Self-Diagnosis and Predictive Maintenance of Smart PDUs: 7-Day Early Warning for Potential Failure Risks

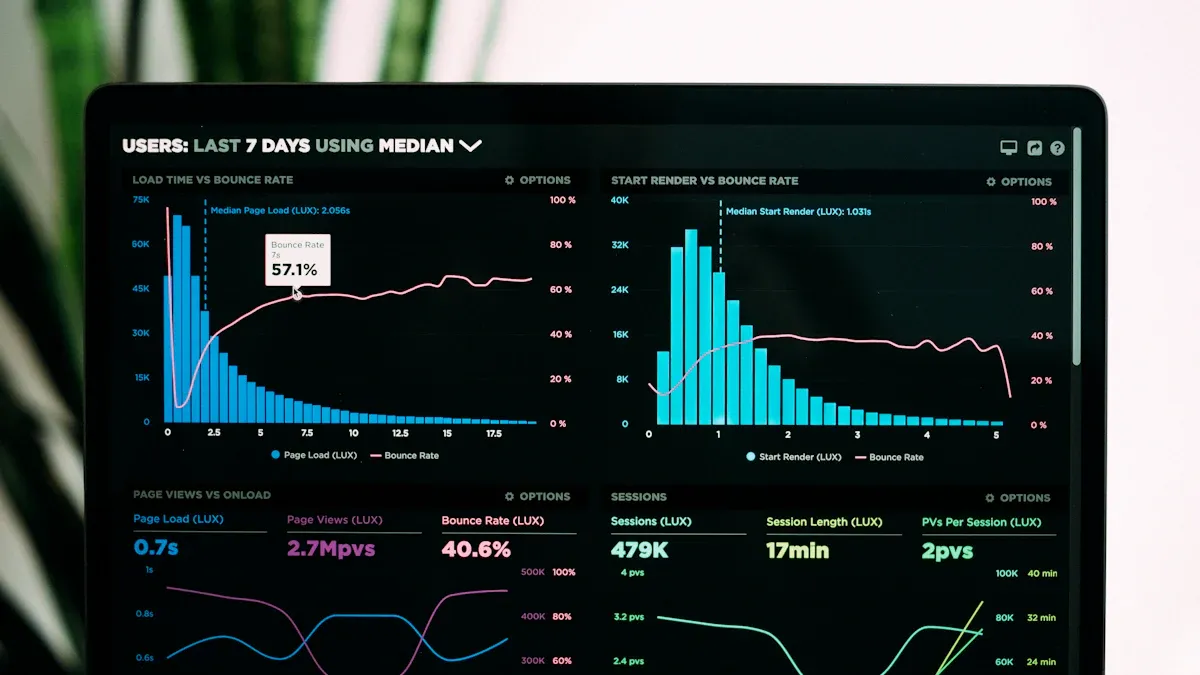

You gain a powerful advantage when you use ESTEL’s Smart Power Distribution Unit. The system alerts you seven days before potential failures, letting you act early and prevent disruptions. Predictive maintenance and self-diagnosis keep telecom and data center environments running smoothly. Real-time monitoring, remote management, and intelligent protocols make your infrastructure safer and more efficient. Industry studies show predictive maintenance can reduce downtime by up to 50%.

Source | Downtime Reduction |

|---|---|

WorkTrek | 35-50% |

Applied Computing | 40% |

NRX | 30-50% |

InfoTech | Up to 45% |

Key Takeaways

Utilize ESTEL’s Smart PDU for early alerts that warn you seven days before potential failures, allowing proactive maintenance.

Implement predictive maintenance to reduce downtime by up to 50% and cut maintenance costs to just 7% of traditional methods.

Leverage real-time monitoring and remote control features to manage your infrastructure efficiently from anywhere, enhancing response times by up to 40%.

Integrate intelligent sensors for continuous data collection, helping you forecast equipment health and prevent unexpected outages.

Follow a clear installation and maintenance process to ensure reliable operation and maximize the benefits of your Smart PDU.

Smart Power Distribution Unit Overview

What Makes a PDU Smart

You need more than basic power distribution to keep your telecom or data center running reliably. A Smart Power Distribution Unit brings advanced technology to your infrastructure. It gives you real-time monitoring, remote control, and automatic alerts. You can track power consumption, manage loads from anywhere, and respond quickly to potential issues. Integrated environmental sensors help you maintain safe operating conditions.

Here’s a quick comparison between smart and basic PDUs:

Feature | Smart PDU | Basic PDU |

|---|---|---|

Function | Advanced power distribution, real-time monitoring, load statistics, alarm functions | Basic power distribution |

Monitoring Capability | Remote monitoring available | No monitoring capabilities |

Control Capability | Remote control features | No control capabilities |

Alarm Function | Automatic alarms for threshold breaches | Typically lacks alarm functions |

Applicability | Suitable for large data centers needing reliability and efficiency | Best for small or traditional data centers |

Cost | Higher cost due to advanced features | Lower cost, budget-friendly |

Smart PDUs enhance energy efficiency and reduce downtime. You benefit from advanced metering and analytics for better resource management. Overload protection and automatic alerts keep your equipment safe.

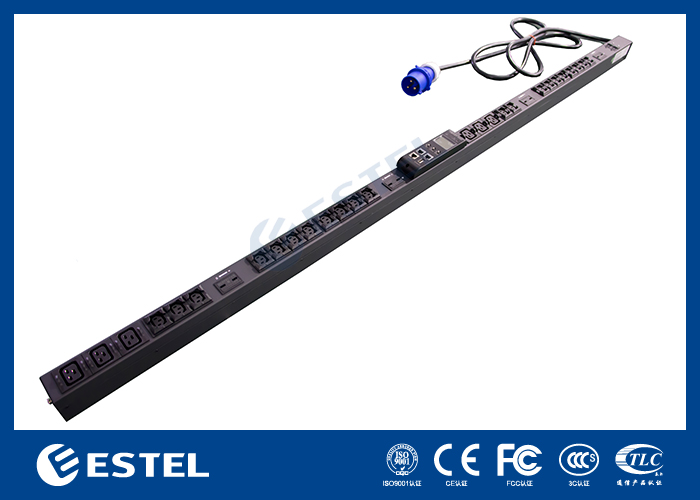

ESTEL’s Quality and Innovation

ESTEL stands out for its commitment to quality and innovation. You get a Smart Power Distribution Unit that meets international standards like ISO9001, UL, RoHS, CE, VDE, IEC CB Scheme, and FCC Compliance.

Certification | Description |

|---|---|

ISO9001 | Ensures consistent manufacturing processes for quality assurance. |

UL | Guarantees compliance with electrical safety standards. |

RoHS | Addresses environmental impact and safety. |

CE | Ensures compliance with health, safety, and environmental protection standards. |

VDE | Validates electrical safety and performance standards. |

IEC CB Scheme | Ensures compliance with international safety standards. |

FCC Compliance | Ensures the unit does not interfere with other devices. |

You experience reliable performance and durability. ESTEL’s Smart Power Distribution Unit offers consistent operation, ease of use, and budget-friendly solutions. Self-diagnosis lets you monitor system health and detect errors early. This proactive approach prevents downtime and ensures efficient operation. You can trust ESTEL to deliver advanced technology that keeps your infrastructure safe and efficient.

Predictive Maintenance & Early Warning

7-Day Failure Risk Alerts

You gain a clear advantage when you use predictive maintenance in your telecom or data center environment. ESTEL’s Smart Power Distribution Unit uses advanced sensors and AI-driven algorithms to forecast potential failures before they happen. You receive alerts seven days in advance, giving you time to plan and act.

The system relies on two main predictive models. Artificial Neural Networks analyze historical data and key influencing factors to forecast reliability. Gray Relational Analysis identifies the main causes of failures and helps you prioritize improvement measures. You can see how these models work in the table below:

Model Type | Description | Key Features |

|---|---|---|

Artificial Neural Networks | Three-layer model for reliability forecasting | Uses historical data and key influencing factors |

Gray Relational Analysis | Prioritizes improvement measures | Identifies main factors causing failures |

You benefit from early warnings that reduce downtime and maintenance costs. When you act on these alerts, you prevent unexpected outages and keep your equipment running smoothly. The average reduction in maintenance costs after implementing predictive maintenance with ESTEL’s Smart Power Distribution Unit reaches 93%. You only spend 7% of what you would with traditional maintenance methods.

Metric | Value |

|---|---|

Maintenance Cost Reduction | 93% (to 7% of traditional) |

Tip: Early alerts help you schedule maintenance during low-traffic hours. You avoid disruptions and keep your operations efficient.

Real-Time Monitoring & Remote Control

You monitor your infrastructure in real time with ESTEL’s Smart Power Distribution Unit. The unit integrates multiple sensors that track environmental and electrical conditions. These sensors include:

Temperature: Monitors internal cabinet temperature for early detection of overheating.

Humidity: Tracks moisture levels to prevent corrosion and static discharge.

Air Quality: Detects dust and contaminants, ensuring optimal airflow.

Current: Monitors electrical flow to identify short circuits or overloads.

Proximity & Security: Detects presence and monitors door status for enhanced security.

Multisensors: Combines various sensing technologies for a comprehensive view.

IoT-enabled Platforms: Connects all sensors for centralized monitoring and alerts.

You control power status for devices remotely. You access the unit through network interfaces, which enhances response times by up to 40%. You reduce the need for physical inspections and manage scheduled power cycling from any location. The table below shows how remote control functionality improves maintenance response times:

Functionality | Impact on Maintenance Response Times |

|---|---|

Remote access through network interfaces | Enhances response times by up to 40% |

Control of power status for devices | Reduces need for physical inspections |

Timed switches for scheduled power cycling | Enables efficient management from any location |

Note: Real-time monitoring and remote control let you respond quickly to any issue. You keep your infrastructure safe and reliable without being onsite.

You use the Smart Power Distribution Unit to maintain optimal conditions and prevent failures. You rely on intelligent sensors and remote management to keep your telecom and data center operations running smoothly.

Early Detection Technology

Sensors & Data Analytics

You rely on intelligent sensors to keep your infrastructure safe. These sensors measure voltage, current, temperature, and humidity in real time. They connect directly to the Smart Power Distribution Unit, which acts as the central hub for data collection. The system records historical load data and environmental readings every minute. This steady stream of information helps you forecast equipment health and spot trends before problems arise.

Advanced modeling techniques analyze the collected data. Time series analysis tracks changes in power loads over time. Deep learning methods, especially Long Short-Term Memory (LSTM) networks, produce accurate short-term forecasts. LSTM networks handle complex time series data and solve issues like gradient explosion and vanishing, which often affect traditional neural networks.

Continuous monitoring gives you several advantages:

You eliminate energy waste, which reduces wear on your equipment.

You manage power loads effectively, keeping devices within safe operating limits.

You maintain balance in three-phase power loads, preventing stress and failure.

Tip: Use sensor data to schedule maintenance and avoid unexpected downtime.

Automated Fault Detection

You benefit from automated fault detection powered by machine learning. The Smart Power Distribution Unit uses several advanced techniques to identify and predict abnormalities. These methods help you spot issues early and respond quickly.

Description | |

|---|---|

LSTM | Effective for time series data, predicting dynamic changes in power systems. |

Autoencoders | Reconstruct input data to identify anomalies, though may miss new issues. |

CNN | High accuracy for time series analysis, requires large labeled datasets. |

Ensemble Learning | Combines models for improved accuracy and robustness, but needs more computing power. |

Transformer-GAN | Merges Transformer architecture with GANs to enhance detection and predict abnormalities. |

Automated alerts notify you when sensors detect unusual patterns. You receive actionable information, so you can address faults before they cause disruptions. Proactive maintenance extends the lifespan of your equipment and keeps your telecom or data center running smoothly.

Practical Applications & Case Studies

ESTEL PDU in Telecom Sites

You see real-world benefits when you deploy ESTEL’s Smart Power Distribution Unit in telecom sites. Operators in Southeast Asia reduced site visits by 38%. Mean time to repair dropped by eight hours. European tower companies improved system uptime by 22%. Emergency trips were cut in half. Telecom power systems saw energy use drop by 25–30%. You save money and boost efficiency with these improvements.

Case Study | Key Results | Impact on Energy Consumption |

|---|---|---|

Southeast Asia Mobile Operator | Reduced site visits by 38%, mean time to repair dropped by 8 hrs | Significant energy savings and improved efficiency |

European Tower Company | Improved system uptime by 22%, cut emergency trips by half | Enhanced reliability and reduced energy waste |

Telecom Power Systems | Energy use reduced by 25-30% with efficient power supplies | Lower bills and less cooling needed |

You learn that proactive maintenance and early warnings help you avoid costly downtime. You keep your network stable and reliable. You also reduce unnecessary travel and maintenance costs.

Tip: Schedule regular checks using remote monitoring to catch issues before they escalate.

Data Center Implementation

You gain operational efficiency when you use ESTEL PDUs in data centers. Surge protection prevents damage from power spikes. Environmental monitoring keeps server racks at optimal temperature and humidity. Modular design allows quick replacements, minimizing downtime.

Feature | Benefit |

|---|---|

Surge Protection | Prevents damage from power spikes, ensuring uninterrupted operations. |

Environmental Monitoring | Maintains optimal temperature and humidity levels for server racks. |

Modular Design | Allows quick replacements, minimizing downtime during maintenance. |

Proactive monitoring gives you real-time data on power usage and environmental conditions.

Remote access lets you troubleshoot and reboot devices without being onsite.

Load balancing minimizes the risk of shutdowns.

Every minute of downtime costs you money and impacts customer trust. ESTEL PDUs help you avoid these losses by ensuring consistent power delivery and efficient troubleshooting. Studies show that proactive monitoring and load balancing can reduce downtime by up to 30%.

Note: Use remote access features to respond quickly and keep your data center running smoothly.

You maximize reliability and efficiency by combining early detection, remote management, and modular design. You build a resilient infrastructure that supports your business goals.

Implementation Steps

Integrating ESTEL Smart PDU

You can integrate the Smart Power Distribution Unit into your existing infrastructure by following a clear process. Start by assessing your cabinet space and layout. This ensures efficient power distribution and avoids overcrowding. Next, verify power requirements and compatibility with your telecom equipment. This step prevents overloads and keeps your system safe. Gather insulated tools and all necessary equipment before you begin installation. Always work in a clean, dry, and clutter-free area to reduce risks. Schedule regular inspections and maintenance to keep your system reliable.

Step | Description |

|---|---|

1 | Assess cabinet space and layout for the PDU to ensure efficient power distribution. |

2 | Verify power requirements and compatibility with existing telecom equipment to prevent overloads. |

3 | Gather insulated tools and necessary equipment for a safe installation. |

4 | Ensure a clean, dry, and clutter-free installation area to reduce risks. |

5 | Schedule regular inspections and maintenance to ensure reliability and performance. |

Tip: Simulate installation scenarios with your team. This prepares everyone for unexpected challenges and builds problem-solving skills.

Setting Up Early Warning Alerts

You need to set up early warning alerts to maximize the benefits of predictive maintenance. Choose a cool and ventilated location for your telecom cabinet. Seal any gaps around cables to block dust and moisture. Make sure the grounding bar is securely connected to protect your equipment from electrical faults. Arrange hardware to allow airflow and use ventilated doors for better cooling. Always follow manufacturer guidelines during installation.

To configure alerts, plan sensor placement and collect baseline data. Install sensors correctly and customize alarm settings based on real measurements. Secure network integration and maintain long-term data retention for accurate analysis. Perform regular firmware updates and verify alarms annually. Train your staff with clear procedures for alarm management.

Schedule annual professional inspections to catch hidden issues.

Ensure proper airflow around PDUs to prevent overheating.

Use certified replacement parts for reliability and safety.

Keep firmware up to date for new features and security.

Educate IT staff on maintenance protocols for early issue detection.

Note: Preventive maintenance, such as cleaning components and calibrating monitoring systems, ensures long-term reliability.

You gain reliable self-diagnosis and predictive maintenance with ESTEL’s Smart Power Distribution Unit. The 7-day early warning system helps you prevent downtime and optimize operations. Operators report up to 97.8% energy efficiency and 30% fewer downtime incidents. Real-time monitoring and overload protection keep your equipment safe. Machine learning and AI-powered alerts let you respond quickly and extend equipment lifespan.

Feature | Benefit |

|---|---|

Early Warning System | Prevents outages and data loss |

Real-Time Monitoring | Tracks energy, temperature, humidity |

Predictive Maintenance | Reduces maintenance costs |

Consider ESTEL for reliable, efficient telecom and data center infrastructure.

FAQ

How does the 7-day early warning system work?

You receive alerts based on real-time sensor data and predictive algorithms. The system analyzes trends and notifies you seven days before a potential failure. This gives you time to schedule maintenance and avoid unexpected downtime.

Can I monitor the Smart PDU remotely?

Yes, you can monitor and control the Smart Power Distribution Unit from any location. The system supports remote access through a secure network interface. You view real-time data and manage power settings without being onsite.

What types of equipment can I connect to the Smart PDU?

You can connect servers, network switches, routers, and other telecom or data center devices. The Smart PDU supports multiple outlet configurations, making it suitable for a wide range of equipment.

How do I set up early warning alerts?

You install sensors, configure alarm thresholds, and connect the PDU to your monitoring platform. The system guides you through setup. You customize alerts based on your environment and operational needs.

What maintenance does the Smart PDU require?

You should schedule regular inspections, keep firmware updated, and clean components as needed. The system’s self-diagnosis features help you detect issues early. Always follow the manufacturer’s maintenance guidelines for best results.

See Also

Smart Maintenance Strategies For Safeguarding Outdoor Cabinets

Understanding ESTEL PDUs And Their Importance In Data Centers

A Complete Overview Of Telecom Cabinet Battery Risk Analysis

Ensuring Consistent Power Supply For Telecom Cabinets Effectively

Enhancing Outdoor Cabinets Through Power, Cooling, And Monitoring

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA