Power Consumption Behavior Analysis Model of Smart PDUs: Machine Learning for Identifying Abnormal Load Patterns

Machine learning transforms power management by enabling real-time detection of abnormal load patterns in a Smart Power Distribution Unit. Advanced analytics play a crucial role in telecom and data center environments. Recent studies show predictive maintenance can reduce maintenance costs by 30% and increase equipment lifespan by 20%. These advantages improve operational efficiency and reliability. ESTEL’s Smart Power Distribution Unit supports modern infrastructure by offering intelligent monitoring and timely alerts.

Key Takeaways

Machine learning enhances power management by detecting abnormal load patterns in real-time, improving operational efficiency.

Smart Power Distribution Units (PDUs) offer features like remote monitoring and overload protection, ensuring safe and efficient power distribution.

Behavior analysis using machine learning can lead to significant energy savings, with some organizations reporting up to 41% reductions in energy use.

Integrating machine learning with Smart PDUs allows for automated alerts and dashboards, enabling quick responses to power anomalies.

Continuous improvement of machine learning models ensures they adapt to changing power consumption patterns, enhancing reliability and performance.

Smart Power Distribution Unit Overview

Definition and Key Functions

A Smart Power Distribution Unit manages and distributes electrical power to multiple devices in network environments. It supports remote monitoring, control, and protection of connected equipment. Industry standards define several main components and functions. The table below outlines these elements:

Component | Function |

|---|---|

Remote control connections | Allows operators remote access to the entire power system. |

EMI filters | Prevents excess electromagnetic noise from entering the power line. |

Control board | Enables users to reconfigure the unit and view metering parameters. |

Auxiliary output | Monitors breaker status and connections. |

Main output | Primary power distributor to devices. |

AC inlet and outlet | Hosts additional power with detachable AC line cords. |

Individual outlets | Provides multiple outputs and allows remote monitoring and control. |

GFI module | Prevents harmful consequences from electrical accidents. |

Relays | Allows users to switch and monitor power across devices. |

Main circuit breaker | Manages the PDU power source. |

Environmental sensors | Monitors heat and moisture levels. |

These features help ensure safe, efficient, and flexible power management.

ESTEL’s Product Features

ESTEL’s Smart Power Distribution Unit stands out in the market. The unit offers a robust build for reliability and overload protection for safety. Its compact design allows for optimal space use, while high capacity supports multiple devices. Installation and operation remain simple and user-friendly. The table below compares key features with competitors:

Feature | ESTEL’s Smart Power Distribution Unit | Competitors |

|---|---|---|

Build Quality | Robust build for reliability | Varies |

Safety Features | Overload protection | Limited options |

Design | Compact for optimal space utilization | Bulky designs |

Capacity | High capacity for multiple devices | Lower capacity |

Installation & Operation | Simple and user-friendly | Complex setups |

Facility managers and IT professionals benefit from real-time monitoring, energy efficiency, surge protection, modular design, granular outlet control, reliable power backup, and advanced reporting tools. These features support better management, cost savings, and operational efficiency.

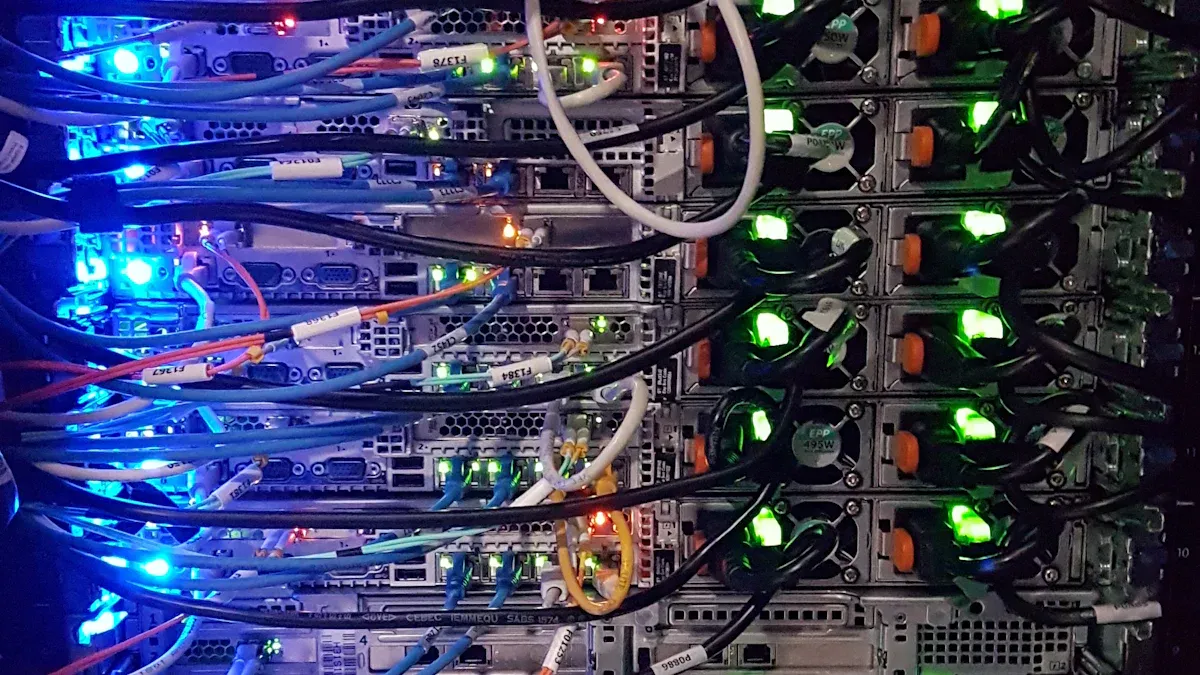

Applications in Telecom and Data Centers

The Smart Power Distribution Unit serves many environments. In remote sites, it manages and reboots equipment without physical access. Data centers use it to schedule power cycling and maintain uptime. Testing labs control power during automated processes. Large data centers monitor and analyze power usage for efficiency. Financial institutions rely on it for power stability. Manufacturing facilities monitor equipment for safety and efficiency. Enterprise data centers integrate it with management software for advanced analytics. Colocation facilities provide clients with detailed power data and control. Smart buildings use it to manage and monitor power across systems. Telecommunications networks depend on it for stable and efficient power to critical infrastructure.

Data Collection and Monitoring

Real-Time Acquisition

Modern power management relies on real-time data collection. IoT technologies play a key role in this process. Sensor nodes gather power usage data from different parts of the grid. These sensors organize the data using spatial methods, such as Hilbert curves, which help process information efficiently. A dual-server system supports fast data transmission and keeps user information private. Edge computing also improves data handling. Local processing in telecom cabinets allows for quick responses and reliable monitoring. This setup gives operators immediate control over power systems, especially during periods of high network activity.

Data Granularity and Accuracy

Accurate and detailed data is essential for effective monitoring. Intelligent PDUs offer metering at the individual outlet level, which increases the detail of the information collected. This high granularity helps operators balance electrical loads and avoid overloading equipment. Real-time power usage data supports quick decision-making and improves reliability. Detailed records also allow for trend analysis. Operators can spot patterns and address issues before they become serious. These practices lead to better operational efficiency and safer power management.

Individual outlet-level metering enhances data granularity.

Real-time usage data helps balance loads and prevent overloads.

Detailed records support trend analysis and proactive management.

Typical Data Features

Smart Power Distribution Units collect a wide range of data for behavior analysis. The table below lists common features and their functions:

Feature | Description |

|---|---|

Remote Access | Allows monitoring of power and PDU status from any location. |

Environmental Monitoring | Utilizes sensors to track temperature, humidity, and other conditions. |

SNMP Traps | Sends automated alerts for power or environmental issues. |

Branch Circuit Protection | Safeguards against overloads to protect the cabinet. |

Authentication Support | Ensures secure access through strong password policies. |

User Interface | Provides an easy-to-use web GUI for management tasks. |

Hot-Swappable Controller | Enables controller replacement without causing downtime. |

These features give operators the tools they need to monitor, analyze, and respond to changes in power consumption.

Behavior Analysis

Usage Pattern Identification

Operators use behavior analysis to understand how devices consume power over time. Machine learning models help identify normal and abnormal usage patterns by analyzing large volumes of data from power systems. These models can detect subtle changes that might signal equipment issues or inefficiencies. The following table highlights several machine learning techniques and their effectiveness in recognizing patterns in power consumption data:

Machine Learning Technique | Description |

|---|---|

Random Forest | Outperformed Logistic Regression and XG-Boost in accuracy for energy consumption predictions. |

XGBoost | Effective but slightly less accurate than Random Forest. |

Extra Trees Regressor | Demonstrated superior effectiveness in capturing non-linear patterns in energy consumption data. |

Gradient Boosting | Strong predictive results, particularly adept at capturing data complexities. |

Long Short-Term Memory | Highlighted for its predictive capabilities in energy consumption. |

These techniques allow facility managers to spot trends, forecast demand, and respond quickly to unusual activity.

Feature Engineering

Feature engineering transforms raw data into meaningful inputs for machine learning models. Analysts select and create features such as average load, peak usage, and time-of-day consumption. These features help models distinguish between regular and abnormal patterns. For example, engineers may use rolling averages to smooth out short-term fluctuations or calculate ratios to compare different circuits. Well-designed features improve model accuracy and make it easier to interpret results. This process ensures that the Smart Power Distribution Unit delivers actionable insights for power management.

Operational Efficiency

Behavior analysis leads to measurable improvements in operational efficiency. Organizations track metrics such as energy savings, cost reduction, and greenhouse gas emissions. The table below summarizes key performance indicators:

Metric | Value |

|---|---|

Energy Savings | Up to 41% |

Estimated Annual Electricity Savings | 1,342 GWh |

Cost Reduction | $163 million per year |

Reduction in Greenhouse Gas Emissions | 596,114 metric tons |

Many companies have reported significant benefits:

A leading data center in Asia achieved a 15% reduction in energy consumption, supporting green initiatives.

A telecommunications company improved equipment uptime by 20% and reduced maintenance costs.

These results show that behavior analysis not only optimizes energy use but also supports sustainability and reliability goals.

Anomaly Detection with Machine Learning

Techniques and Algorithms

Machine learning algorithms play a central role in identifying abnormal load patterns in Smart Power Distribution Units. Researchers have explored various models to detect anomalies in electricity consumption. Each algorithm offers unique strengths for analyzing power usage data. The table below summarizes several commonly used methods:

Algorithm | Description |

|---|---|

LSTM-NDT | Uses LSTM networks with autoregressive neural networks to focus on local patterns in time series. |

MAD-GAN | Employs generative adversarial networks to reconstruct multivariate time series and spot anomalies. |

DAGMM | Combines autoencoders and Gaussian mixture models to extract latent features for anomaly detection. |

Gated Recurrent Units + Variational Autoencoders | Applies complex neural architectures for multivariate time series, though training may be slower. |

Transformer + K-Means | Integrates deep learning and clustering for power consumption prediction and anomaly detection. |

Transformer | Originally designed for language translation, now adapted for power consumption analysis. |

Unsupervised learning techniques often excel in this domain. These methods analyze historical data without requiring labeled examples. They can detect critical events and abnormal patterns even when predefined categories are unavailable. Supervised learning, in contrast, depends on labeled data for training. This requirement limits its application in real-world scenarios where labeling is difficult. The table below compares these approaches:

Aspect | Unsupervised Learning | Supervised Learning |

|---|---|---|

Data Requirement | Works with historical data without labeling | Requires labeled data for training |

Application Context | Suitable for detecting anomalies without predefined categories | Limited by the availability of labeled data |

Challenges | No need for labeled data, but may struggle with variability in data | Difficulty in obtaining labeled data due to real-world variability |

Societal Importance | Can detect critical events like occupant immobilization | Less applicable in scenarios lacking labeled data |

Model Selection and Training

Selecting the right model for anomaly detection depends on the characteristics of the power consumption data. Engineers evaluate models based on their ability to capture complex patterns and adapt to changing environments. Deep learning models, such as LSTM and Transformer architectures, handle time series data effectively. Clustering methods, like K-Means, group similar patterns and highlight outliers.

Training involves feeding historical power usage data into the model. Unsupervised models learn from the data without explicit labels. They identify deviations from normal behavior by comparing current readings to learned patterns. Supervised models require labeled examples of normal and abnormal events. This process helps the model distinguish between typical and unusual load patterns.

Feature selection plays a crucial role during training. Analysts use prior knowledge to choose relevant features, such as average load, peak usage, and environmental conditions. They may apply convergent validation, evaluating multiple feature sets from different datasets. This approach ensures the model learns from diverse sources and improves its accuracy.

Tip: Engineers often calibrate models to address class imbalance. This step ensures the model does not overlook rare but important anomalies.

Validation Metrics

Validating machine learning models ensures reliable performance in detecting abnormal load patterns. Engineers follow several best practices to assess model quality:

Check model consistency across different batches to confirm robustness and performance stability.

Use prior knowledge for feature selection through convergent validation, evaluating multiple feature sets from various datasets.

Calibrate metrics affected by class imbalance to guarantee accurate performance evaluation.

Benchmark against state-of-the-art tools to establish credibility and demonstrate superiority.

Validate models on heterogeneous datasets to assess generalizability and robustness.

Common validation metrics include precision, recall, F1-score, and area under the receiver operating characteristic curve (AUC-ROC). These metrics measure how well the model identifies anomalies without generating false alarms. Facility managers rely on these evaluations to select models that deliver actionable insights and maintain operational reliability.

Note: Consistent validation across diverse datasets helps ensure the model performs well in different environments, such as telecom sites and data centers.

Implementation Steps

Integration with ESTEL Smart Power Distribution Unit

Integrating machine learning models with the ESTEL Smart Power Distribution Unit begins with understanding the device’s communication protocols and data interfaces. ESTEL’s unit supports remote management and real-time monitoring, which allows seamless data flow between the hardware and analytics platforms. Engineers connect the PDU to a secure network, enabling data transmission to a central server or cloud environment. They configure the unit to export power consumption data at regular intervals. This setup ensures that the machine learning system receives accurate, timely information for analysis.

The integration process often follows these steps:

Review the technical documentation for ESTEL’s Smart Power Distribution Unit, available on the official website.

Establish secure network connectivity between the PDU and the analytics server.

Set up data export protocols, such as SNMP or Modbus, to transmit power usage and environmental data.

Develop or deploy a data ingestion pipeline that collects, cleans, and formats the incoming data for machine learning analysis.

Test the connection and verify that the system receives real-time data from the PDU.

Tip: Engineers should ensure that all network connections use encryption and strong authentication to protect sensitive infrastructure data.

Deployment and Monitoring

After integration, the next step involves deploying the machine learning model and establishing a monitoring framework. The deployment process includes installing the trained model on a server or cloud platform that receives data from the Smart Power Distribution Unit. Engineers configure the system to process incoming data streams and generate predictions or alerts in real time.

Key deployment and monitoring activities include:

Scheduling regular model inference tasks to analyze new data as it arrives.

Setting up automated alert systems that notify operators of detected anomalies.

Creating dashboards that visualize power consumption trends, anomaly events, and system health metrics.

Implementing logging and audit trails to track model decisions and system actions.

Periodically reviewing system performance to ensure accuracy and reliability.

Facility managers and IT teams use these tools to respond quickly to abnormal load patterns. They can take corrective action before issues escalate, reducing downtime and protecting critical equipment.

Continuous Improvement

Continuous improvement forms the backbone of an effective anomaly detection system. Teams must refine the machine learning model as new data and operational feedback become available. This process involves several best practices:

Correctly identifying and resolving anomalies reinforces the model’s learning and enhances system performance.

Combining unsupervised learning techniques with supervised models creates a scalable framework for real-time predictive maintenance.

Regularly retraining the model with updated data ensures that it adapts to evolving power consumption patterns.

Reviewing false positives and negatives helps engineers fine-tune detection thresholds and feature selection.

Gathering feedback from operators and facility managers provides valuable insights for further optimization.

Note: Continuous improvement not only boosts detection accuracy but also extends the lifespan of the Smart Power Distribution Unit and connected equipment.

For more information about ESTEL’s Smart Power Distribution Unit and integration support, visit the official website.

Insights and Benefits

Automated Alerts and Dashboards

Smart Power Distribution Units equipped with machine learning generate a variety of automated alerts and dashboards. These tools help facility managers and IT professionals monitor and respond to power events quickly. The following table summarizes the main types of alerts and dashboards available:

Type of Alert/Dashboard | Description |

|---|---|

Predictive Maintenance | Alerts for potential equipment failures based on AI analytics to minimize repair times. |

Real-time Monitoring | Continuous tracking of energy usage with immediate alerts for anomalies. |

Anomaly Detection | Identifies unusual patterns in energy consumption and notifies managers for investigation. |

Energy Consumption Analytics | Provides insights into energy usage trends and identifies inefficiencies for operational optimization. |

Proactive Alerting for Anomalies | Notifications for overload conditions to prevent downtime and associated costs. |

These features allow teams to act before small issues become major problems.

Energy Savings

Machine learning-based analysis in power management leads to significant energy savings. A forecasting system that uses machine learning can analyze large datasets to improve the accuracy of energy consumption predictions. This approach streamlines data processing and boosts the efficiency of power distribution. In industrial settings, machine learning algorithms have predicted energy demand savings with high accuracy, sometimes within a 17% error margin. These results show that organizations can quantify and achieve real energy savings by adopting advanced analytics.

Reliability and Security

Machine learning improves reliability and security in several ways:

Fault detection and predictive maintenance reduce unexpected failures.

Real-time monitoring enables immediate responses to anomalies.

Adaptive control systems optimize power distribution using current data.

Models identify patterns that signal potential faults, allowing for faster and more accurate predictions.

Neural networks monitor infrastructure continuously, detecting anomalies that may indicate equipment failures or security threats.

Processing large datasets from sensors helps uncover patterns that traditional methods might miss, leading to better performance and less downtime.

These capabilities help organizations maintain stable operations and protect critical assets.

ESTEL Case Example

ESTEL’s Smart Power Distribution Unit demonstrates these benefits in real-world applications. Telecom operators and data centers use the unit to monitor power usage, receive automated alerts, and optimize energy consumption. The system’s dashboards provide clear insights into operational trends. Facility managers report fewer outages and faster response times to anomalies. By leveraging machine learning, ESTEL’s solution supports both energy efficiency and infrastructure reliability.

Machine learning has transformed power management in Smart Power Distribution Units. Organizations now see measurable results, such as an 8–14% reduction in power use and improved efficiency in power conversion. The table below highlights key impacts:

Impact Type | Measurement |

|---|---|

Power Reduction | 8–14% less power used |

Return on Investment | Payback in under two years |

Energy Waste Reduction | Higher efficiency, less waste |

Facility managers report up to 30% lower maintenance costs and a 25% boost in operational performance. ESTEL’s Smart Power Distribution Unit supports these gains with advanced analytics and reliable infrastructure protection. Readers can explore ESTEL’s solutions to achieve energy savings, reliability, and future-ready power management.

FAQ

What is a Smart Power Distribution Unit (PDU)?

A Smart PDU distributes electrical power to multiple devices. It supports remote monitoring, real-time control, and advanced safety features. Facility managers use it to improve efficiency and reliability in data centers and telecom sites.

How does machine learning detect abnormal load patterns?

Machine learning models analyze power usage data. They identify patterns that differ from normal behavior. When the system finds an anomaly, it sends alerts to operators for quick action.

What are the main benefits of ESTEL’s Smart Power Distribution Unit?

ESTEL’s Smart PDU offers remote management, surge protection, and real-time monitoring. It helps reduce downtime, saves energy, and protects equipment. IT professionals value its robust design and user-friendly interface.

Can ESTEL’s Smart PDU integrate with existing monitoring systems?

Yes. ESTEL’s Smart PDU supports standard protocols like SNMP and Modbus. This compatibility allows easy integration with most network management and analytics platforms.

See Also

Understanding ESTEL PDUs and Their Importance in Data Centers

Enhancing Outdoor Cabinets Through Power, Cooling, and Monitoring

A Complete Overview of Telecom Cabinet Battery Risk Analysis

Methods for Calculating Power Systems and Telecom Cabinet Batteries

Innovative Energy Storage Solutions for Telecom Cabinets with Microgrids

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA