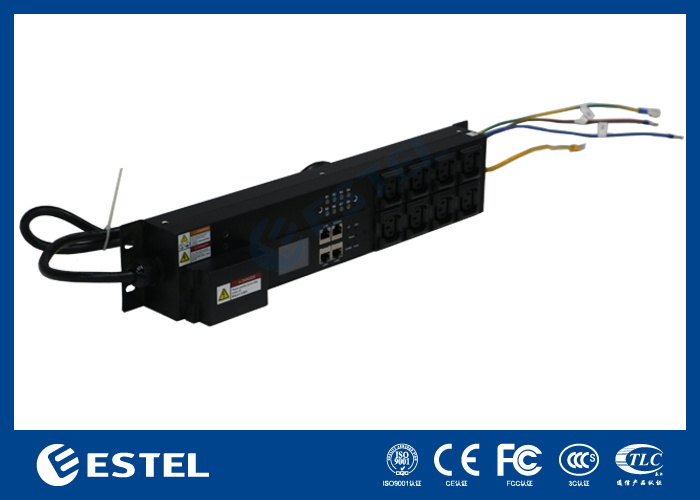

Equipment Aging in Smart Power Distribution Unit

Aging Effects on Capacitors and Resistors

You depend on the stability of capacitors and resistors inside your Smart Power Distribution Unit. Over time, these components face several aging mechanisms that can change their performance. For capacitors, you may see issues such as:

Short-circuiting conditions

Dielectric breakdown of the oxide layer

Electrode corrosion

Increased equivalent series resistance (ESR)

Resistors can also degrade due to thermal stress and oxidation. These changes often result from high temperatures, electrical stress, and environmental factors. As a result, you might notice a gradual loss of efficiency in your power distribution system. ESTEL designs its Smart Power Distribution Unit with advanced monitoring to help you detect these changes early. This approach reflects ESTEL’s commitment to quality and innovation, ensuring your equipment remains reliable.

Impact on Reliability and Performance

Aging components can threaten the reliability of your telecom or data center infrastructure. As capacitors and resistors drift from their original parameters, you may experience unexpected failures. For example, a municipal data center once faced major disruptions due to an electrical bus failure caused by aging components. Such incidents highlight the importance of monitoring equipment aging.

When you use a Smart Power Distribution Unit with real-time monitoring, you reduce the risk of downtime. You also gain the ability to plan maintenance before problems escalate. ESTEL’s products meet international standards, including ENERGY STAR and ASHRAE compliance, which support their reliability claims. By choosing a solution with aging monitoring, you protect your investment and ensure continuous operation for your critical systems.

Parameter Drift Detection & Early Warning

Real-Time Monitoring in ESTEL Smart PDUs

You need to know exactly what happens inside your power distribution system. ESTEL equips each Smart Power Distribution Unit with advanced sensors that track critical parameters in real time. These sensors monitor temperature, humidity, voltage, and current. They also detect subtle changes in capacitor and resistor values, which often signal early stages of aging or failure.

You benefit from instant feedback on system health. The LCD display gives you a clear, intuitive view of real-time data, making energy management simple and effective. You can see power usage, temperature, and humidity at a glance. This immediate access helps you spot trends and anomalies before they become serious problems.

Remote monitoring takes your control even further. You can access energy efficiency data from anywhere, which enhances your ability to manage multiple sites efficiently. You do not need to be on-site to check the status of your Smart Power Distribution Unit. This saves you time and allows you to respond quickly to any issues.

Common failure modes detected during real-time monitoring include:

Power failures, voltage drops, and battery faults

Cooling and ventilation system malfunctions

Unauthorized access or theft

Environmental hazards like dust, water intrusion, and smoke

Operational risks such as battery overheating or internal short circuits

You can address these risks proactively, reducing the chance of unplanned outages.

Early Warning Algorithms and Notifications

You rely on early warning systems to keep your operations running smoothly. ESTEL integrates advanced algorithms into each Smart Power Distribution Unit. These algorithms analyze sensor data continuously. When they detect parameter drift in capacitors or resistors, they trigger alerts before the situation escalates.

You receive notifications if any condition exceeds safe limits. These alerts enable you to take action before failures occur. The system supports both local and remote notifications, so you stay informed wherever you are. Predictive analytics help you plan maintenance activities, reducing downtime and preventing costly disruptions.

Here’s how the LCD display and remote management features enhance your experience:

Feature | Benefit |

|---|---|

Intuitive display | Provides real-time data, making energy management simple and effective. |

Remote monitoring | Allows access to energy efficiency data from anywhere, enhancing site management efficiency. |

Energy-saving control | Enables you to monitor and control power usage in real time, leading to cost savings. |

You also gain these advantages:

Real-time monitoring provides instant feedback on system health.

Alerts notify you if conditions exceed safe limits, enabling proactive maintenance.

Predictive maintenance helps you spot early warning signs, significantly reducing the risk of unplanned outages.

Remote management capabilities save you time and minimize the need for on-site visits.

Graphical displays of load changes help you understand power trends and make informed decisions.

Tip: Use the remote management feature to schedule regular checks and review historical data. This practice helps you identify patterns and optimize maintenance schedules.

You can trust ESTEL’s Smart Power Distribution Unit to deliver reliable early warning for parameter drift. This proactive approach protects your infrastructure and ensures continuous operation.

Benefits & Implementation

Reliability and Maintenance Advantages

You gain significant benefits when you use ESTEL’s Smart Power Distribution Unit with equipment aging monitoring. You see a dramatic reduction in downtime and emergency site visits. For example:

Average downtime drops from 12 hours per year to just 2 hours.

Emergency site visits decrease from 150 to 40 per year.

You also experience fewer outages and improved network uptime. Many facility managers report a 15% reduction in outages and a 25% improvement in operational performance. You save on energy costs, too. Users have seen up to a 20% reduction in energy consumption and a 30% decrease in maintenance costs, leading to as much as 20% overall cost savings. Surveys show that 33% of downtime incidents come from power outages, so reliable power distribution is essential for your operations.

You benefit from remote monitoring and control, which means you do not need to send technicians on-site as often. Advanced energy management features help you cut energy use by up to 20%. You also extend the lifespan of your equipment, which gives you better value over time.

Tip: Regularly review your system’s performance data to spot trends and schedule maintenance before issues arise.

Integration Steps for ESTEL Smart PDUs

You can follow best practices to ensure smooth integration of ESTEL Smart Power Distribution Units into your telecom or data center setup:

Integrate remote monitoring to enhance oversight.

Implement environmental controls for optimal equipment conditions.

Use surge protection to guard against electrical disturbances.

Plan for scalability to support future growth.

Add thermal regulation and moisture sealing for extra protection.

Connect smart PDUs with your existing management systems.

Best Practice | Description |

|---|---|

Schedule Regular Checks | Verify load balancing to minimize downtime and extend equipment life. |

Perform Routine Maintenance | Inspect components, clean dust, and monitor voltage and temperature. |

Plan for Scalability | Monitor metrics to ensure future demands are met. |

Choose Modular PDUs | Select modular designs for easy upgrades. |

Organize Cables | Keep cables neat for better airflow and easier maintenance. |

Label Connections | Use clear labels for quick identification during maintenance. |

You ensure reliable performance and long-term value by following these steps. Facility managers often praise the seamless integration and reliability of ESTEL’s solutions, noting uninterrupted service even during power outages.

You improve reliability and maintenance when you use ESTEL’s Smart Power Distribution Unit. Continuous monitoring lets you detect faults early and shift to proactive asset management. Predictive maintenance reduces downtime and extends equipment life. You see lower operational costs and less frequent maintenance compared to traditional units.

Feature | ESTEL Smart PDUs | Traditional PDUs |

|---|---|---|

Reduced with predictive systems | Higher with reactive systems | |

Operational Costs | Lower due to energy efficiency | Higher due to energy waste |

Monitoring | Real-time and continuous | Limited or none |

Energy Efficiency | High | Lower |

Consider ESTEL solutions to protect your assets and boost performance in your facility.

FAQ

What is parameter drift in Smart PDUs?

Parameter drift means the values of capacitors or resistors change over time. You may see this as a loss of efficiency or unexpected failures. Monitoring helps you catch these changes early.

How do you receive early warnings from ESTEL Smart PDUs?

You get alerts through the LCD display and remote notifications. The system sends messages when it detects abnormal conditions. You can act quickly to prevent downtime.

Can you monitor your Smart PDU remotely?

Yes, you can. ESTEL Smart PDUs support remote management. You access real-time data and control your system from anywhere. This feature saves you time and improves efficiency.

Why should you monitor capacitor and resistor aging?

You protect your equipment from sudden failures. Early detection lets you schedule maintenance before problems grow. This approach extends the life of your power distribution system.

What maintenance tasks should you perform with Smart PDUs?

You should check system data regularly, clean dust from components, and review alert logs. These steps help you keep your equipment running smoothly and avoid unexpected issues.

See Also

Enhancing Outdoor Cabinet Security Through Intelligent Upkeep

Understanding ESTEL PDUs and Their Importance in Data Centers

A Detailed Overview of Telecom Cabinet Battery Risk Assessment

Improving Outdoor Cabinet Efficiency Through Power and Cooling

Ensuring Effective Monitoring Solutions for Outdoor Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA